Plugging agent and plugging slurry for drilling fractured leakage and plugging construction method

A construction method and plugging agent technology, which can be used in drilling compositions, chemical instruments and methods, earthwork drilling and mining, etc., can solve the problems of low plugging success rate of the plugging agent, and reduce the difficulty and strength of plugging. Moderate, quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

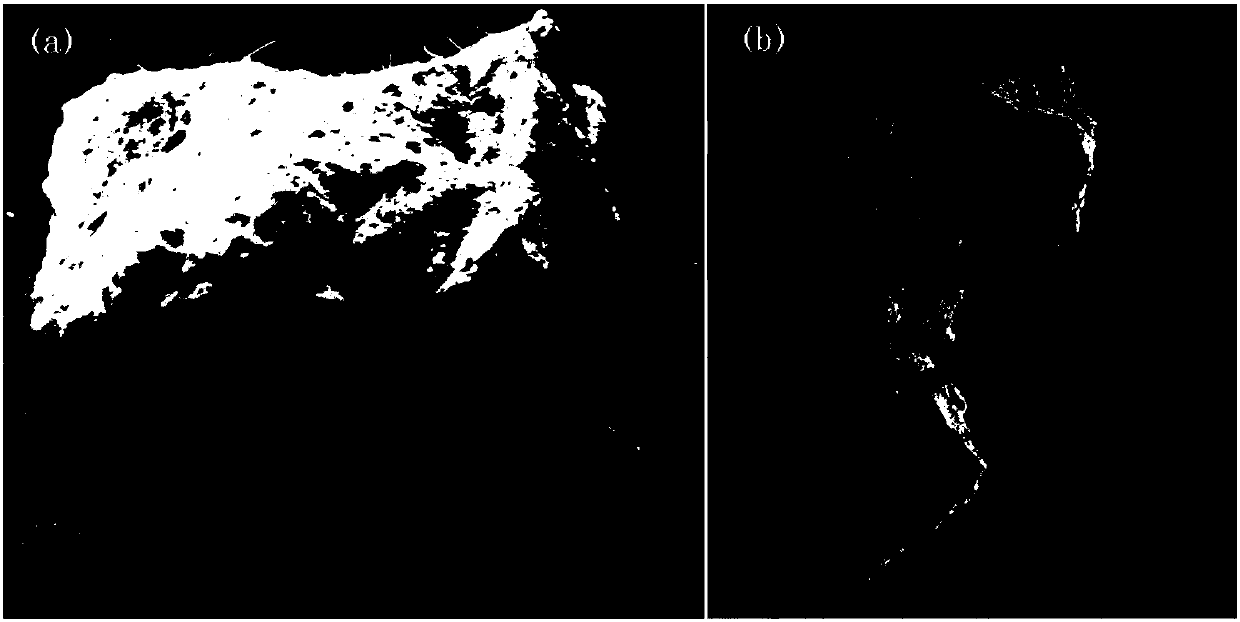

[0056] The plugging agent of this embodiment consists of the following components by weight: 84 parts of G grade cement, 8 parts of floating beads, 8 parts of micro silicon, 2 parts of asbestos fiber, 1.8 parts of fluid loss reducer, 1 part of expansion agent, 0.22 parts of retarder, 0.05 parts of potassium polyacrylate (KPAM); the cumulative percentage of cement in the particle size range of 0.68 to 63 μm reaches 93.8%; the floating beads are power plant floating beads, and the cumulative percentage in the particle size range of 0.063 to 0.256 mm reaches 95.21 %(Such as figure 1 with figure 2 shown); the cumulative percentage of micro-silicon in the particle size range of 0.04-0.68 μm reaches 97.4%; asbestos fibers are composed of short asbestos fibers with a length of 1mm≤length<3mm and long asbestos fibers with a length of 3mm≤length≤6mm in a mass ratio of 2:1 Compounded, the two types of fibers are mixtures of various lengths within their respective length ranges.

[00...

Embodiment 2

[0079]The plugging agent of this embodiment is composed of the following components by weight: 81 parts of G grade cement, 7 parts of floating beads, 10 parts of micro silicon, 1 part of asbestos fiber, 1 part of fluid loss reducer, 0.8 part of expansion agent, 0.2 parts of retarder, 0.03 parts of potassium polyacrylate (KPAM); asbestos fibers are compounded by short asbestos fibers with a length of 1mm≤length<3mm and long asbestos fibers with a length of 3mm≤length≤6mm in a mass ratio of 1.8:1.

[0080] The plugging slurry of this embodiment is made by mixing the plugging agent of this embodiment and water, and the water-cement ratio is 0.82.

Embodiment 3

[0082] The plugging agent of this embodiment is composed of the following components by weight: 85 parts of G grade cement, 10 parts of floating beads, 7 parts of micro silicon, 3 parts of asbestos fiber, 2 parts of fluid loss reducer, 1.2 parts of expansion agent, Retarder 0.28 parts, potassium polyacrylate (KPAM) 0.06 parts; asbestos fibers are compounded by short asbestos fibers with a length of 1mm≤length<3mm and long asbestos fibers with a length of 3mm≤length≤6mm in a mass ratio of 2.2:1.

[0083] The plugging slurry of this embodiment is made by mixing the plugging agent of this embodiment and water, and the water-cement ratio is 0.88.

[0084] The plugging slurry in Example 2 and Example 3 is used for the plugging construction, and the technical process can refer to Example 1, and a similar plugging effect can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com