Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

141 results about "Asbestos fibres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asbestos is a set of six naturally occurring silicate minerals, which all have in common their eponymous asbestiform habit: i.e. long (roughly 1:20 aspect ratio), thin fibrous crystals, with each visible fiber composed of millions of microscopic "fibrils" that can be released by abrasion and other processes.

Plugging agent and plugging slurry for drilling fractured leakage and plugging construction method

ActiveCN107722954AQuick plugging effectShort cycle timeDrilling compositionSealing/packingFiberSlurry

The invention relates to a plugging agent and plugging slurry for drilling fractured leakage and a plugging construction method. The plugging agent is prepared from the following components in parts by weight: 80 to 85 parts of cement, 6 to 10 parts of floating beads, 6 to 10 parts of micro-silicon and 1 to 3 parts of asbestos fibers. The plugging agent for the drilling fractured leakage, disclosed by the invention, is characterized in that the cement, the floating beads, the micro-silicon and the asbestos fibers are compounded to form a main body of the plugging agent, wherein the asbestos fibers can be used as a bridge plug for bridging to fractures; the floating beads and the micro-silicon realize filling and plugging effects on the fractures; all the components are coordinated with oneanother, so that the plugging agent easily enters a leakage layer and realizes the comprehensive effects of serving as the bridge plug, bridging, filling and plugging; the plugging agent is especially suitable for the fractured leakage with the width of 3 to 10mm and leakage rate of 5 to 100m<3>; in addition, the plugging agent has the advantages of quick plugging effects, short operation periodand high success rate of plugging leakage.

Owner:SINOPEC SSC +1

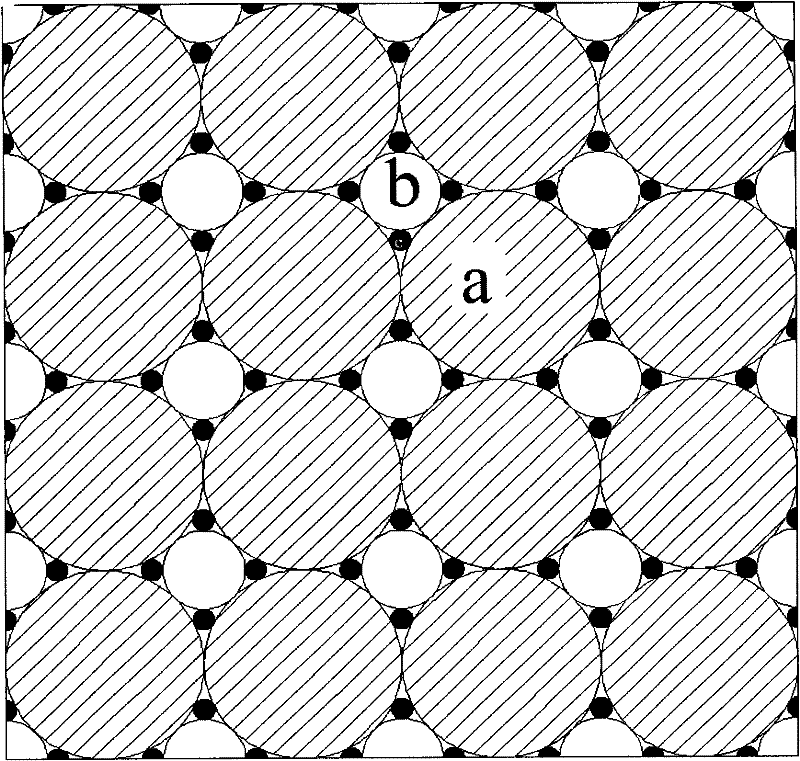

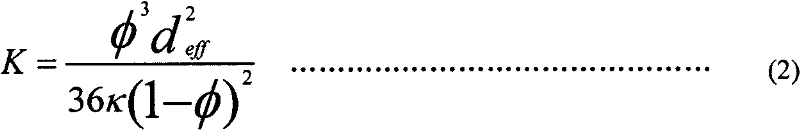

Asbestos fiber or non-asbestos fiber composite sealing material

The invention relates to an asbestos fiber or non-asbestos fiber composite sealing material, in particular to a high-performance paper-making method material. The invention belongs to the crossing field of material science and paper-making technology. The fiber composite sealing material consists of asbestos fiber, non-asbestos fiber, latex, mixed inorganic filler and auxiliary aids, wherein the mixed inorganic filler is prepared by grading at least three and at most six fillers with different average particle sizes; and the average particle size of the higher grade of filler is 2.4 times of that of the adjacent lower grade of filler. As the invention accords with the most compact arrangement theory and the principle of different particle size grain grading is applied in the composition of the filler, the microporous material structure adopting compact arrangement can be obtained by using a little latex, the sealing property of the product and the important indexes such as mechanical strength and heat resistance can be greatly improved and the high-performance fiber composite sealing material can be obtained. By adopting filler grading, the paper machine papermaking performance of slurry can be improved.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

Flame-retardant heat-resisting ageing-resistant cable sheath material

InactiveCN104098900AHigh mechanical strengthImprove fatigue resistanceInsulated cablesInsulated conductorsFiberMelamine phosphate

The invention discloses a flame-retardant heat-resisting ageing-resistant cable sheath material. The cable sheath material comprises the following raw materials in parts by weight: 5-8 parts of polybutylene terephthalate (PBT), 20-25 parts of polyphenylene sulfone (PPSU) resin, 15-20 parts of polyethylene (PE), 10-14 parts of chopped glass fiber, 3-5 parts of asbestos fiber, 1-1.5 parts of alumina whiskers, 7-9 parts of montmorillonite, 10-12 parts of diatomite, 15-17 parts of plaster, 10-11 parts of magnesium hydroxide, 3-5 parts of melamine phosphate, 1-3 parts of zinc stearate, 0.7-1.3 parts of glycerol monostearate, 1.5-1.9 parts of epoxy soybean oil, and 2-3 parts of a silane coupling agent. The cable sheath material disclosed by the invention has the advantages of excellent heat resistance, excellent ageing resistance, high tensile strength, high shock strength and excellent flame-retardant property.

Owner:安徽宁国市高新管业有限公司

Manufacturing process for asbestos-free sealing gasket

The invention discloses a manufacturing process for an asbestos-free sealing gasket. An asbestos-free beater-addition sealing paperboard is manufactured through a beater-addition process by taking aramid fibre 1414 pulp as a main material, matching cellulose fibres and mineral cotton fibres as hybrid fibres to replace asbestos fibres, selecting a mixture of butadiene-acrylonitrile latex and styrene-butadiene latex as latex, selecting kaolin, talcum powder and mica powder as filler, and determining a reasonable formula range of the compositions, wherein the asbestos-free beater-addition sealing paperboard has the ignition loss of less than or equal to 35 percent, the compression ratio of equal to 25+ / - 5 percent, the rebound rate of greater than or equal to 45 percent, the tensile strength of greater than or equal to 5 MPa, and the creep relaxation rate of less than or equal to 30 percent.

Owner:TONGLING JINLI ELECTRONICS

Diaphragm For Electrolytic Cell

Describes a diaphragm for an electrolytic diaphragm cell, e.g., a chlor-alkali cell, in which the diaphragm comprises fibrous material substantially resistant to the environment within the electrolytic cell and spheroidal ceramic microspheres at least partially resistant to the environment within the electrolytic cell associated with said diaphragm. Also describes a diaphragm for an electrolytic cell in which the diaphragm comprises a base mat of fibrous material chosen from asbestos fibers, resin-modified asbestos fibers, synthetic fibers, or mixtures of such fibers on which base mat is applied a coating comprising spheroidal ceramic microspheres. Further describes a synthetic diaphragm for an electrolytic cell, e.g., a chlor-alkali cell, on which is applied a coating comprising substantially water-insoluble inorganic particulate material, e.g., clay material, and spheroidal ceramic microspheres. Still further describes adding a dopant composition comprising spheroidal ceramic microspheres to the anolyte compartment of an electrolytic cell, e.g., a chlor-alkali cell, while the cell is operating.

Owner:AXIALL OHIO

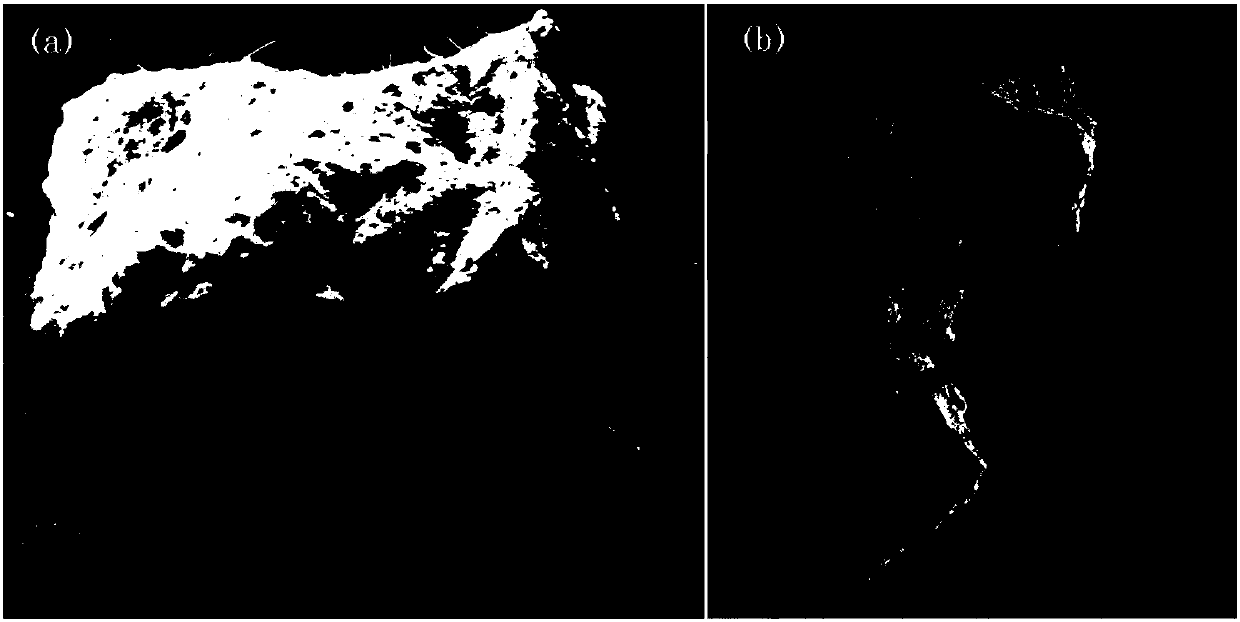

Breaking and separation integrated comprehensive recovery method of chrysotile tailings

