Adhesive for packaging and preparation method of adhesive

A technology of adhesive and toughening agent, applied in the field of packaging adhesive and its preparation, can solve the problems of poor effect and achieve the effects of reducing cost, improving performance, increasing fusion degree and dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

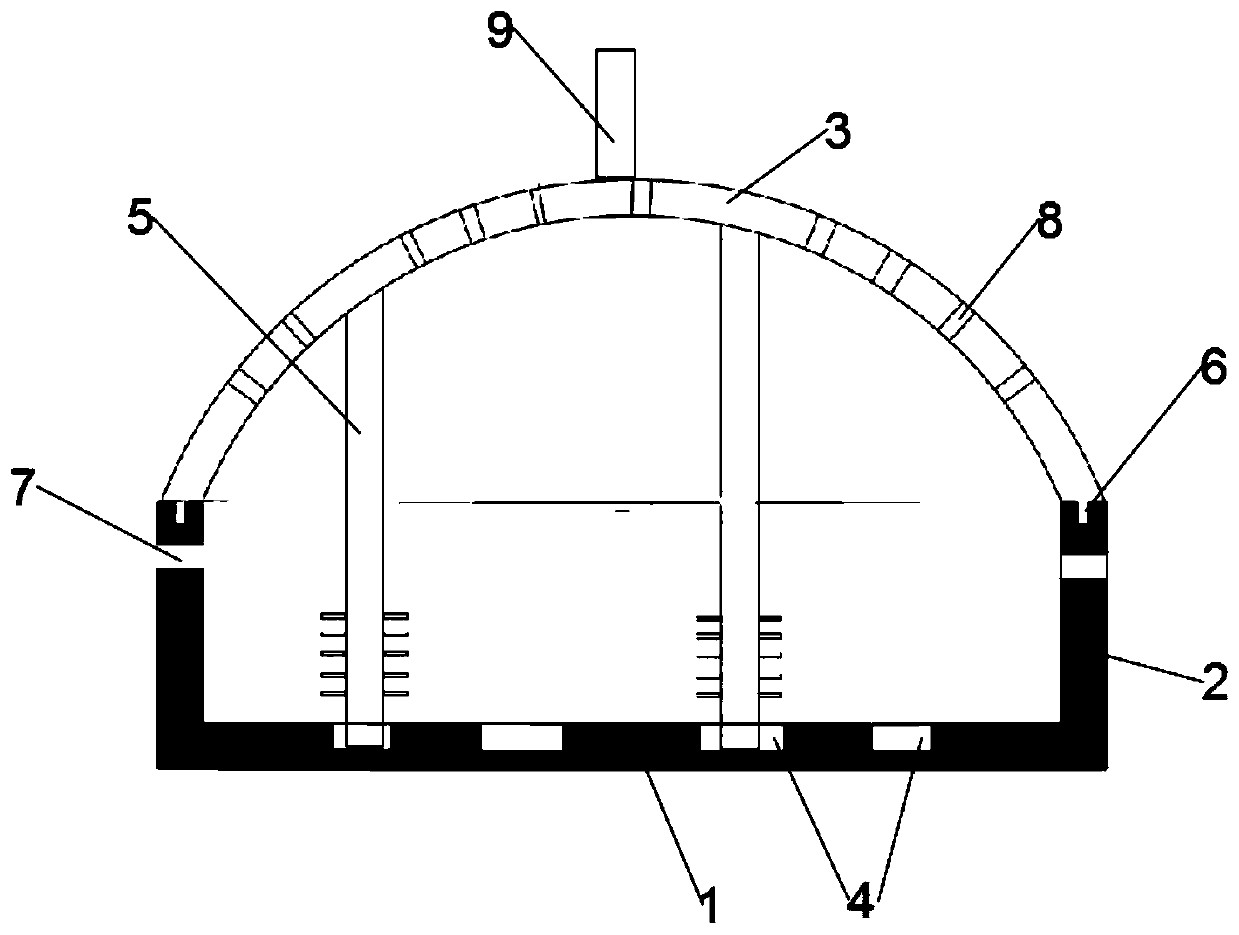

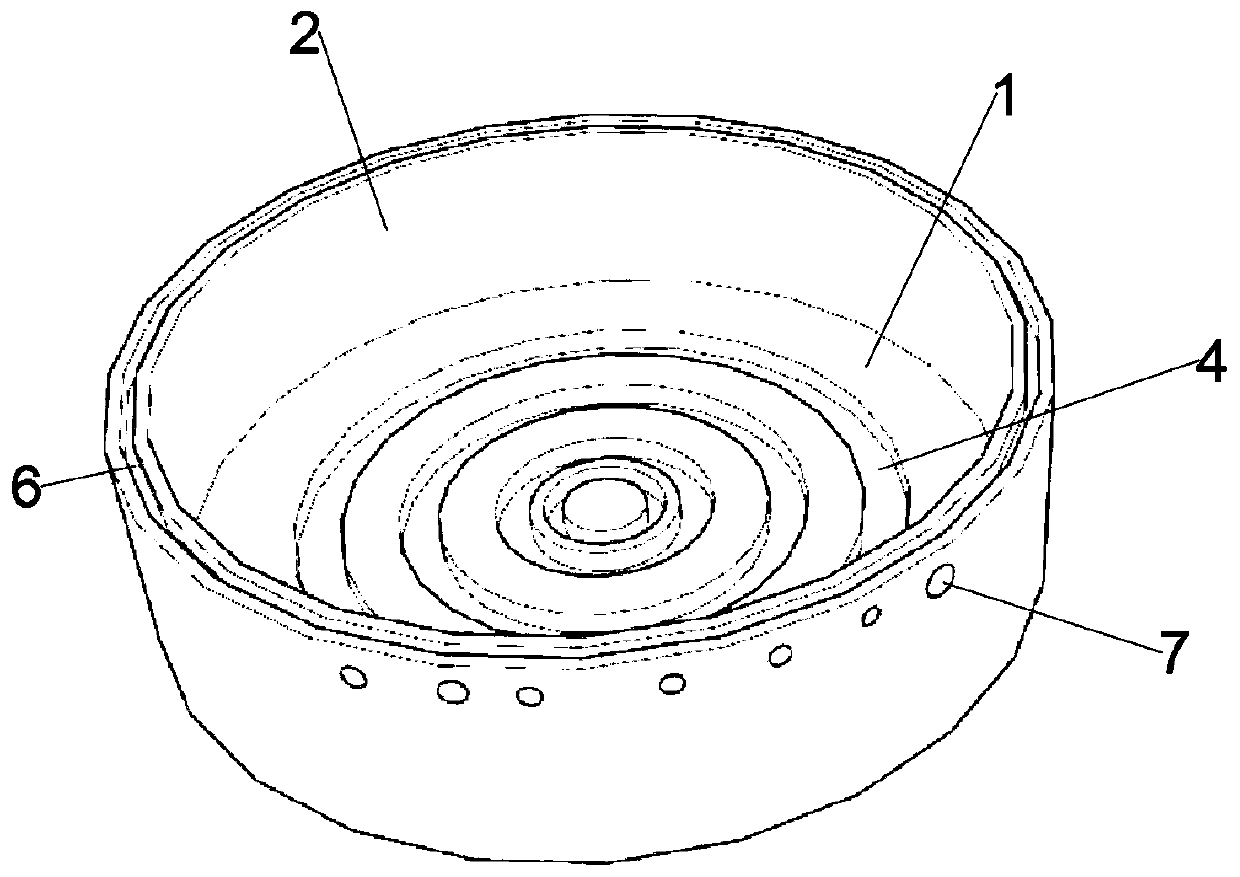

Image

Examples

Embodiment 1

[0038] The invention provides an adhesive for packaging, comprising the following raw materials in parts by mass:

[0039] 250 parts of acrylic resin, 250 parts of corn starch, 600 parts of deionized water, 5 parts of curing agent, 9 parts of vegetable toughening agent, 150 parts of asbestos fiber, 150 parts of porcelain powder, 7 parts of oxidizing agent, 4 parts of hydrogen peroxide, hydrogen 2 parts of sodium oxide, 4 parts of polyvinyl alcohol, 2.5 parts of formaldehyde, 1.5 parts of hydrochloric acid, 6 parts of esterification assistant and 1.5 parts of emulsifier.

[0040] Vegetable tougheners include starch tougheners, citric acid ester tougheners and vegetable oil bases or any combination of several; vegetable oil bases are epoxidized vegetable oils, including but not limited to epoxidized soybean oil, linseed oil, rice bran oil, sunflower oil, castor oil, cottonseed oil and sunflower oil.

[0041] Acrylic resins include butyl acrylate and methyl acrylate;

[0042] T...

Embodiment 2

[0067] The difference from Example 1 is that an adhesive for packaging provided by the present invention includes the following raw materials in parts by mass:

