Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "The cooling rate is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

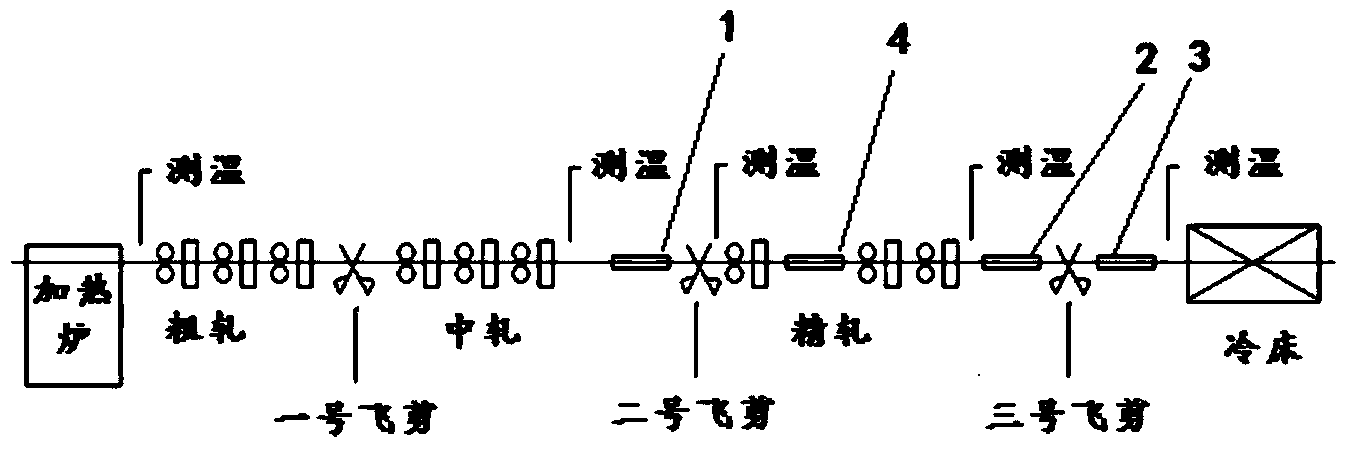

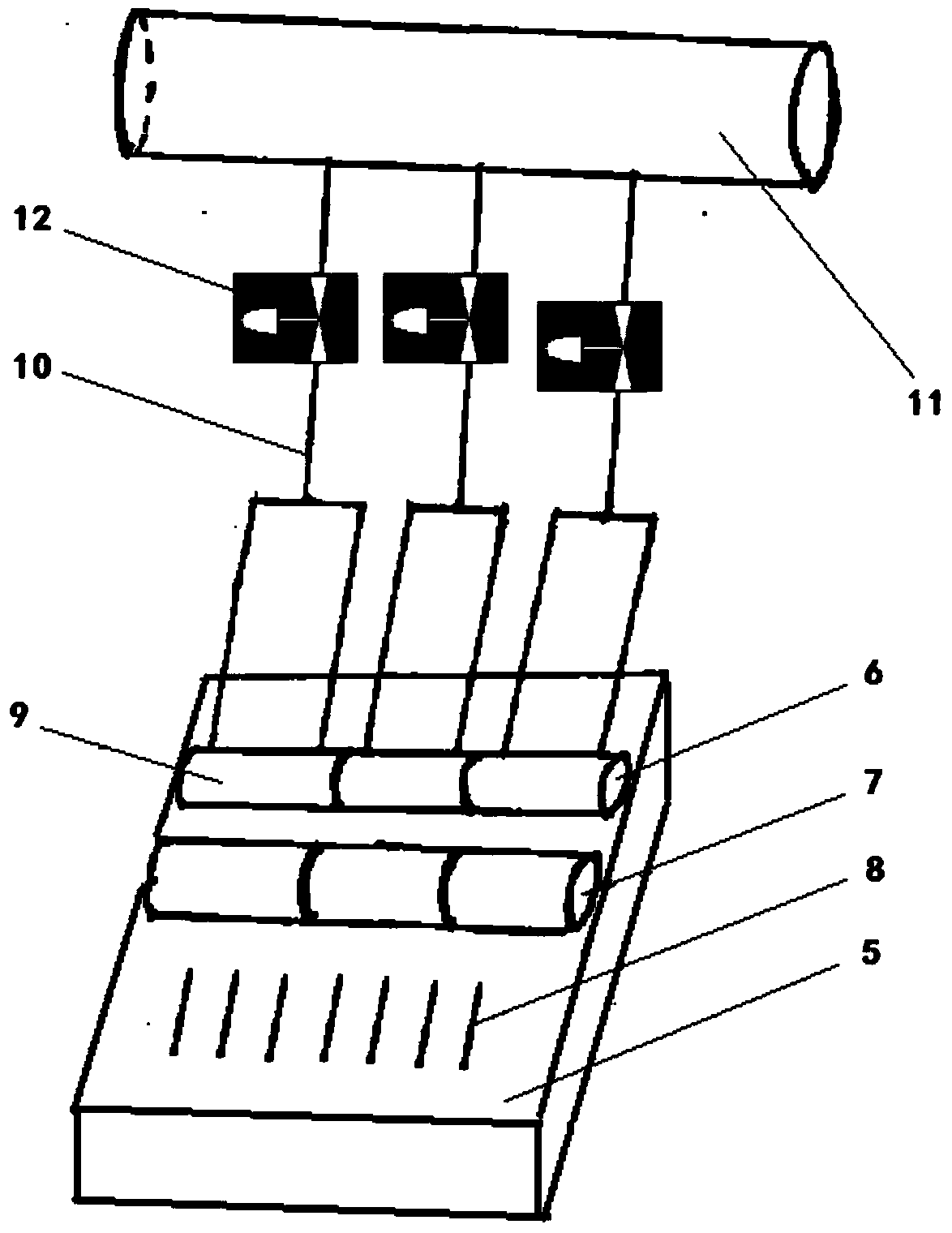

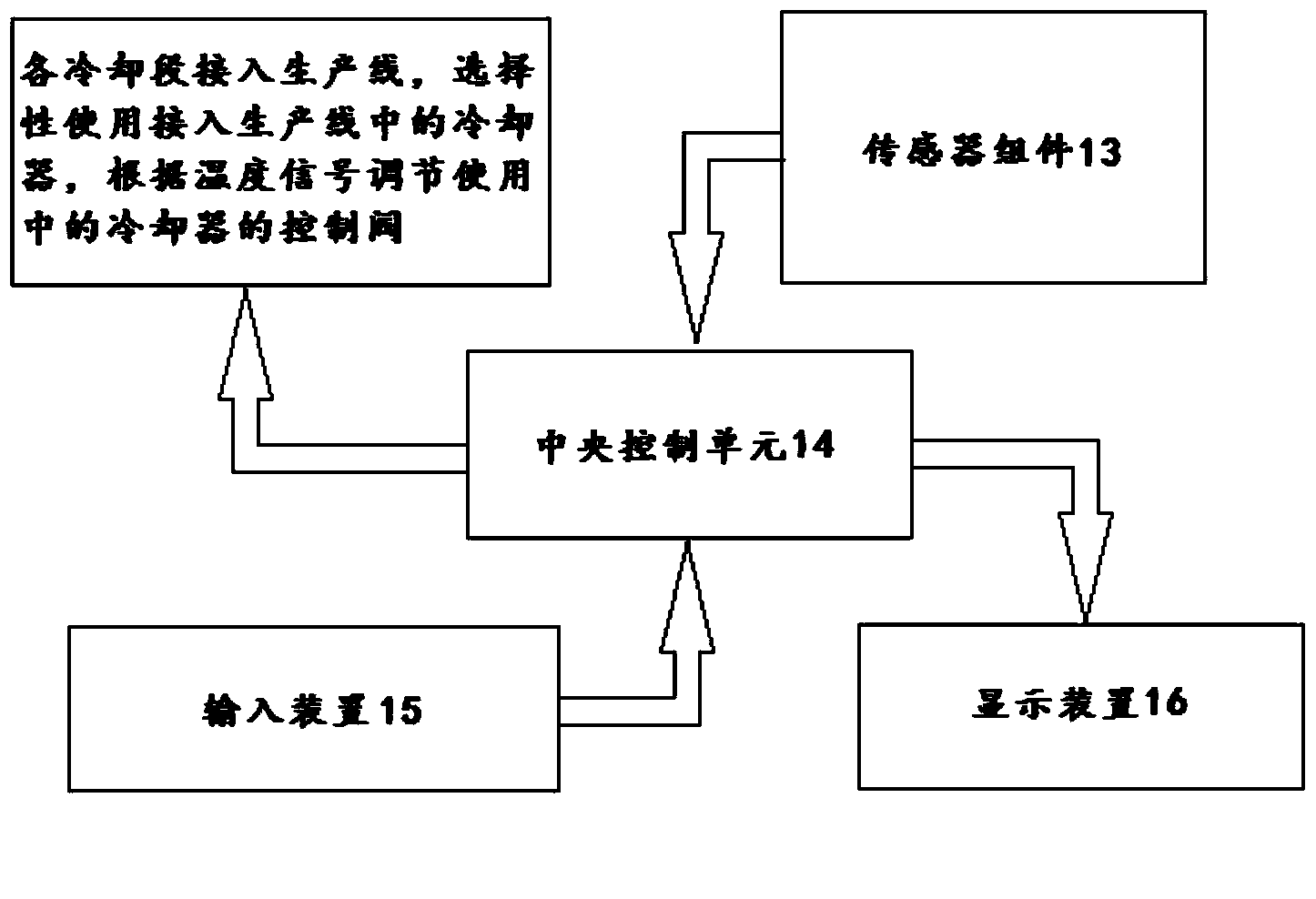

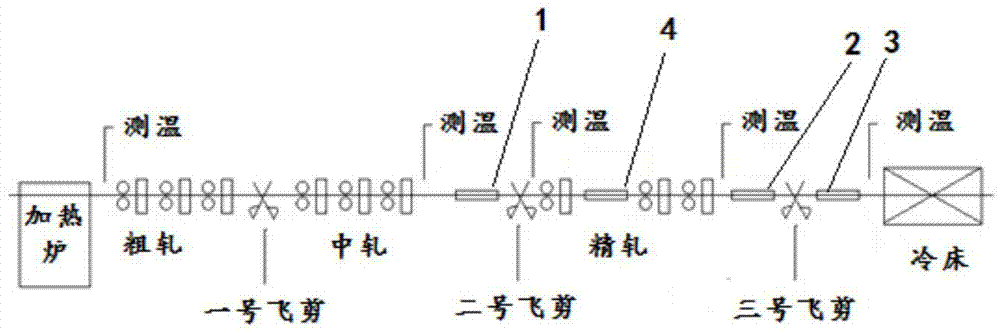

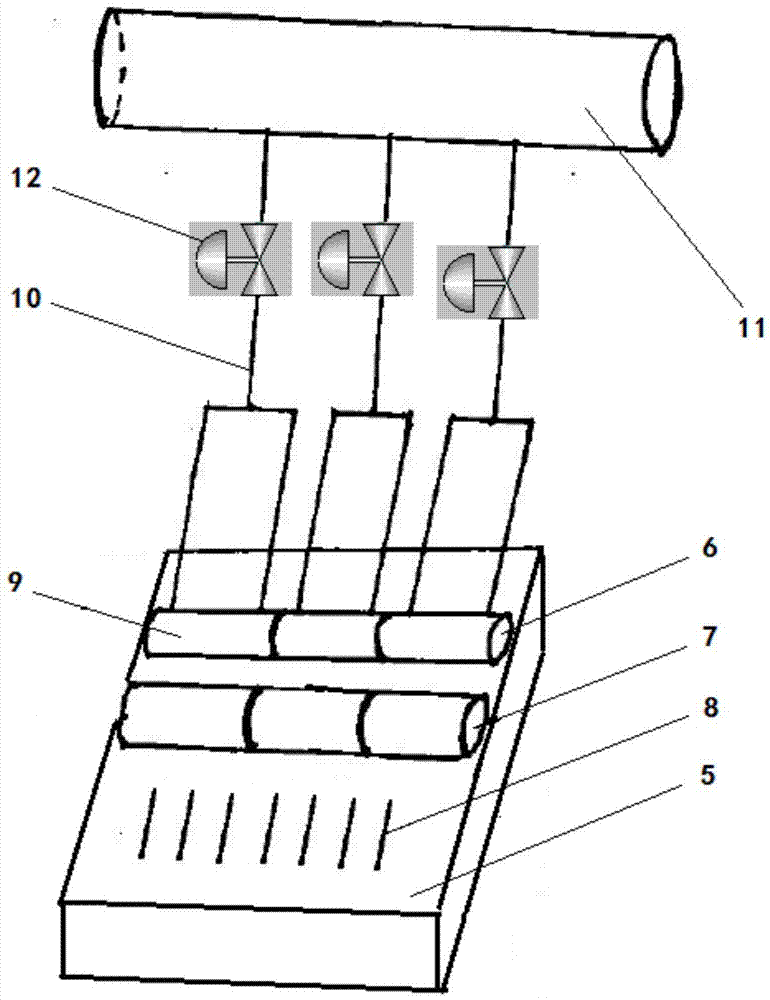

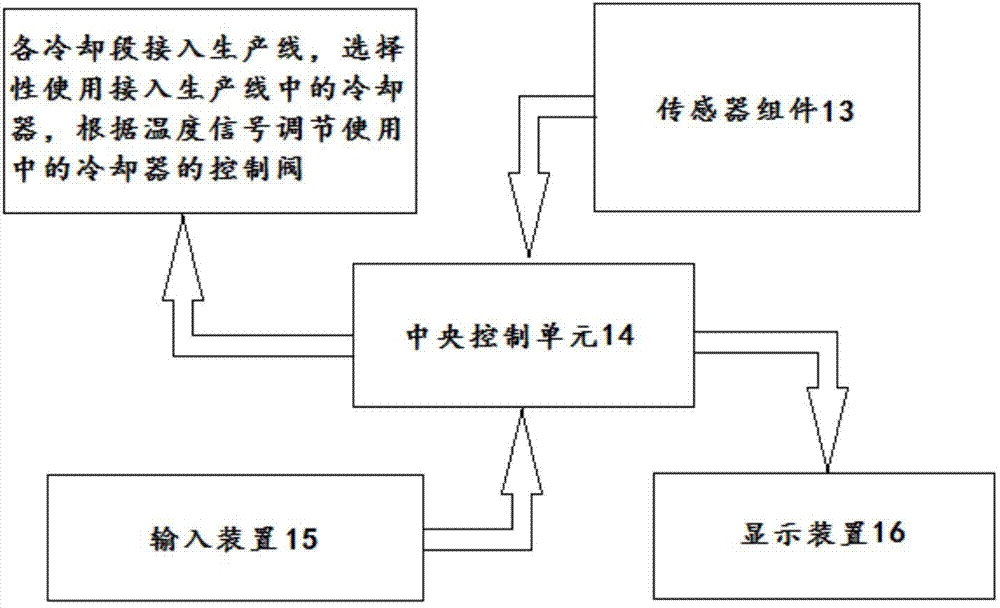

Controlled rolling and controlled cooling system for bars

ActiveCN103551403APrevent "overcooling"Large temperature difference in the axial directionTemperature control deviceWork treatment devicesProduction lineEngineering

A controlled rolling and controlled cooling system for bars comprises a first cooling section at the position of an outlet of an intermediate mill group, a machine cooling section of a finishing mill group, a second cooling section between the finishing mill group and a third flying shear, a third cooling section between the third flying shear and a cooling bed, a sensor module and a central control unit. The first cooling section, the second cooling section and the third cooling section respectively comprise one or a plurality of cooling lines arranged on a horizontal moving trolley and a bypass roll table, one cooling line or the bypass roll table can be selectively connected to a production line by horizontally moving the horizontal moving trolley, and every production line comprises one or a plurality of series connection coolers. Every cooler is connected to a water supply main pipe through one water supply branched pipe, control valves are arranged in the water supply branched pipes, and the coolers connected to the production lines are selected and used by opening and closing of the control valves. According to the controlled rolling and controlled cooling system, a plurality of cooling sections can be selected flexibly, the coolers in every cooling section can also be selectively used simultaneously, and accordingly the system not only is good in applicability, but also improves bar finished product performances.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