InactiveCN103433137AReduce the delivery linkReduce lossesMagnetic separationGrain treatmentsRecovery methodMagnetic separator

The invention provides a breaking and separation integrated comprehensive recovery method of chrysotile tailings, which is characterized by comprising the steps of putting the dried chrysotile tailings in breaking and separation integrated equipment consisting of a pulverizer and a cyclone powder collector, achieving pulverizing and separation by adding 4-8 sand discharge ports on a pulverizing disc of the pulverizer, separating a chrysotile mixed material containing dust and tailing waste, conveying the chrysotile mixed material to a plane revolving screen or a plane shaking screen for classification and dedusting, removing fine sand and the dust, obtaining chrysotile products of different levels, roughing the tailing waste, the fine sand and the dust with a weak magnetic separator, obtaining magnetic middlings and tailings, and conveying the magnetic middlings into a ball mill for milling, and a wet weak magnetic separator for concentrating to obtain magnetite concentrates and tailings. According to the method, two production processes, grinding & asbestos fiber opening, and separation, of the chrysotile tailings are organically combined into a whole, effects of energy conservation and consumption reduction are achieved, and the chrysotile products of different levels and the magnetite concentrates are obtained simultaneously.

Owner:十堰源禹工贸有限公司

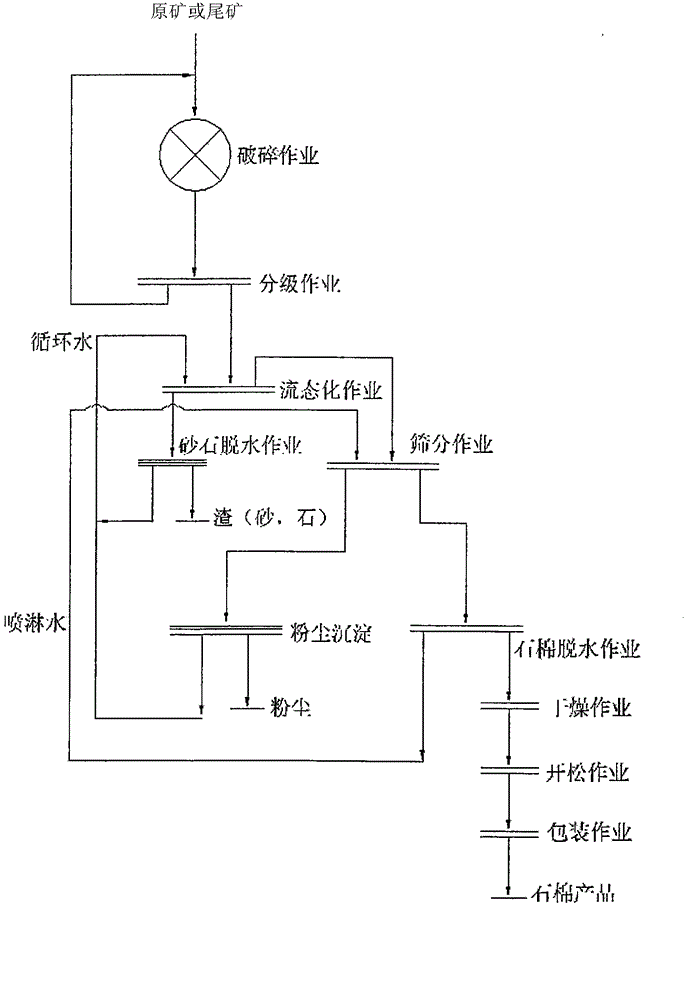

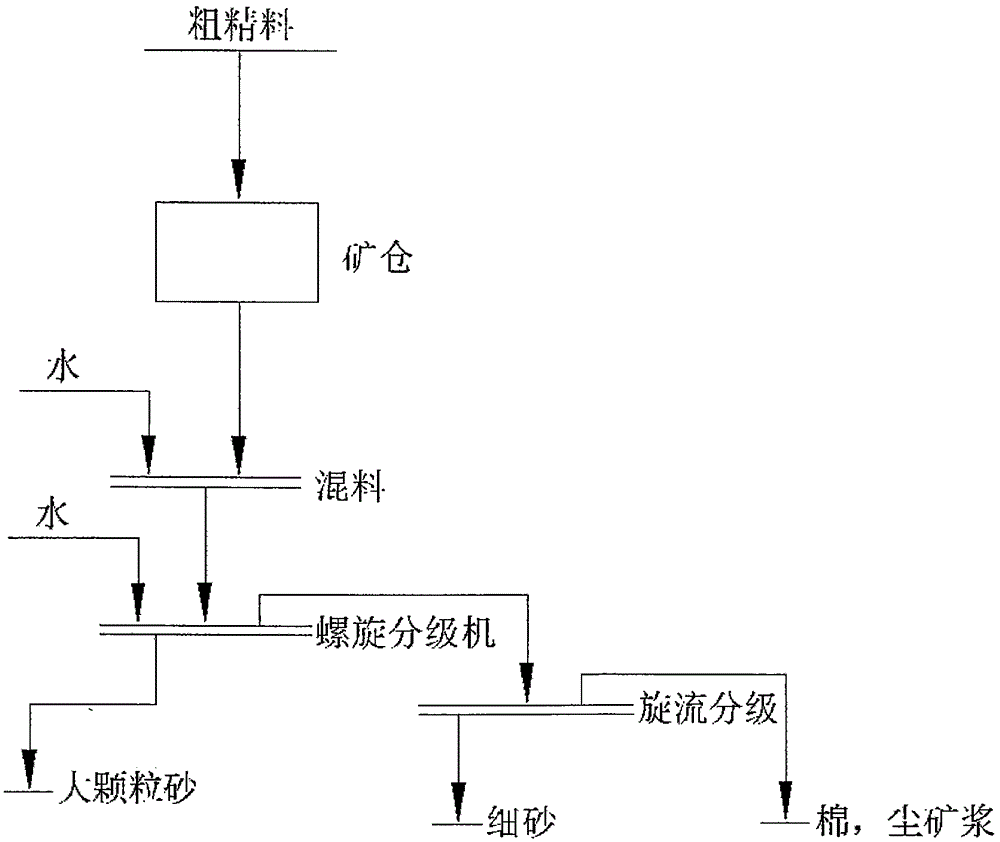

Wet technology for recycling asbestos and mineral fibers in asbestos mineral tailings

The invention relates to a mineral processing technology, in particular to a wet technology for recycling asbestos and mineral fibers in asbestos mineral tailings. According to the technological process, breaking, fluidization separation, water washing spraying purifying, sand stone dehydration and overflow tail water recycling, asbestos dehydration and filter cake smashing and drying are carried out. During water washing, special requirements for water quality are avoided, and a PH value does not need to be adjusted. During wet technology working, products of each working section are subjected to subsection dehydration and tail water subsection recycling. The wet technology has the advantages that produced asbestos fibers are good in quality and high in ore dressing recovery percentage, chemical agents are completely avoided, pollution is avoided during the whole production process, the problem of fiber ore pulp net pasting is solved with a special rotating spraying type vibration drum sieve, so that washing, stripping and screening of the asbestos fibers are completed together, the asbestos recovery rate and the return water using rate are improved, and accordingly the economical benefit of an enterprise is improved. The wet technology is very suitable for asbestos and fiber mineral tailings during mineral separation.

Owner:王玉亮

Heat-resistant modified plastic material with high abrasion resistance and high toughness

The invention discloses a heat-resistant modified plastic material with high abrasion resistance and high toughness. The heat-resistant modified plastic material is prepared from the following raw materials: modified urea-formaldehyde resin, polyvinyl chloride, polystyrene, trimethyl phosphate, polyvinyl chloride, barium sulfate, low-density polyethylene, polystyrene, calcium sulfate whiskers, talcum powder, heavy calcium carbonate, nano calcium carbonate, magnesium hydroxide, aluminum hydroxide, zinc borate, nano zinc powder, antimony trioxide, aluminum powder, asbestos fibers, jute fibers, ethyl trimethoxysilane, trifluoropropyl methyl silicone oil, zinc sulfate, a compatibilizer, a crosslinking agent, an antioxidant, a modifying auxiliary agent and glycerin. The modified plastic material provided by the invention has excellent abrasion resistance and heat resistance as well as good toughness.