[0068] 200 parts of acrylic resin, 200 parts of corn starch, 500 parts of deionized water, 2 parts of curing agent, 4 parts of vegetable toughening agent, 100 parts of asbestos fiber, 50 parts of porcelain powder, 6 parts of oxidizing agent, 3 parts of hydrogen peroxide, hydrogen 1 part of sodium oxide, 3 parts of polyvinyl alcohol, 2 parts of formaldehyde, 1 part of hydrochloric acid, 4 parts of esterification assistant.

[0069] The preparation method of the adhesive is as follows: according to the component ratio of the above-mentioned adhesive mass meter, the specific steps are as follows:

[0070] Step 100. Prepare water-based acrylic resin emulsion: Take 200 parts of acrylic resin and 250 parts of deionized water, add them to the mixer, add 1 part of emulsifier continuously while stirring, stir until an emulsion...

Embodiment 3

[0079] The invention provides an adhesive for packaging, comprising the following raw materials in parts by mass:

[0080] 300 parts of acrylic resin, 300 parts of corn starch, 700 parts of deionized water, 8 parts of curing agent, 15 parts of plant-type toughening agent, 200 parts of asbestos fiber, 200 parts of porcelain powder, 9 parts of oxidizing agent, 6 parts of hydrogen peroxide, hydrogen 3 parts of sodium oxide, 5 parts of polyvinyl alcohol, 3 parts of formaldehyde, 2 parts of hydrochloric acid, 8 parts of esterification auxiliary agent, and 2 parts of emulsifier.

[0081] The preparation method of the adhesive is as follows: according to the component ratio of the above-mentioned adhesive mass meter, the specific steps are as follows:

[0082] Step 100, prepare water-based acrylic resin emulsion: take 300 parts of acrylic resin and 350 parts of deionized water, add them to the mixer, add 2 parts of emulsifier continuously while stirring, stir until an emulsion is for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com