Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Reduce the delivery link" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

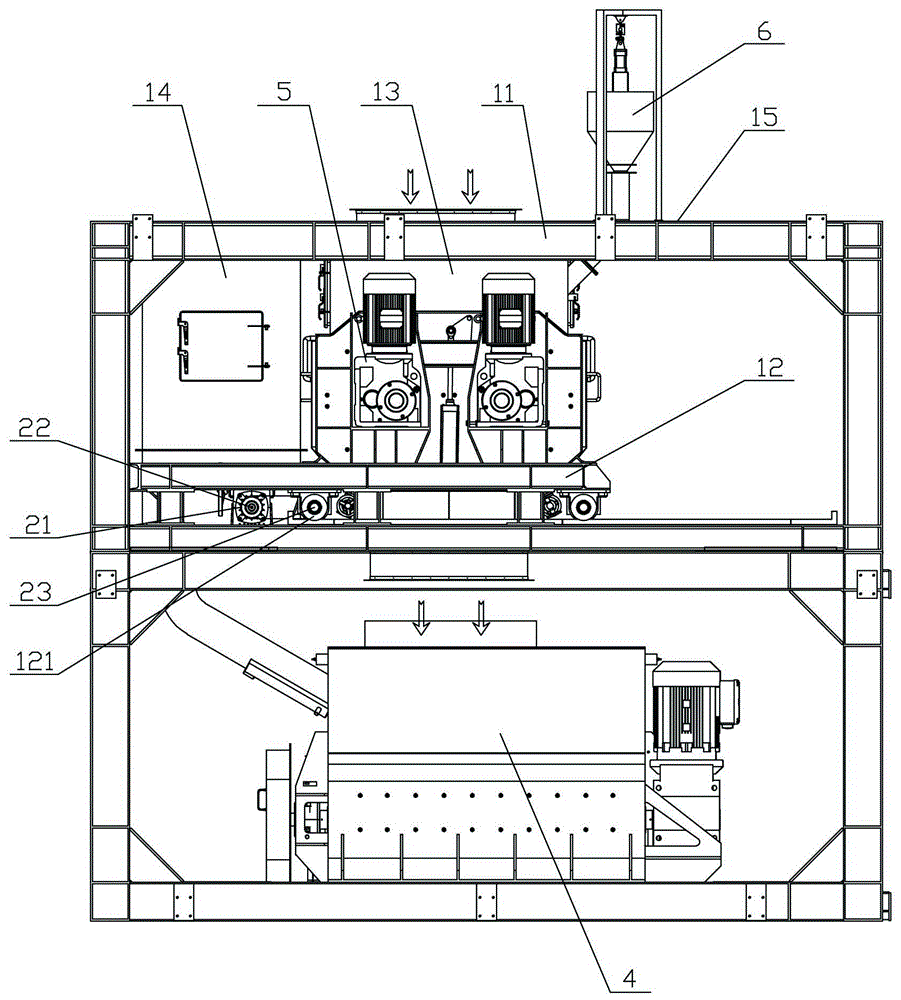

Breaking and separation integrated comprehensive recovery method of chrysotile tailings

InactiveCN103433137AReduce the delivery linkReduce lossesMagnetic separationGrain treatmentsRecovery methodMagnetic separator

The invention provides a breaking and separation integrated comprehensive recovery method of chrysotile tailings, which is characterized by comprising the steps of putting the dried chrysotile tailings in breaking and separation integrated equipment consisting of a pulverizer and a cyclone powder collector, achieving pulverizing and separation by adding 4-8 sand discharge ports on a pulverizing disc of the pulverizer, separating a chrysotile mixed material containing dust and tailing waste, conveying the chrysotile mixed material to a plane revolving screen or a plane shaking screen for classification and dedusting, removing fine sand and the dust, obtaining chrysotile products of different levels, roughing the tailing waste, the fine sand and the dust with a weak magnetic separator, obtaining magnetic middlings and tailings, and conveying the magnetic middlings into a ball mill for milling, and a wet weak magnetic separator for concentrating to obtain magnetite concentrates and tailings. According to the method, two production processes, grinding & asbestos fiber opening, and separation, of the chrysotile tailings are organically combined into a whole, effects of energy conservation and consumption reduction are achieved, and the chrysotile products of different levels and the magnetite concentrates are obtained simultaneously.

Owner:十堰源禹工贸有限公司

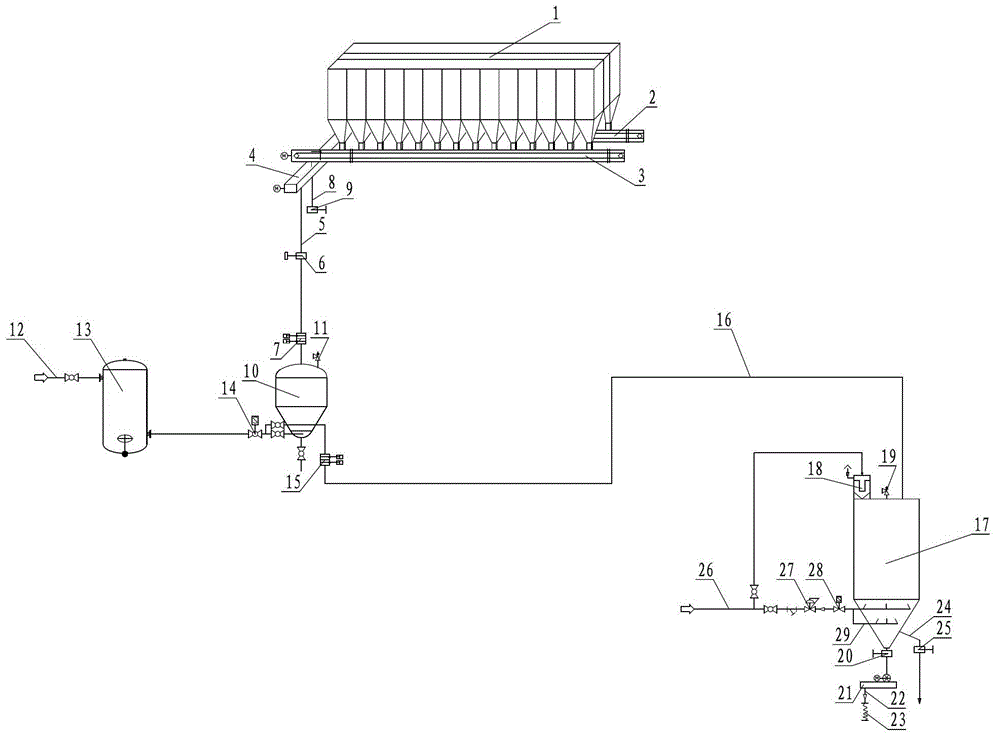

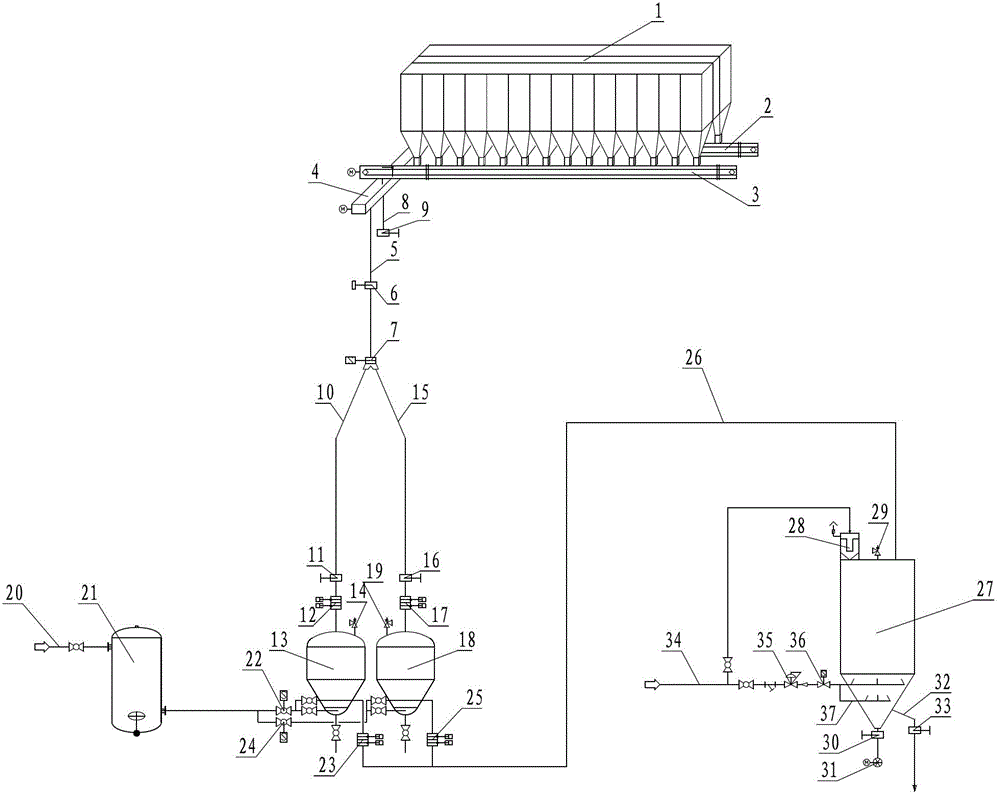

Pneumatic transmission method for dry dedusting of fine ash in converter gas

ActiveCN103388046AReduce the delivery linkLow failure rateManufacturing convertersNitrogenNitrogen gas

The invention relates to a pneumatic transmission method for dry dedusting of fine ash in converter gas, which comprises the following steps: S1, constructing a pneumatic transmission system for dry removal of dust and fine ash in converter gas; S2, material feeding: discharging ash into a first bin pump (13) or a second bin pump (18); S3, fluidizing: transporting nitrogen from a gas tank (20) into a first fluidizing device or a second fluidizing device; S4, conveying: conveying evenly fluidic gas ash mixture to a fine ash cabin (27) via a pneumatic conveying pipe (26); S5, blowing; and S6, transporting. The invention adopts a dry filter bag deduster with no spark discharge, which thoroughly solves the problem of easy explosion venting caused by a static deduster. By the method, conveying step of fine dust is minimized, and equipment failure rate is substantially reduced. Storage and transportation of ash in the fine ash cabin are not limited by site or distance.

Owner:WISDRI ENG & RES INC LTD

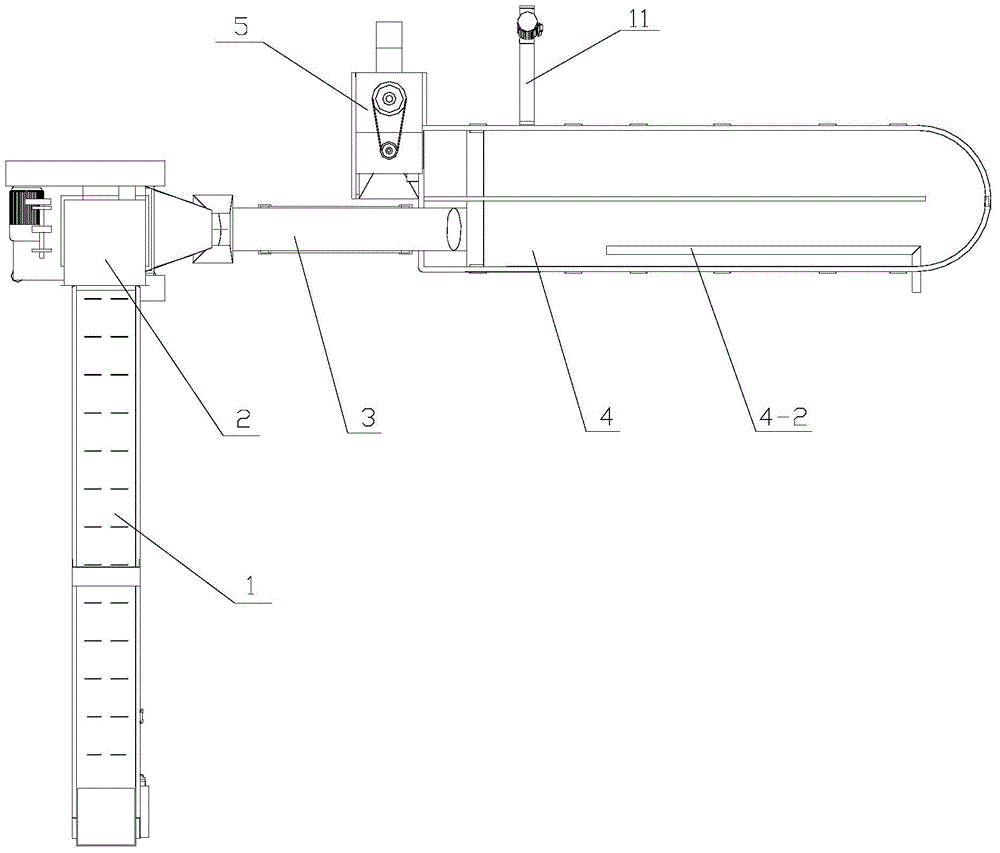

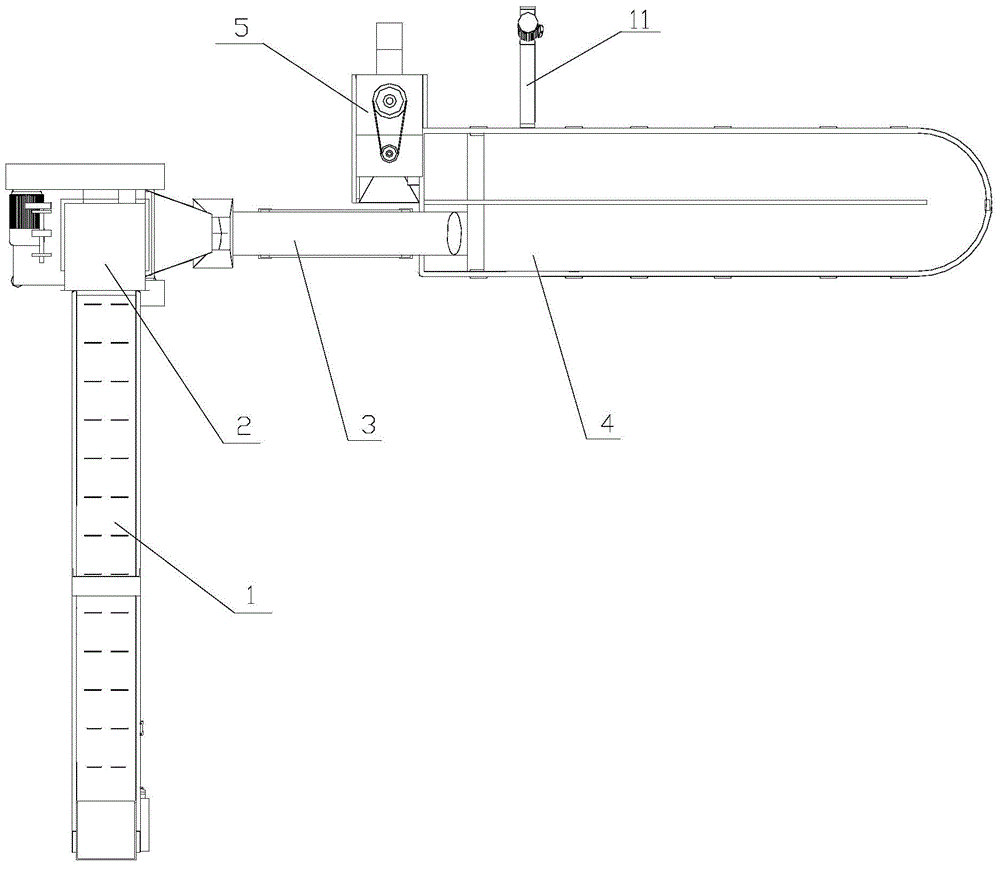

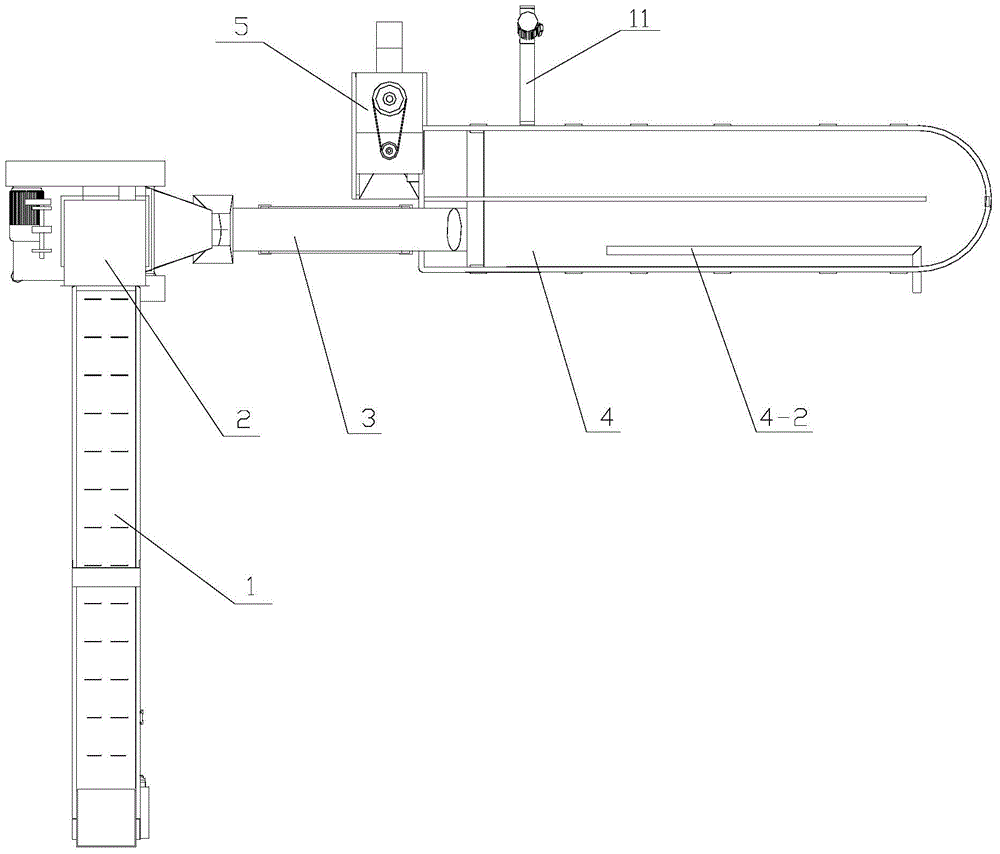

Alumina conveying system and method

InactiveCN101698493AReduce power consumptionReduce wearLoading/unloadingConveyor partsBucket elevatorDelivery system

The invention relates to an alumina conveying system and method, including directly conveying alumina to the hopper of a bucket type hoister from chute and hoisting the alumina to top of alumina bin by the bucket type hoister. The invention conveys alumina by utilizing a bucket type hoister instead of a pneumatic hoisting device initially in alumina production, thus greatly reducing power consumption of hoisting alumina vertically; besides a travelling apron is spared, conveying link is reduced, and horizontal conveying power consumption is reduced; and dynamic conveying is changed into static conveying, thus greatly reducing abrasion in conveying process. Practice shows that power is reduced to 75kW from original 185kWx2 under the conditions that conveying capacity is 300t / h and material is hoisted to the top of alumina bin by utilizing a steel wire adhesive tape bucket type hoister instead of a pneumatic hoisting device.