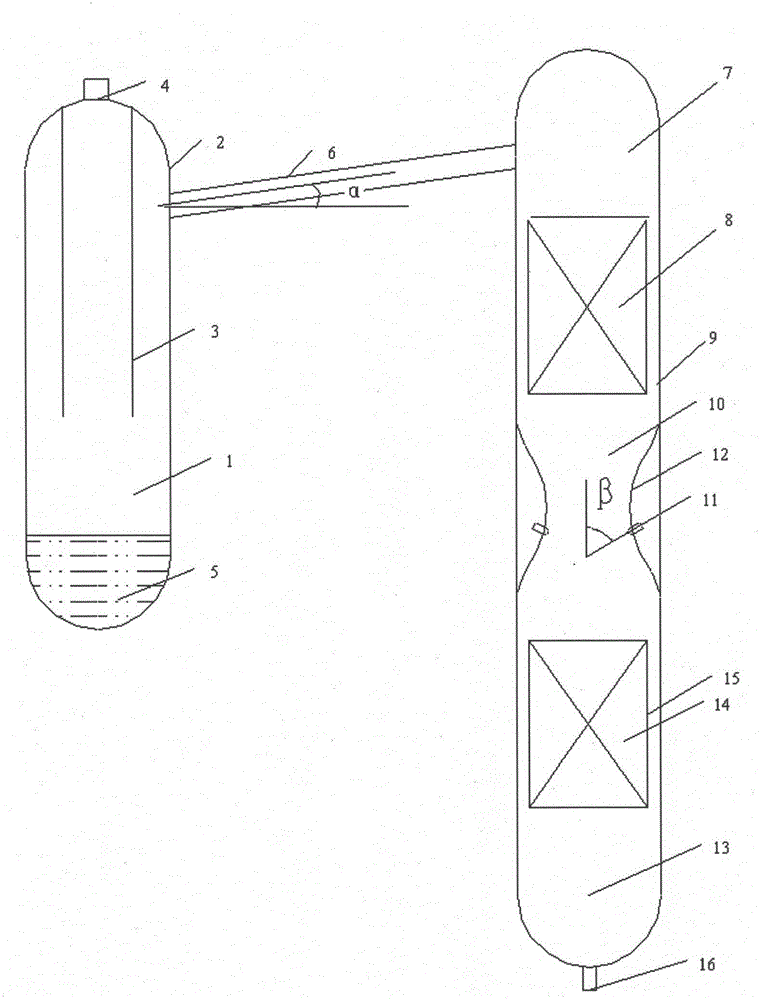

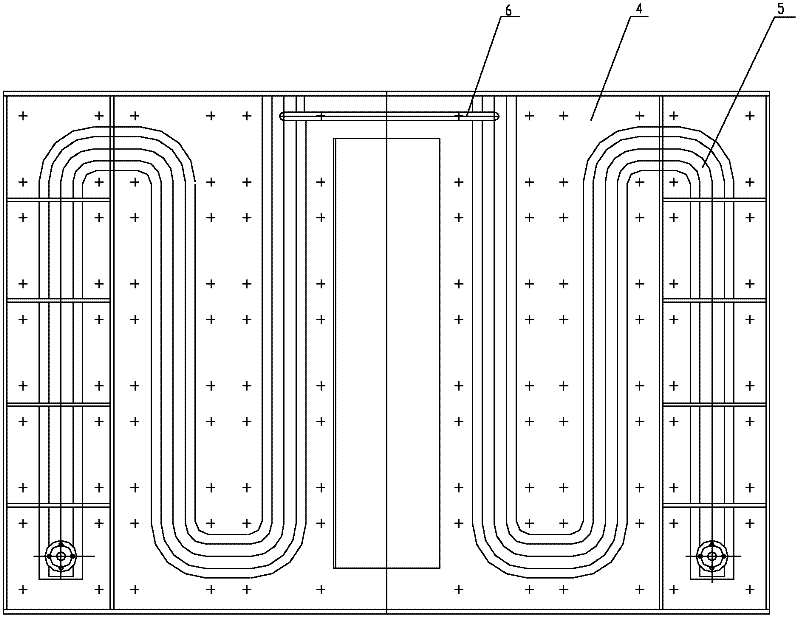

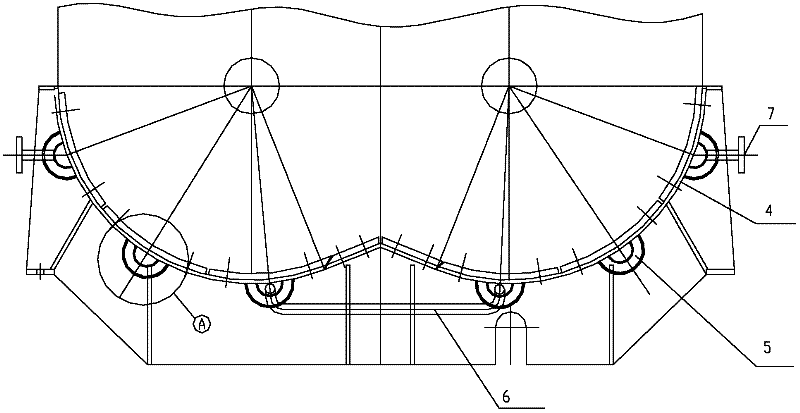

Framework of agricultural greenhouse, with function of heat storage

ActiveCN104488601AThe cooling rate is smallReduce the temperature difference between day and nightClimate change adaptationRenewable energy machinesAgricultural scienceGreenhouse

The invention discloses a framework of an agricultural greenhouse, with the function of heat storage, and relates to a framework of an agricultural greenhouse. The framework consists of heat storage headers, rising discharge pipes, a rising header pipe, declining straight pipes, a declining header pipe, declining bent pipes and supporting stand columns, wherein the rising discharge pipes are arranged in an inverted V shape on the left side and the right side of the rising header pipe, the lower ends of the rising discharge pipes are connected to branch output interfaces of the heat storage headers, and the upper ends of the rising discharge pipes are connected to branch input interfaces of the rising header pipe; the declining straight pipes are connected to a position between a backwater outlet in the bottom of the rising header pipe and a backwater inlet in the top of the declining header pipe; the declining bent pipes are arranged on the left side and the right side of the declining linking box pipe in an arched manner, the upper ends of the declining bent pipes are connected to loop output interfaces of the declining header pipe, and the lower ends of the declining bent pipes are connected to loop input interfaces of the lower parts of the heat storage headers. Through the use of the framework disclosed by the invention, solar energy heat is stored in the framework, and when the temperature in the greenhouse is lowered at night, the heat is gradually released, so that the temperature drop range in the greenhouse is reduced, and a diurnal temperature difference in the greenhouse is reduced.