Owner:TIANCHANG KANGNING PLASTIC TECH

Refractory brick of ladle slag line

The invention discloses a refractory brick of a ladle slag line. The refractory brick is prepared from the following raw materials in parts by weight: 24-26 parts of waste magnesia brick, 46-48 parts of fused magnesite, 1-2 parts of -20mesh graphite powder, 3-5 parts of -100mesh silicon carbide, 15-17 parts of -100mesh zirconium oxide, 6-8 parts of -150mesh fused millite, 8-10 parts of magnesite powder, 2-3 parts of asbestos fibers, 4-6 parts of Suzhou bentonite, 10-12 parts of zirconium boride, 1.5-2.5 parts of -200mesh boron nitride, 2.5-3.5 parts of -200mesh cerium oxide, 2-3 parts of asphalt powder, 1-2 parts of phenolic resin, 3-5 parts of sodium hexametaphosphate and 16-18 parts of water, wherein the waste magnesia brick of which the granularity is -20 mesh to +40 meshes accounts for 50%; the waste magnesia brick of which the granularity is -40 mesh to +100 meshes accounts for 25%; the waste magnesia brick of which the granularity is -100 mesh to +200 meshes accounts for 25%; the fused magnesite of which the granularity is -5 mesh to +18 meshes accounts for 35%; the fused magnesite of which the granularity is -18 mesh to +80 meshes accounts for 35%; and the fused magnesite of which the granularity is -80 mesh to +150 meshes accounts for 30%.

Owner:偃师市诚鼎耐火材料有限公司

Ultra-bright negative ion glazed brick and production process thereof

ActiveCN108331281AEvenly distributedSufficient and balanced bonding areaCovering/liningsBrickUltra fine

The invention discloses an ultra-bright negative ion glazed brick. The negative ion concentration of the ultra-bright negative ion glazed brick is 5-10 times higher than that of a common glazed brick,and at the same time, a crystal structure reflects light to enable the glazed brick more bright. The glazed brick comprises a bottom layer green body, a sound-insulation insulating layer, a top layergreen body, a base glaze layer, a functional layer and an overglaze layer; the bottom green body and the top green body comprise stone powders, sand, ultra-fine negative ion powders, diatom mud, mud,waste residues and broken mud of ceramic and water; the sound-insulation insulating layer includes a polyamide mesh, asbestos fibers and gypsum powders; the base glaze layer includes potassium sodiumfeldspar, quartz, alumina, washed soil, burnt talc, zirconium silicate and ultra-fine negative ion crystals; the functional layer includes ultra-fine negative ion crystals, activated carbon, diatom mud and glass beads; and the overglaze layer includes potassium sodium feldspar, barium carbonate, dolomite, zinc oxide, burnt talc, burnt soil, washed soil, corundum, nanometer titanium dioxide, and ultra-fine negative ion crystals.