Owner:HANGZHOU JINJIANG GROUP

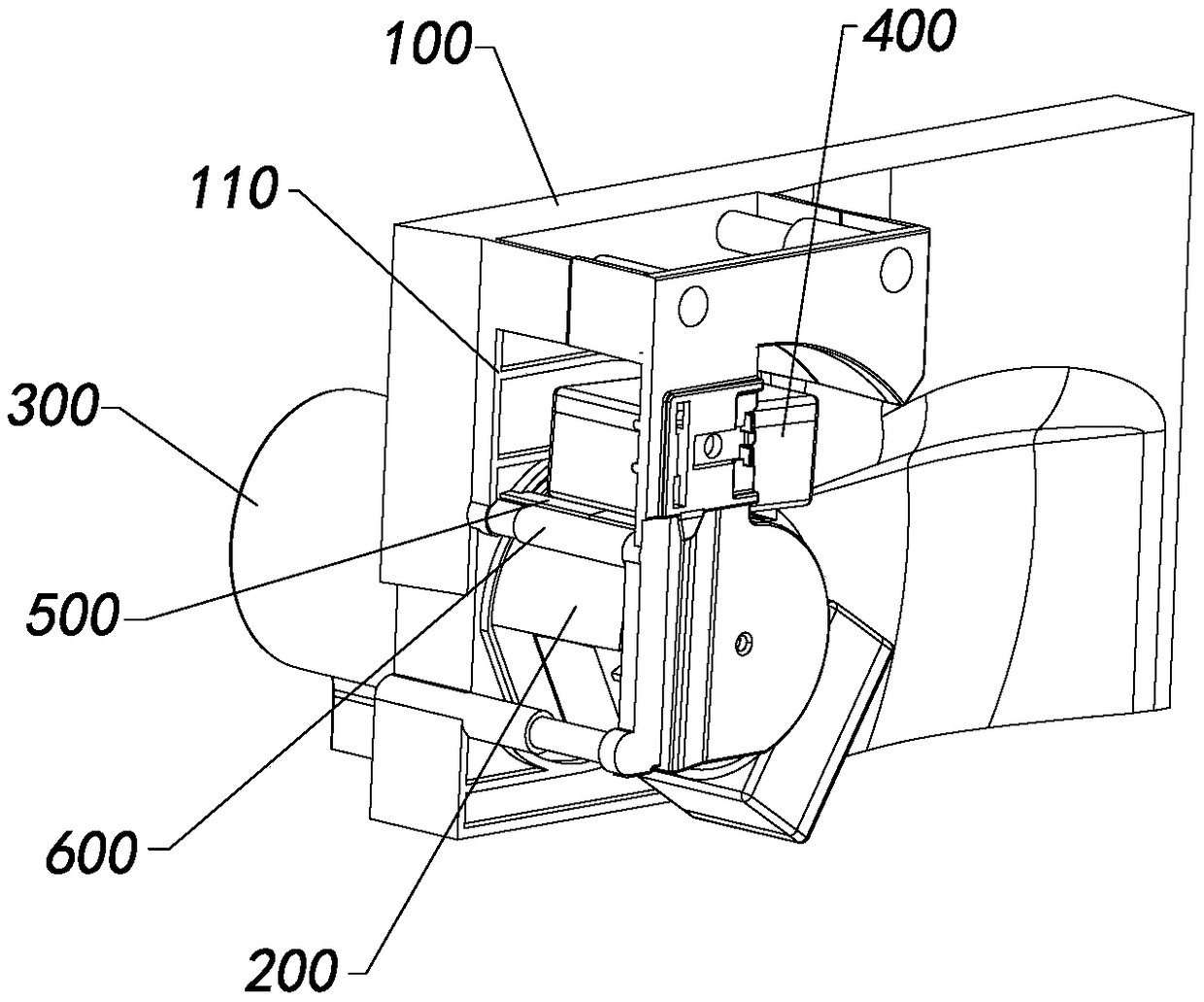

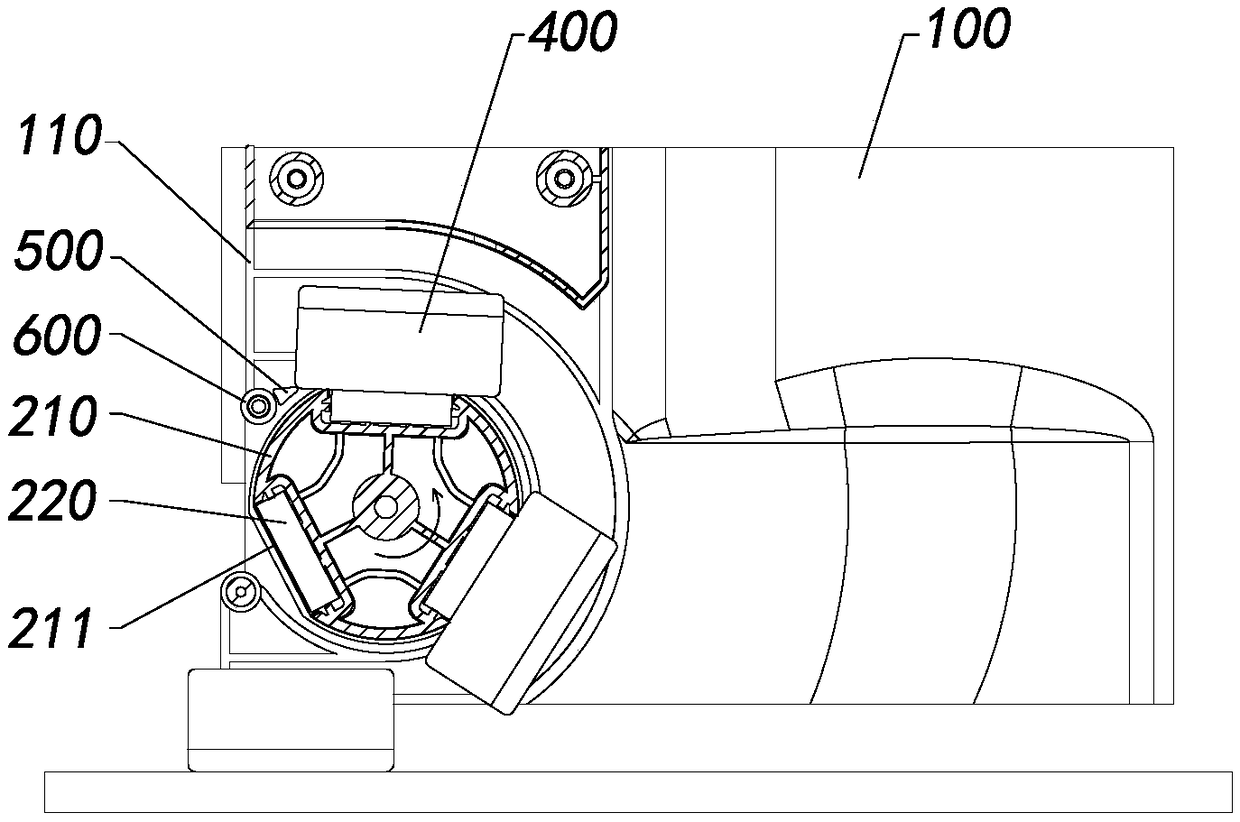

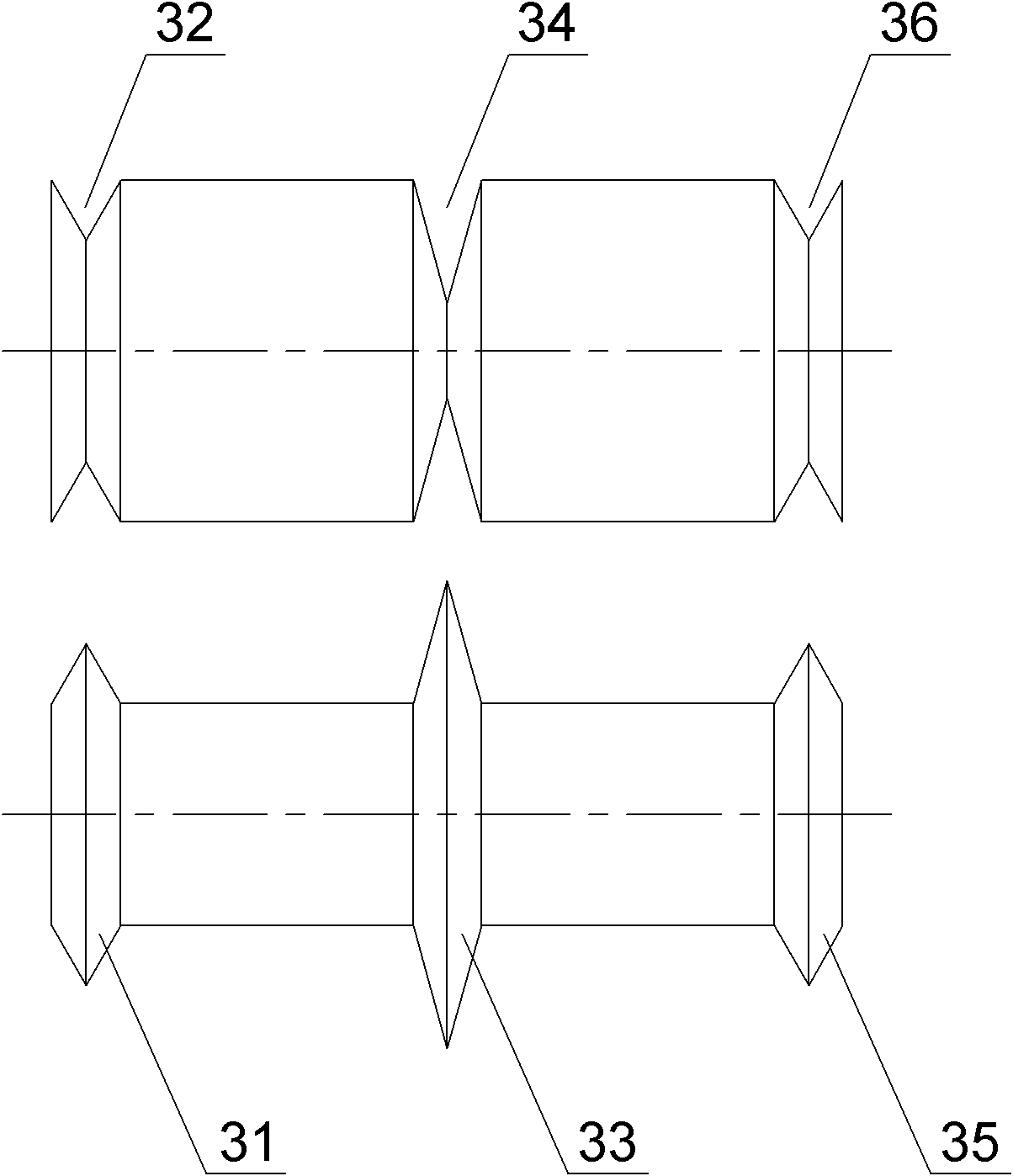

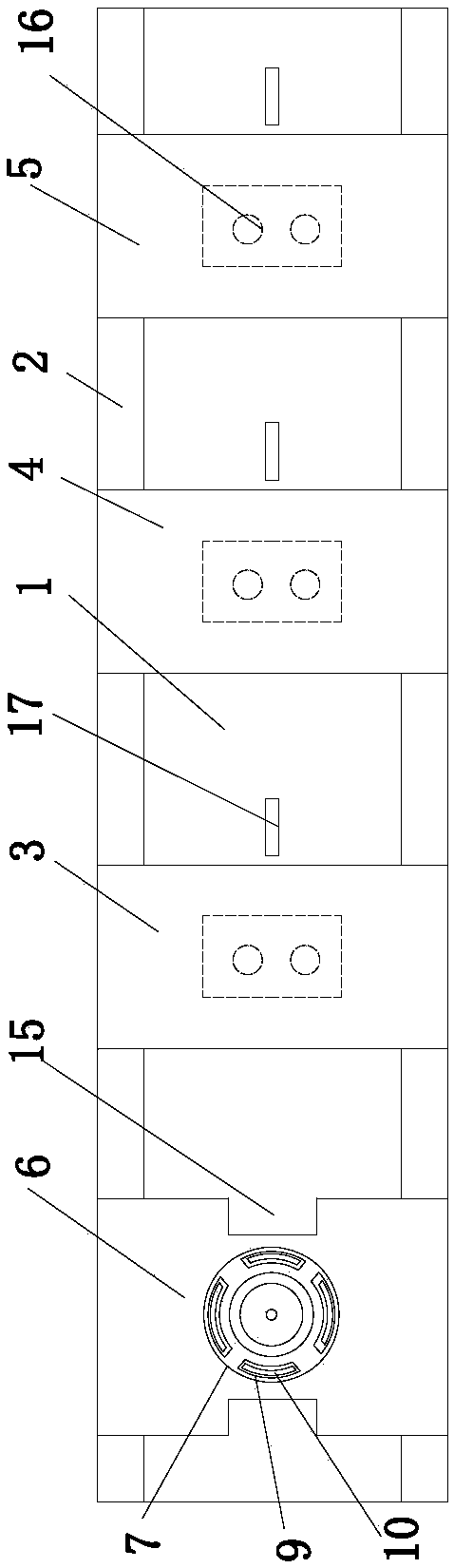

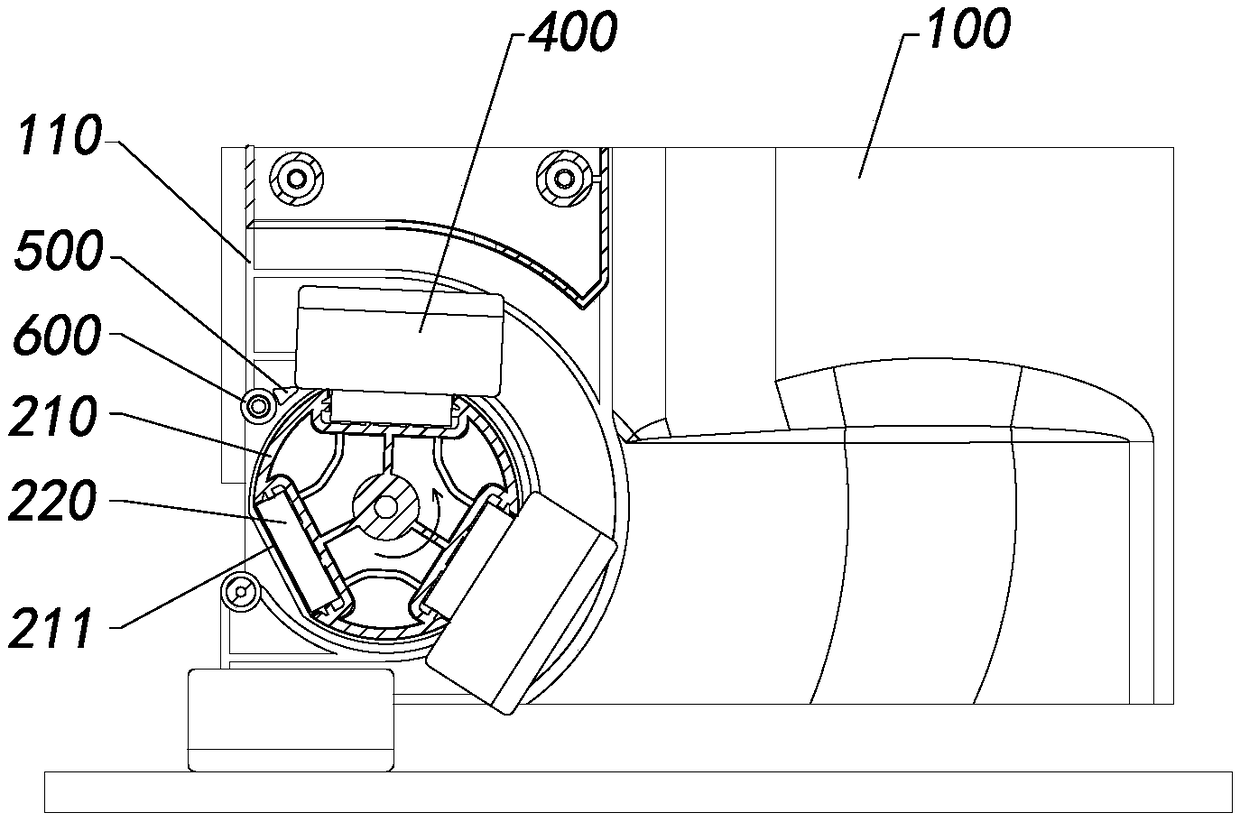

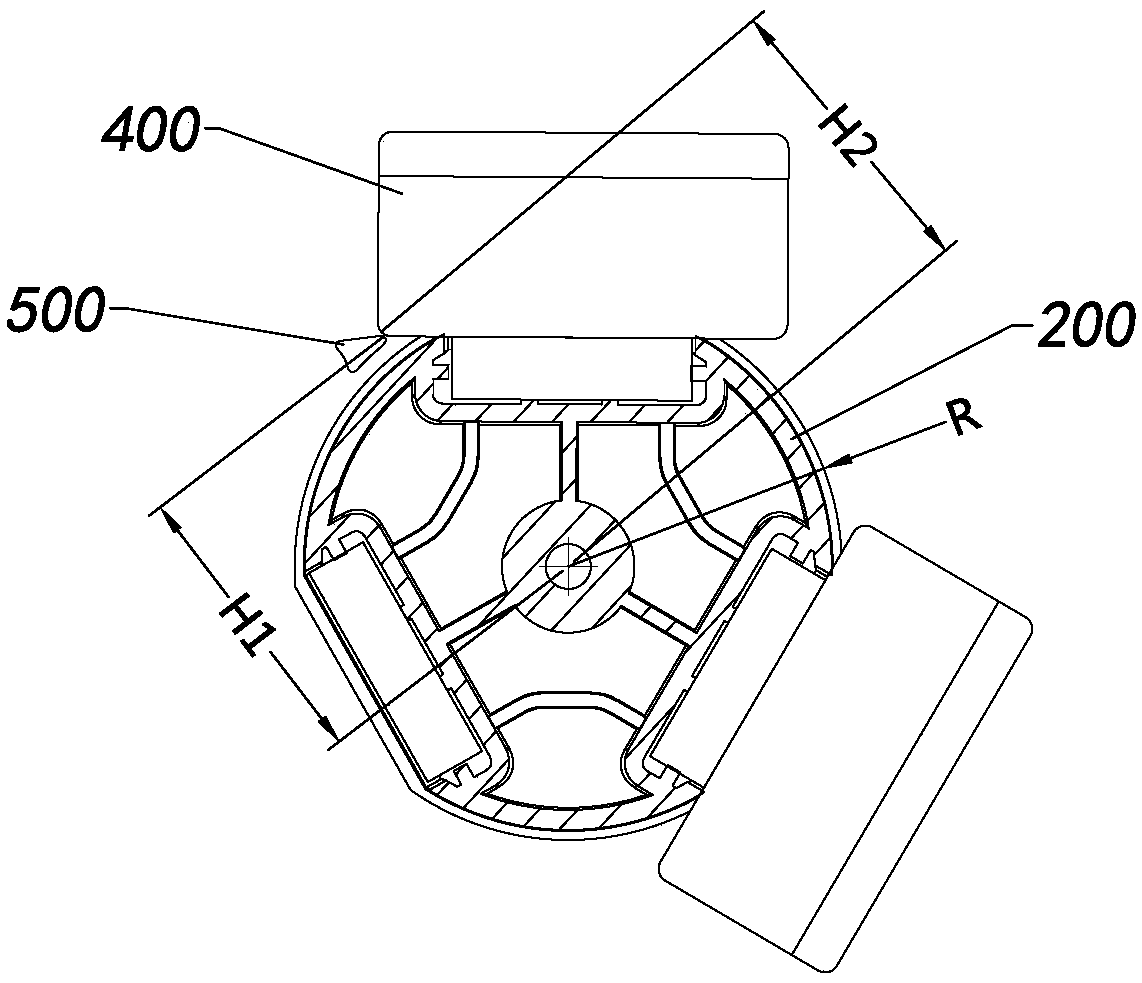

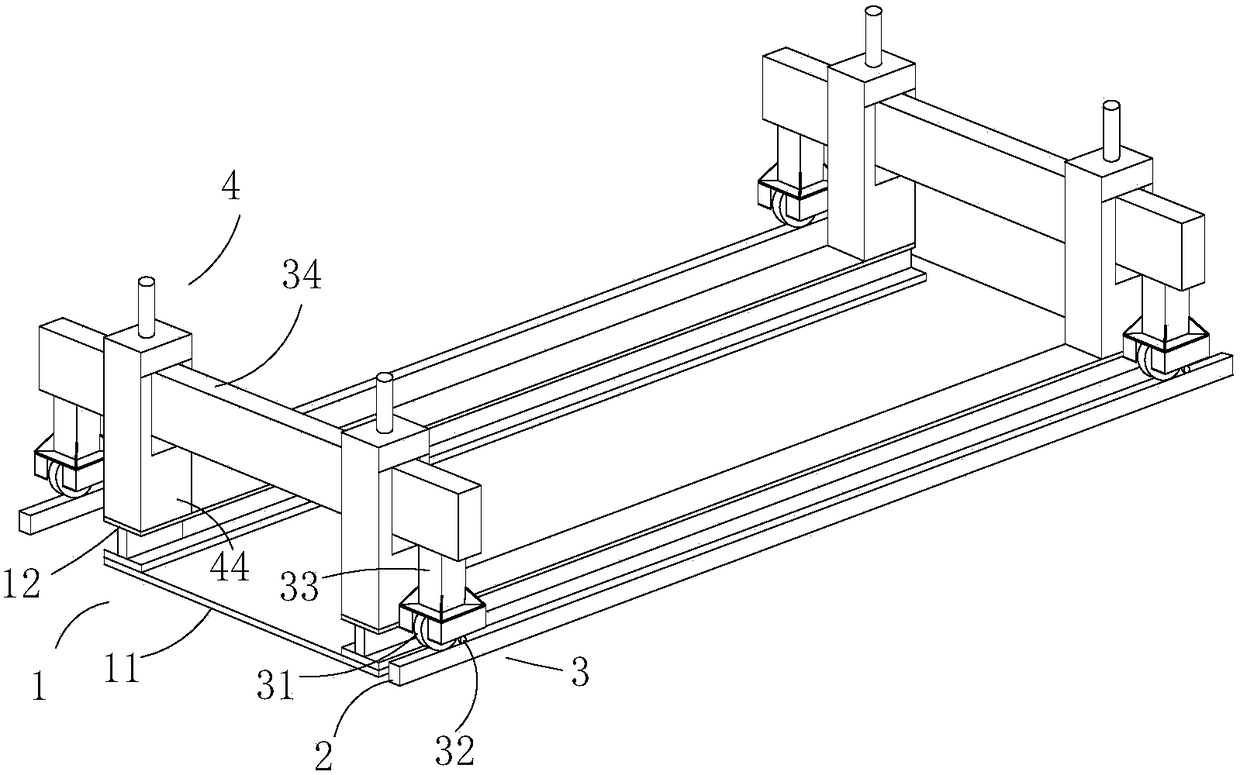

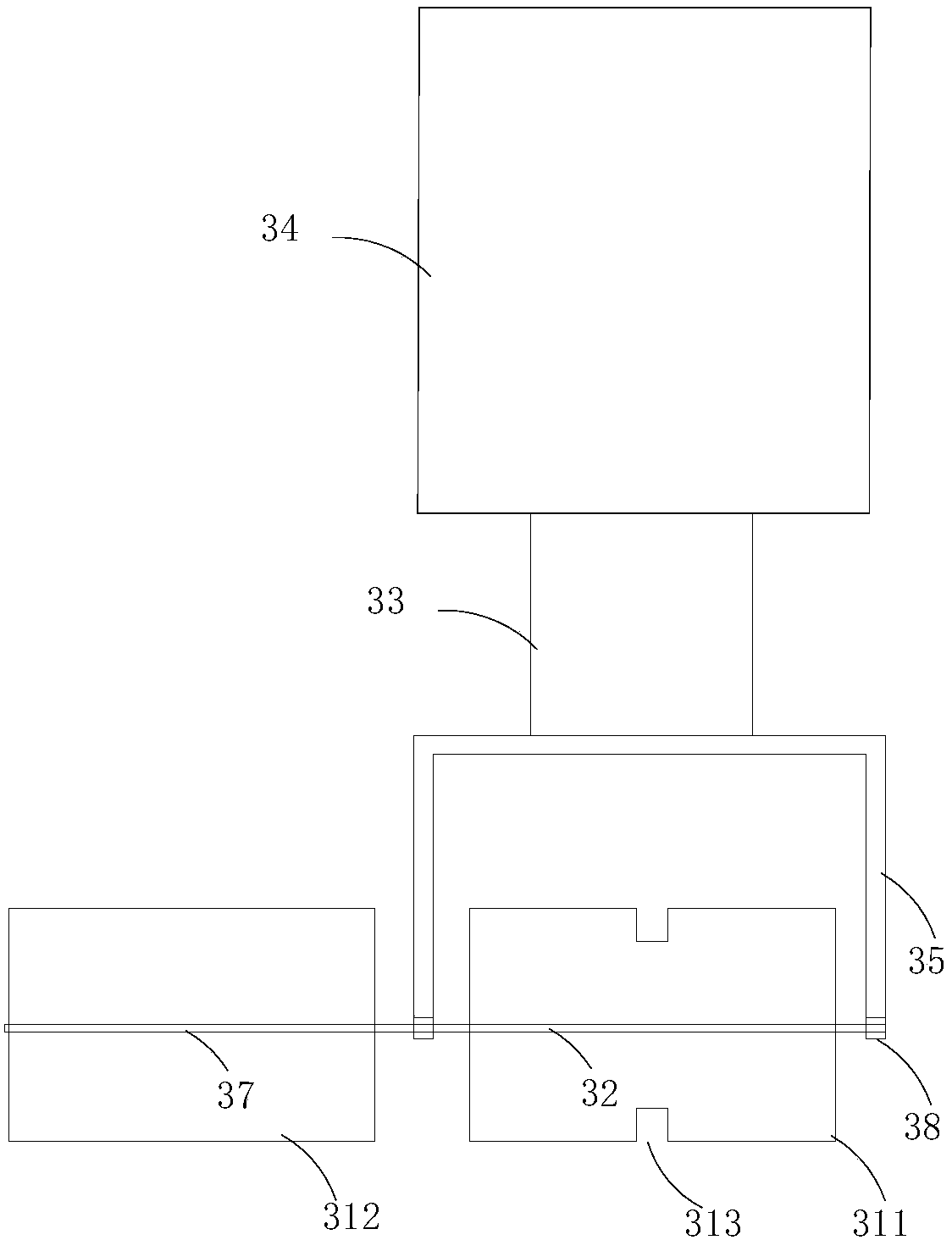

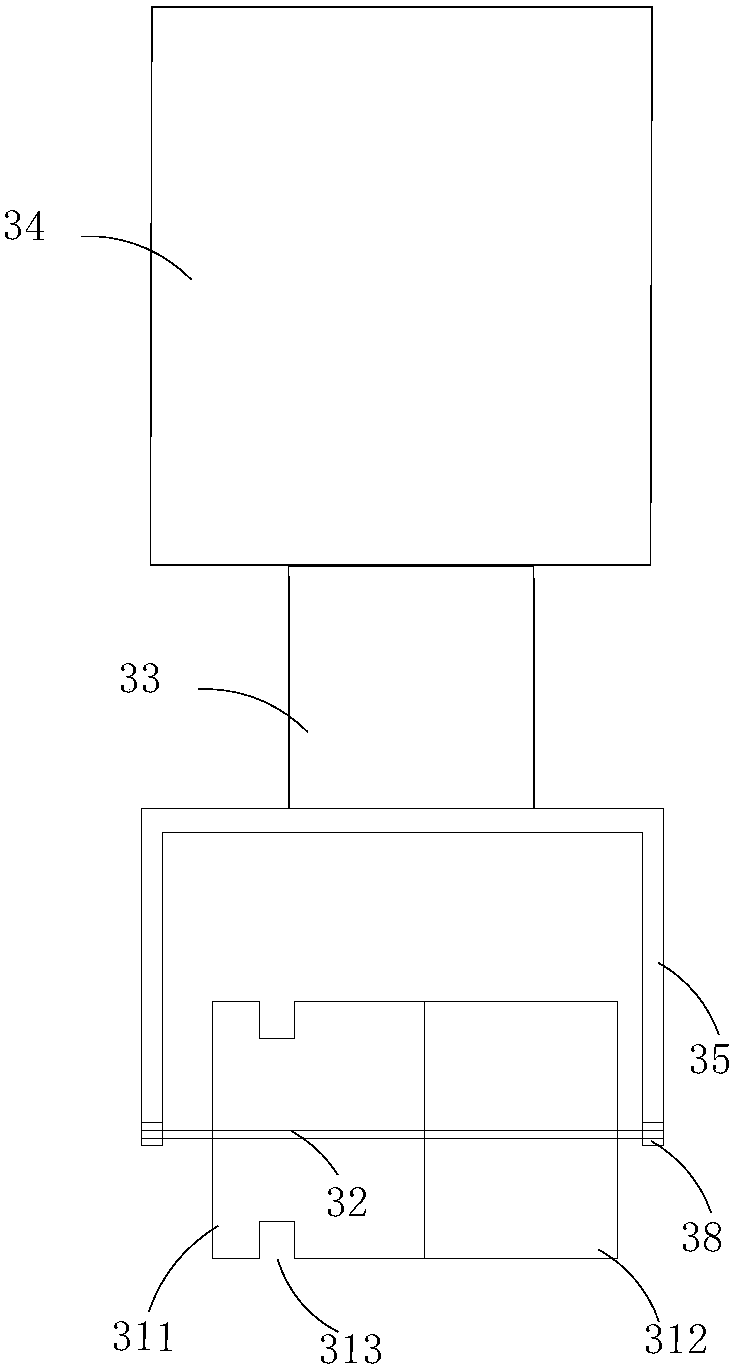

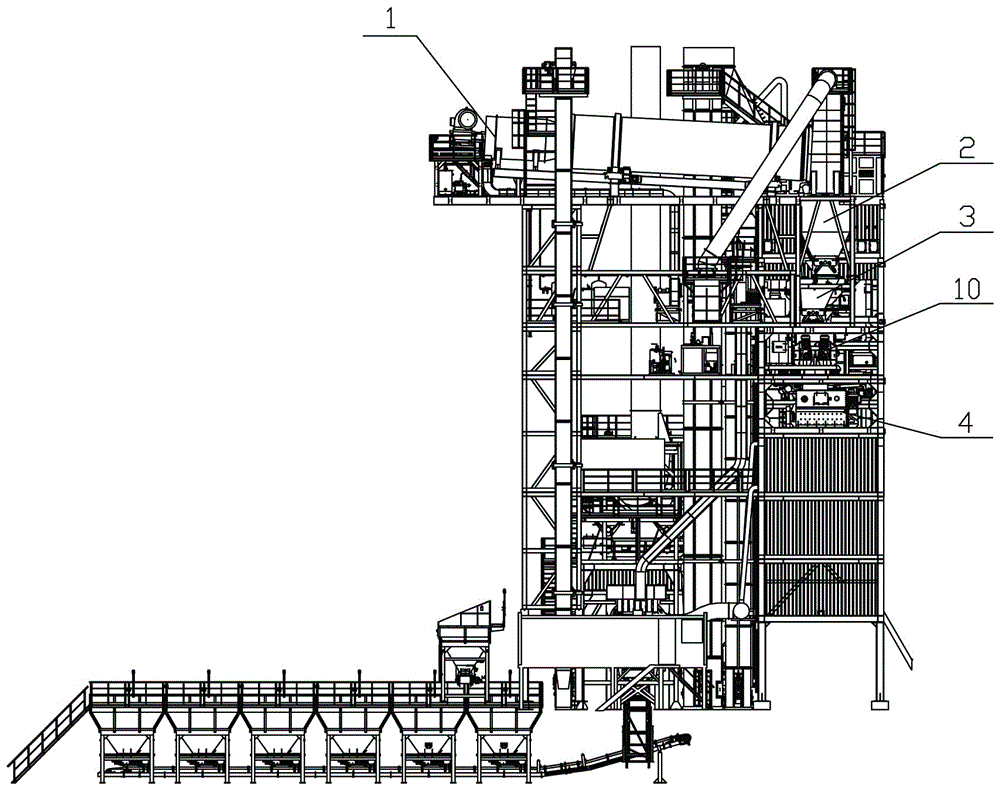

Tile conveying device for automatic mahjong machine and automatic mahjong machine

PendingCN108786098ASimple structureShorten the lengthIndoor gamesMechanical engineeringElectric machine

The invention discloses a tile conveying device for an automatic mahjong machine and the automatic mahjong machine, and belongs to the field of chess and card entertainment equipment. The defects thatexisting tile conveying devices are complicated in tile conveying mode and structure, high in cost and the like are overcome. The tile conveying device for the automatic mahjong machine comprises a tile conveying bracket, a tile sucking wheel and a tile blocking piece; the tile sucking wheel is installed on the tile conveying bracket and driven by a tile conveying motor to rotate, mahjong tiles are sucked to the tile sucking wheel and rotate along with the tile sucking wheel, the tile blocking piece is located on a rotation track of the mahjong tiles and used for blocking the mahjong tiles moving to the tile blocking piece so that the mahjong tiles moving to the tile blocking piece can be separated from the tile sucking wheel and conveyed out of the tile conveying bracket. By means of thetile conveying device, the existing tile conveying mode relying on a conveying belt is changed, the conveying belt and a tile discharging wheel are omitted, a tensioning mechanism of the conveying belt is also omitted, the length of the tile conveying bracket is shortened, the structure of the tile conveying device is greatly simplified, and the space occupied by the tile conveying device is reduced.

Owner:MATSUOTA MECHANICAL & ELECTRICAL CHINA CO LTD

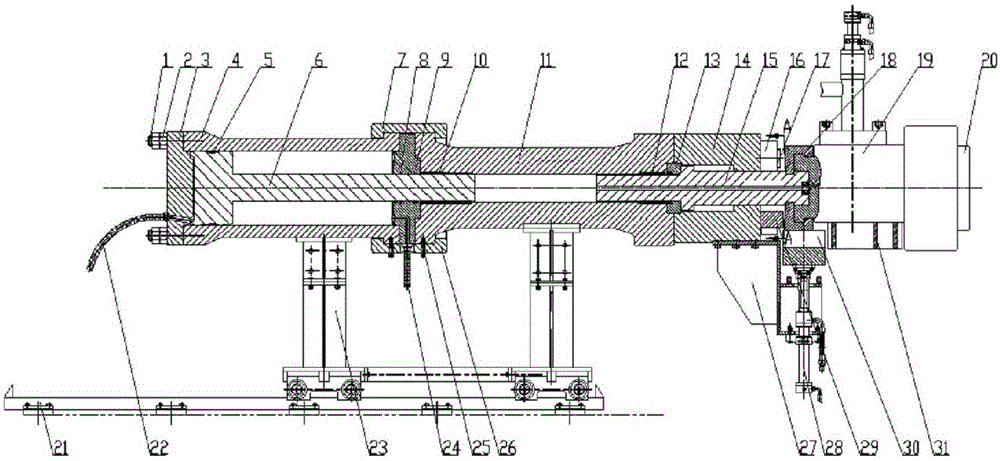

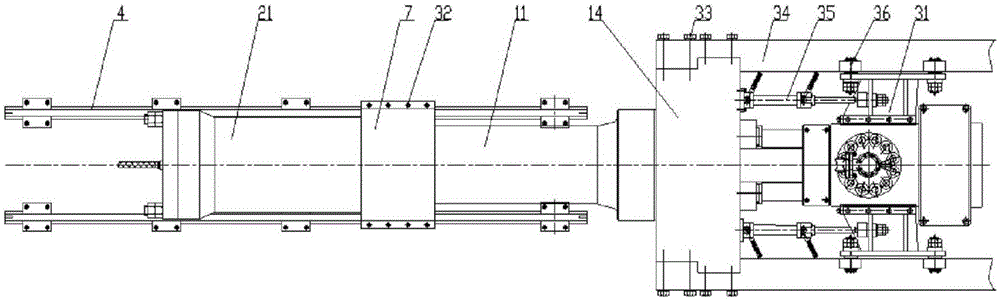

Supercharging system integrated steel pipe hydrostatic testing machine water-filling apparatus

ActiveCN105372134AReduce the delivery linkEasy maintenanceMaterial strength using tensile/compressive forcesFluid-tightness measurement using fluid/vacuumInternal pressureWhole body