Owner:CHONGQING WEST LINE TECH

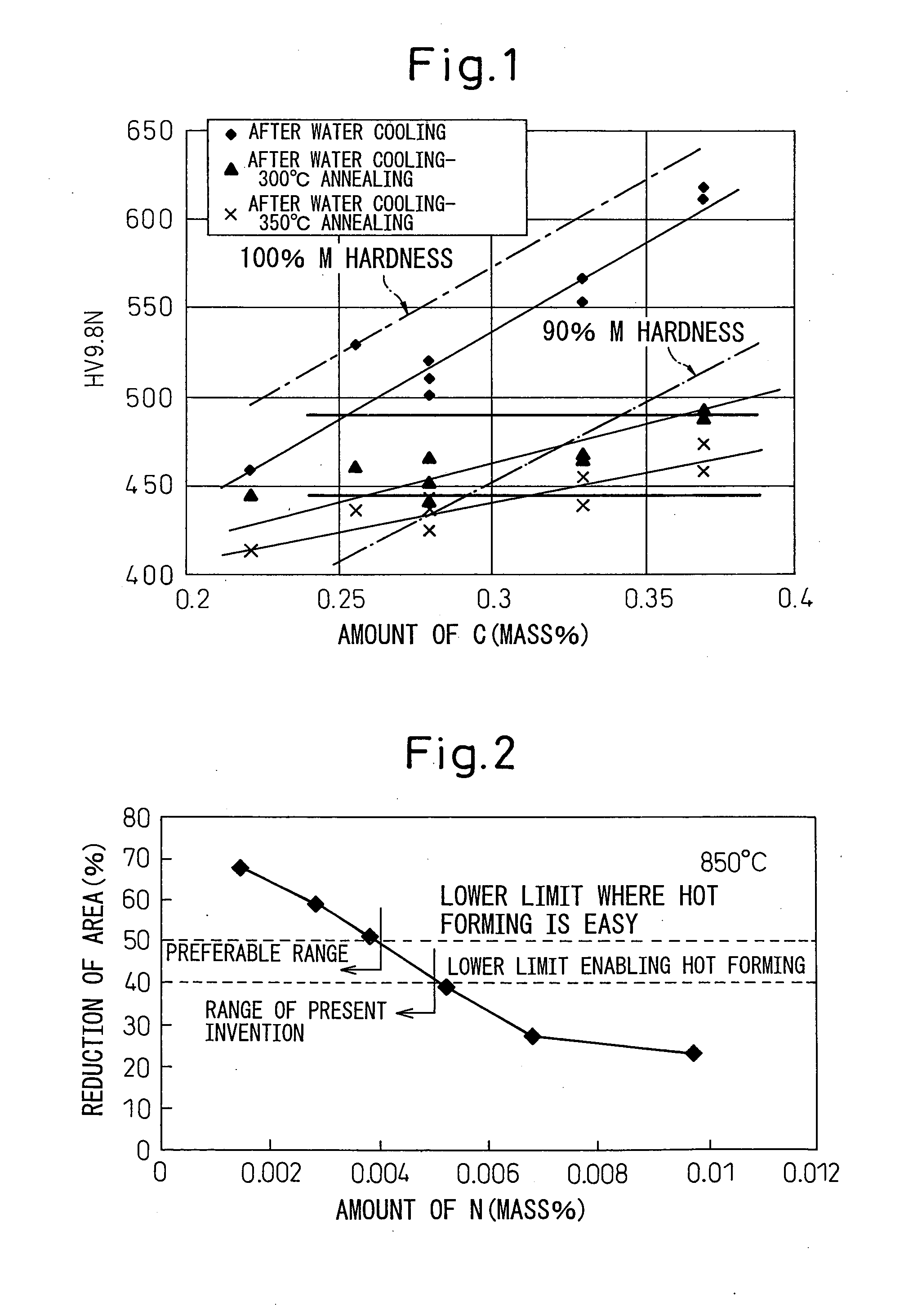

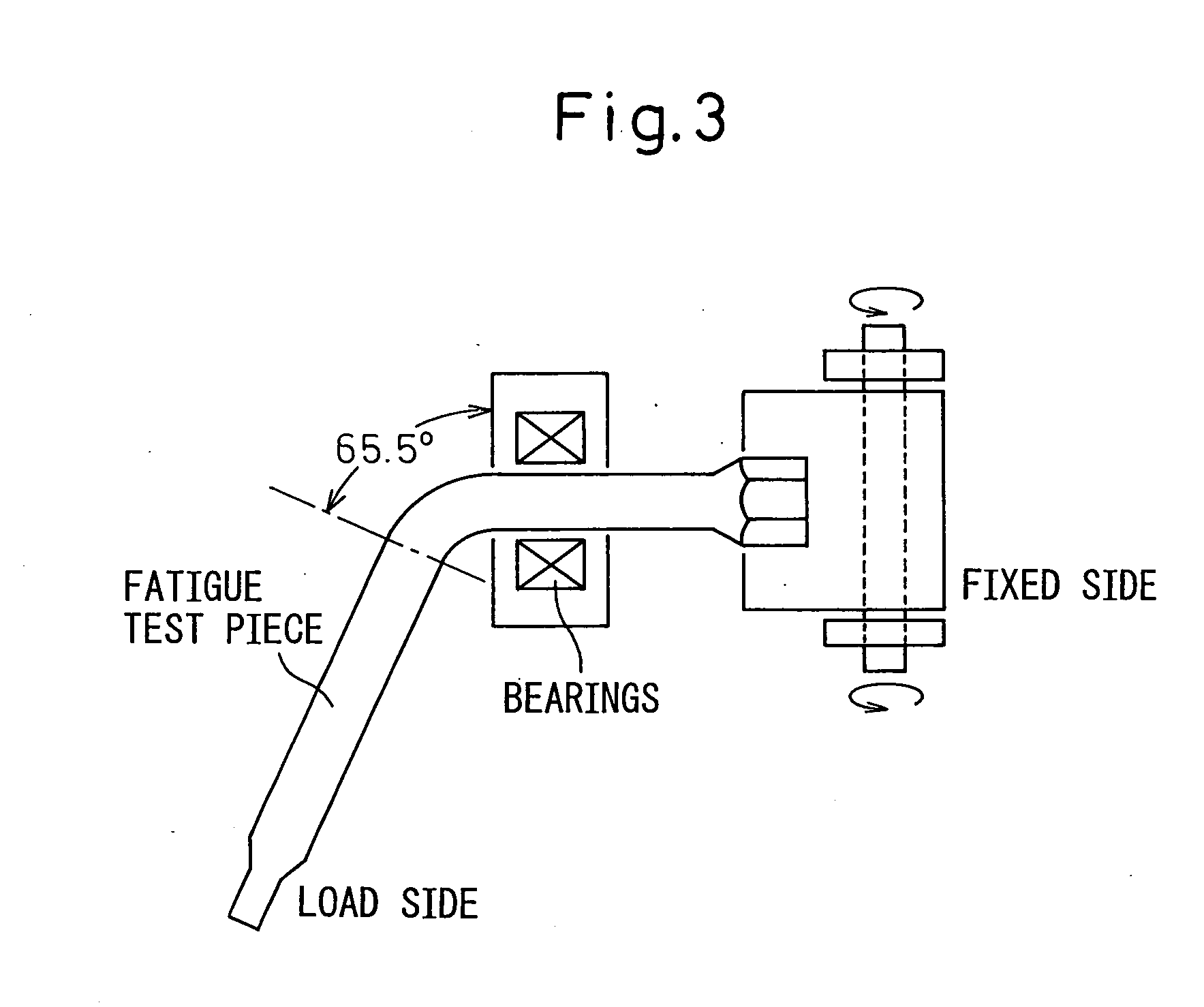

High Strength Thick-Gauge Electric-Resistance Welded Steel Pipe Excellent in Hardenability, Hot Workability and Fatigue Strength and Method of Production of the Same

InactiveUS20090250146A1Not impairing weldability and toughnessHigh strengthFurnace typesInterconnection systemsHigh intensityMethods of production

The present invention provides high strength thick-gauge electric-resistance welded steel pipe excellent in hardenability, hot workability, and fatigue strength and a method of production of the same, that is, thick-gauge electric-resistance welded steel pipe containing, by mass %, C: 0.25 to 0.4%, Si: 0.01 to 0.50%, Mn: 0.8 to 1.5%, P: 0.05% or less, S: 0.05% or less, Al: 0.05% or less, Ti: 0.005 to 0.05%, B: 0.0005 to 0.01%, N: 0.001 to 0.05%, and a balance of Fe and unavoidable impurities, having a critical cooling rate Vc expressed by equation <1> of less than 30° C. / s, and having a ratio of thickness t and outside diameter D, t / D, of over 0.15 to 0.30 in range:log Vc=2.94−0.75β <1>where, β=2.7C+0.4Si+Mn