Owner:GUANGDONG BAIQIANG CERAMICS CO LTD

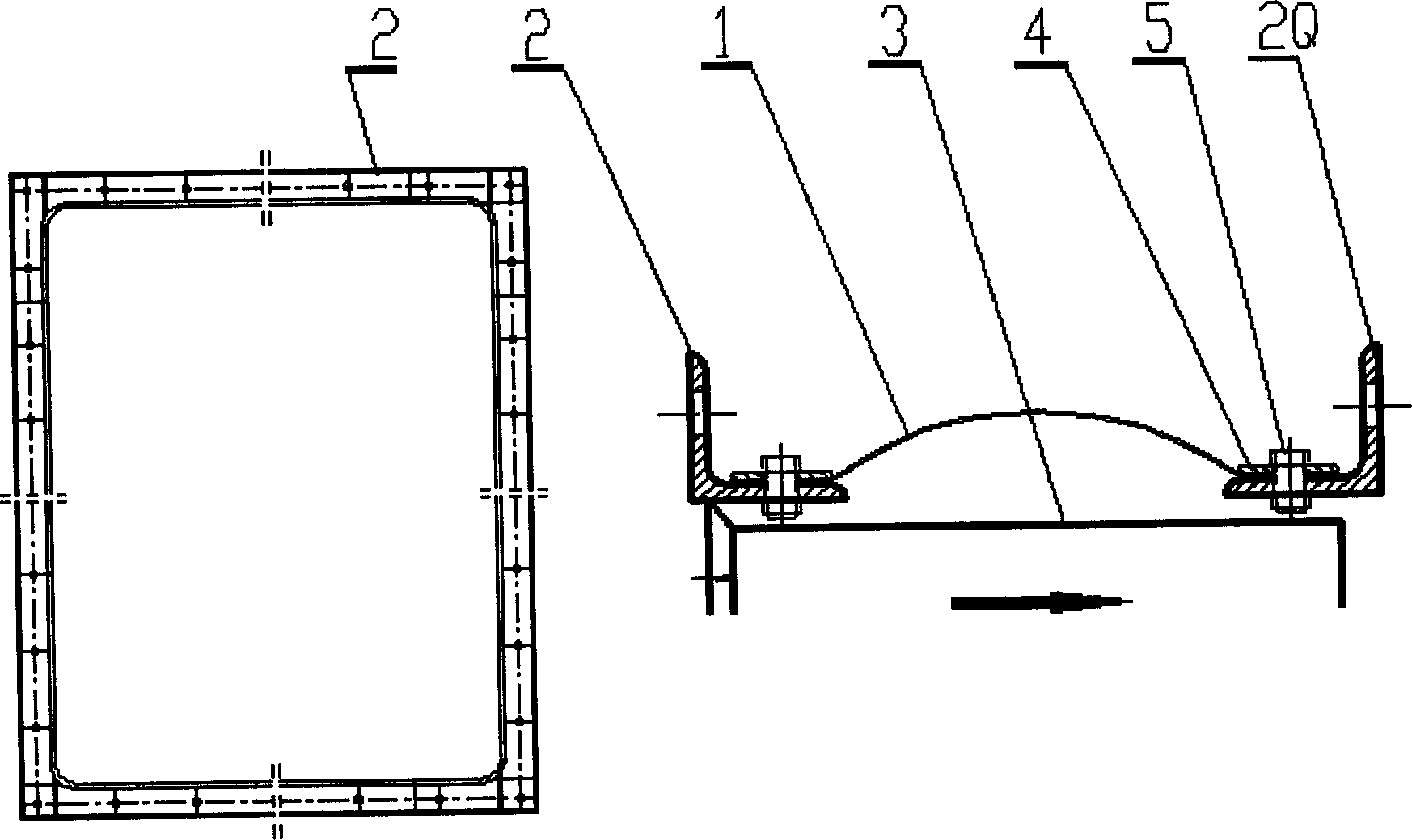

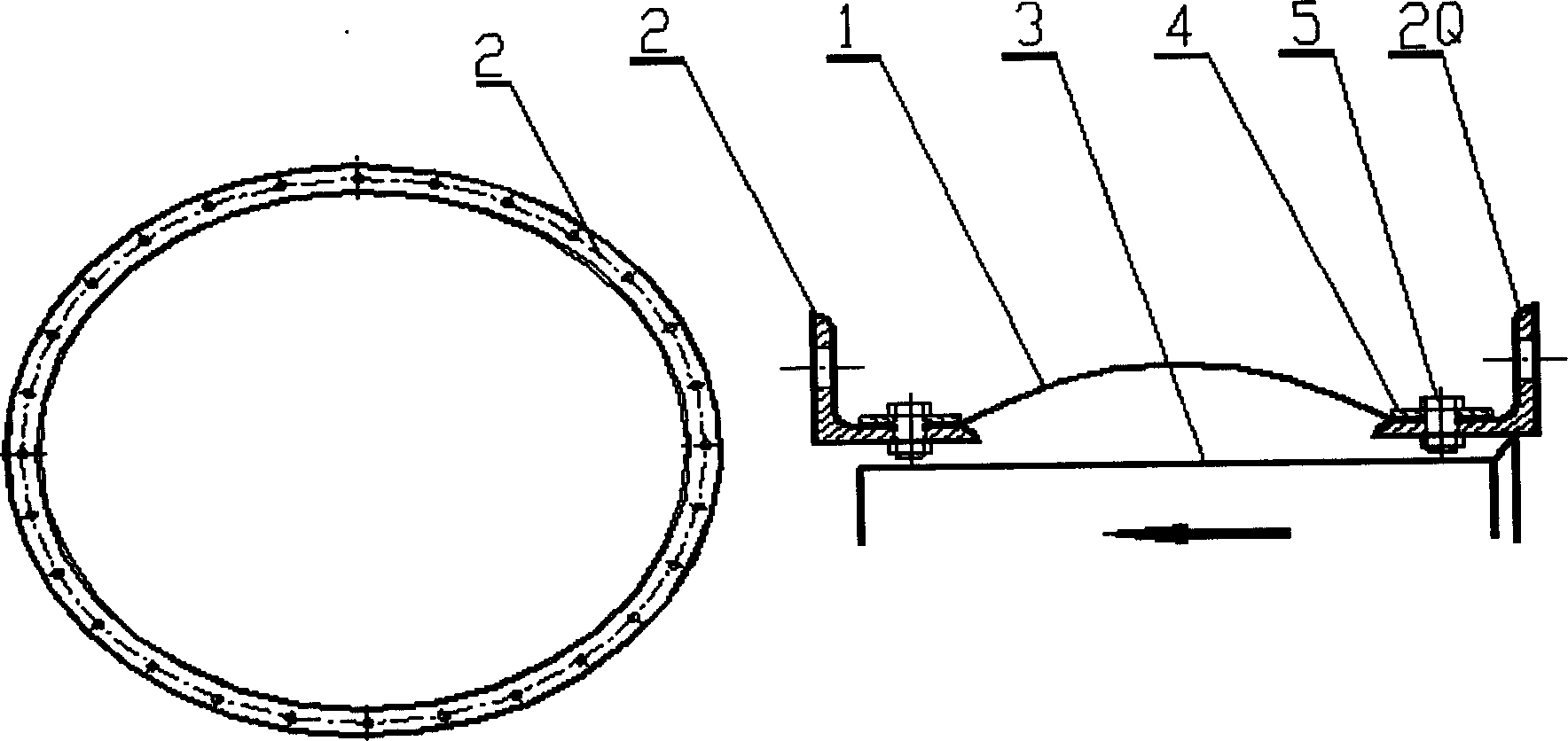

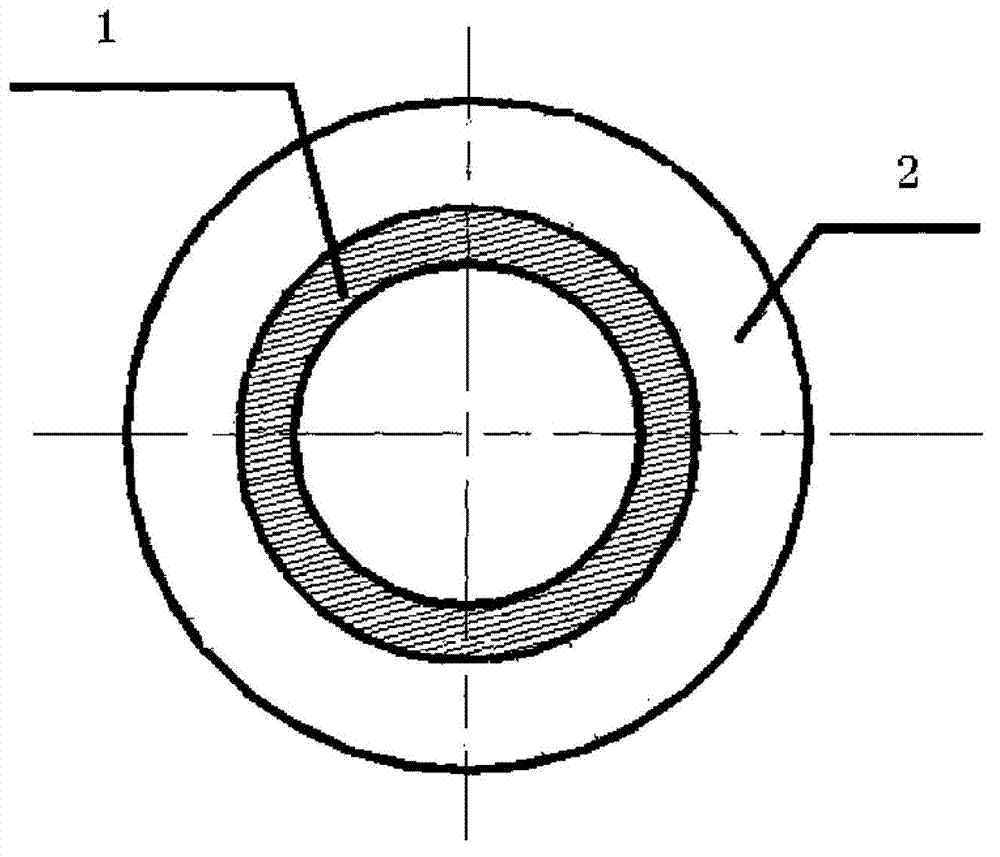

Sandwich construction fiber reinforced elastic body pipe compensator and forming method thereof

InactiveCN1570453ANo pollution in the processHigh tensile strengthPipeline expansion-compensationEngineeringGlass wool

Belonging to field of composite material technics, the invention relates to fibre with multi-layer structure enhanced elastomer pipeline compensator. The compensator is made up with compensate pipeline, two flanges fixedly connected with the compensate pipeline and a diversion knot fixedly connected with one of the two flanges and installed in compensate pipeline. Tube wall's structure is as follows: outer layer is fibre enhanced elastomer composite material (FEC) whose concrete form is fibre cloth enhanced latex mixedly weaved by non-asbestos fibre and steel wire; the second layer is anti corrosive coating wax cloth made by polytetrafluoroethylene (PTFE); the third layer is thermal protective coating made by glass wool or refractory wool in block shape between two layers of glass fibre clothes; inter layer is dust layer made by glass fibre dilatants voile fabric braided after surface treatment. With a new structure, the pipeline compensator has an environment-friendly, high intensity.

Owner:SHANGHAI UNIV

Composite roll outer periphery material and preparation method thereof

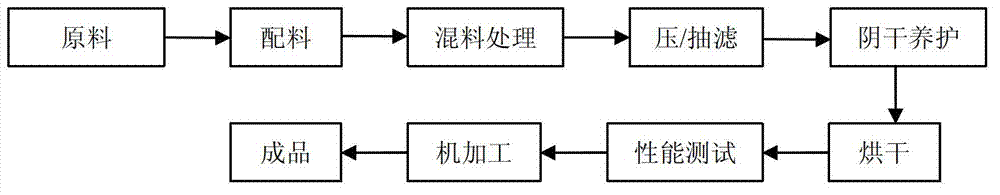

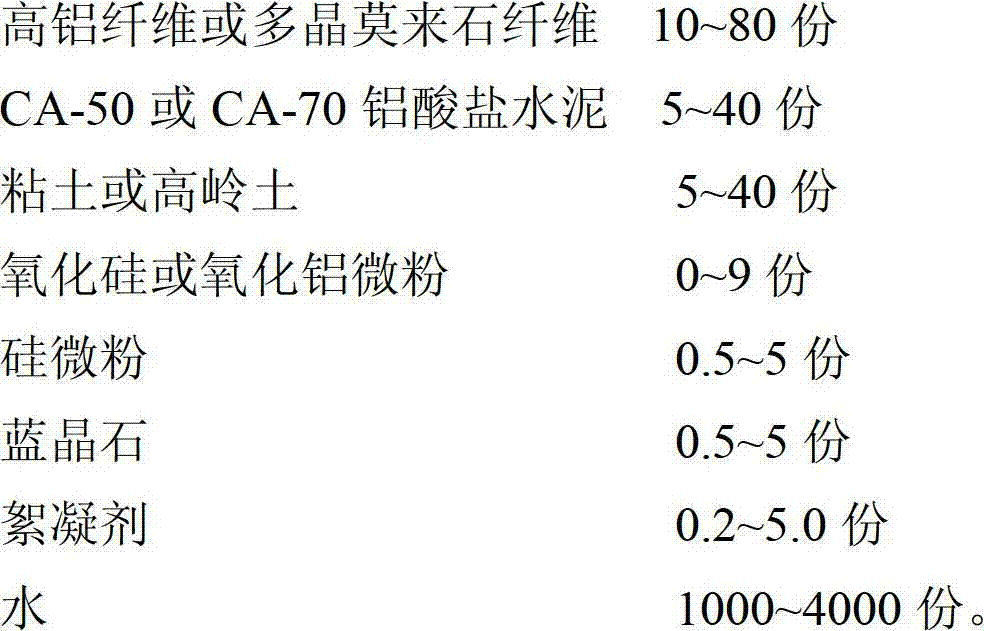

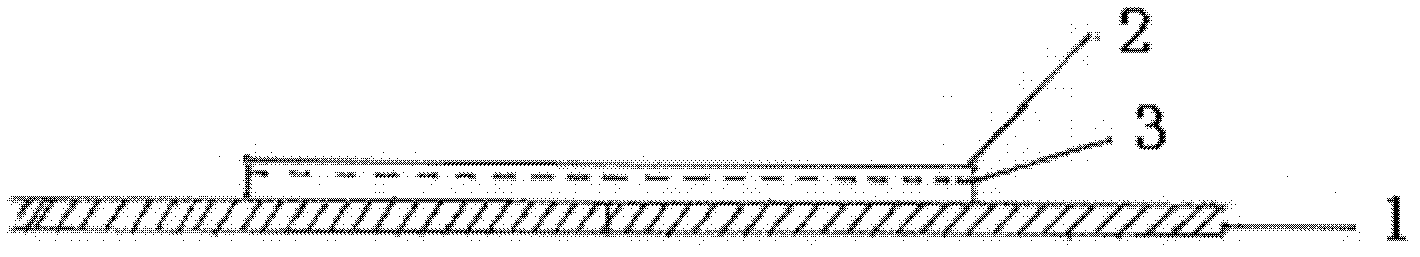

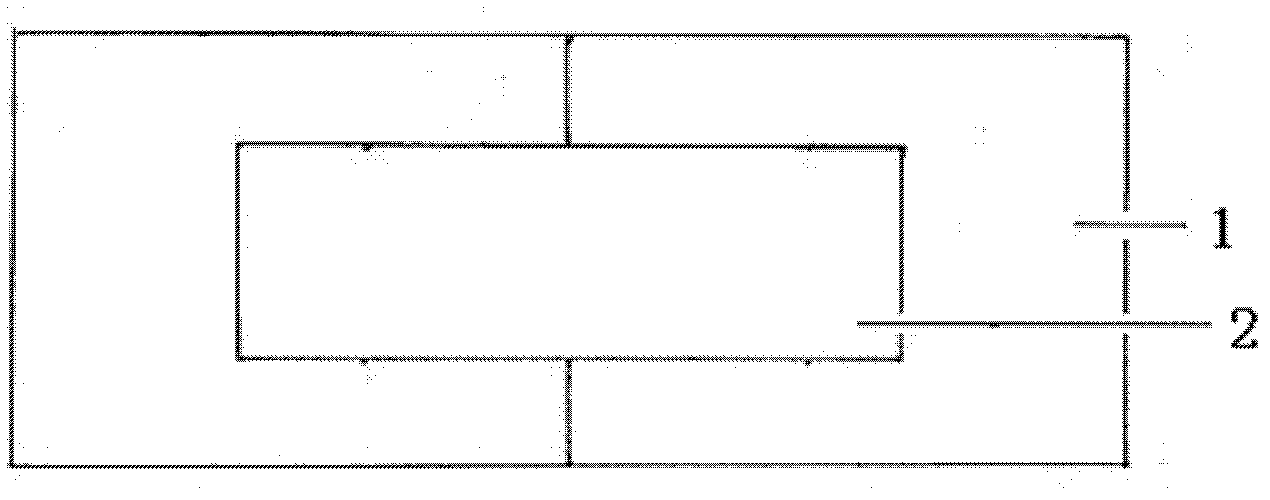

The invention discloses a composite roll outer periphery material which comprises 10-80 parts of high-aluminum fibers or polycrystalline mullite fibers, 5-40 parts of CA-50 or CA-70 aluminate cement, 5-40 parts of clay or kaoline, 0-9 parts of silicon oxide or aluminum oxide micro-powder, 0.5-5 parts of silica micro-powder, 0.5-5 parts of kyanite, 0.2-5.0 parts of flocculants and 1000-4000 parts of water. The invention further discloses a preparation method of the composite roll outer periphery material, and the method includes: dispersing the high-aluminum fibers or the polycrystalline mullite fibers in water, and then adding the residual raw materials to stir for 5-60 minutes; and forming by means of pressure filtration or suction filtration, drying in shade and conserving for 8-72 hours, and curing for 2-48 hours at the temperature of 80-160 DEG C. The composite roll outer periphery material has the advantages of service life longer than six months, no asbestos fibers, resistance to high temperature of 1200-1500 DEG C, anti-oxidation, high abrasive resistance, good thermal shock resistance and excellent nodulation resistance.