A supercharging system integrated steel pipe hydrostatic testing machine water-filling apparatus comprises a low pressure cylinder body, a piston rod, a high pressure cylinder body and a water-filling head, etc. By controlling motion of the piston rod, internal pressure of a pipe is raised, pipe hydrostatic testing is realized, and the water delivery link is saved. During the pressure testing process, the water-filling head is prevented from being drawn back due to the effect of an anti-back block, and axial force is transmitted to a rack to make force on the whole structure to be more reasonable. Strength requirement of the whole body is reduced. A supercharging system and the water-filling apparatus are integrated. Thus, leak points are greatly reduced, supercharging efficiency is raised, the structure is simpler, operation is stable and reliable, safety is high, cost is low, and control is convenient.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

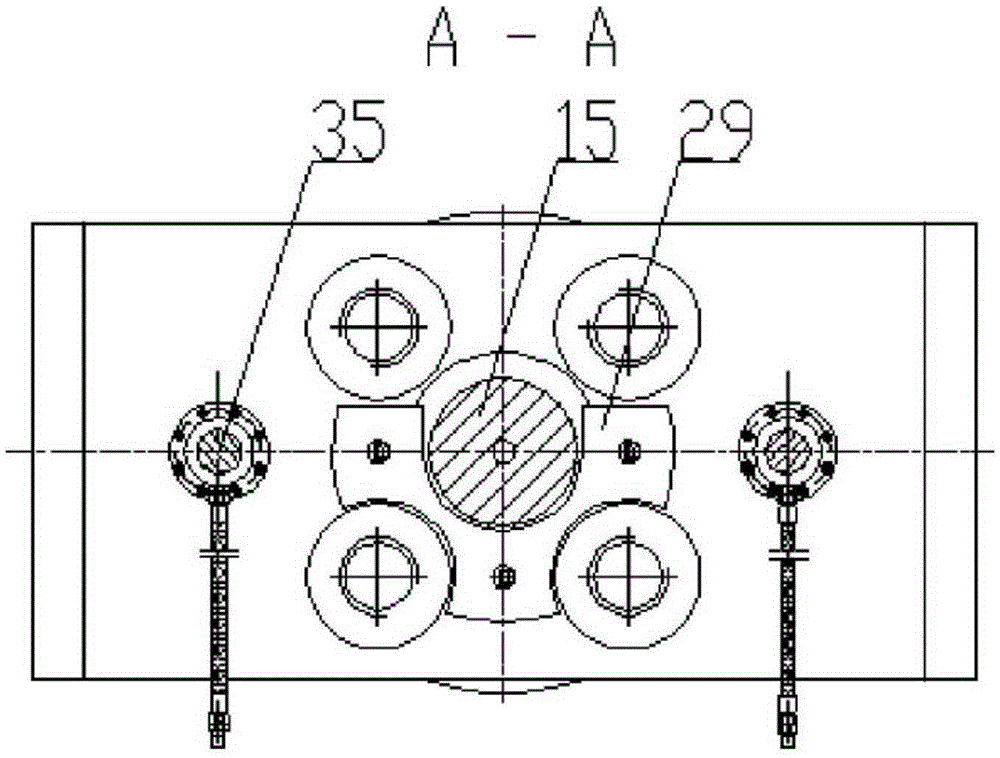

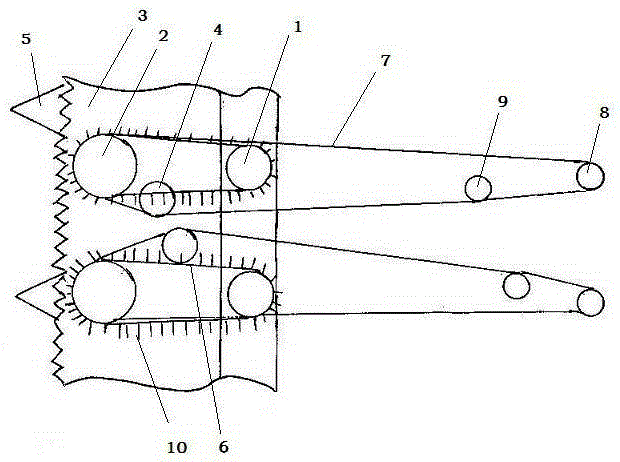

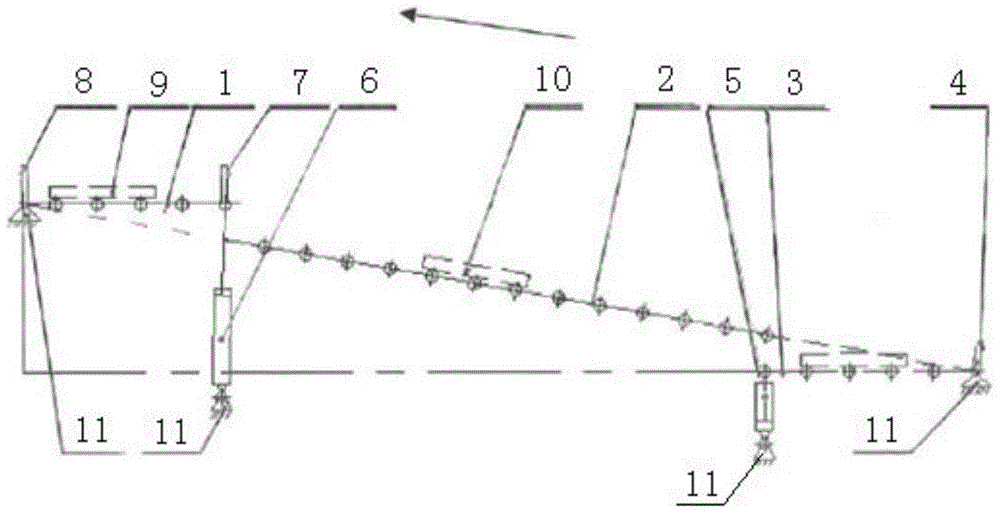

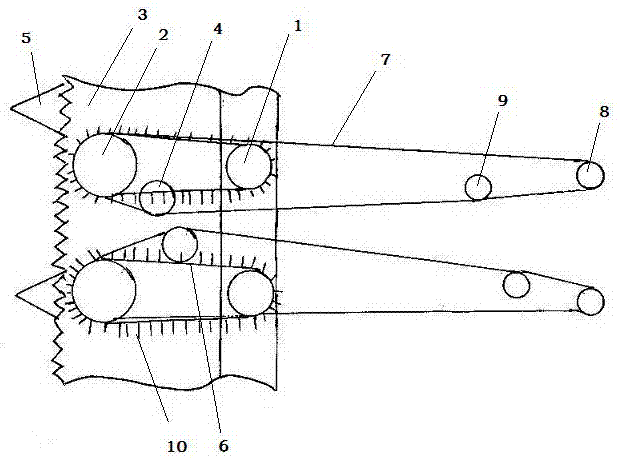

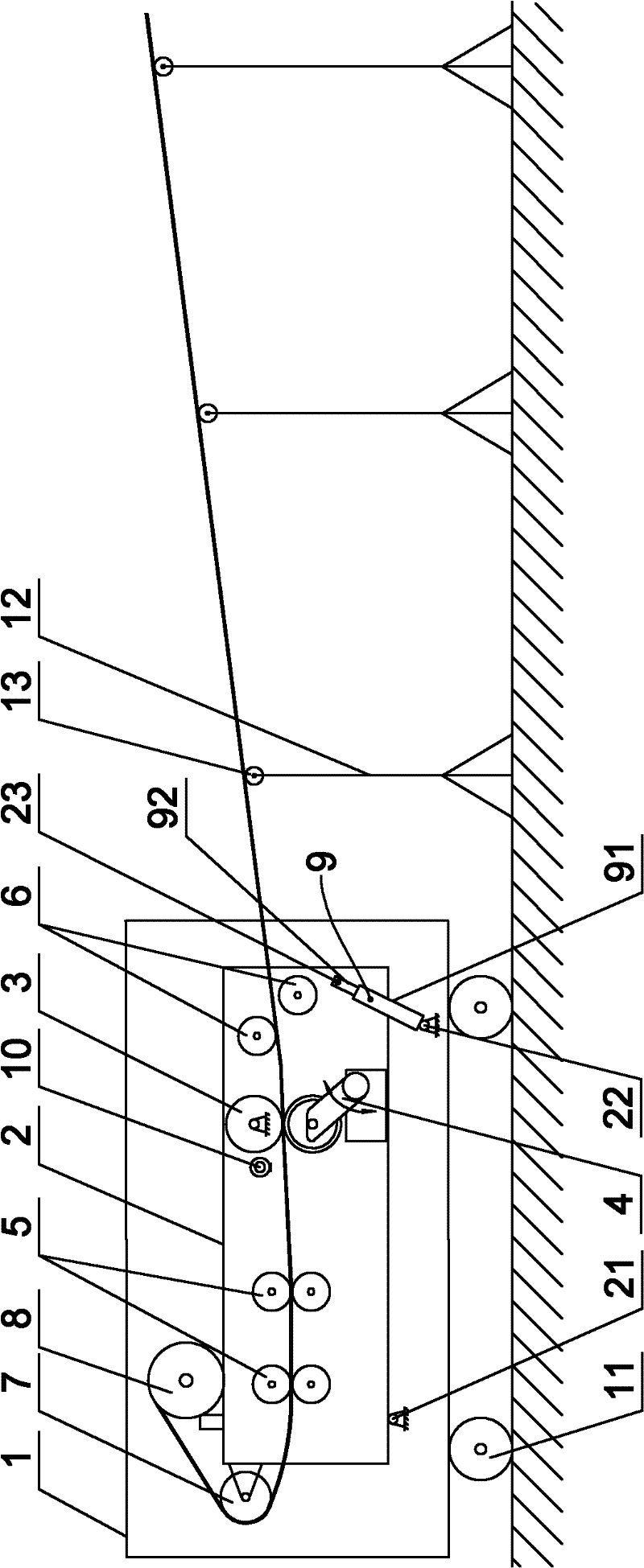

Multi-path conveying cutting platform of whole-feeding and half-feeding dual-purposed harvesting machine

The invention relates to a multi-path conveying cutting platform of whole-feeding and half-feeding dual-purposed harvesting machine, which comprises a supporting rack connected with a harvesting machine body, and a gear box and a seedling separating plate arranged at the end part of the supporting rack, and is characterized in that upper and lower layers of belt wheels are arranged on the supporting rack, two sets of belt wheels are oppositely arranged to form a group, and two or more groups constitute the multi-path conveying cutting platform; a driving wheel is connected with a transmission shaft of the gear box, the driving wheel and the transmission shaft of the gear box are powered by a power machine, the driving wheel is connected with a front driven wheel by a seedling supporting belt, seedling supporting teeth are formed on the seedling supporting belt, and the front driven wheel is connected with a front tensioning wheel, a rear tensioning wheel and a rear driven wheel by a seedling supporting conveyer belt. The multi-path conveying cutting platform is capable of automatically conveying the harvested straws to the direction of the harvesting machine body, is simple in structure, easy to manufacture, small in volume, and light, and is capable of reducing conveying links and greatly reducing the loss generated by floating of the straws.

