Method for measuring crack resistance of composite coating coated on outer wall

A composite coating and measurement method technology, applied in the field of crack resistance measurement, can solve the problem that crack resistance does not have relevant national or industrial testing standards and methods, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A thermal insulation plastering layer composed of polymer plastering mortar and grid cloth, wherein the polymer plastering mortar has a folding ratio of less than 3.0, and the tensile bond strength with cement blocks is greater than 0.6MPa; the mesh cloth is glass fiber mesh Grape cloth, the mass per unit area is 160g / m 2 , Alkali-resistant breaking strength values in the warp and weft directions are all greater than 750 (N / 50mm).

[0033] Among them, the measuring method of the crack resistance of the polymer plastering mortar and the grid cloth is:

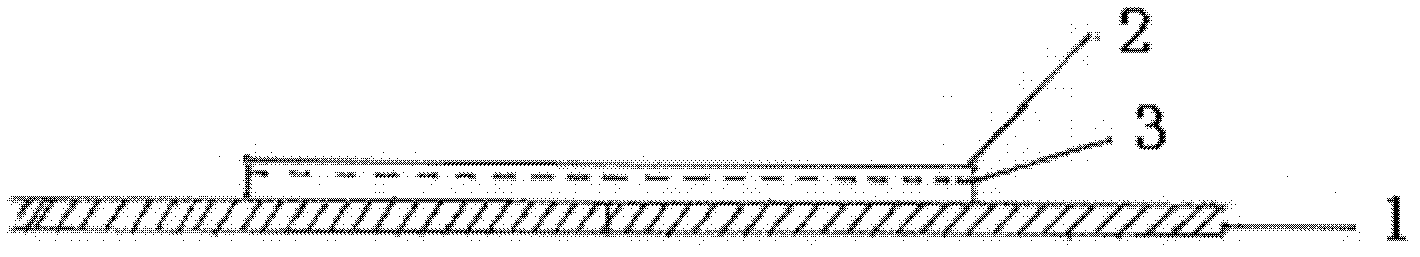

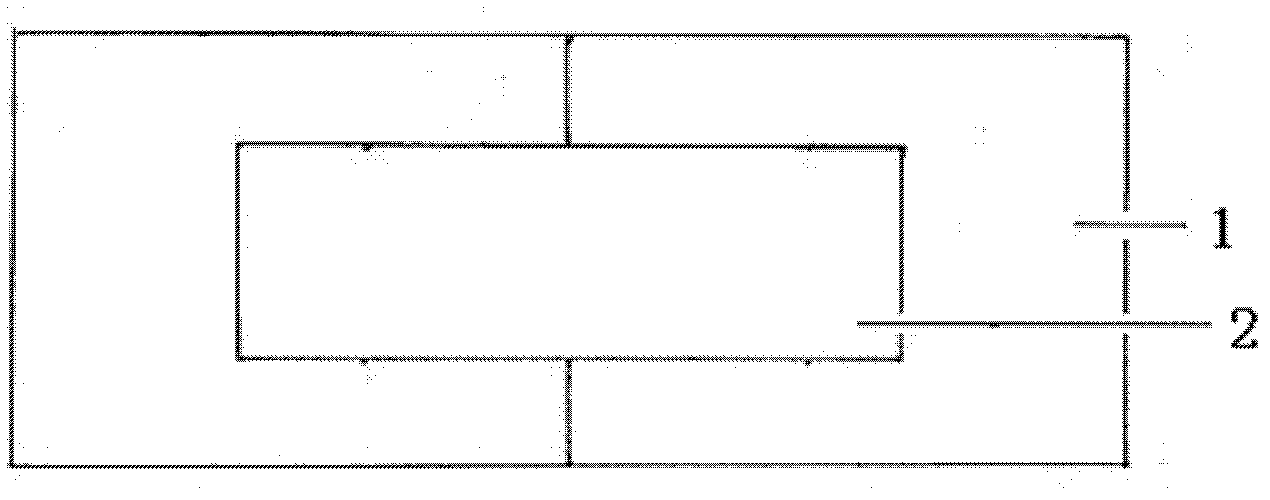

[0034] (1) Preparation of pre-cracked slabs: put an asbestos-free fiber cement slab with a specification of 205mm×80mm×3mm into a dynamic anti-cracking instrument for pre-capping, until the cement slab is broken into two pieces, and then put it back together, and use a textured Fix it on the cement board of the same specification with paper, and the front side of the pre-cracked board faces up;

[0035] (2) Prepare th...

Embodiment 2

[0042] An external thermal insulation plastering layer composed of lightweight plastering mortar and mesh cloth, wherein the lightweight plastering mortar has a dynamic crack resistance greater than 0.08mm, and a tensile bond strength with cement blocks greater than 0.7MPa; the mesh cloth is Glass fiber mesh cloth, the mass per unit area is 160g / m 2 , Alkali-resistant breaking strength values in the warp and weft directions are all greater than 750 (N / 50mm).

[0043] The method for measuring the crack resistance of lightweight plastering mortar and grid cloth: includes the following steps:

[0044] (1) Preparation of pre-cracked slabs: put an asbestos-free fiber cement slab with a specification of 205mm×80mm×3mm into a dynamic anti-cracking instrument for pre-capping, until the cement slab is broken into two pieces, and then put it back together, and use a textured Fix it on the unpre-cracked cement board of the same specification with paper, and the front side of the pre-c...

Embodiment 3

[0052] A composite coating composed of ordinary dry powder putty and mesh cloth, wherein the dry powder putty meets the requirements of P-type putty in the JG / T157-2009 standard, with a flexibility of 100mm without cracks and a tensile bond strength of 0.60MPa; The grid cloth is glass fiber mesh cloth, the mass per unit area is 100g / m 2 , Alkali-resistant breaking strength values in the warp and weft directions are all greater than 700 (N / 50mm).

[0053] Wherein the measurement method of the crack resistance of the dry powder putty and the grid cloth composite layer is:

[0054] (1) Preparation of pre-cracked slabs: put an asbestos-free fiber cement slab with a specification of 205mm×80mm×3mm into a dynamic anti-cracking instrument for pre-capping, until the cement slab is broken into two pieces, and then put it back together, and use a textured Fix it on the cement board of the same specification with paper, and the front side of the pre-cracked board faces up;

[0055] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile bond strength | aaaaa | aaaaa |

| Tensile bond strength | aaaaa | aaaaa |

| Mass per unit area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com