Owner:NINGBO VULCAN TECH CO LTD

Diaphragm for electrolytic cell

Describes a diaphragm for an electrolytic diaphragm cell, e.g., a chlor-alkali cell, in which the diaphragm comprises fibrous material substantially resistant to the environment within the electrolytic cell and spheroidal ceramic microspheres at least partially resistant to the environment within the electrolytic cell associated with said diaphragm. Also describes a diaphragm for an electrolytic cell in which the diaphragm comprises a base mat of fibrous material chosen from asbestos fibers, resin-modified asbestos fibers, synthetic fibers, or mixtures of such fibers on which base mat is applied a coating comprising spheroidal ceramic microspheres. Further describes a synthetic diaphragm for an electrolytic cell, e.g., a chlor-alkali cell, on which is applied a coating comprising substantially water-insoluble inorganic particulate material, e.g., clay material, and spheroidal ceramic microspheres. Still further describes adding a dopant composition comprising spheroidal ceramic microspheres to the anolyte compartment of an electrolytic cell, e.g., a chlor-alkali cell, while the cell is operating.

Owner:AXIALL OHIO

Plugging agent with good curing effect

The invention relates to the technical field of chemical materials, and specifically relates to a plugging agent with a good curing effect. The plugging agent is composed of the following components in percentage by weight: 25 to 44% of curable material (blast furnace slag), 11 to 22% of acid-soluble material (calcium carbonate), 13 to 19% of fiber materials (asbestos fiber, cotton fiber, or corn core), and 5 to 22% of high fluid loss material (diatomite or fly ash). The application of the provided plugging agent is flexible, and the plugging effect is prominent.

Owner:荆春芳

Flame-retardant rubber and production method therefor

InactiveCN105482202AImprove insulation performanceImprove impact resistanceProductsReagentsFiberPolymer science

The invention discloses flame-retardant rubber which is prepared from the following raw materials in percentage by weight: 0.1-0.3% of sodium stearate, 3-5% of titanium dioxide, 3-5% of zinc oxide, 3-5% of magnesium oxide, 0.1-1% of an antistatic agent, 3-15% of calcium carbonate powder, 5-15% of insulating ceramic particles, 2-5% of an accelerant, 5-10% of asbestos fiber, 1-3% of carbon black, 0.01-0.3% of a smoke suppressant and the balance of chloroprene rubber. According to the flame-retardant rubber disclosed by the invention, the impact resistance, the antistatic property, the ageing resistance and the toughness of a rubber product are improved to a great extent and the thermal decomposition temperature of the rubber product is increased while the insulating performance of rubber is enhanced. Fire hazards can be further effectively reduced while the electric insulating property is improved and electric leakage accidents are prevented, and moreover, fire spread can be effectively prevented, so that an effect of reducing damages by fire is achieved.

Owner:STATE GRID CORP OF CHINA +1

Flame-retardant resin

The invention discloses flame-retardant resin, belonging to the technical field of high polymer materials. The technical scheme of the invention is as follows: the flame-retardant resin is composed of the following components in parts by weight: 25-60 parts of unsaturated polyester resin, 5-25 parts of glass wool, 2-10 parts of copper naphthenate, 1-5 parts of cobalt iso-octoate, 15-35 parts of calcium carbonate, 1-5 parts of talcum powder, 1-5 parts of polyvinyl fluoride, 6-14 parts of silicon dioxide, 2-12 parts of clay fiber, 2-12 parts of asbestos fiber, 2-10 parts of alumina cellucotton, and 2-6 parts of accelerant. Compared with the prior art, because the flame-retardant resin provided by the invention is low in viscosity and good in infiltrating property, the flame-retardant resin has a good penetration property to various fiber products; moreover, the flame-retardant resin is adjustable in viscosity and long in service life, therefore, the flame-retardant resin can be widely applied to processes of mechanical warping, casting, manual lay-up, mould pressing and the like, and has broad market values and huge market potential.

Owner:SHANDONG JIQING CHEM

Waterproof glue

InactiveCN105086846AEasy to makeEasy to useNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveFiberDehydroacetic acid

The invention discloses waterproof glue. The waterproof glue comprises, by weight, 24-60 parts of poly-isobutyl ester, 30-40 parts of aluminum hydroxide, 18-24 parts of phosphotriester, 12-18 parts of antimonous oxide, 8-12 parts of asbestos fibers, 20-30 parts of graphite nodules, 20-40 parts of methoxyphenol, 10-12 parts of acetone, 4-12 parts of acrylamide, 10-28 parts of styrene, 10-24 parts of ethyl alcohol, 20-30 parts of poly-isobutyl ester, 150-200 parts of butyl methacrylate, 20-40 parts of methacrylic acid, 8-16 parts of dehydroacetic acid and 20-40 parts of butanol. The waterproof glue is easy to manufacture, adopted and selected production raw materials are free of toxicity, the glue is good in use effect and environmentally friendly, a tough coating can be formed, and permanent waterproofness and antistatic performance are achieved.

Owner:启东寅昶精密铸造有限公司

Method for measuring crack resistance of composite coating coated on outer wall

InactiveCN102607968ACrack resistance data quantificationEasy to operateInvestigating material ductilityFiberCrack resistance

The invention relates to a method for measuring the crack resistance of a composite coating coated on an outer wall. The method comprises the following steps of: (1) cutting an asbestos fiber-free cement flat slab into two sections, splicing the two sections again, and fixing the spliced flat slab on a fixed slab to prepare a pre-cracked slab; (2) coating the composite coating with certain thickness on the front side of the pre-cracked slab by using a mold, maintaining, and taking the pre-cracked slab coated with the composite coating out of the fixed plate to obtain a sample slab; (3) measuring the maximum tensile load value F and the extension value L of the sample slab when the composite coating is damaged by using an electronic pull tester, and repeating the step for at least 5 times; (4) taking the value: removing the highest values and lowest values of the tensile load values and the extension values of the sample slab acquired in the (3), and respectively taking an arithmetic mean value of 3 data; and (5) calculating the breaking tensile strength by using a formula that sigma=F / S, and calculating the breaking displacement by using a formula that s=(L-L0) / L0*1,000.

Owner:上海天补建筑科技有限公司

Ceramic brake block

InactiveCN104214249ALow densityStrong wear resistanceOther chemical processesBraking membersPolyesterCarbon fibers

The invention discloses a ceramic brake block, which consists of the following ingredients in the following parts: 20 to 30 parts of alumina silicate fiber, 30 to 50 parts of glass fiber, 40 to 50 parts of carbon fiber, 30 to 35 parts of bamboo charcoal fiber, 50 to 80 parts of ceramic fiber, 20 to 25 parts of asbestos fiber, 30 to 40 parts of polyester fiber, 40 to 45 parts of polyacrylonitrile fiber, 20 to 25 parts of polyvinyl alcohol fiber, 10 to 15 parts of polypropylene fiber, 15 to 25 parts of ultra to high molecular weight polyethylene fiber, 10 to 15 parts of sepiolite fiber, 20 to 25 parts of fibrilia, 15 to 18 parts of viscose, 5 to 10 parts of hollow particles, 4 to 6 parts of glass particles, 5 to 7 parts of silicon carbide, 5 to 8 parts of aluminium carbide, 2 to 5 parts of silicon dioxide, 2 to 5 parts of magnesium oxide, 3 to 6 parts of graphite, 10 to 12 parts of frictionpowder, 10 to 12 parts of reclaimed rubber, 8 to 10 parts of silicon carbide whiskers, 8 to 10 parts of magnesium borate whiskers and 6 to 8 parts of vanadium pentoxide. The ceramic brake block provided by the invention has the advantage that through the ingredient improvement matching and the composition, the technical problems of easy rustiness, higher noise, unstable high-temperature friction performance, easy locking or dragging friction, lower abrasion resistance performance and the like in the prior art are solved.

Owner:黄惠娟

Plywood putty and preparation method thereof

InactiveCN106479242AIncrease stickinessImprove uniformityFilling pastesSilicon dioxidePetroleum coke

The invention discloses a plywood putty and a preparation method thereof. The plywood putty is composed of the following components in parts by mass: 20-30 parts of modified organopolysiloxane, 8-10 parts of starch ester, 5-9 parts of urea-formaldehyde glue, 5-15 parts of hydroxymethyl fiber, 10-20 parts of white cement, 8-10 parts of nano silicon dioxide, 14-18 parts of petroleum coke powder, 13-15 parts of lime powder, 1-3 parts of thickener, 14-18 parts of titanium white, 14-18 parts of asbestos fiber, 20-22 parts of talcum powder, 16-20 parts of wood meal and 100-140 parts of water. The plywood putty has the advantages of high viscosity, high fineness, high uniformity, high drying rate and high hardness after forming, and can not easily shed.