Owner:郭春生

Multilevel cleaning device and multilevel cleaning method for various waste plastics

ActiveCN104149225AThe principle is simpleAvoid crossing each otherPlastic recyclingCleaning using liquidsCrusherWater pipe

The invention discloses a multilevel cleaning device and a multilevel cleaning method for various waste plastics. The multilevel cleaning device comprises a belt conveyer, a crusher, a washing cage, a rinsing tank and a terminal dehydrator, which are connected sequentially, wherein a primary circulating water treating pond is arranged under the washing cage and is connected with the crusher and the feeding end of the washing cage by a primary water return pipe respectively, and a secondary circulating water treating pond is arranged under the terminal dehydrator and is connected with the rinsing tank by a secondary water return pipe; the multilevel cleaning method comprises the steps of crushing waste plastics, primarily cleaning the crushed waste plastics in the washing cage and separating from cleaning water, then feeding the cleaned waste plastics into the rinsing tank for further cleaning with fluid mediums, and finally, feeding the cleaned waste plastics into the terminal dehydrator for dehydration, wherein the primary circulating water treating pond recycles the cleaning water, and the secondary circulating water treating pond recycles the fluid mediums. The device and the method can separately manage the cleaning water or the fluid mediums in different treating levels, so that the fluid mediums and the cleaning water can be circulated conveniently.

Owner:冯愚斌

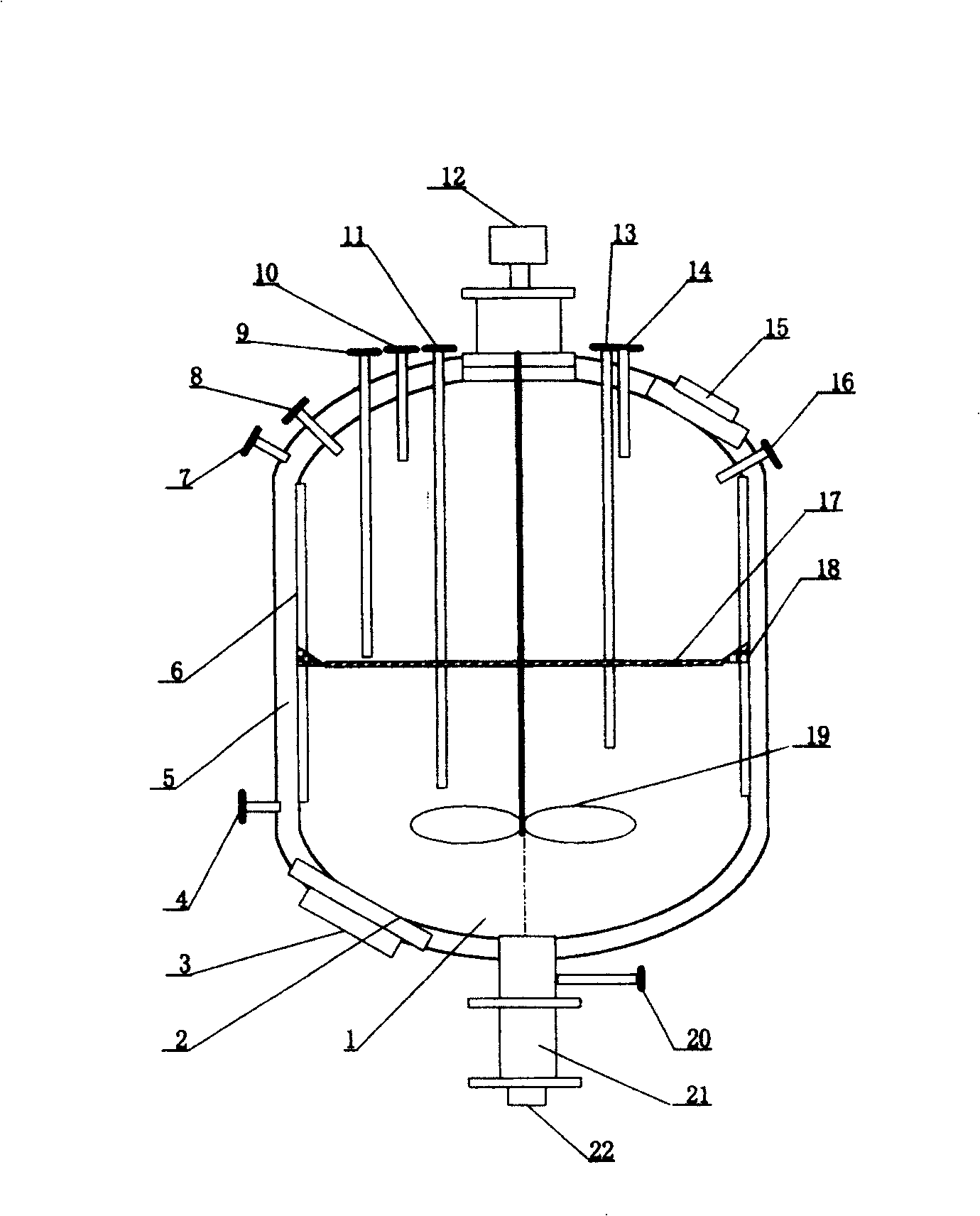

Multifunctional reactor for preparing ionic liquid

ActiveCN100411727CIndustrial Application GuaranteeReduce the delivery linkRotary stirring mixersChemical/physical/physico-chemical stationary reactorsProduct gasSlurry

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

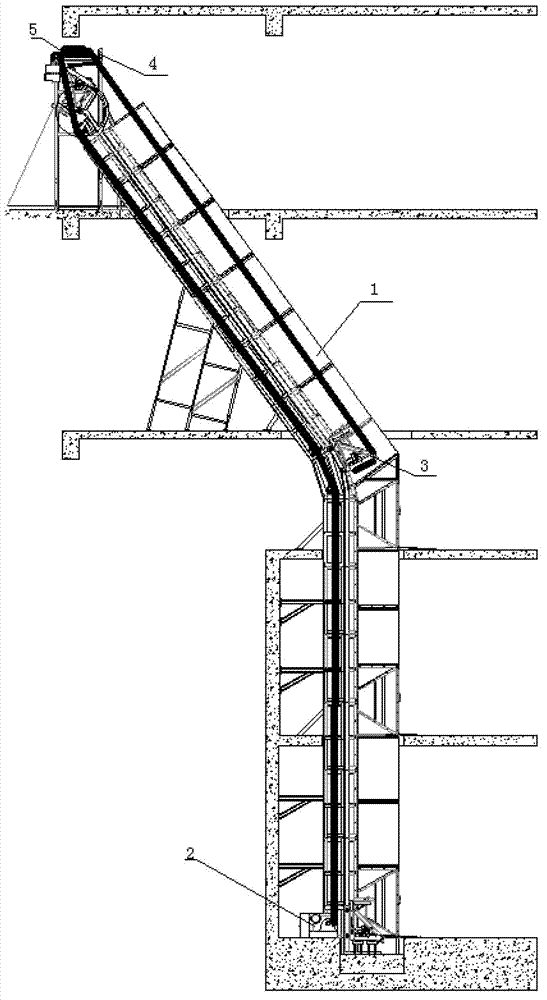

Automatic material dumping lifter

ActiveCN102774586ASave manpower and material resourcesImprove securityRefuse gatheringBottle emptyingTurning framesMedical waste

The invention relates to an automatic material dumping lifter which comprises a main frame body, a winch, a feeding trolley, a turning mechanism and a steel wire rope pulley mechanism, wherein the winch is positioned on the lower part of the main frame body; the turning mechanism is positioned on the upper part of the main frame body; the steel wire rope pulley mechanism is positioned on the top of the main frame body; and an automatic return mechanism is arranged on the turning frame body of the turning mechanism. The automatic return mechanism includes a return stick, a return frame, a redirection idler wheel bracket and a counter-balanced carriage. Two hooks are arranged on the return frame and hook the return stick. The return stick is connected to steel wire rope. The steel wire rope reaches the counter-balanced carriage through idler wheels of the redirection idler wheel bracket. The automatic material dumping lifter is special machinery for meeting the design of feeding of medical waste incineration treatment, and is high in degree of automation, easy and convenient to operate and safe; and the lots of manpower and material resources are saved, and the opportunity of touching the medical wastes for a worker is reduced.

Owner:天津百利阳光环保设备有限公司

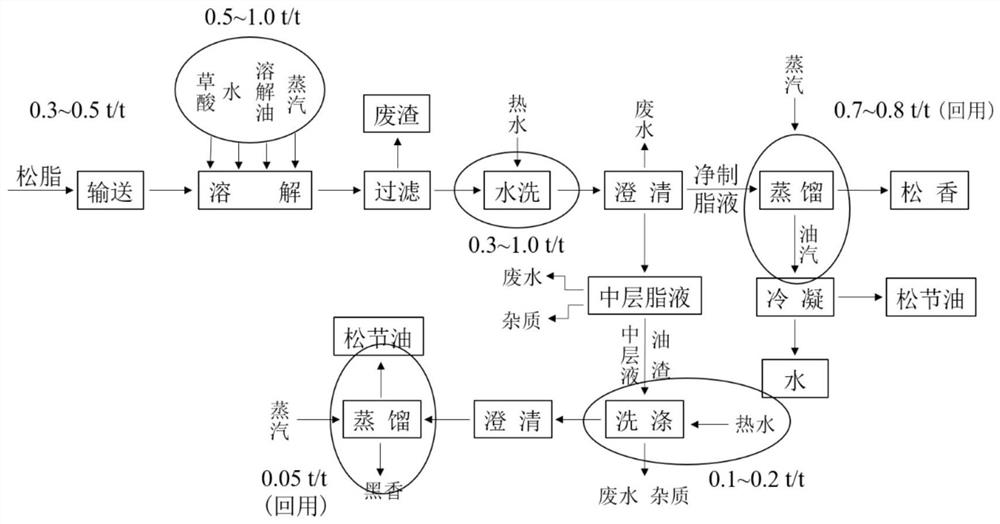

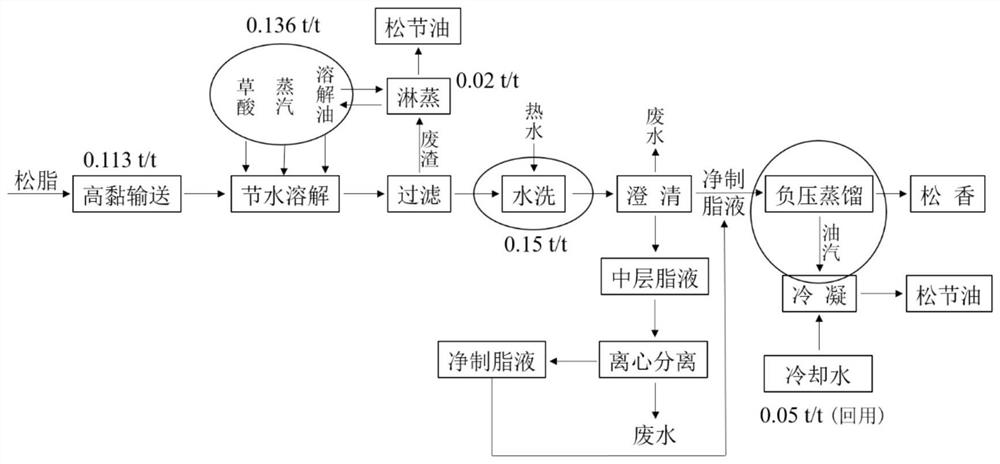

Low-water-consumption and low-emission turpentine processing method

ActiveCN112080206AReduce viscosityReduce consumptionTurpentine spiritsNatural resin purificationLiquid waterDistillation

The invention discloses a method for processing rosin with low water consumption and low emission. The invention belongs to the field of water-saving processing of turpentine. The method comprises thefollowing steps: 1) water-saving conveying: not adding water into turpentine, and conveying the turpentine by adopting a plunger pump; 2) water-saving dissolving: not adding liquid water into the turpentine in the turpentine dissolving process, and dissolving the turpentine by adopting an oil-steam mixture generated by mixing hot dissolved oil and high-temperature steam by using a vertical continuous dissolver; 3) water-saving washing: enhancing the contact between water and the grease liquid by adopting a small amount of repeated hot water washing mode and forced stirring, then standing forlayering to discharge water and impurities at the lower layer, separately collecting to a middle-layer grease liquid tank, putting middle-layer grease liquid into a dissolving kettle, adding a small amount of dissolved oil, heating for dissolving, and separating by a horizontal screw centrifuge and a butterfly centrifuge to obtain pure lipid liquids; and 4) water-saving distillation: distilling the turpentine by adopting a conduction oil heating and reduced pressure distillation process in a turpentine distillation and separation process.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