Owner:NIPPON STEEL CORP

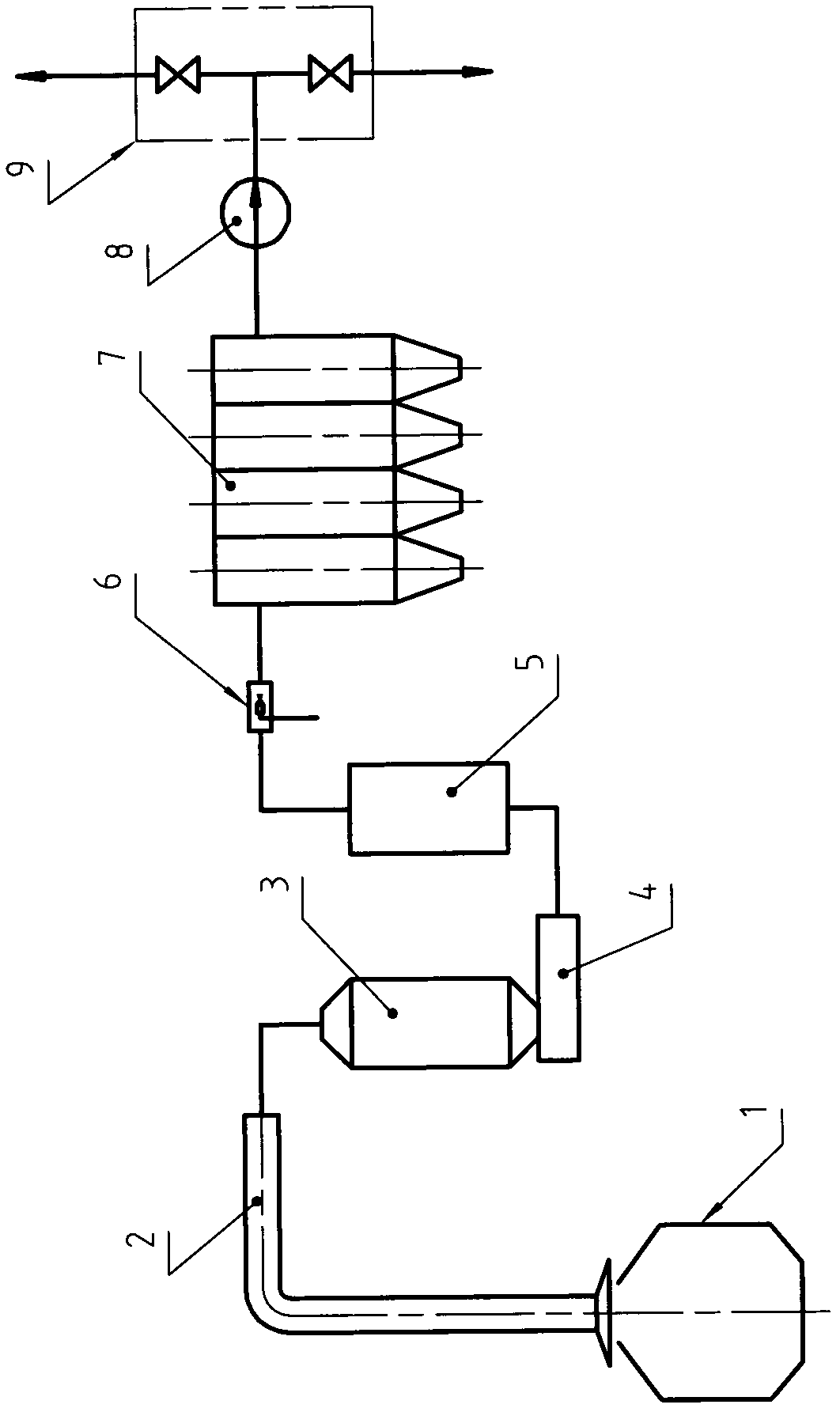

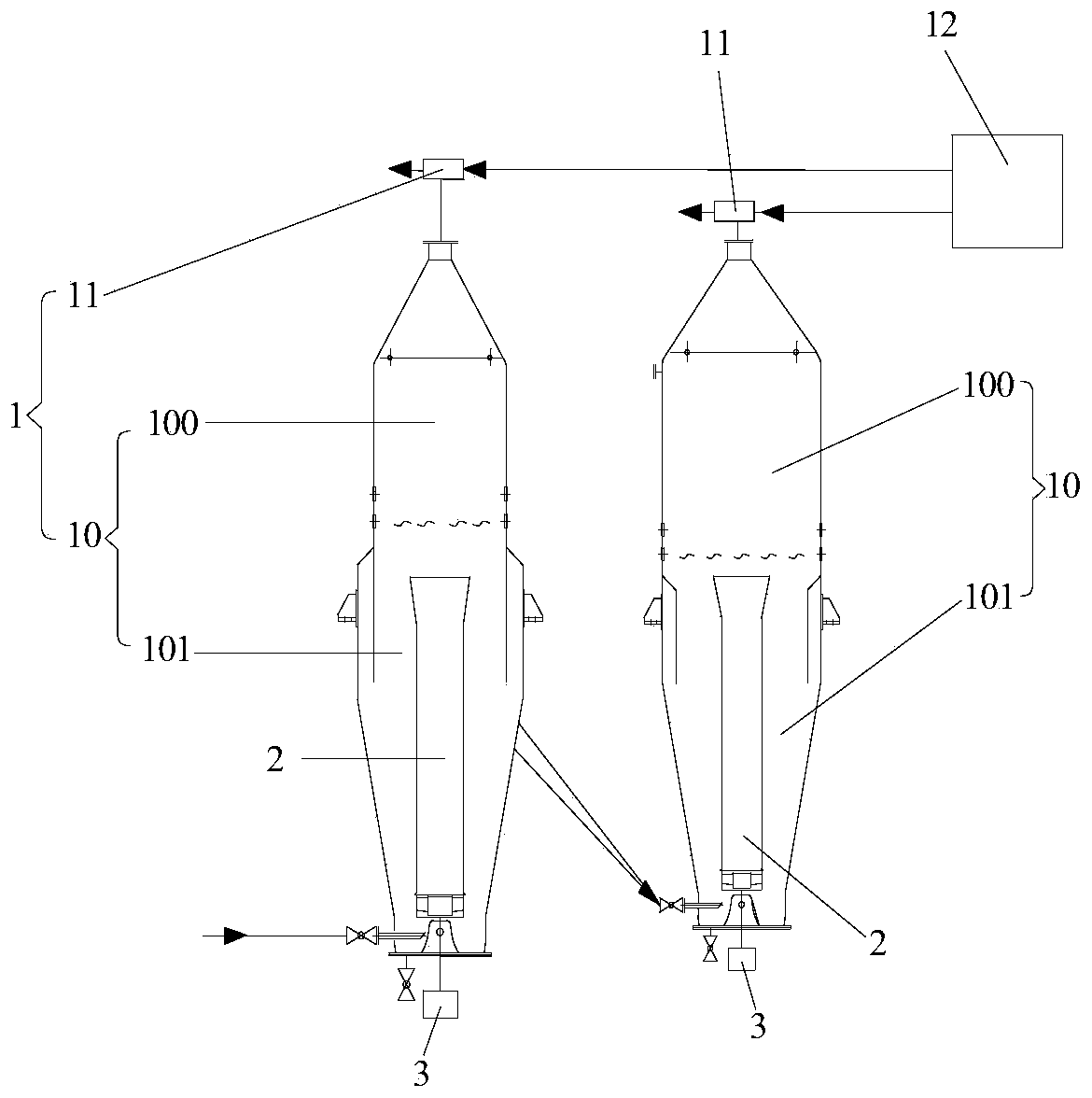

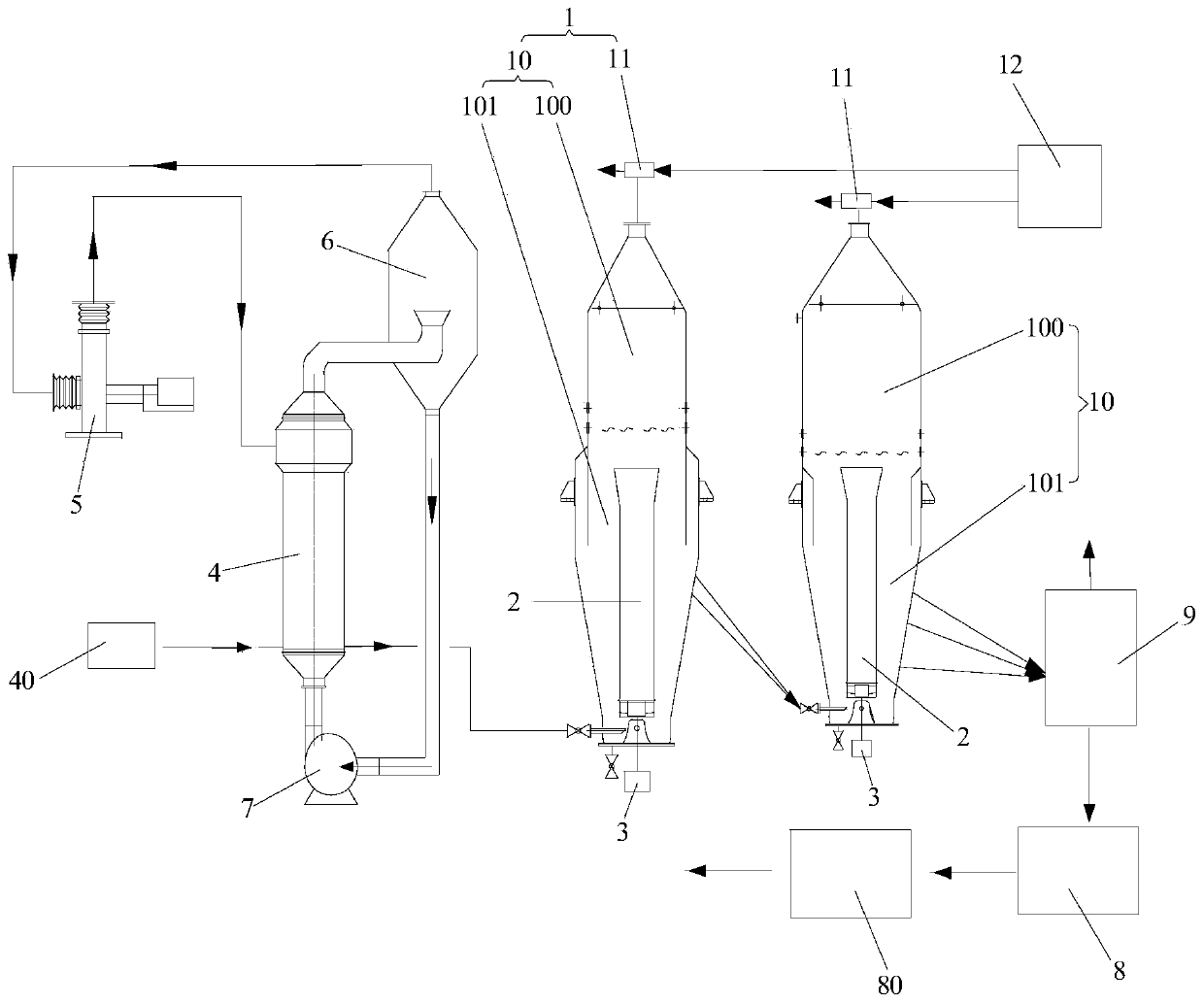

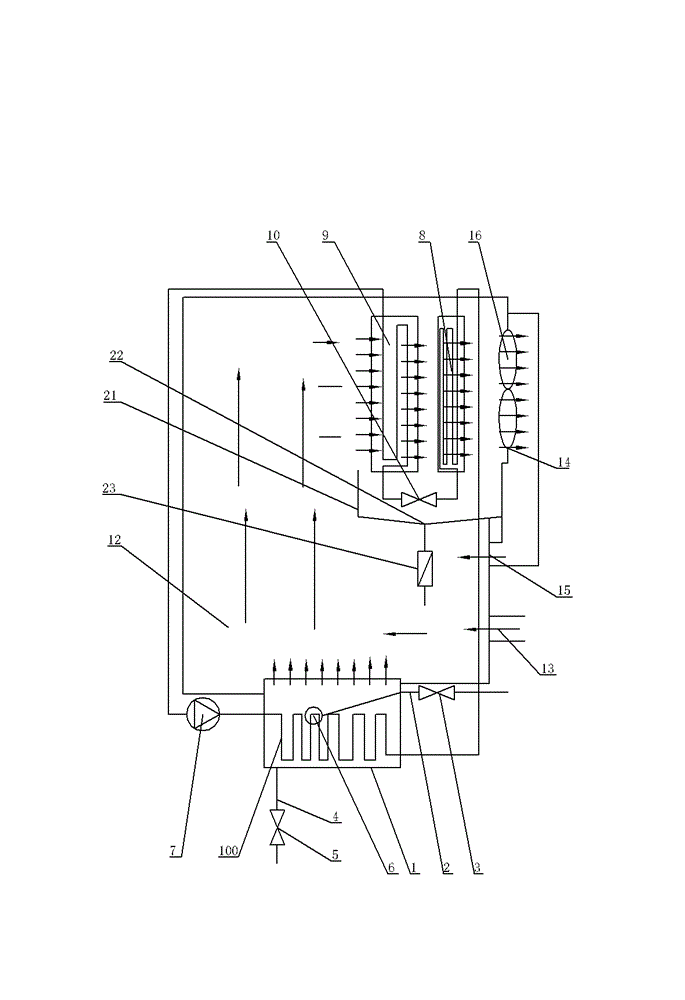

Physical-sensible-heat recovery method and device of converter flue gas

InactiveCN103388048AThe cooling rate is smallEconomic recyclingIncreasing energy efficiencyManufacturing convertersEvaporative coolerFlue gas