Owner:浦北县建业胶合板有限责任公司

Fireproof coating for environmental protection equipment and preparation method thereof

InactiveCN107286760AEasy to makeGood mechanical propertiesFireproof paintsAntifouling/underwater paintsFiberAntimony trioxide

The invention discloses a fireproof coating for environmental protection equipment, belonging to the technical field of environmental protection equipment. The fireproof coating comprises the following raw materials by weight: 40-44 parts of styrene-acrylic emulsion, 20-22 parts of polyvinyl acetate emulsion, 6-8 parts of asbestos fiber 12-16 parts of ceramic fibers, 9-13 parts of starch, 6-8 parts of ammonium dihydrogen phosphate, 3-5 parts of dicyandiamide, 1-3 parts of urea, 10-14 parts of mica powder, 5-7 parts of antimony trioxide, 1 to 4 parts of zinc oxide, 3-7 parts of titanium boride, 1-3 parts of carboxymethylcellulose, 2-4 parts of a defoaming agent, 1-2 parts of an antibacterial preservative and a proper amount of water. The invention also discloses a preparation method for the fireproof coating. The fireproof coating provided by the invention has the advantages of simple preparation, excellent mechanical properties and excellent fire resistance.

Owner:HEFEI ZHENXUN LOW TEMPERATURE TECH CO LTD

Prick resistant tire and preparation method thereof

InactiveCN106928514AWith shock absorption functionImprove structural strengthSpecial tyresPneumatic tyre reinforcementsFiberSilicon dioxide

The invention discloses a prick resistant tire comprising an outer tire body, an inner tire body and a honeycomb structure, wherein the honeycomb structure is arranged between the outer tire body and the inner tire body, the outer tire body, the inner tire body and the honeycomb structure are integrally formed, an antiskid grooves are formed in the surface of the outer tire body, the antiskid grooves are distributed in an annular array, the thickness of the outer tire body is 2-4cm, and the thickness of the inner tire body is 1cm; and the prick resistant tire is made of the following raw materials in parts by weight: 45-55 parts of butadiene styrene rubber, 38-44 parts of brominated butylene rubber, 7-12 parts of nano clay, 2-4 parts of zinc oxide, 6-10 parts of dithiocar-bamate, 14-18 parts of silicon dioxide, 20-25 parts of ethyl carbamate, 3-6 parts of sulfur, 18-22 parts of 4-nitrobenzyl phthalate, 16-20 parts of pitch, 15-20 parts of gamma-mercaptopropyltrimethoxysilane, 32-38 parts of graphene fibers, 7-14 parts of asbestos fibers and 5-10 parts of styrene resin. The tire has the advantages of high structural strength, aging resistance, low manufacturing cost and good prick resistant effect.

Owner:苏州信宏天科技有限公司

Rubber for cable insulation outer walls and production method thereof

Owner:STATE GRID CORP OF CHINA +1

Integzal type oxidation catalyst of sulfur dioxide possessing regular channels and its preparing method

InactiveCN1431046AHigh strengthIncrease production capacityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsGlass fiberFiber

An integral catalyst with regulator channels for oxidizing SO2 is prepared from vanadium oxide, alkali-metal compound, silicon oxide or the mixture of silicon oxide and silicon aluminium oxide as carrier, and glass fibres and / or asbestos fibres and / or meallic wool through mixing, moulding, demoulding, drying and calcining.

Owner:成都川大天华科技开发有限责任公司

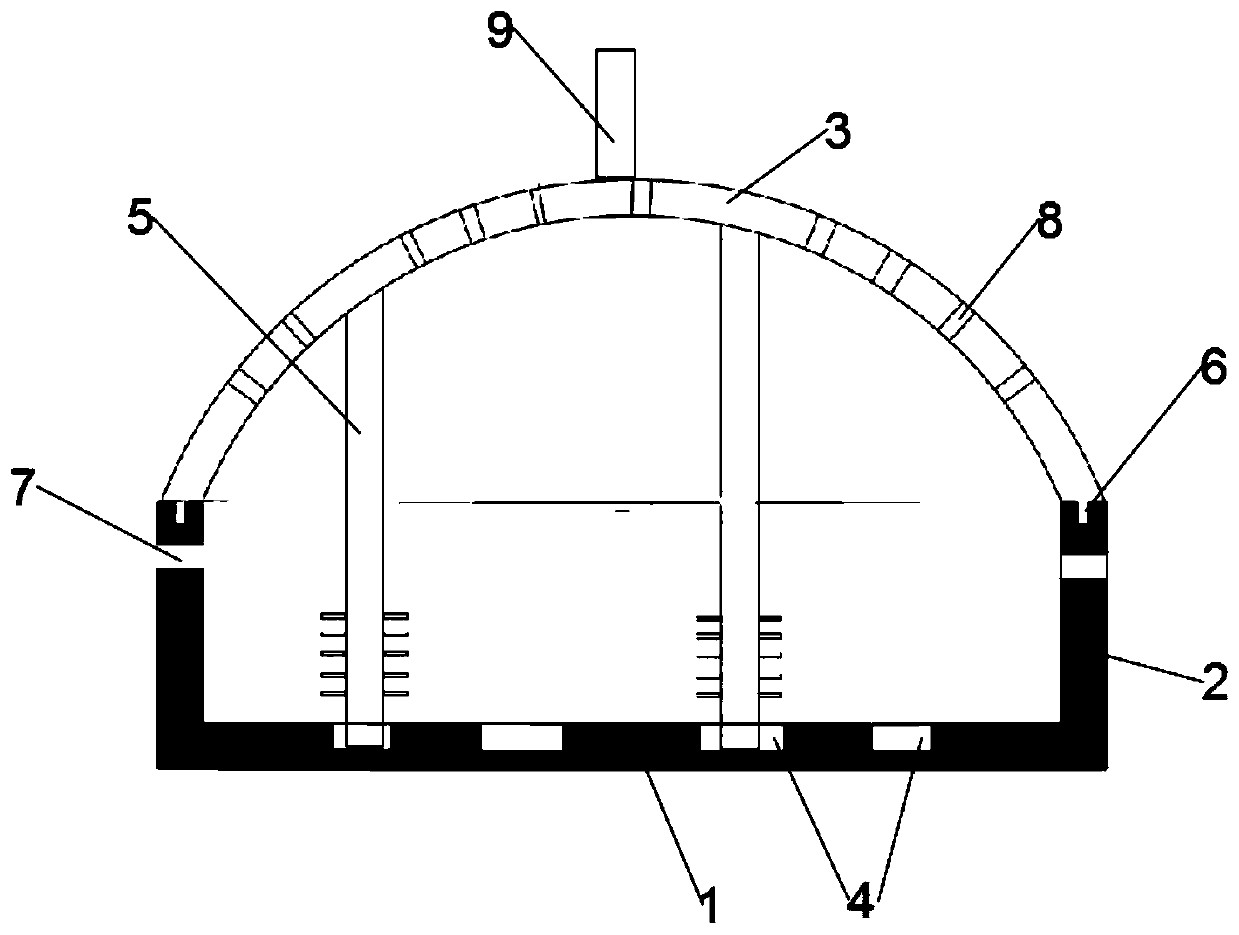

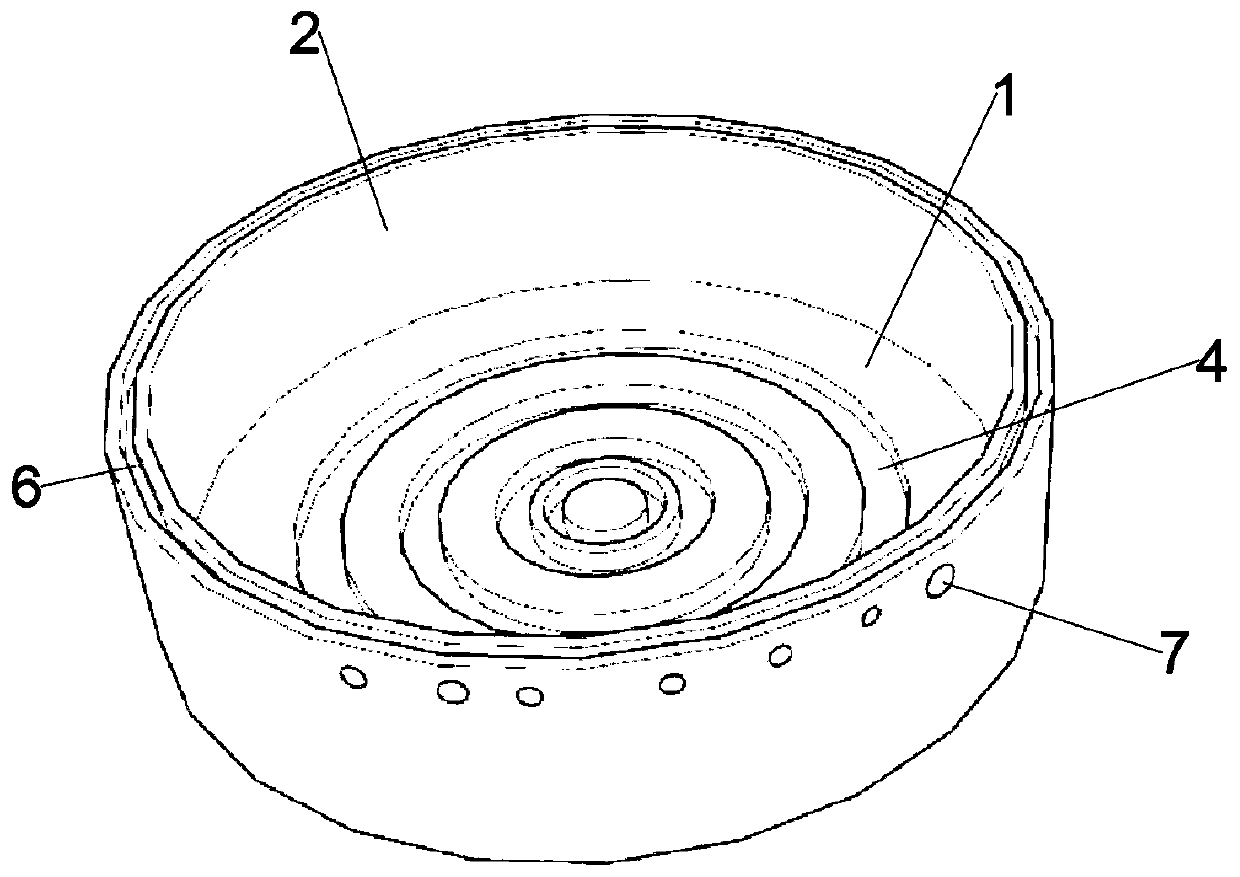

Drying and separation integrated machine for vibrating fluidized bed

ActiveUS20160054056A1Simple structureGuaranteed uptimeDrying solid materials with heatPneumatic tablesFiberWater vapor