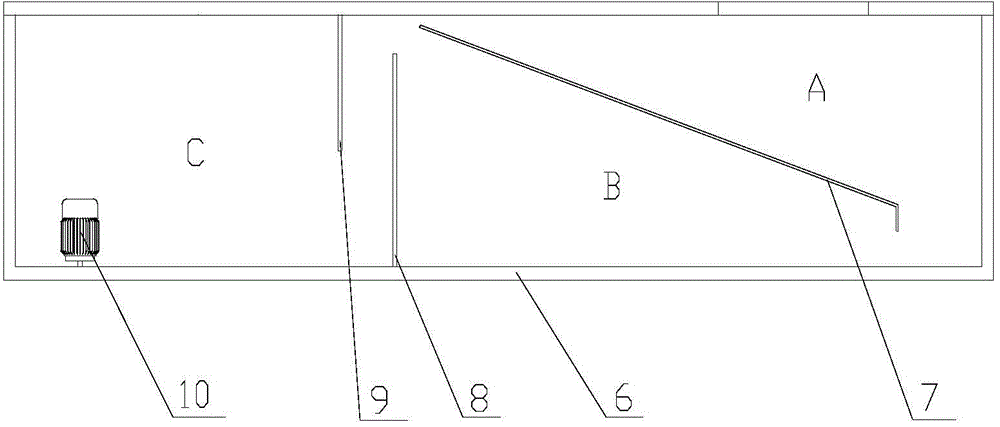

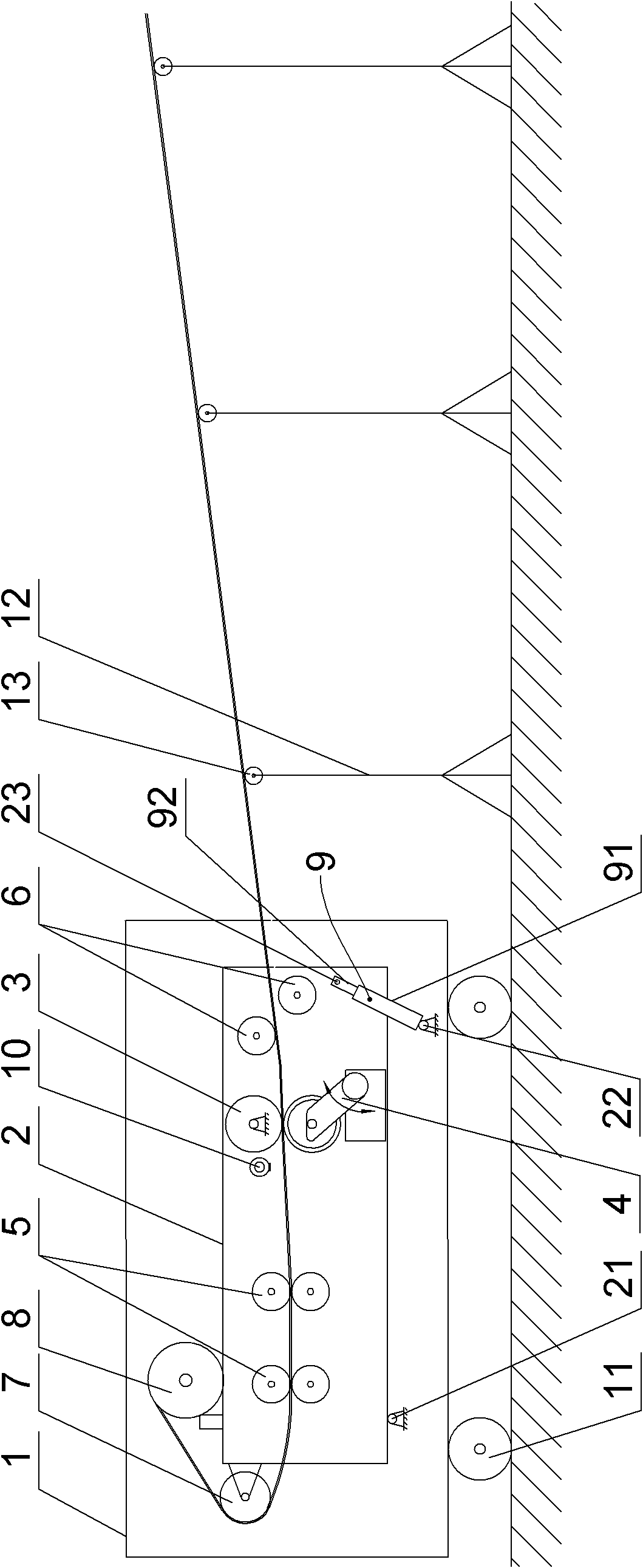

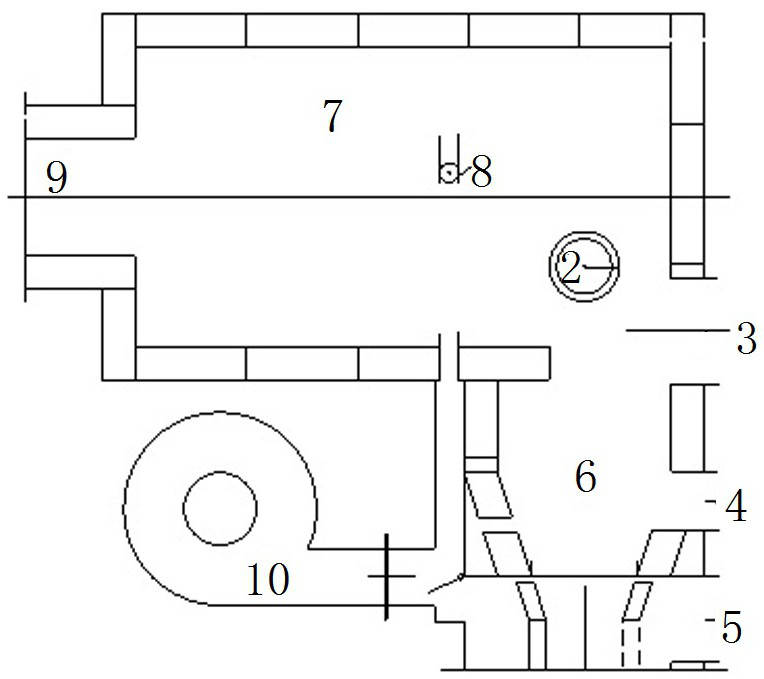

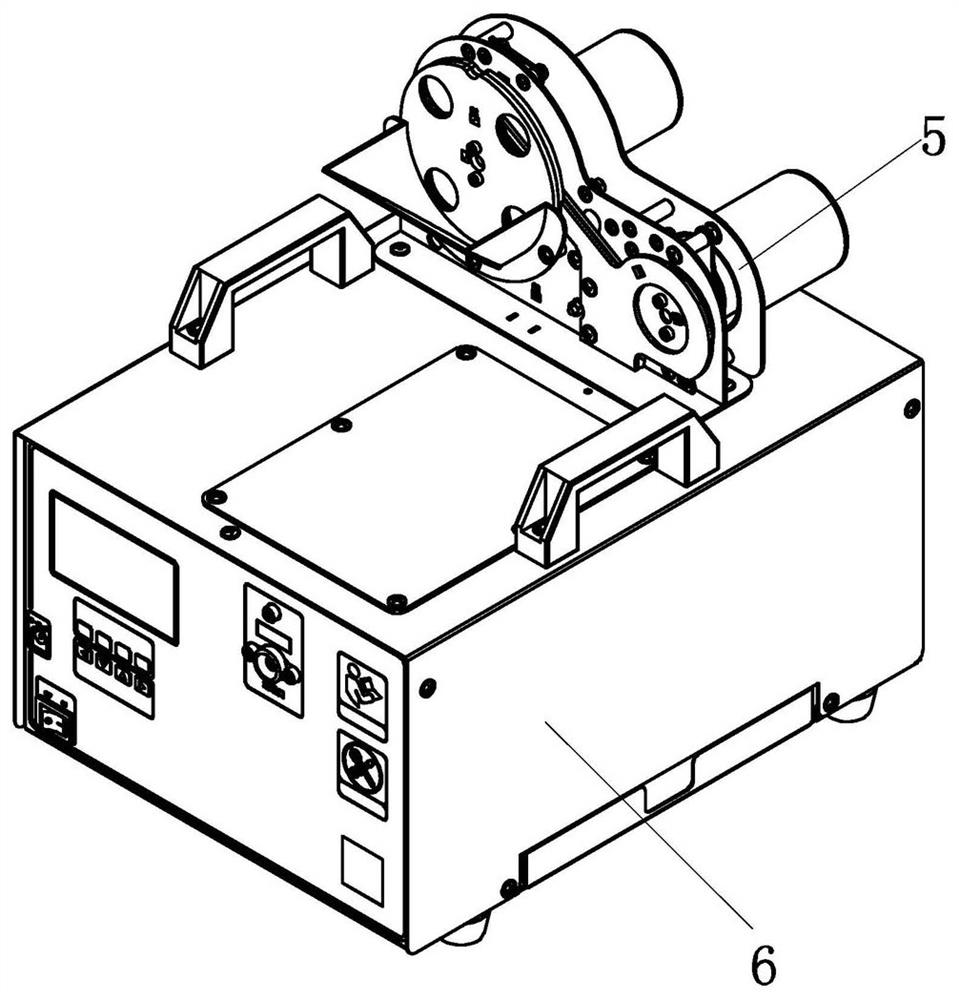

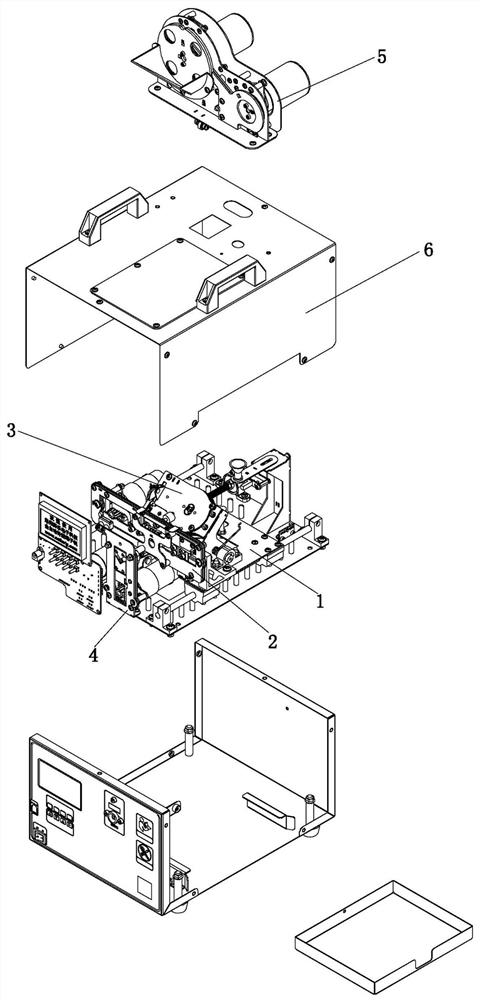

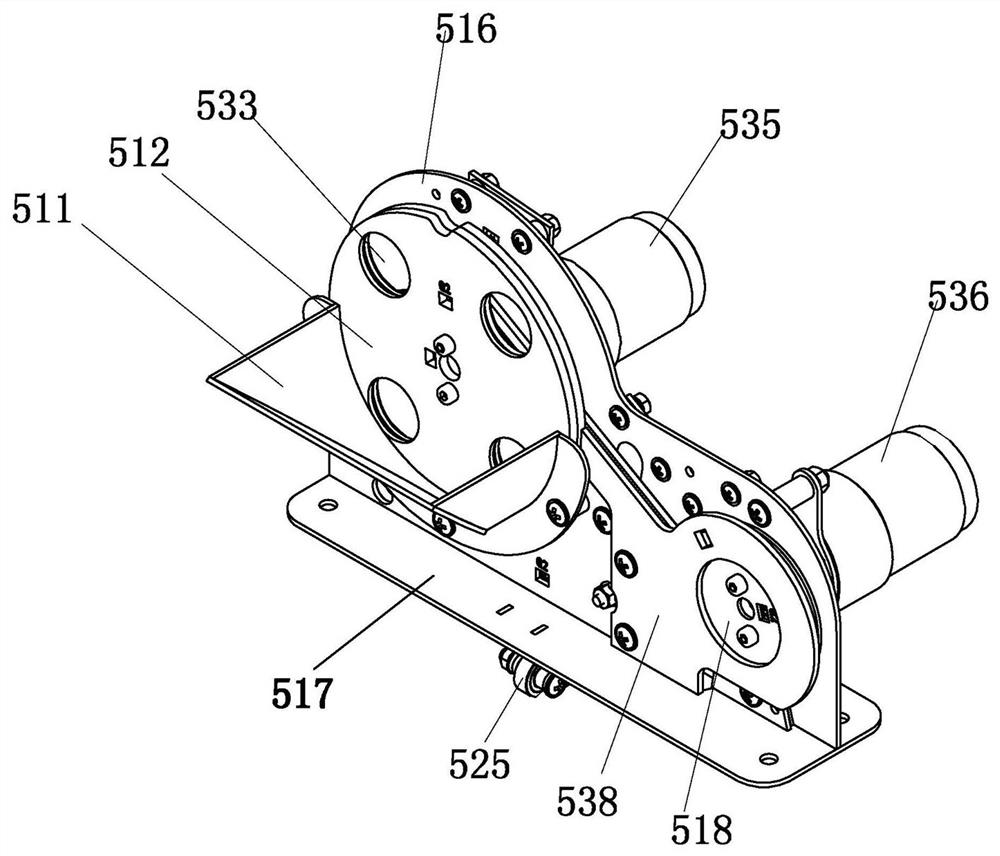

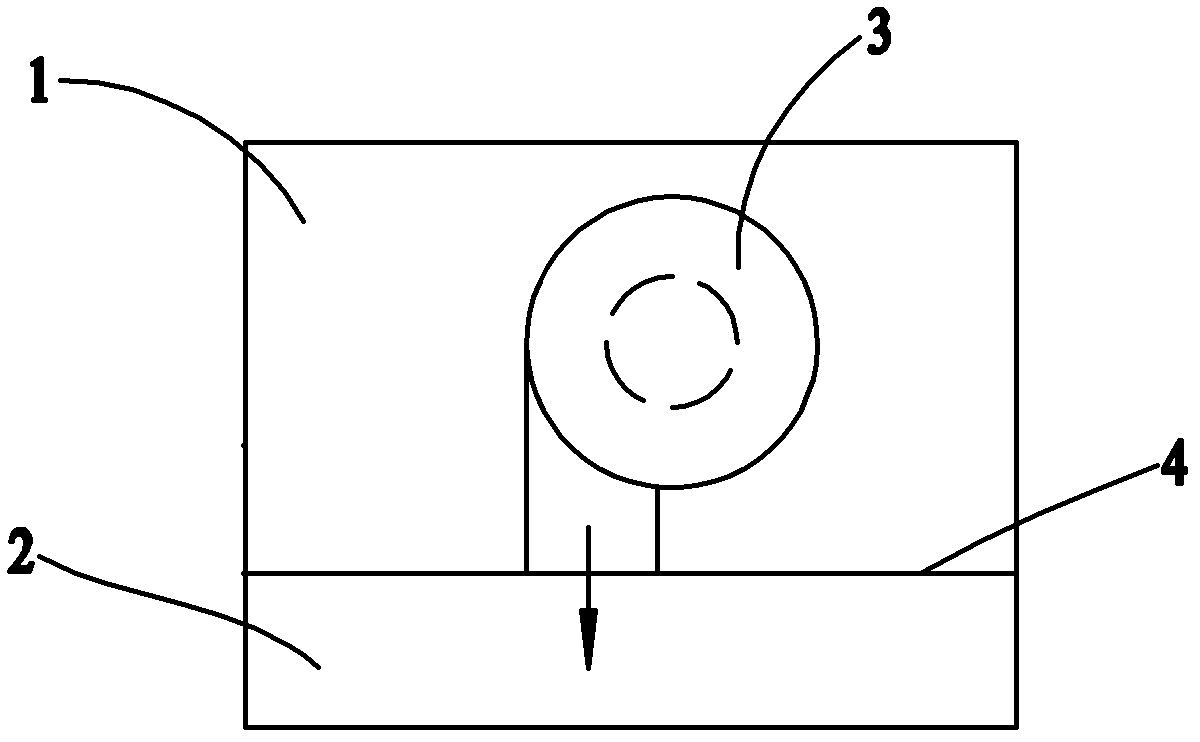

Metal roof board forming device

The invention discloses a metal roof board forming device, which can regulate the discharge angle, be high in construction efficiency and facilitate the direct conveying of a roof board to a roof after forming. The metal roof board forming device comprises a forming frame (2), a forming roller group (3), a feed roller group (5), a discharge roller group (6), a box body (1), a cutting and guide roller group (7) and a frame lifting device (9), wherein a metal coiled material (8) is placed at the top of the forming frame (2), the metal coiled material (8) sequentially passes through a cutting and guide roller group (7), a feed roller group (5), the forming roller group (3) and the discharge roller group (6) for performing cutting, feeding, forming and discharging, a metal roof board after forming is sent out of the box body (1), the front part of the forming frame (2) can rotate around a first pivot shaft (21) fixedly connected with the box body (1), and the frame lifting device (9) is arranged at the rear part of the forming frame (2) so as to lift the rear part of the forming frame (2) and adjust the discharge angle of the metal roof board after forming. The metal roof board forming device can be widely applied in the field of forming of the metal roof boards.

Owner:BAIANLI STEEL STRUCTURE APPL SCI TECH

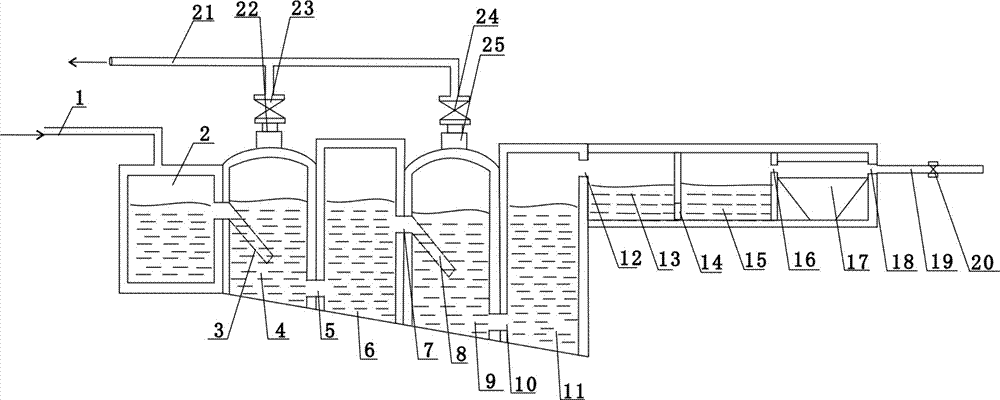

Bean product waste water treatment device

InactiveCN107162311AExtended stayReduce BODTreatment involving filtrationWaste based fuelHazardous substanceFermentation

Disclosed is a bean product waste water treatment device. The bean product waste water treatment device is composed of a waste water buffer pool, a first biogas digester, a first water pressure chamber, a second biogas digester, a second water pressure chamber, a settling pond, a waste water aeration tank and a concentration filter tank, wherein the waste water buffer pool is connected with a water inlet pipe and connected with the first biogas digester through a first inclined water inlet pipe; the first biogas digester is communicated with the first water pressure chamber through a first diversion hole; the first water pressure chamber is connected with the second biogas digester through a second inclined water inlet pipe; the second biogas digester is communicated with the second water pressure chamber through a third diversion hole; the second water pressure chamber is communicated with the settling pond through a fourth diversion hole; the settling pond is communicated with the waste water aeration tank through a fifth diversion hole; the waste water aeration tank is communicated with the concentration filter tank through a sixth diversion hole and connected with a discharge pipe; the first biogas digester is connected with a first biogas outlet pipe, and the second biogas digester is connected with a second biogas outlet pipe. The bean product waste water treatment device prolongs the staying time of waste water to ensure sufficient fermentation reaction and further to effectively reduce BOD (biochemical oxygen demand) and other hazardous substance in waste water.

Owner:YIDU QIAOHE FOOD CO LTD

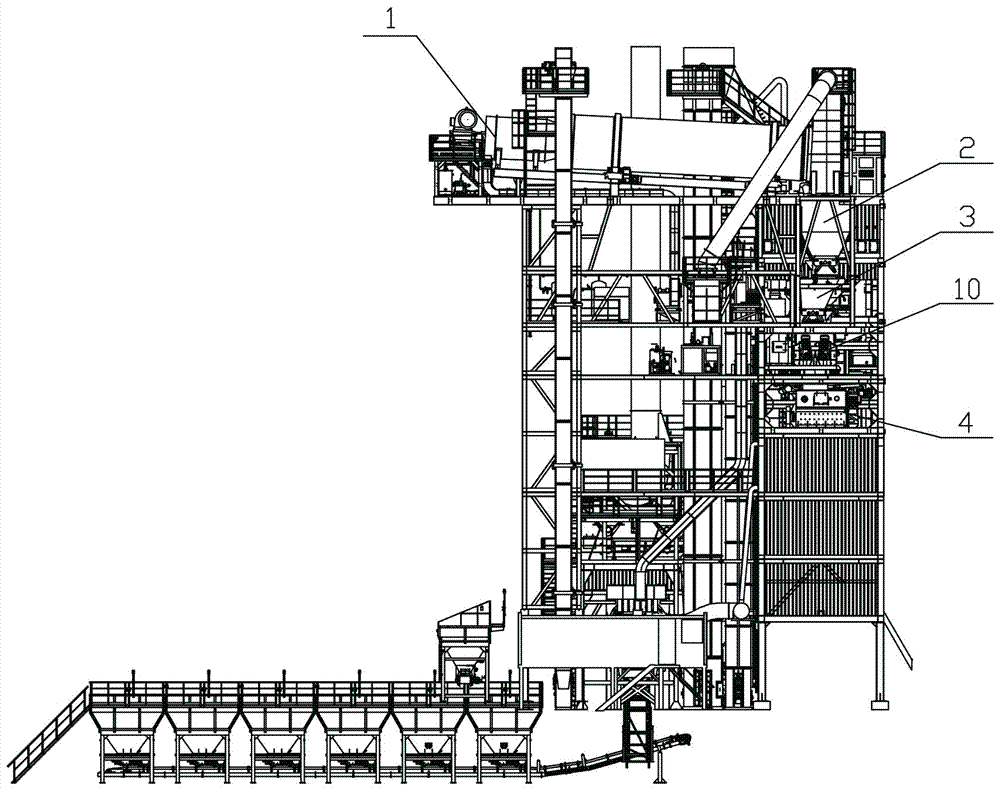

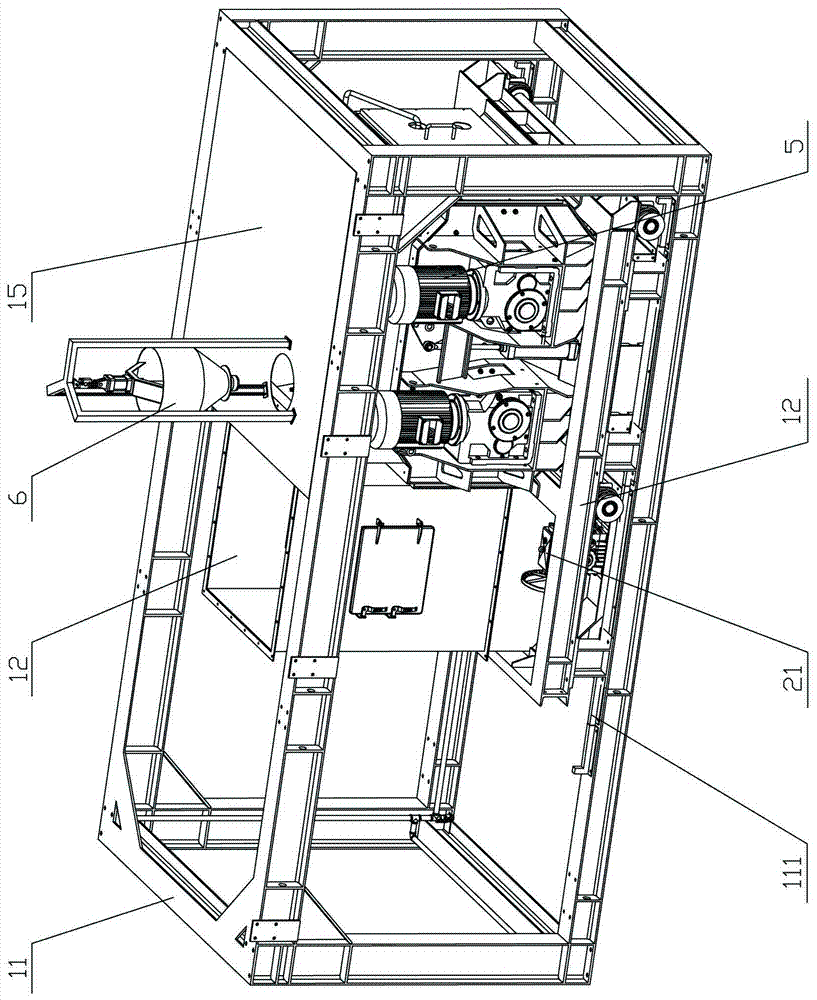

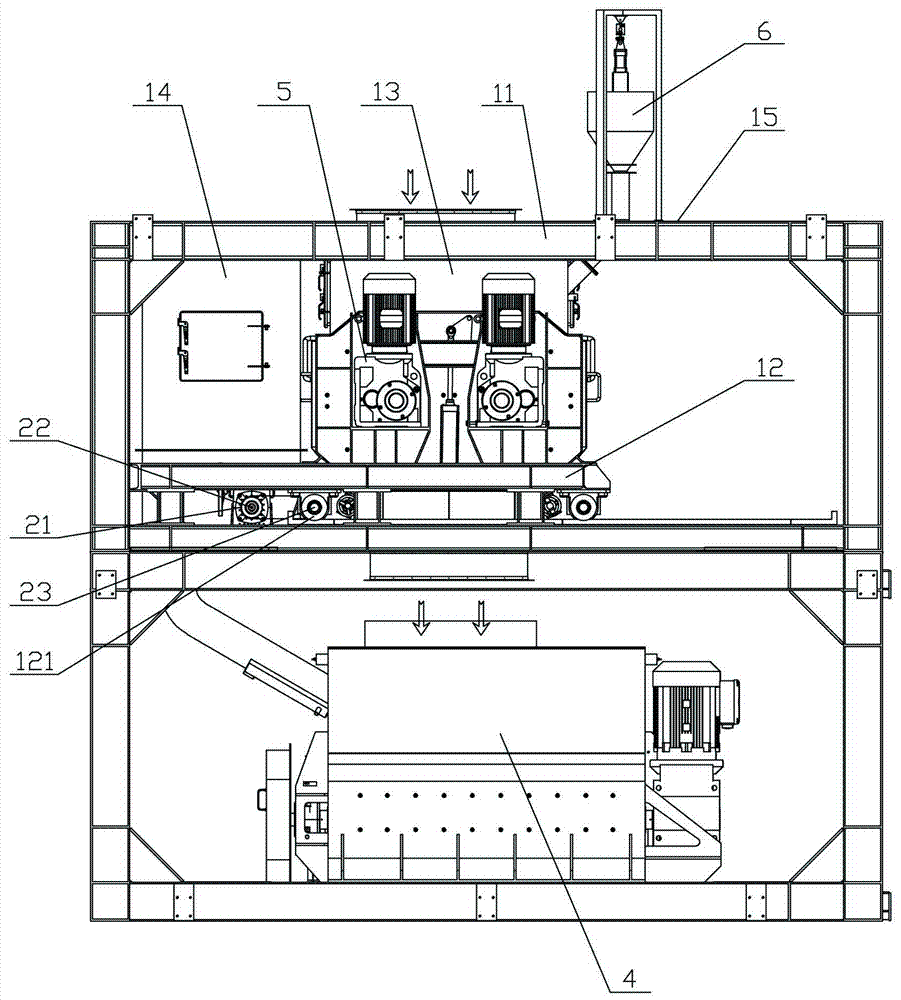

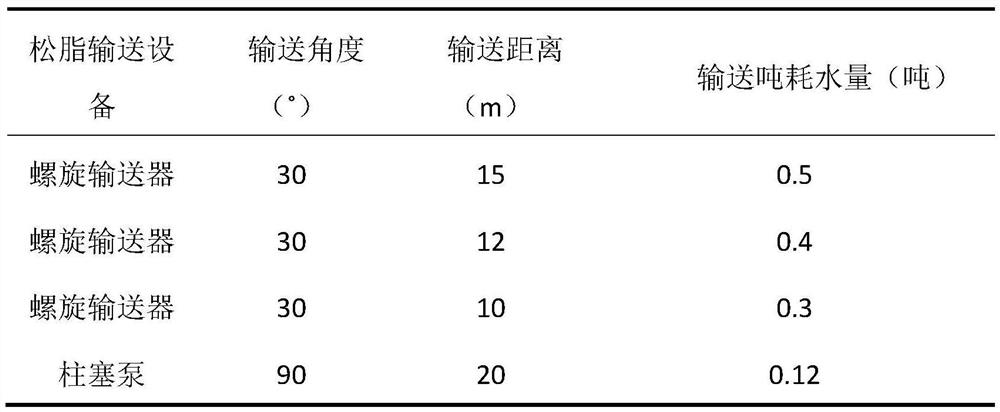

A kind of heat recycling equipment for asphalt mixture plant

ActiveCN106012766BReduce the delivery linkIncrease productivityRoads maintainenceButt jointEngineering

The invention discloses novel mixing heat regeneration equipment for an asphalt mixture factory. The novel mixing heat regeneration equipment comprises a regeneration material heating system, a regeneration material storage silo, a regeneration material measuring hopper and a main mixing cylinder, wherein the main mixing cylinder is arranged right below the regeneration material measuring hopper, a regeneration material pre-mixing device is arranged between the regeneration material measuring hopper and the main mixing cylinder, the regeneration material pre-mixing device comprises a mixing layer framework, a sliding table trolley, a first regeneration material chute and a second regeneration material chute, the sliding table trolley is arranged on the mixing layer framework in a sliding manner, a mixing mechanism is arranged in the first regeneration material chute, a regeneration agent measuring hopper is correspondingly arranged in the first regeneration material chute, and the first regeneration material chute or the second regeneration material chute are respectively in butt joint with the regeneration material measuring hopper and the main mixing cylinder after the sliding table trolley moves in place. when a user chooses the first regeneration material chute in production, and a failure occurs in the first regeneration material chute, the sliding table trolley can be driven to move to the other side, and then the second regeneration material chute is in butt joint with the regeneration material measuring hopper and the main mixing cylinder, so that uninterrupted production is achieved.

