Mahjong tile collating mechanism of automatic Mahjong machine, Mahjong tile collating control method and automatic Mahjong machine

A control method and technology of a mahjong machine, which can be used in sports accessories, indoor games, etc., can solve the problems of high production cost, long conveying distance, and low production line assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

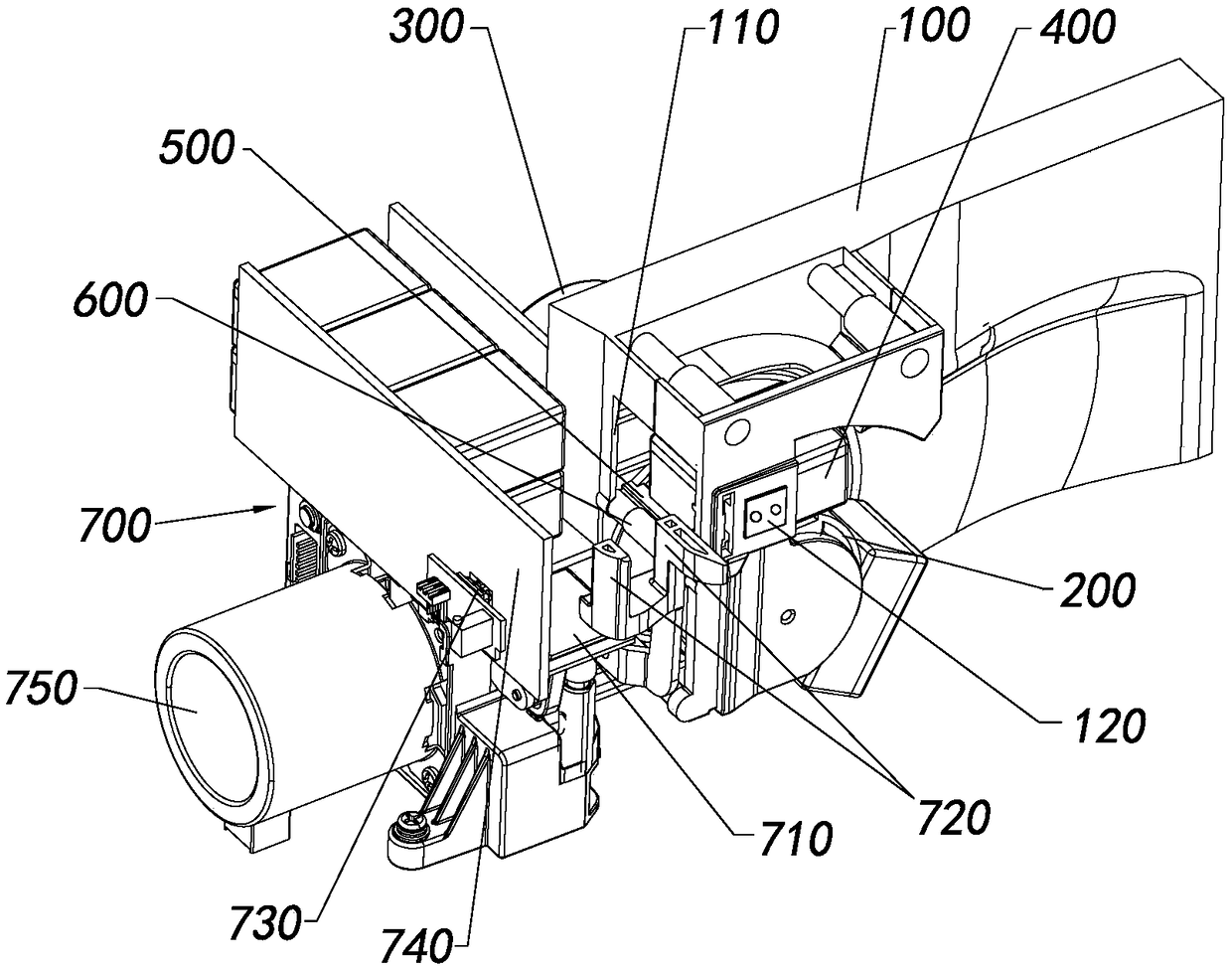

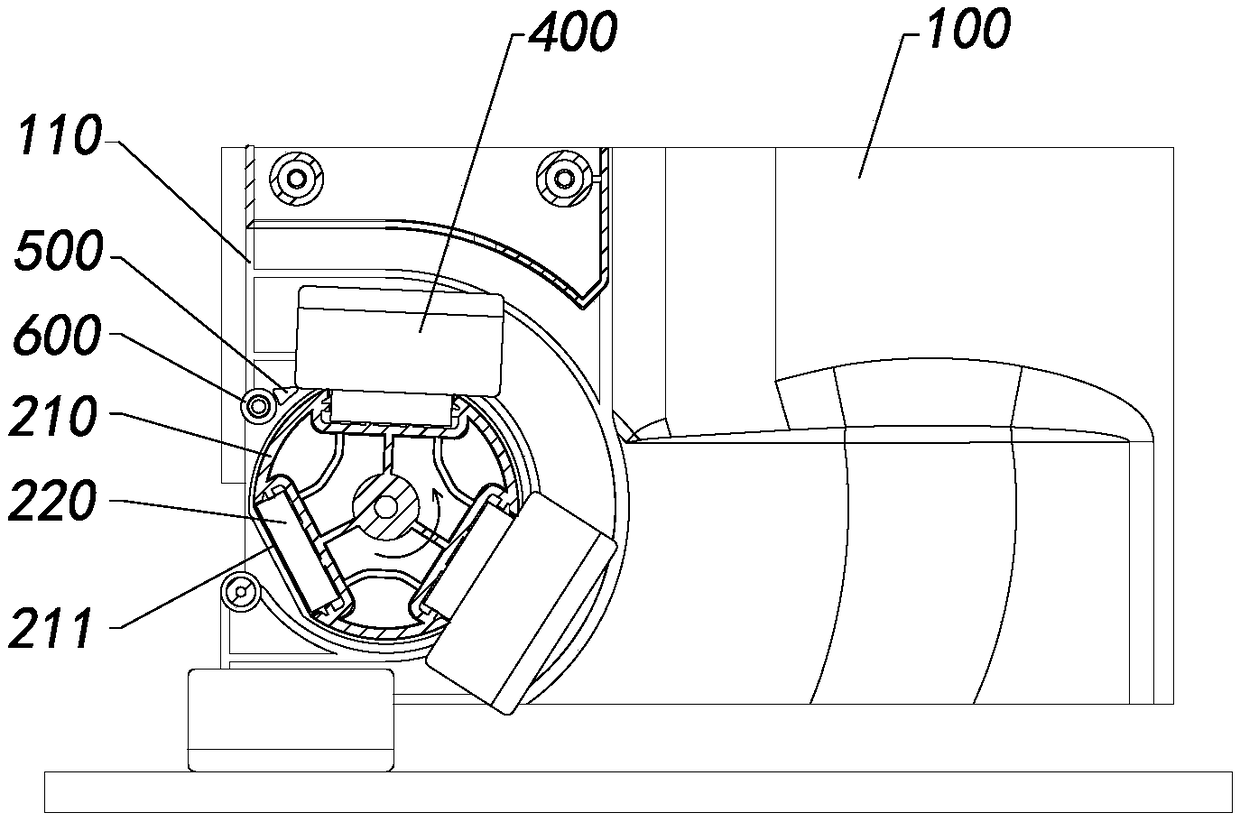

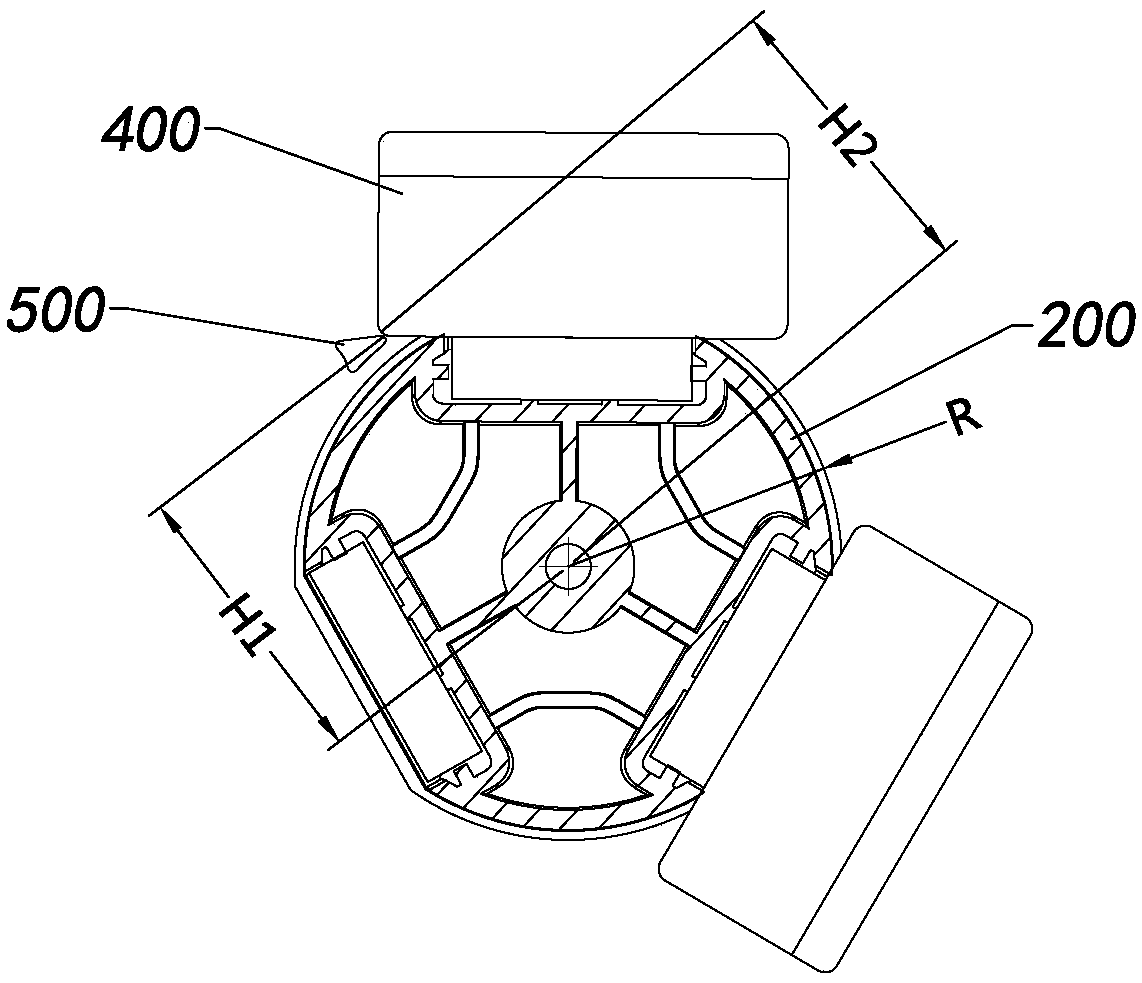

[0064] refer to Figure 1-3The card sorting mechanism of the automatic mahjong machine proposed in Embodiment 1 of the present invention includes a card feeding device and a stacking push device, wherein the card feeding device includes: a card feeding bracket 100, a card suction wheel 200 and a card baffle plate 500, a card suction wheel 200 is installed on the card delivery bracket 100 and is driven by the card delivery motor 300 to rotate. The mahjong tiles 400 are adsorbed on the card suction wheel 200 and rotate with the card suction wheel 200. The shield plate 500 is located on the rotation track of the mahjong tiles 400 for Block the mahjong tiles moving