A drying and separation integrated machine for a vibrating fluidized bed comprises a front rack (10), a rear rack (12), a separation bed (6), and a rotary plow feeder (1) disposed at the upper portion at the front end of the separation bed (6). The tail end of the separation bed (6) is provided with a waste-rock rotary plow feeder (14) and a fine-coal rotary plow feeder (8), the upper portion of the separation bed (6) is provided with a dust-removing air-induced hood (4), the bottom thereof is provided with an air distribution chamber (3), the upper portion of the air distribution chamber (3) is provided with an air distribution plate (15), and the front rack (10) and the rear rack (12) are connected to the separation bed (6) by a spring (17) and a spring support (16). The bottom of the rear rack (12) is provided with a hydraulic cylinder (13), the lower portion of the rotary plow feeder (1) is provided with a feeding distribution device (2), two dust-removing air-induced hoods (4) and two air distribution chambers (3) are respectively provided on the top and the bottom of the separation bed (6), a heat-insulation coating is sprayed on the outer surfaces of the dust-removing air-induced hood (4) and the air distribution chamber (3), and the lower portion at the front end of the separation bed (6) is provided with a separating eccentric shaft vibration exciter (9). The air distribution plate (15) is formed of upper and lower porous metal plates and asbestos-fiber filter cloth sandwiched between the porous metal plates, the bottom of each air distribution chamber (3) is provided with a gas separator (5), and the gas separators (5) are connected to a hot-air pipe (19) sprayed with a heat-insulation coating. The wet coal in the vibrating fluidized bed is fluidized by high-temperature hot air, heat transfer and mass transfer proceed between the high-temperature air and the wet coal particles, and the moisture in the coal is taken out of the vibrating fluidized bed by the fluidization gas in a form of water vapor. During drying, the coal particles are fluidized by air flow together with vibration. The drying and separation integrated machine for a vibrating fluidized bed is of a simple structure, operates stably, and has high reliability.