Owner:FUJIAN TIETUO MACHINERY

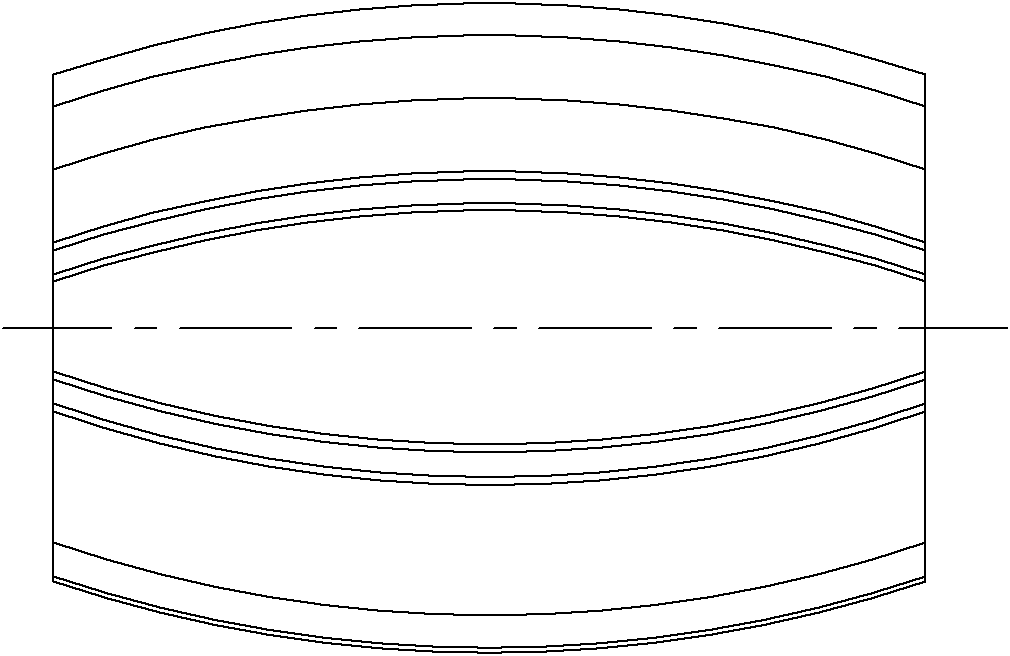

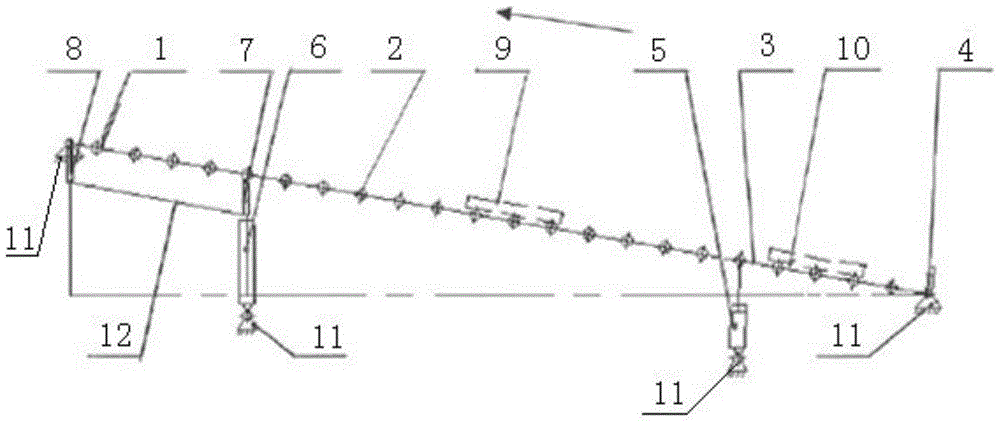

Slab conveying device with variable track

ActiveCN104801686BThe cooling rate is smallReduce the delivery linkEngineeringMechanical engineering

The invention discloses a slab conveying device with a variable track. The slab conveying device comprises a fixedly arranged middle-end conveying track, wherein the middle-end conveying track is inclined; the front end and the rear end of the middle-end conveying track are respectively connected with a front-end conveying track and a rear-end conveying track; the front end of the front-end conveying track is fixed on a stander; the lower side at the rear end of the front-end conveying track is connected with a second push cylinder; when the second push cylinder is in a contraction state, the rear end of the front-end conveying track is butted with the front end of the middle-end conveying track to form a plane; the rear end of the rear-end conveying track is fixed on the stander; the lower side of the rear-end conveying track is connected with a first push cylinder; when the first push cylinder is in an extending state, the front end of the rear-end conveying track is butted with the rear end of the middle-end conveying track to form a plane; oil cylinders are used for pushing the conveying tracks, so that the conveying tracks can be freely converted between a horizontal state and an inclined state; the number of the conveying steps is small; lifting and conveying can be synchronously realized; the conveying time is effectively shortened; the slab conveying device has the characteristics of low cost, energy conservation and high efficiency.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

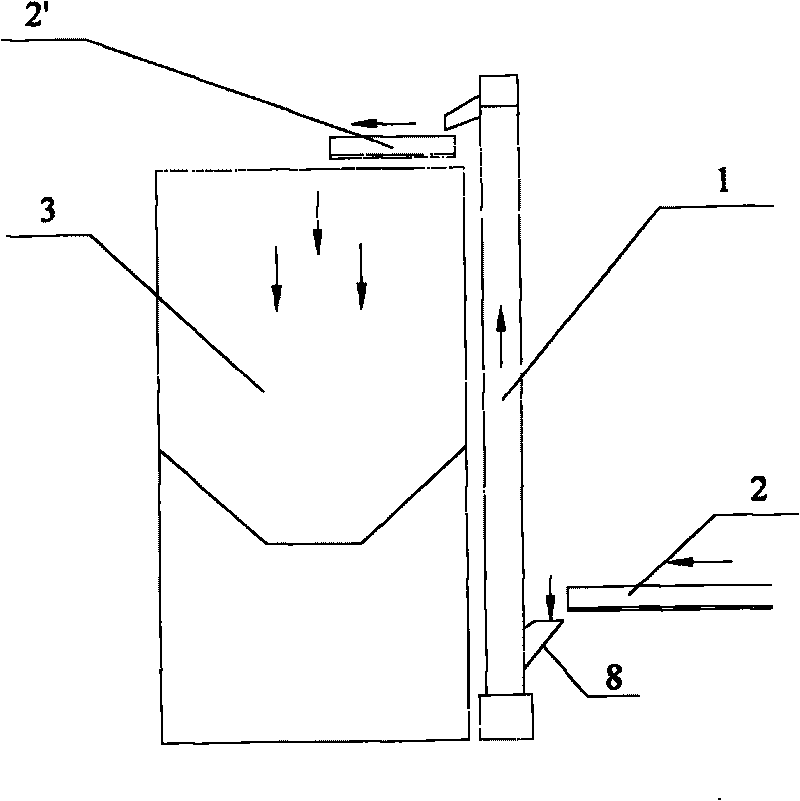

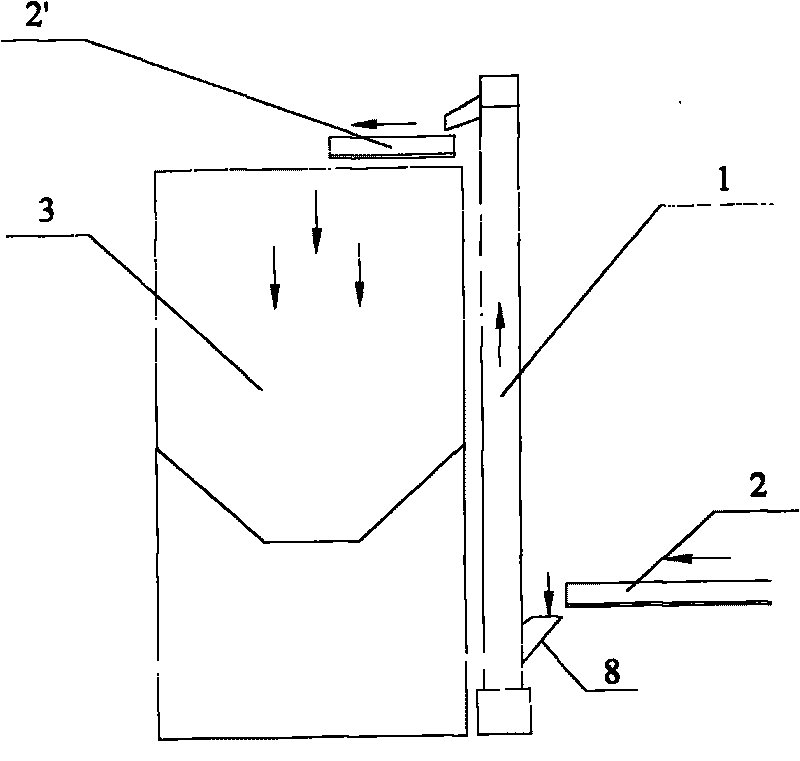

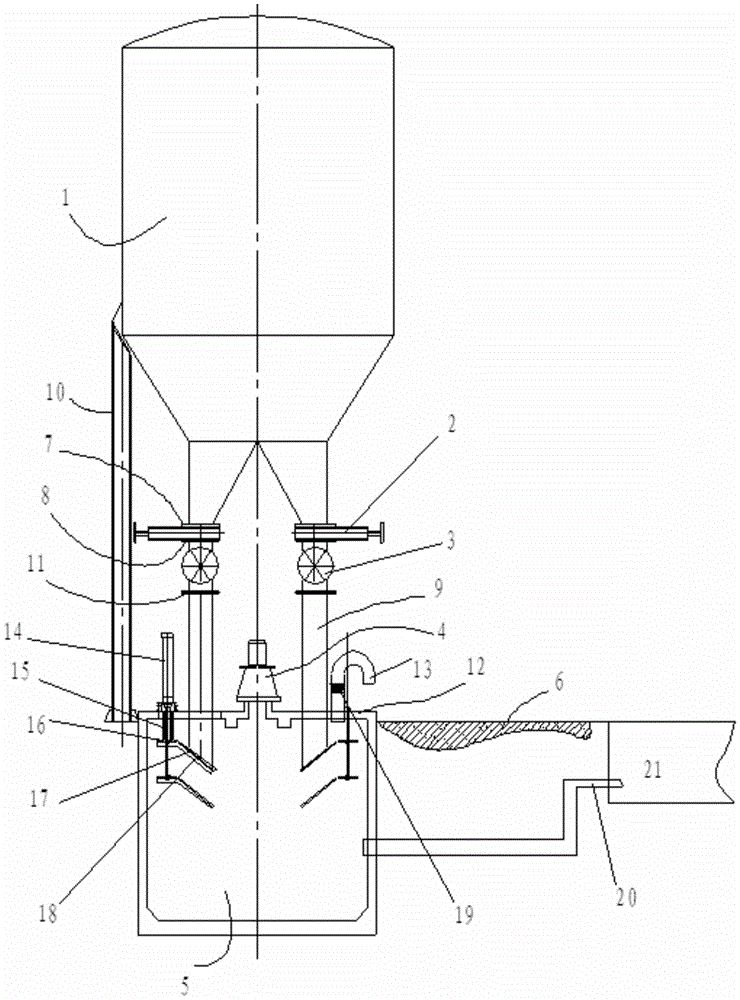

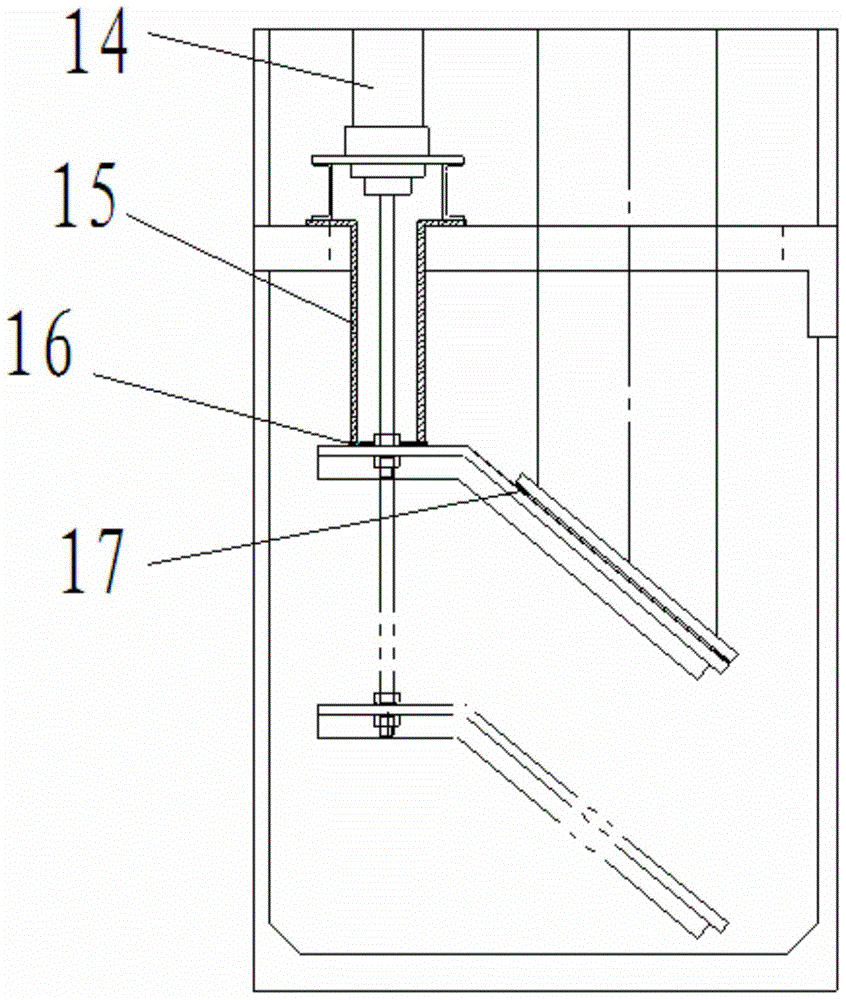

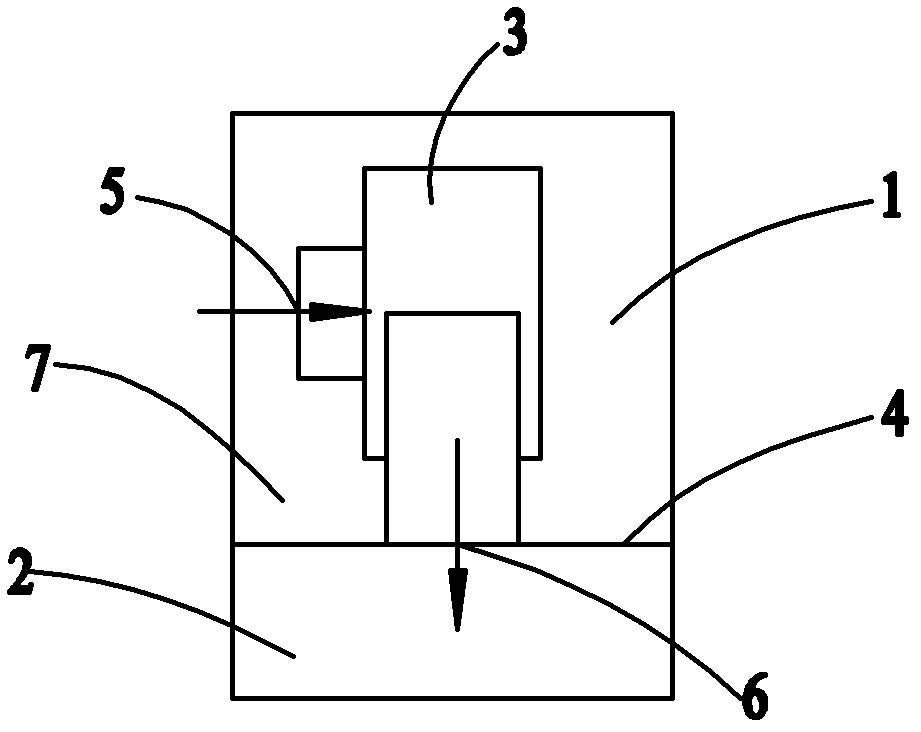

Wet desulfurization pulping system

ActiveCN104368237BReduce the delivery linkReduce leakageDispersed particle separationEngineeringEnergy consumption

The invention discloses a wet desulfurization pulping system, which comprises a limestone powder bin and a pulping tank, the limestone powder bin is fixed on the ground through steel structure legs, the pulping tank is arranged vertically below the limestone powder bin, and the limestone There is a weighing feeder between the powder silo and the pulping tank, the lower part of the limestone powder silo is connected with the blanking hopper, the lower part of the blanking hopper is provided with a discharge valve, and the lower part of the slide valve or gate valve is provided with a lower flange. The upper part of the weighing feeder is provided with an upper flange, and the feeding valve is connected with the weighing feeder through the lower flange and the upper flange. The lower part of the weighing feeder is provided with a feeding pipe. The pipe is connected to the weighing feeder through the flange, and the feeding pipe extends downwards to the pulping tank. There is an agitator in the middle of the upper part of the pulping tank, and the pulping tank is located below the ground. The powder material of the present invention directly falls into the pulp supply tank located below, which can reduce the occupied area, shorten the conveying path, reduce investment and energy consumption, reduce the phenomenon of "secondary dust raising", and improve the on-site environment.

Owner:SHANDONG HUANNENG DESIGN INST

Automatic troweling machine

The invention discloses an automatic troweling machine comprising a feeding system, a storage system and a troweling system. The systems are connected through a delivery pipe, the feeding system comprises a power output device connected with piston cylinders and feeding boxes, each cylinder is connected with one end of a feeding pipe, the feeding boxes are fixed above the feeding pipes and connected with the same through check valves, and the feeding pipes are connected with the delivery pipe through the check valves. The storage system comprises a storage vat with the bottom connected with the delivery pipe, a pressing plate is disposed in the storage vat, and feeding holes are formed on the side wall of the storage vat and connected with a machine head of the troweling system through the delivery pipe. The troweling system comprises rails and the machine head, the rails include vertical rails transversely sliding on horizontal rails and a machine head rail vertically sliding on the vertical rails, the machine head rail is parallel to the horizontal rails, and the machine head sliding horizontally is connected to the machine head rail. By the designed automatic troweling machine, the problems of low efficiency, inconvenience in moving, proneness to shedding of trowelled surfaces and the like of an existing mode are solved.