to the baffle plate 500 , so that the mahjong tiles moving to the baffle member 500 are separated from the card suction wheel 200 and sent out of the card delivery bracket 100 . Preferably: the card delivery side of the card delivery bracket 100 is provided with a card outlet 110, and the above-mentioned baffle plate 50...

Embodiment 2

[0074] refer to Figure 6 , the difference between this embodiment and Embodiment 1 is that the shield part adopts the shield wheel 800, and the shield wheel 800 can be fixed or freely rotated relative to the card sending bracket 100, and the shield wheel 800 is located on the rotation track of the mahjong tiles 400 above, it is used to block the mahjong tiles moving to the shielding wheel 800, so that the mahjong tiles moving to the shielding wheel 800 are separated from the suction wheel 200 and sent out the card sending bracket 100. Compared with the baffle plate, the baffle wheel 800 has less contact area with the mahjong tiles, which can reduce the motion resistance of the mahjong tiles, especially when the speed of the tile suction wheel is slow and the movement inertia of the mahjong tiles is small. The probability of mahjong tiles staying on the shield wheel 800 is reduced, and the sending of tiles is smoother.

[0075] According to the solutions described in the abov...

Embodiment 3

[0077] refer to Figure 7 , 8 , Embodiment 3 of the present invention proposes the card sorting control method of the card sorting mechanism, wherein, the card sorting mechanism adopts the card sorting mechanism of the automatic mahjong machine described in any one of the above embodiments, and its card sorting control method includes:

[0078] In the card delivery process, the card delivery motor 300 drives the card suction wheel 200 to rotate to deliver the mahjong tiles 400 to the stacking device 700, and the first sensor 120 generates a card delivery signal when detecting the mahjong tiles 400;

[0079]In the stacking and pushing process, the tile receiving board 710 receives the mahjong tiles 400 sent by the tile delivery device, and the second sensor 730 generates a tile pushing signal when the preset number of stacked tiles is satisfied, so that the tile pushing block 720 performs a tile pushing action to push the mahjong tiles away. Bearing plate 710;

[0080] The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com