Owner:CHINA UNIV OF MINING & TECH

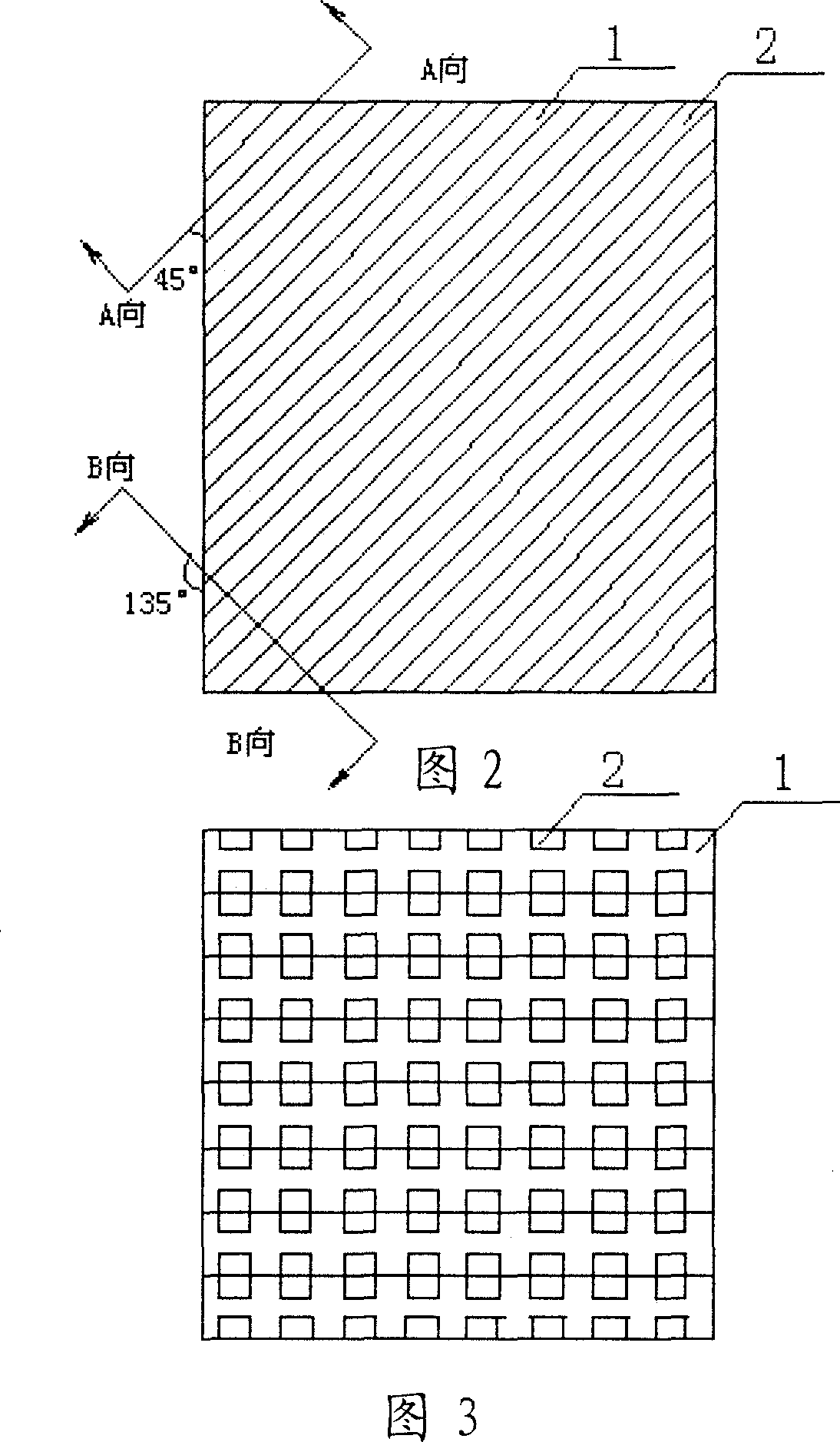

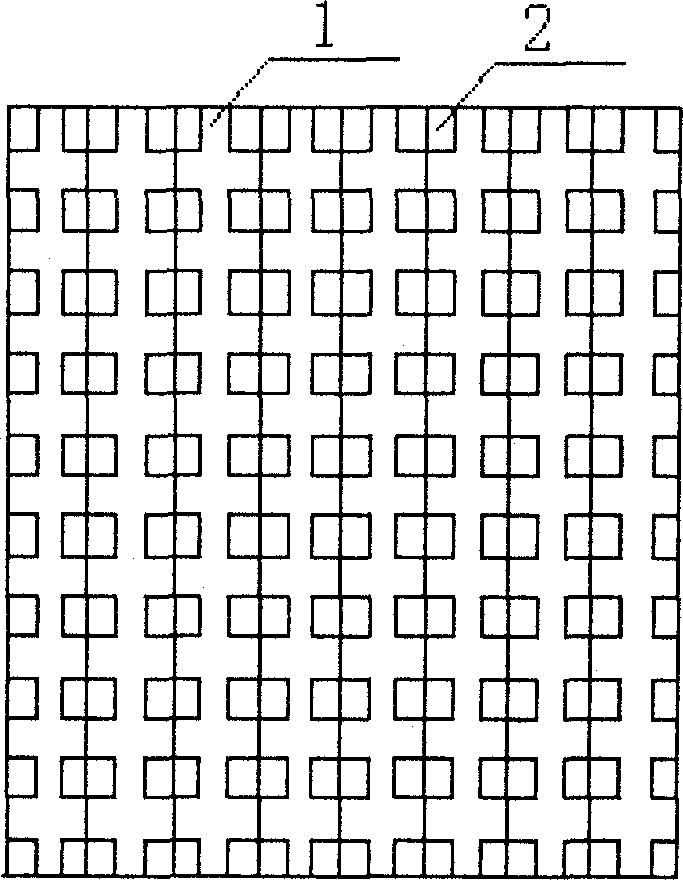

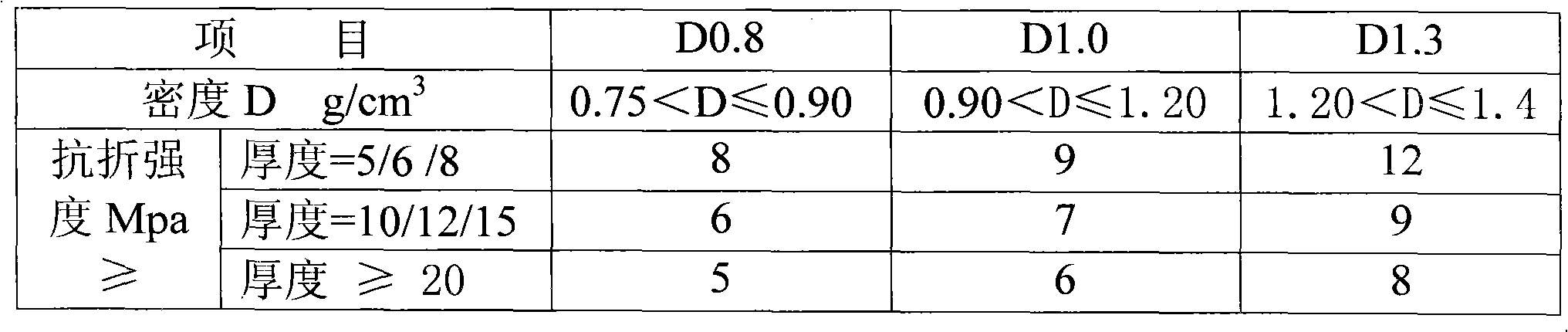

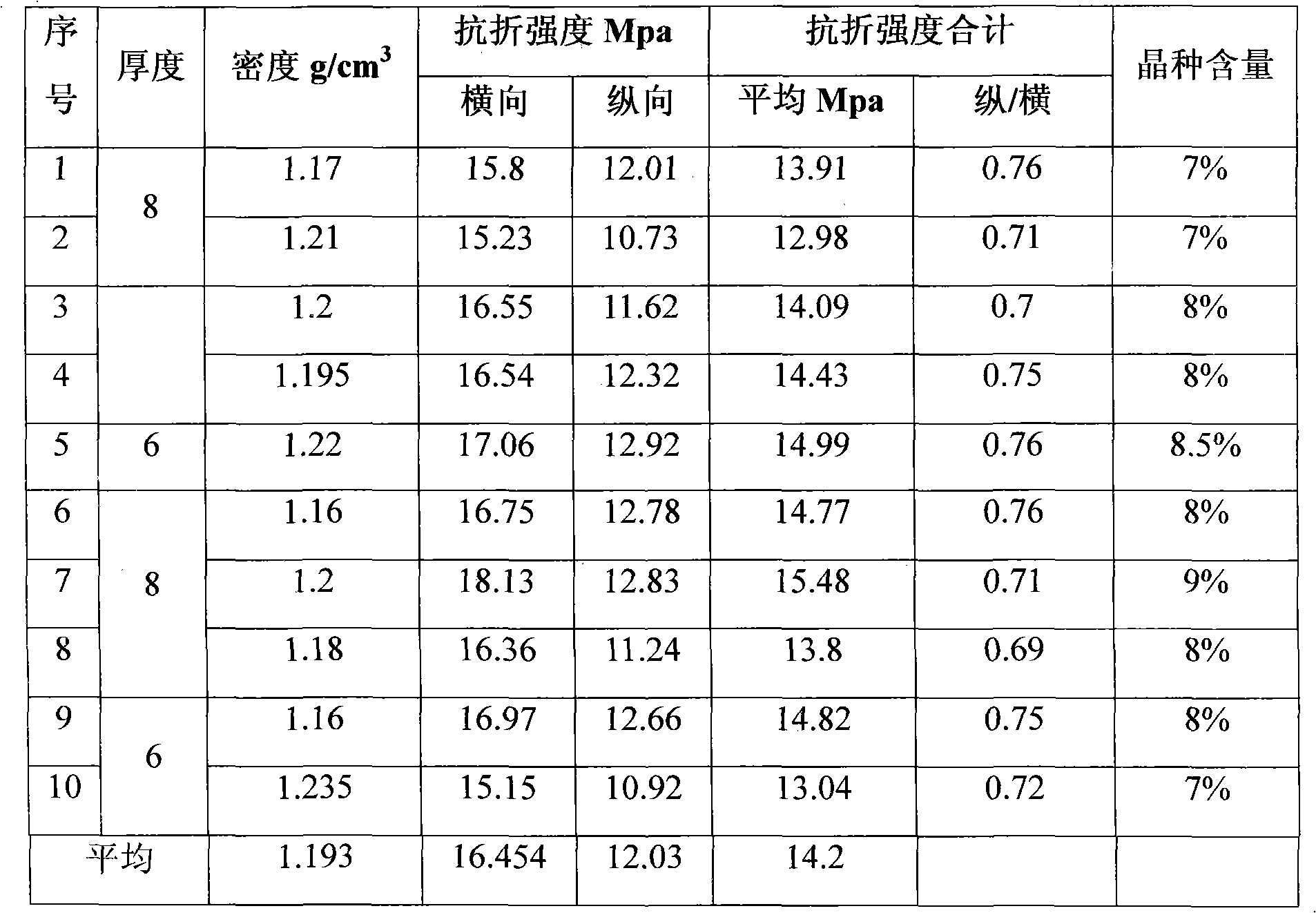

Process for manufacturing high-strength low-density asbestos fiber-free enhanced silicate plate

ActiveCN101967052ACompact structureLow densitySolid waste managementHydration reactionCellulose fiber

The invention relates to a process for manufacturing a high-strength low-density asbestos fiber-free enhanced silicate plate. The process comprises the following steps of: 1, adding 5 to 10 mass percent of cellulose fiber into solution containing 38 to 42 mass percent of quartz and 33 to 37 mass percent of lime, and filtering out water to obtain silicate crystal seeds with size within 2 mu m under the high pressure of between 0.85 and 1.1Mpa and at the high temperature of between 175 and 185 DEG C; and 2, adding 3 to 8 mass percent of silicate crystal seeds into the solution containing 38 to 42 mass percent of quartz and 33 to 37 mass percent of lime, adding 5 to 10 mass percent of cellulose fiber into the solution, filtering out water, performing hydration reaction under the high pressure of between 0.85 and 1.1Mpa and at the high temperature of between 175 and 185 DEG C for secondary crystallization and finally pressing the mixture in a plate molding machine. A new material producedby the process has various superior chemical, physical and mechanical properties, such as low density, high bending strength and the like.

Owner:广东新元素板业有限公司

Fireproof paint

InactiveCN105440945AImprove fire performanceLow toxicityFireproof paintsAnti-corrosive paintsFiberWater soluble

The invention discloses fireproof paint which contains the following raw materials (by weight): 10-15 parts of antimony oxide, 3-5 parts of butyl stearate, 5-7 parts of water soluble resin, 7-12 parts of asbestos fiber, 4-6 parts of borax, 4-6 parts of zeolite powder, 6-7 parts of triethanolamine and 7-9 parts of tung oil. The fireproof paint of the invention can resist fire spreading, has good fireproof performance, has little toxicity, has strong anticorrosion ability, can adhere to the surface of an object for a long time, and is durable in use.

Owner:QINGDAO HONGYU ENVIRONMENTAL PROTECTION AIR CONDITIONING EQUIP

Autoclaved aerated concrete block with good mechanical strength and preparation method of autoclaved aerated concrete block

The invention discloses an autoclaved aerated concrete block with good mechanical strength. According to the autoclaved aerated concrete block, by virtue of acetylation on cedar wood fibers, free hydroxyl in cellulose is closed, so that the hydrophobic property and the thermal stability of a material are improved; by adding other effective components through a physical modification method, the durability and the dispersibility of the fibers in autoclaved aerated concrete are improved; by adding the raw materials including coal gangue, palygorskite powder, papermaking white clay, asbestos fiber and the like, the aerated concrete block has excellent mechanical strength, high temperature resistance and water resistance, can be used for a long time at a high temperature environment, can be further used at a wet environment for a long time without mildewing and is long in service life and wide in application range.

Owner:DANGTU COUNTY KEHUI TRADING

Adhesive for packaging and preparation method of adhesive

InactiveCN110079252ALow costEasy to integrateNon-macromolecular adhesive additivesStarch adhesivesFiberAdhesive

The invention discloses an adhesive for packaging. The adhesive is prepared from raw materials in parts by mass as follows: 200-300 parts of acrylic resin, 200-300 parts of corn starch, 500-700 partsof deionized water, 2-8 parts of a curing agent, 4-15 parts of a plant type toughening agent, 100-200 parts of asbestos fiber, 50-200 parts of porcelain powder, 6-9 parts of an oxidizing agent, 3-6 parts of hydrogen peroxide, 1-3 parts of sodium hydroxide, 3-5 parts of polyvinyl alcohol, 2-3 parts of formaldehyde, 1-2 parts of hydrochloric acid, 4-8 parts of an esterification aid and 1-2 parts ofan emulsifier. The combination form of a prepared waterborne acrylic resin emulsion and a starch dispersion is adopted, the problem of combination of the two components is solved, the use cost of acrylic resin is reduced, meanwhile, by adopting a superfine grinding technology and a disc stirring container stirring manner, the fusion degree and dispersion uniformity among all raw materials are increased, the properties of the adhesive product are greatly improved, and the problem that part of the adhesive product has good effects and part of the adhesive product has poor effects during use is solved.

Owner:东莞市奥嘉特高分子材料有限公司

High-temperature resistant silicon carbide reducing tank and preparation method thereof

The invention discloses a high-temperature resistant silicon carbide reducing tank. After silicon carbide and a bonding agent are fully mixed, the silicon carbide and the bonding agent are added into a tank production mould, and are vibrated, compacted, and solidified, and the weight ratio of the silicon carbide to the bonding agent is 88-92: 12-8; the silicon carbide comprises four silicon carbide raw materials with particles sizes of 3-5 mm, 1-3 mm, 0.1-1 mm and 200 meshes, and the bonding agent comprises clay, feldspar, asbestos fiber, high-purity metal silicon and furan resin. The high-temperature resistant silicon carbide reducing tank, provided by the invention, is used under the high-temperature environment, and has the advantages of strong heat stability, high mechanical intensityand difficulty in destroying after heat and cold alternative use, the silicon carbide tank filled with the material enters into a burning furnace, after burning at 900-1200 DEG C, the rupture strength is 80 MPa, and the repeated times can reach 200 times per silicon carbide tank. The high-temperature resistant silicon carbide reducing tank, provided by the invention, has the advantages of simple production method, high production efficiency, small production energy consumption and low production cost.

Owner:连云港市东茂矿业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com