Owner:王刚

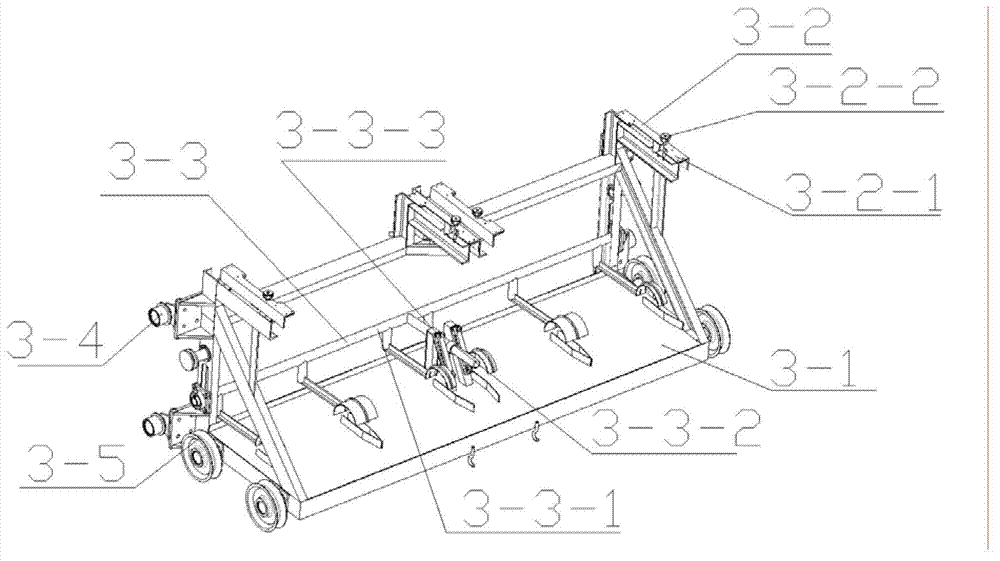

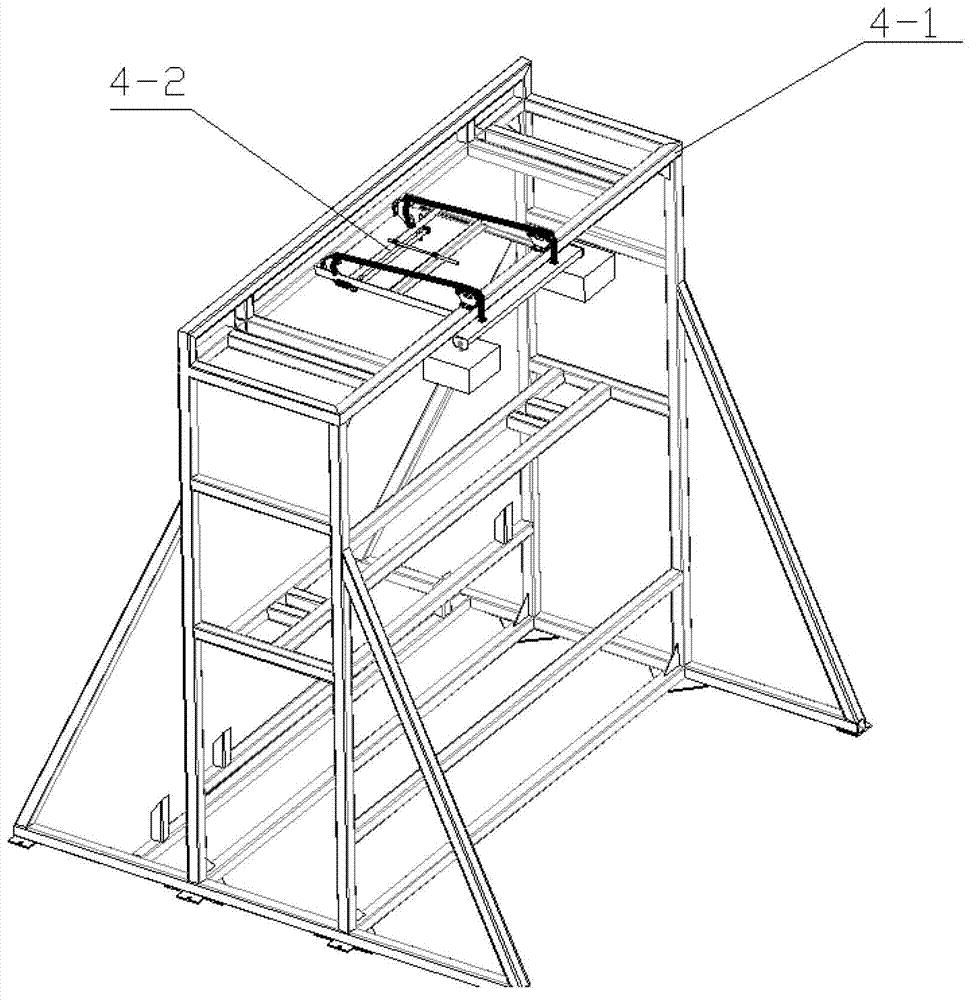

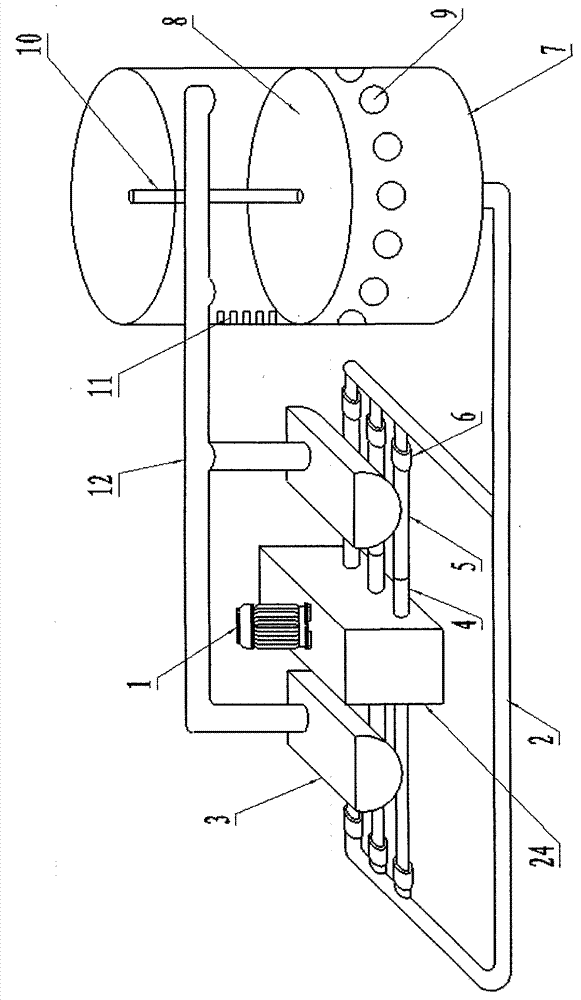

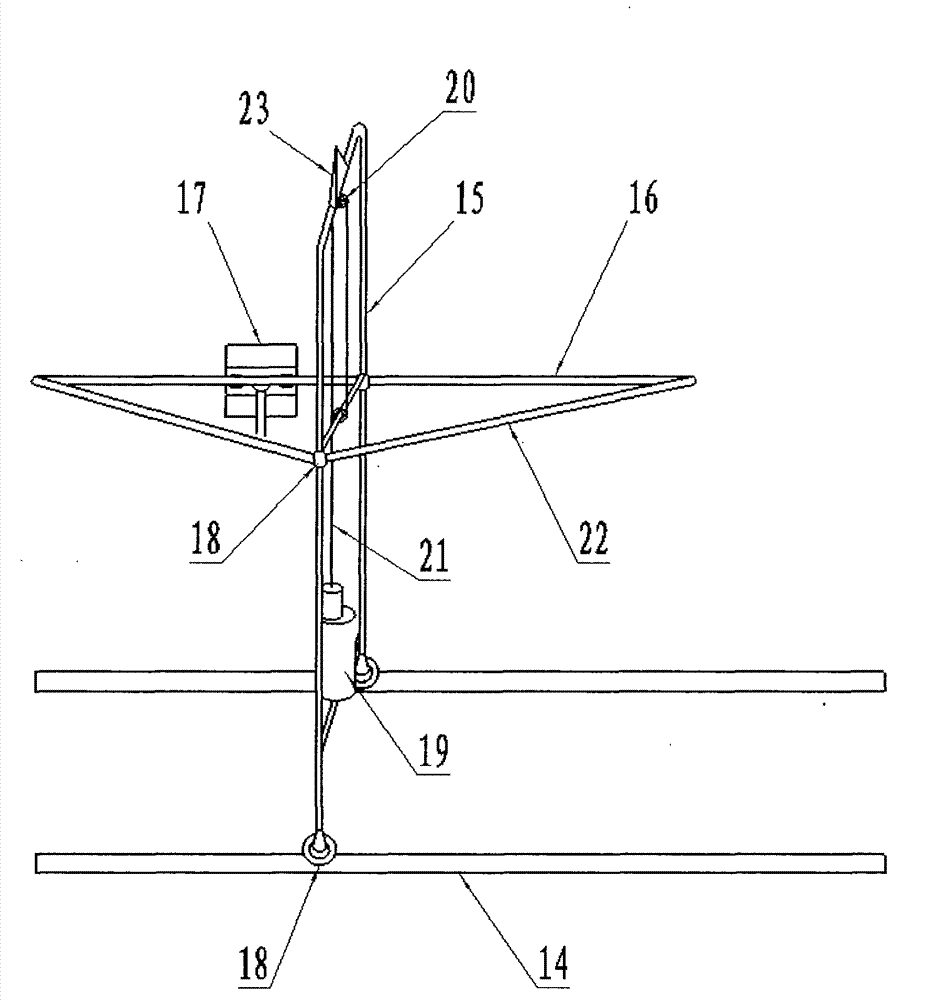

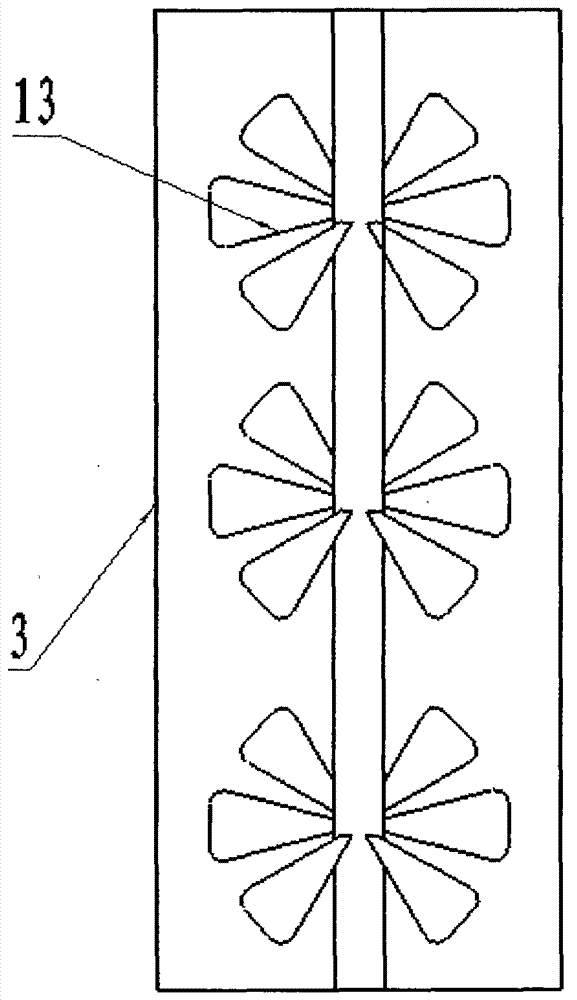

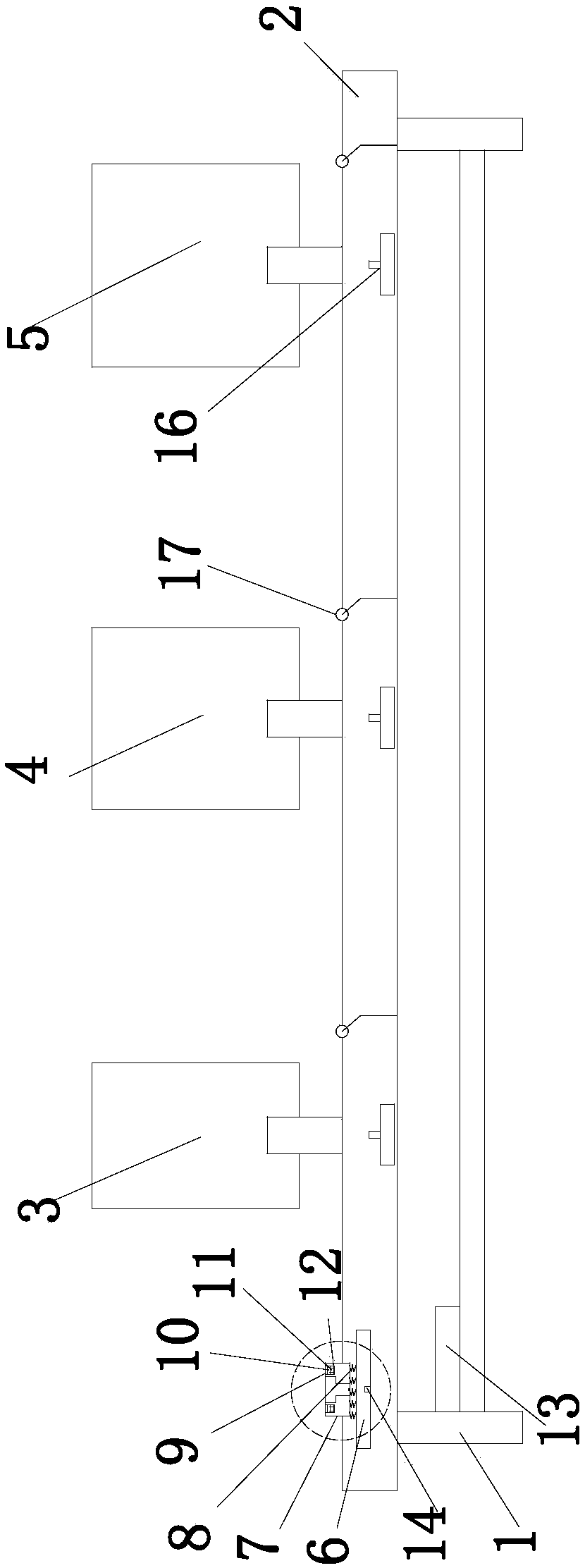

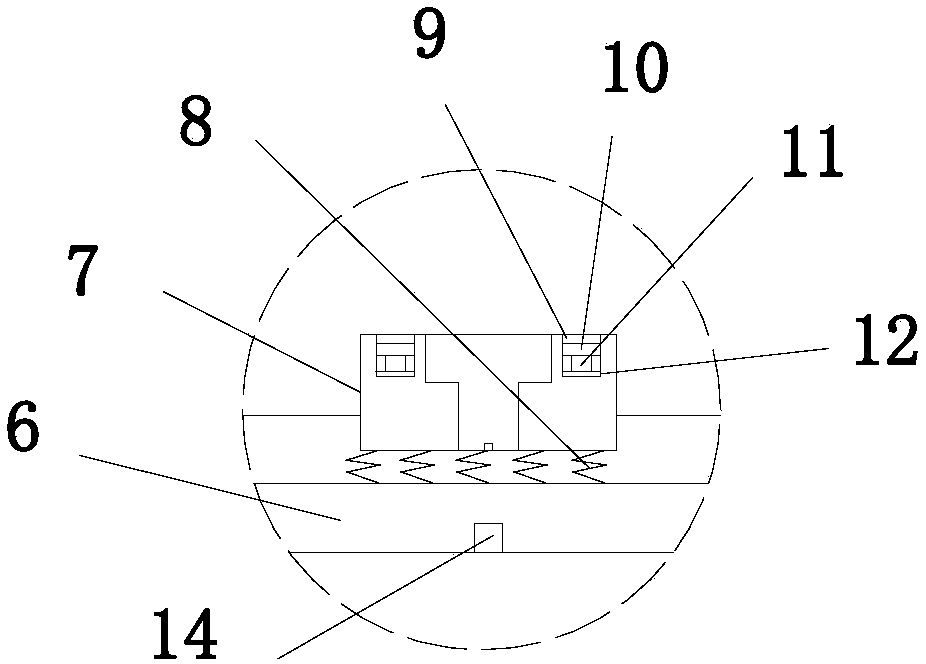

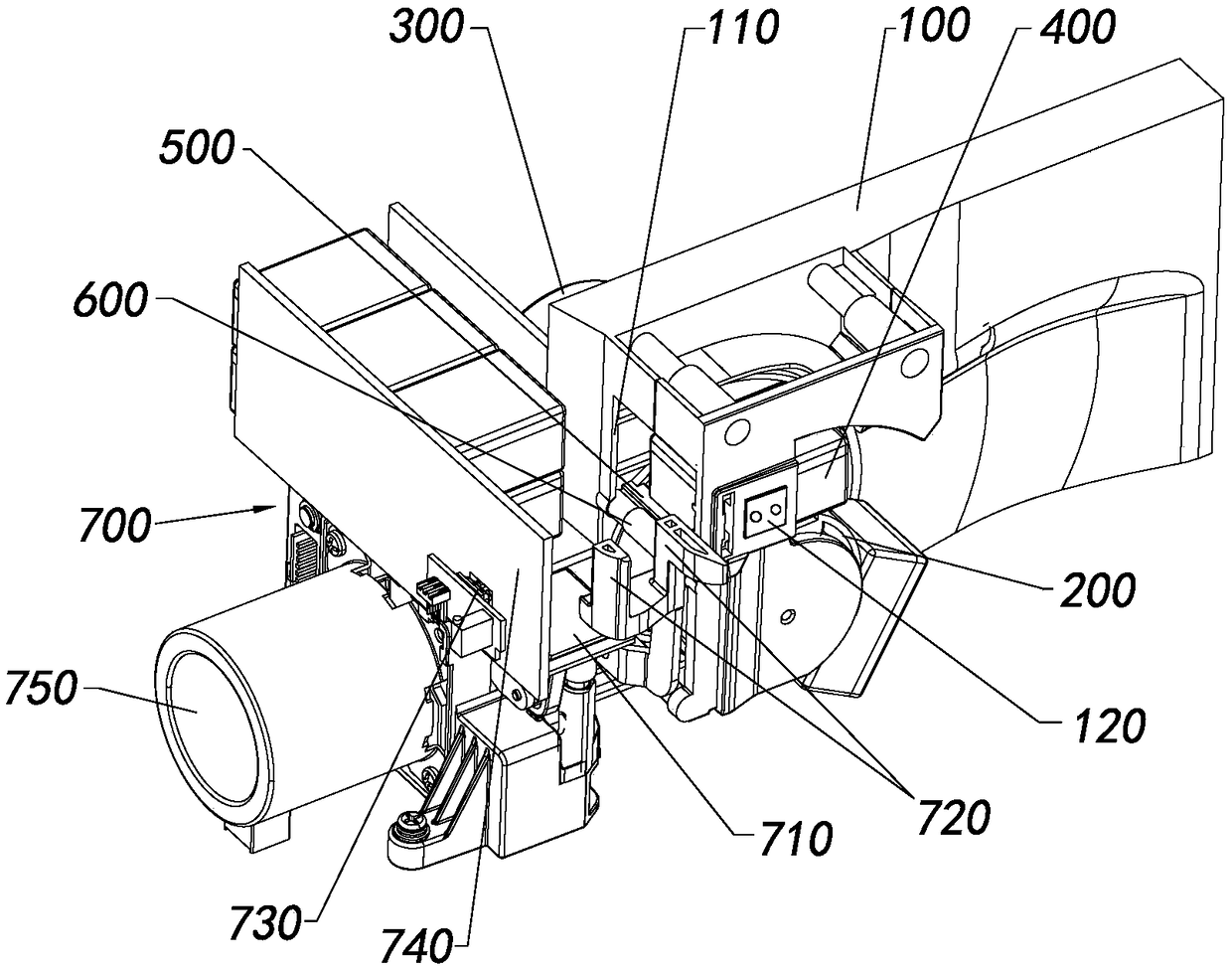

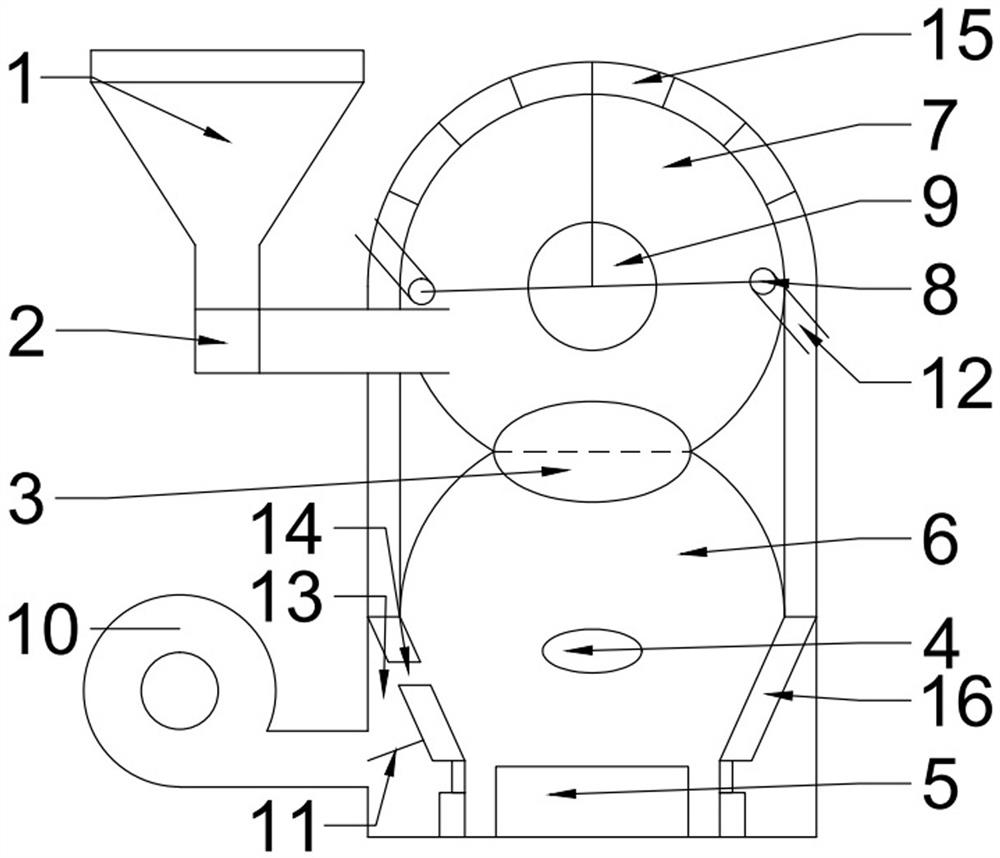

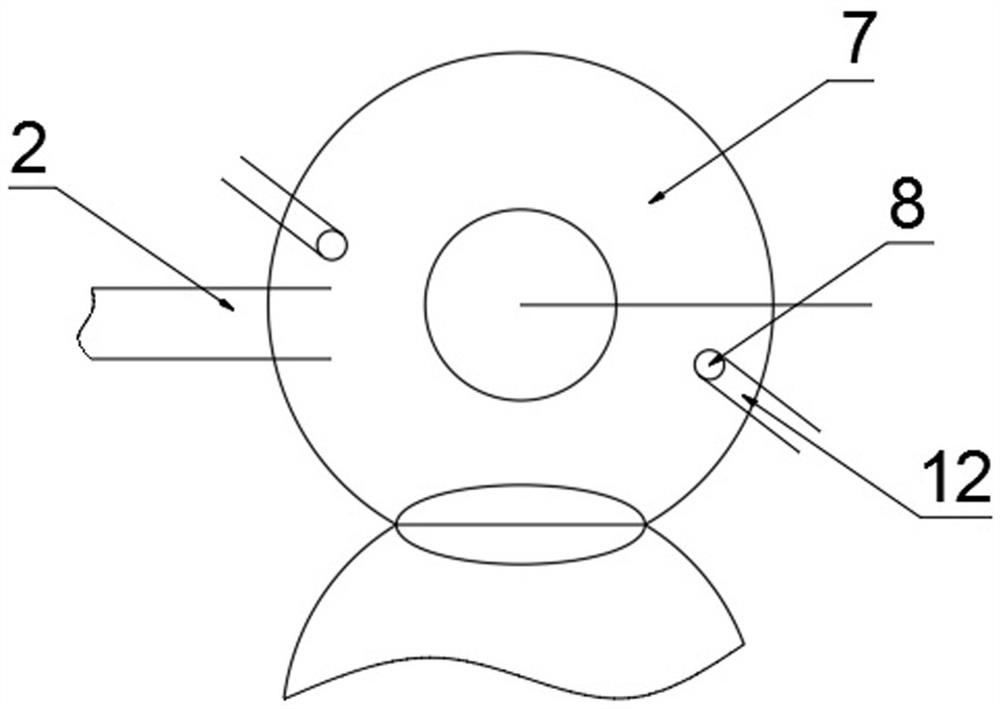

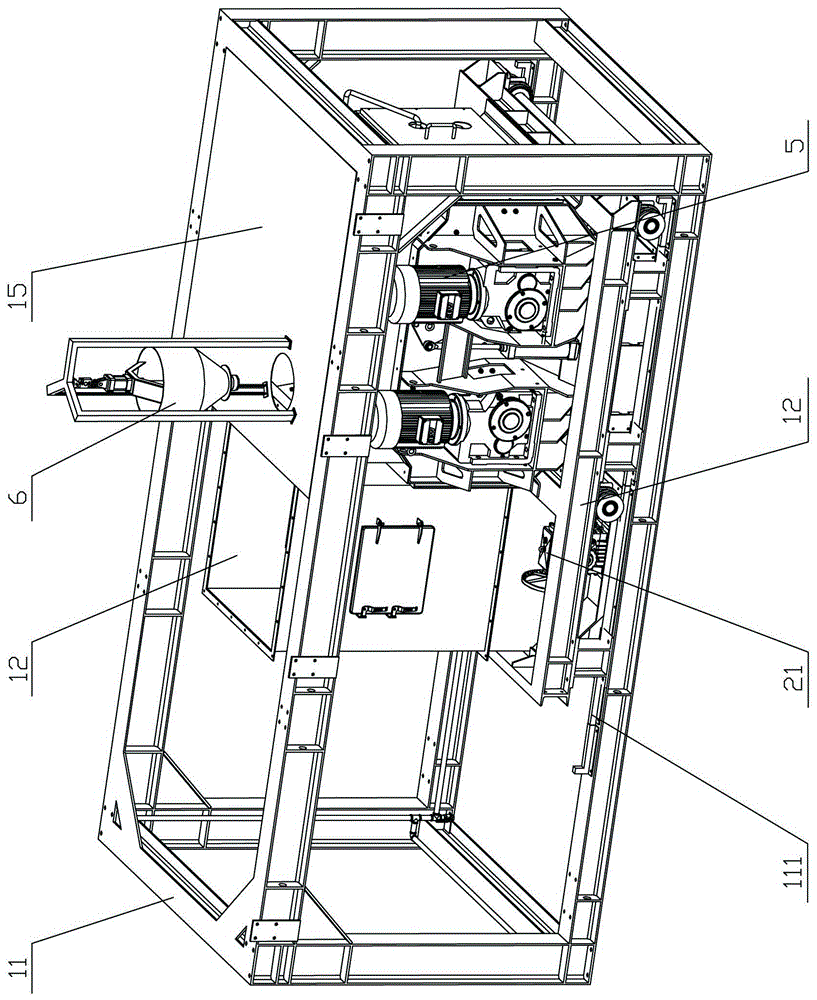

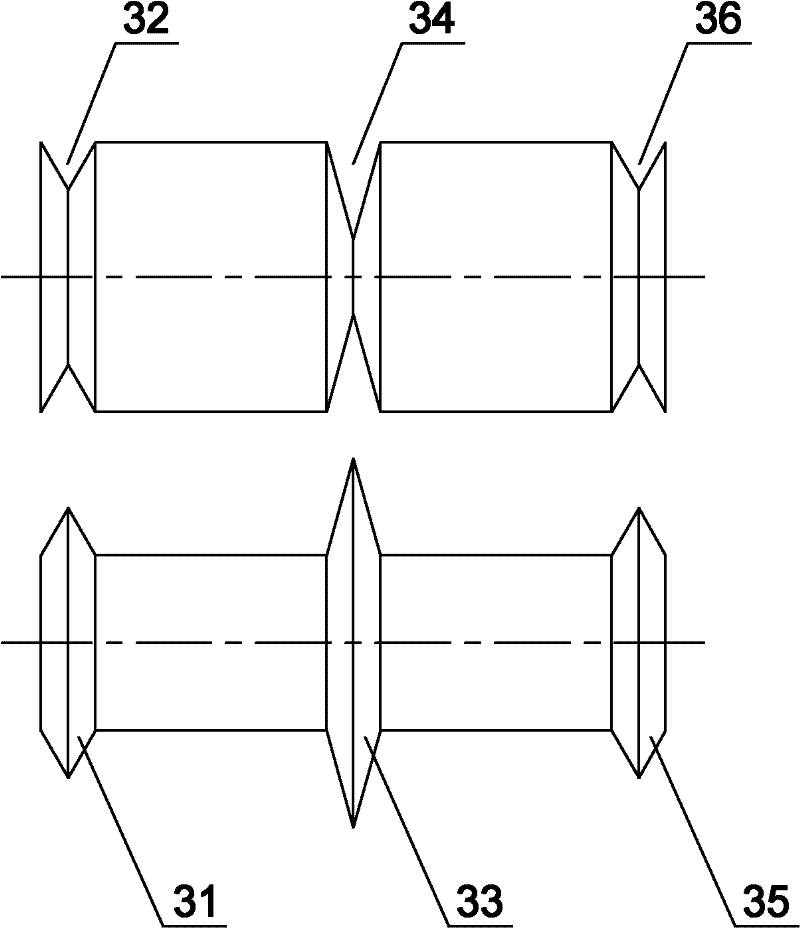

A motor automatic assembly line

ActiveCN106230201BEasy to assembleImprove assembly efficiencyManufacturing dynamo-electric machinesProduction lineElectric machine

The invention discloses an automatic motor assembly production line, comprising a frame (1), wherein a conveying chain (2) is arranged on the frame (1), and a stator installation device (3), a rotator installation device (4) and an end cover installation device (5) are arranged above the conveying chain (2) in sequence; a fixed base (6) is arranged above the conveying chain (2), an enclosure fixing mold (7) is arranged on the fixed base (6) and provided with an annular arc groove (9), a fixed ring (10) is arranged in the annular arc groove (9), a group of hydraulic rod (11) is arranged between the fixed ring (10) and the annular arc groove (9), the end of the hydraulic rod (11) is connected with a rotating assembly (12), and both the rotating assembly (12) and the hydraulic rod (11) are connected with a controller (13). The automatic motor assembly production line has the advantages of high assembly efficiency, low assembly cost, low worker labor intensity, small assembly error and good assembly quality.

