Process for manufacturing high-strength low-density asbestos fiber-free enhanced silicate plate

A non-asbestos fiber, production process technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of lack of international competitiveness, low physical and mechanical properties, waste of resources, etc. , the effect of low density and high flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

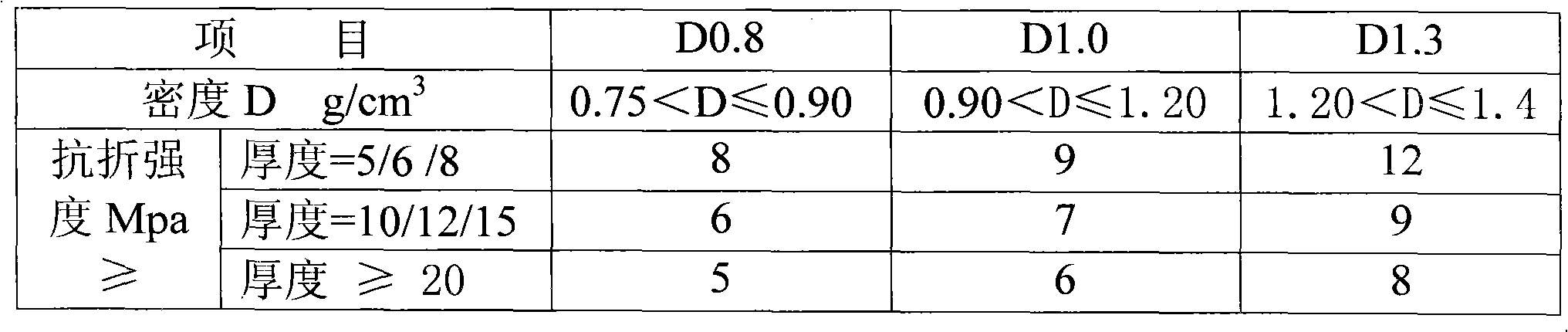

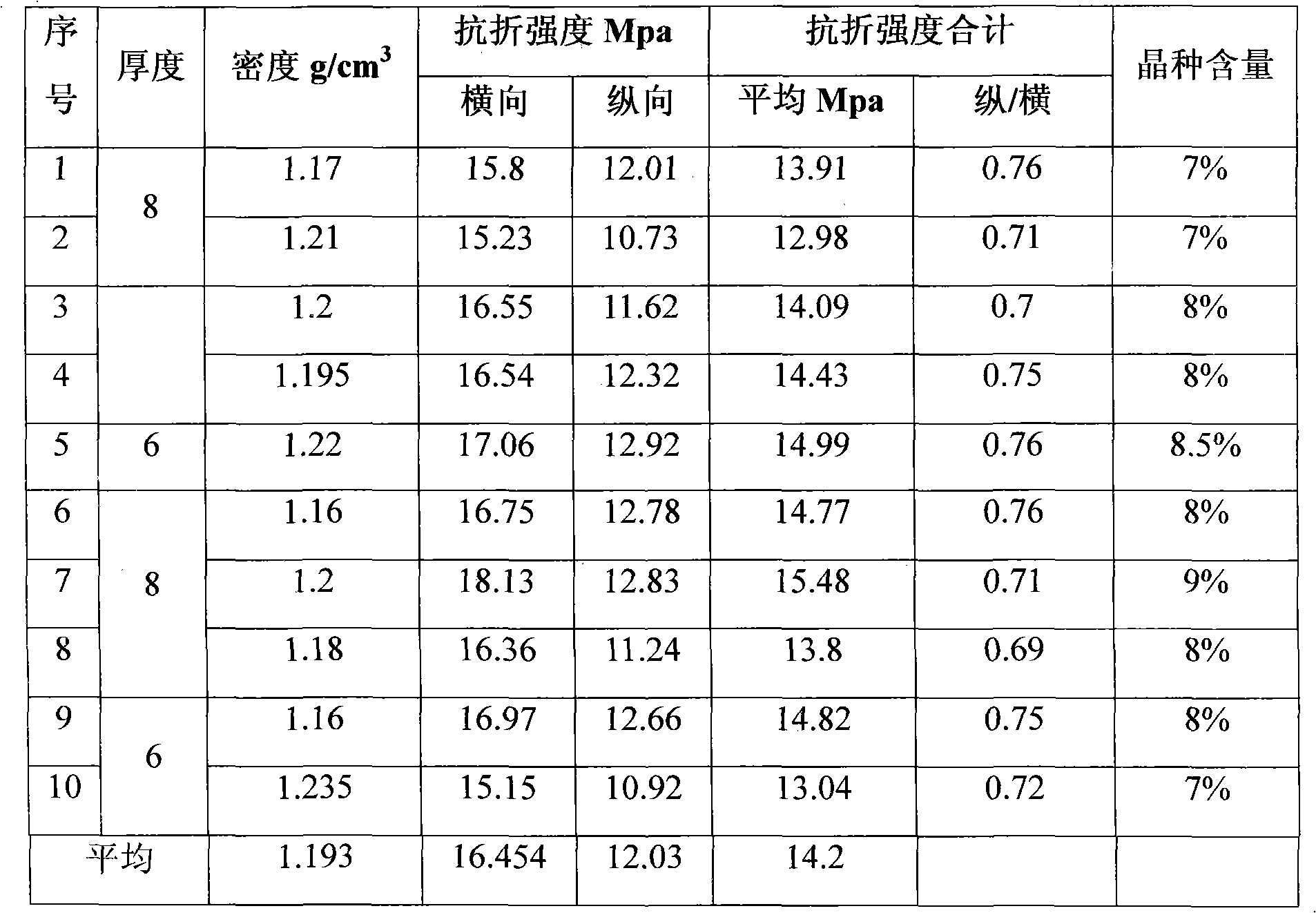

[0011] The present invention will be further described below in conjunction with the examples, China Building Materials Industry JC / T564-2000 fiber reinforced calcium silicate board, the product physical and mechanical characteristics requirements of this standard are:

[0012]

[0013] Note: The flexural strength in this table is the average value of the longitudinal and transverse flexural strength of the specimen.

[0014] The concrete steps of the technique of the present embodiment are: Step 1, first add 5-10% of cellulose fiber in the solution containing 38%-42% of quartz and 33%-37% of lime in mass ratio (the cellulose fiber is selected perennial arbor fiber or unbleached sulfate coniferous wood fiber), filter out the water, and under the action of 0.85-1.1Mpa high pressure and 175°C-185°C high temperature, obtain silicate crystal seeds with a size within 2 μm; step 2, Take the silicate seed crystal mass ratio obtained in step 1 as 3-8%, add it to the solution contai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com