Owner:HUZHOU YUEQIU MOTOR

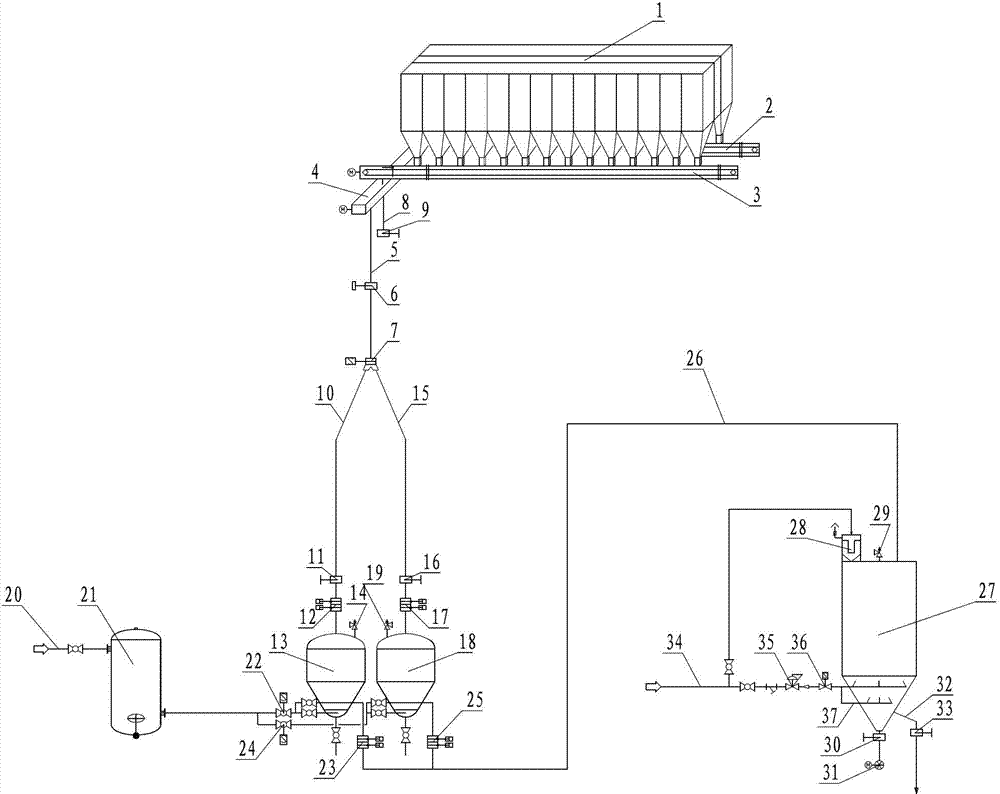

A converter gas dry dust removal fine ash pneumatic conveying system

ActiveCN103332458BSolve the problem of explosive ventingReduce the delivery linkDispersed particle filtrationBulk conveyorsNitrogenEngineering

The invention relates to a pneumatic conveying system for removing dust and fine ash in a dry process of converter gas. The system comprises a dry filter bag dust removing device (1), an ash discharging pipe (5), a cabin pump (10), a pneumatic conveying pipe (16) and a fine ash cabin (17) which are sequentially connected; the pneumatic conveying pipe (16) is connected with a gas storage tank (13), the inlet of the gas storage tank (13) is connected with a first nitrogen pipe (12), and the inlet of the first nitrogen pipe (12) is connected with a nitrogen main pipe; and the cabin pump (10) and the fine ash cabin (17) are connected through the pneumatic conveying pipe (16). By adopting the dry filter bag dust removing device, no sparks and discharging exist, and the problem that an electrostatic dust removing device is easily subjected to venting explosion is thoroughly solved. According to the pneumatic conveying system, the process of conveying fine ash is eliminated, and the fault rate of equipment is greatly reduced. The ash storage and the ash transportation of the fine ash cabin are not limited by a place and a distance.

Owner:WISDRI ENG & RES INC LTD

Pneumatic transmission method for dry dedusting of fine ash in converter gas

ActiveCN103388046BSolve the problem of explosive ventingReduce the delivery linkManufacturing convertersNitrogenEngineering

The invention relates to a pneumatic transmission method for dry dedusting of fine ash in converter gas, which comprises the following steps: S1, constructing a pneumatic transmission system for dry removal of dust and fine ash in converter gas; S2, material feeding: discharging ash into a first bin pump (13) or a second bin pump (18); S3, fluidizing: transporting nitrogen from a gas tank (20) into a first fluidizing device or a second fluidizing device; S4, conveying: conveying evenly fluidic gas ash mixture to a fine ash cabin (27) via a pneumatic conveying pipe (26); S5, blowing; and S6, transporting. The invention adopts a dry filter bag deduster with no spark discharge, which thoroughly solves the problem of easy explosion venting caused by a static deduster. By the method, conveying step of fine dust is minimized, and equipment failure rate is substantially reduced. Storage and transportation of ash in the fine ash cabin are not limited by site or distance.

Owner:WISDRI ENG & RES INC LTD

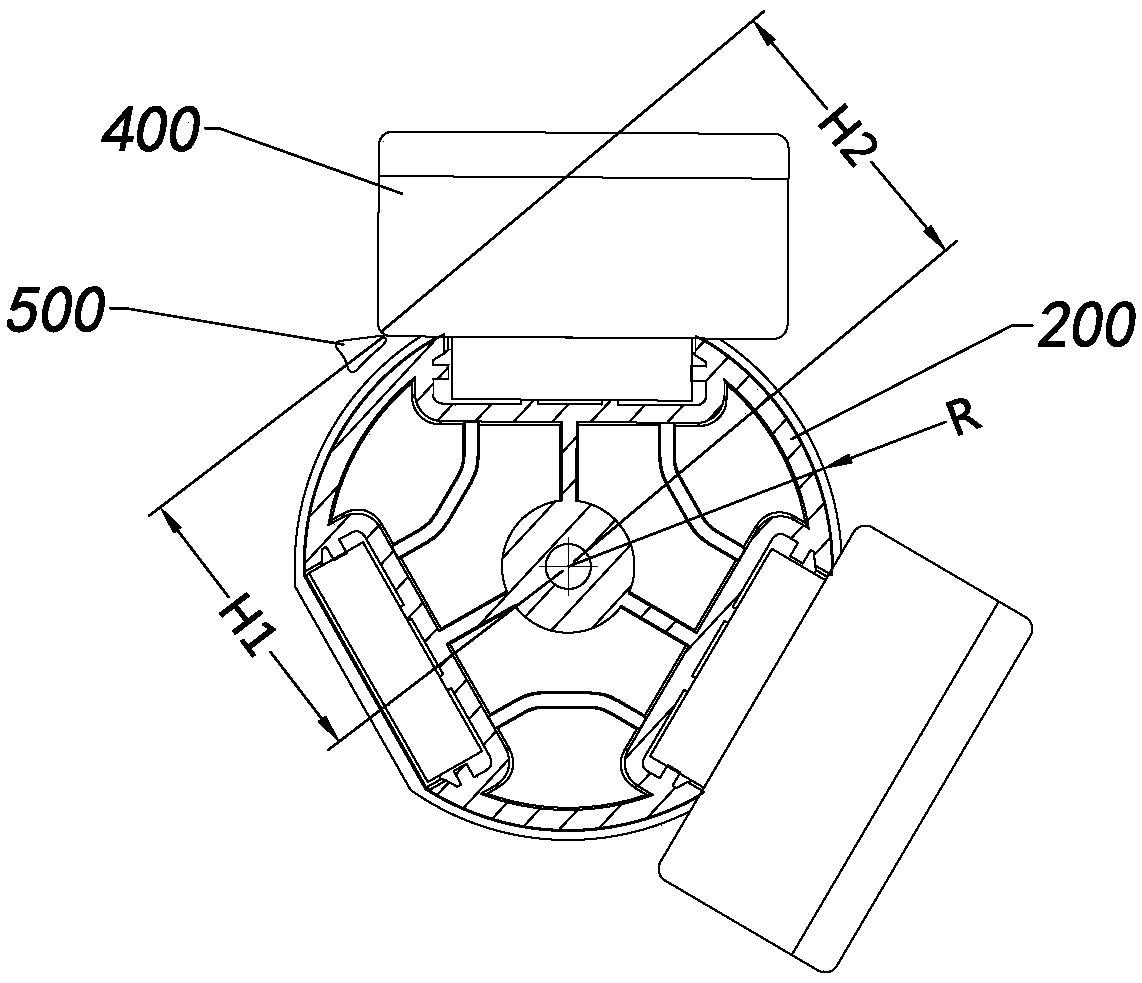

Mahjong tile collating mechanism of automatic Mahjong machine, Mahjong tile collating control method and automatic Mahjong machine

PendingCN108704305ASimple structureShorten the lengthIndoor gamesStructural engineeringMechanical engineering

The invention discloses a Mahjong tile collating mechanism of an automatic Mahjong machine, a Mahjong tile collating control method and the automatic Mahjong machine and belongs to the field of chessand Mahjong tile entertainment equipment. The Mahjong tile collating mechanism comprises a controller, a Mahjong tile sending device and a Mahjong tile stacking device; the Mahjong tile sending devicecomprises a Mahjong tile sending support, a Mahjong tile suction wheel, a Mahjong tile stopper and a first sensor, wherein the Mahjong tile suction wheel is mounted on the Mahjong tile sending support and is driven by a Mahjong tile sending motor to rotate, Mahjong tiles are sucked by the Mahjong tile suction wheel and rotate along with the same, the Mahjong tile stopper is arranged on a rotationtrack of each Mahjong tile and used for stopping the Mahjong tile moving to the position of the Mahjong tile stopper so as to allow the Mahjong tile to be separated from the Mahjong suction wheel andbe sent to the Mahjong tile sending support, the first sensor is connected with the controller and used for detecting the Mahjong tiles on the Mahjong tile suction wheel; the Mahjong tile stacking device comprises a Mahjong tile carrier plate, a Mahjong tile pushing block and a second sensor, wherein the Mahjong tile carrier plate is used for carrying the Mahjong tiles sent from the Mahjong tilesending support, the Mahjong tile pushing block is used for pushing the Mahjong tiles out of the Mahjong tile carrier plate, and the second sensor connected with the controller is used for detecting the Mahjong tiles on the Mahjong tile carrier plate.

Owner:MATSUOTA MECHANICAL & ELECTRICAL CHINA CO LTD

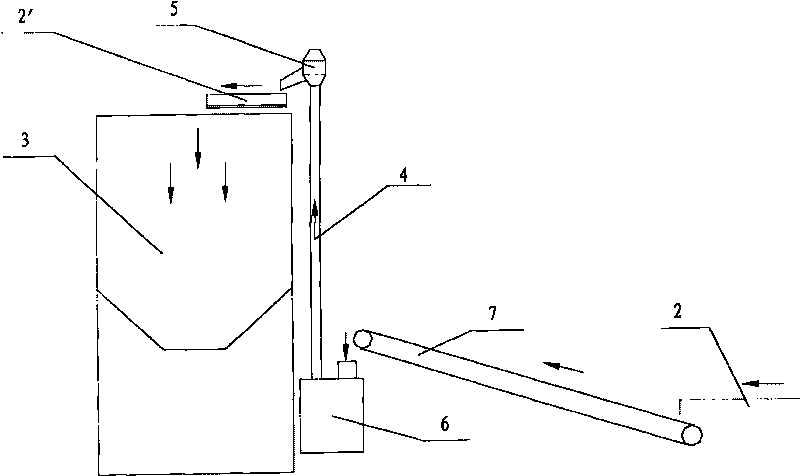

Particle circulating burner for biomass gasification combustion

PendingCN112240546AReduce the delivery linkReduce heat lossGaseous fuel burnerHeating efficiencyEnvironmental geology

The invention discloses a particle circulating burner for biomass gasification combustion. The particle circulating burner comprises a high-pressure fan, a cyclone cylinder shell and a gasifier shell,wherein a low-temperature gasification area is arranged inside the gasifier shell, and a gasification air duct is further arranged inside the gasifier shell. According to the particle circulating burner, the biomass low-temperature gasification area is connected with a cyclone combustion area, and the conveying link of biomass gasification gas is reduced, so that the heat dissipation loss is reduced, and the heat efficiency is improved; a cyclone combustion technology is used for the combustion of the biomass gasification gas, a cyclone nozzle is tangentially arranged on the cyclone cylindershell, and the biomass gasification gas rotates under the driving of cyclone air, so that the mixing disturbance of air and the biomass gasification gas is strengthened, and the combustion efficiencyof the biomass gasification gas is improved; and the combustion of the biomass gasification gas belongs to non-premixed combustion, and according to the cyclone combustion mode, flame fullness in a cyclone cylinder is good, and the heat load distribution is uniform.

Owner:李效清

Automatic wire-stripping crimping tubular terminal machine

PendingCN114865419AReduce complexityReduce usageConnection formation by deformationElectronic waste recyclingWire rodEngineering

An automatic wire stripping and crimping tubular terminal machine effectively solves the problems of low working efficiency, high cost and the like, and comprises a shell, a wire clamping mechanism, a sliding platform, a wire stripping and bunching mechanism and a pressing clamp mechanism are sequentially arranged in the shell from left to right, a terminal feeding mechanism is fixed on the shell, a blanking port of the terminal feeding mechanism is located in the shell, and the sliding platform is fixed on the shell. The wire stripping and bunching mechanism is fixed on the sliding platform, the pressing clamp mechanism is rotatably connected with the sliding platform, the pressing clamp mechanism has a horizontal state and a vertical state, and the pressing clamp mechanism is used for fixing a tubular terminal fed by the terminal feeding mechanism; the sliding platform can drive the wire stripping and bunching mechanism to strip the outer skin of the electric wire behind the wire clamping mechanism and enable the stripped electric wire to penetrate through the tubular terminal of the pressing clamp mechanism in the horizontal state, and a switching device used for switching the horizontal state or the vertical state of the pressing clamp mechanism is arranged in the shell.

Owner:洛阳赛乐电子科技有限公司

Multifunctional air supply box

InactiveCN102352857ALess turnsReduce the delivery linkPump componentsPump installationsPositive pressureInstability

The invention relates to a multifunctional air supply box comprising a box body. The box body is provided with a splint and is divided into a closed positive-pressure box body and a closed negative-pressure box body by the splint; the box body is internally provided with at least one centrifugal blower; the centrifugal blower comprises an air inlet and an air outlet; the negative-pressure box body is provided with a negative-pressure connection hole and the negative-pressure connection hole is communicated with the negative-pressure box body and the air inlet; the positive-pressure box body is provided with a positive-pressure connection hole and the positive-pressure connection hole is communicated with the positive-pressure box body and the air outlet. In the invention, by using the positive-pressure box body and the negative-pressure box body, pipeline turns and delivery links are reduced and no loss is caused, so that the energy is saved; the negative-pressure box body not only can be used as the wind inlet and wind outlet of the centrifugal blower but also can store the energy, so that the instability of the positive and negative pressure caused by the interruption of the centrifugal blower is avoided and the positive and negative pressure which flows in the box body has the better effects on cooling the centrifugal blower; and the multifunctional air supply box has the advantages of simple and compact structure, convenience in mounting and use, energy conservation, environmental friendliness, safety and reliability.

Owner:朱青东

Converter gas dry dedusting fine dust pneumatic transport system

ActiveCN103332490BSolve the problem of explosive ventingReduce the delivery linkConveyorsTransport systemChain conveyor

Owner:WISDRI ENG & RES INC LTD

Rail dual-purpose mobile breaking platform

ActiveCN105944818BPrevent rolloverLarge support surface for safetyGrain treatmentsLoading/unloadingMultiple platformArchitectural engineering

The invention discloses a breaking platform capable of moving both on roads and railways. The breaking platform comprises a base, a support assembly and a lifting assembly, wherein the base is connected to the bottom of the lifting assembly; the support assembly is movably connected with the lifting assembly and comprises two split support bodies arranged in the front position and the rear position of a bottom plate; each split support body comprises wheels, an axle, support columns and a support beam, the two support columns are arranged at the bottom of the support beam and are close to two end parts of the support beam respectively, the wheels are arranged on the axle, and two end parts of the axle are fixed at the bottoms of the support columns. The breaking platform capable of moving both on roads and railways has a wide range of application, multiple platforms can be freely connected, a production process is extended, and an industrial chain is easy to form.

Owner:郭大军

A low-water consumption, low-discharge and fat-releasing processing method

ActiveCN112080206BReduce viscosityReduce consumptionTurpentine spiritsNatural resin purificationLiquid waterDistillation

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Novel mixing heat regeneration equipment for asphalt mixture factory

ActiveCN106012766AReduce the delivery linkIncrease productivityRoads maintainenceButt jointEngineering

The invention discloses novel mixing heat regeneration equipment for an asphalt mixture factory. The novel mixing heat regeneration equipment comprises a regeneration material heating system, a regeneration material storage silo, a regeneration material measuring hopper and a main mixing cylinder, wherein the main mixing cylinder is arranged right below the regeneration material measuring hopper, a regeneration material pre-mixing device is arranged between the regeneration material measuring hopper and the main mixing cylinder, the regeneration material pre-mixing device comprises a mixing layer framework, a sliding table trolley, a first regeneration material chute and a second regeneration material chute, the sliding table trolley is arranged on the mixing layer framework in a sliding manner, a mixing mechanism is arranged in the first regeneration material chute, a regeneration agent measuring hopper is correspondingly arranged in the first regeneration material chute, and the first regeneration material chute or the second regeneration material chute are respectively in butt joint with the regeneration material measuring hopper and the main mixing cylinder after the sliding table trolley moves in place. when a user chooses the first regeneration material chute in production, and a failure occurs in the first regeneration material chute, the sliding table trolley can be driven to move to the other side, and then the second regeneration material chute is in butt joint with the regeneration material measuring hopper and the main mixing cylinder, so that uninterrupted production is achieved.

Owner:FUJIAN TIETUO MACHINERY

Multi-stage cleaning device and method suitable for various waste plastics

ActiveCN104149225BThe principle is simpleAvoid crossing each otherPlastic recyclingCleaning using liquidsCrusherWater pipe

The invention discloses a multilevel cleaning device and a multilevel cleaning method for various waste plastics. The multilevel cleaning device comprises a belt conveyer, a crusher, a washing cage, a rinsing tank and a terminal dehydrator, which are connected sequentially, wherein a primary circulating water treating pond is arranged under the washing cage and is connected with the crusher and the feeding end of the washing cage by a primary water return pipe respectively, and a secondary circulating water treating pond is arranged under the terminal dehydrator and is connected with the rinsing tank by a secondary water return pipe; the multilevel cleaning method comprises the steps of crushing waste plastics, primarily cleaning the crushed waste plastics in the washing cage and separating from cleaning water, then feeding the cleaned waste plastics into the rinsing tank for further cleaning with fluid mediums, and finally, feeding the cleaned waste plastics into the terminal dehydrator for dehydration, wherein the primary circulating water treating pond recycles the cleaning water, and the secondary circulating water treating pond recycles the fluid mediums. The device and the method can separately manage the cleaning water or the fluid mediums in different treating levels, so that the fluid mediums and the cleaning water can be circulated conveniently.

Owner:冯愚斌

Metal roof board forming device

The invention discloses a metal roof board forming device, which can regulate the discharge angle, be high in construction efficiency and facilitate the direct conveying of a roof board to a roof after forming. The metal roof board forming device comprises a forming frame (2), a forming roller group (3), a feed roller group (5), a discharge roller group (6), a box body (1), a cutting and guide roller group (7) and a frame lifting device (9), wherein a metal coiled material (8) is placed at the top of the forming frame (2), the metal coiled material (8) sequentially passes through a cutting and guide roller group (7), a feed roller group (5), the forming roller group (3) and the discharge roller group (6) for performing cutting, feeding, forming and discharging, a metal roof board after forming is sent out of the box body (1), the front part of the forming frame (2) can rotate around a first pivot shaft (21) fixedly connected with the box body (1), and the frame lifting device (9) is arranged at the rear part of the forming frame (2) so as to lift the rear part of the forming frame (2) and adjust the discharge angle of the metal roof board after forming. The metal roof board forming device can be widely applied in the field of forming of the metal roof boards.

Owner:BAIANLI STEEL STRUCTURE APPL SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com