The invention discloses a physical-sensible-heat recovery method and device of a converter flue gas, belongs to the technical fields of recovery and utilization of physical sensible heat in the converter flue gas, and mainly solves the problems comprising: intercepting some of the physical sensible heat from a high-temperature flue gas discharged by a converter flue cooling and heat-exchanging device, to make effective use; reducing water waste; and intercepting some of the physical sensible heat from high-temperature steam produced by an evaporative cooling process, to make effective use. The physical-sensible-heat recovery method of the converter flue gas is characterized in that: in an evaporative cooler, the temperature of the high-temperature flue gas is reduced to 350-700 DEG C, a waste-heat boiler is adopted for heat exchange, and the temperature of the high-temperature flue gas is further reduced to 120-250 DEG C. The physical-sensible-heat recovery device of the converter flue gas comprises a flue heat exchanger, the evaporative cooler, a coarse dust removal device, the waste heat boiler, a fine dust removal device, a draught fan and a switching station which are arranged in sequence. The invention is applicable to the technical fields of the recovery and utilization of the physical sensible heat in the converter flue gas.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

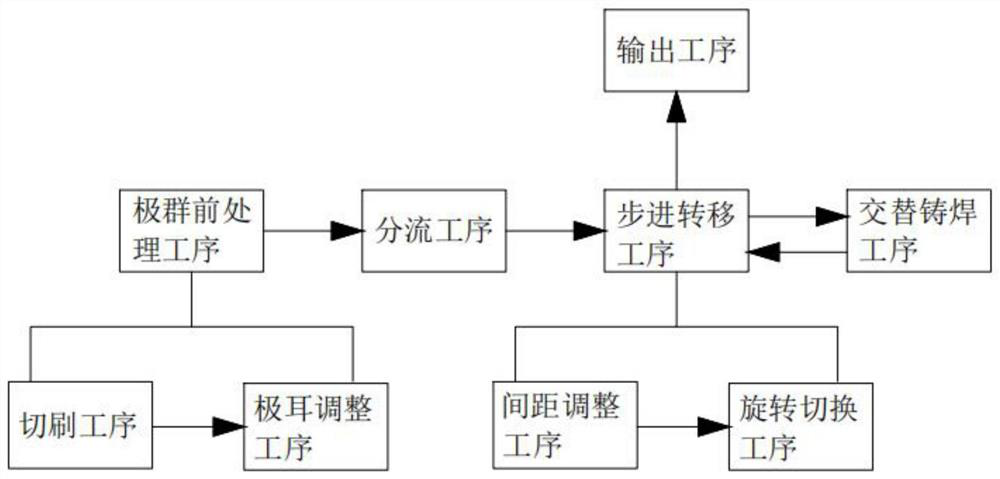

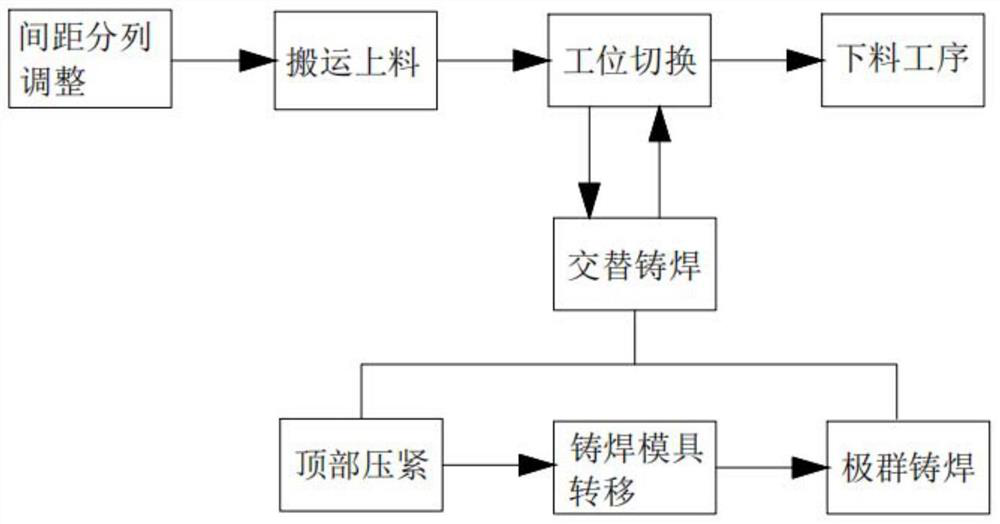

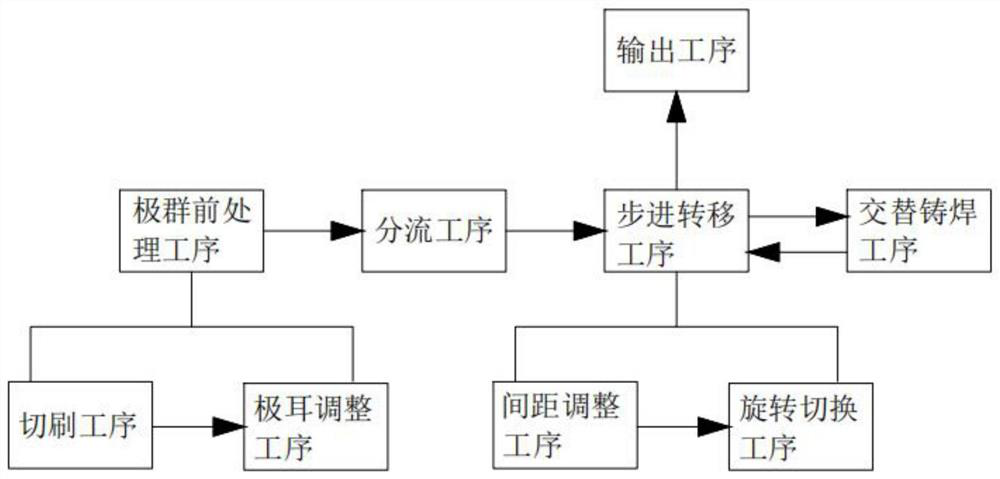

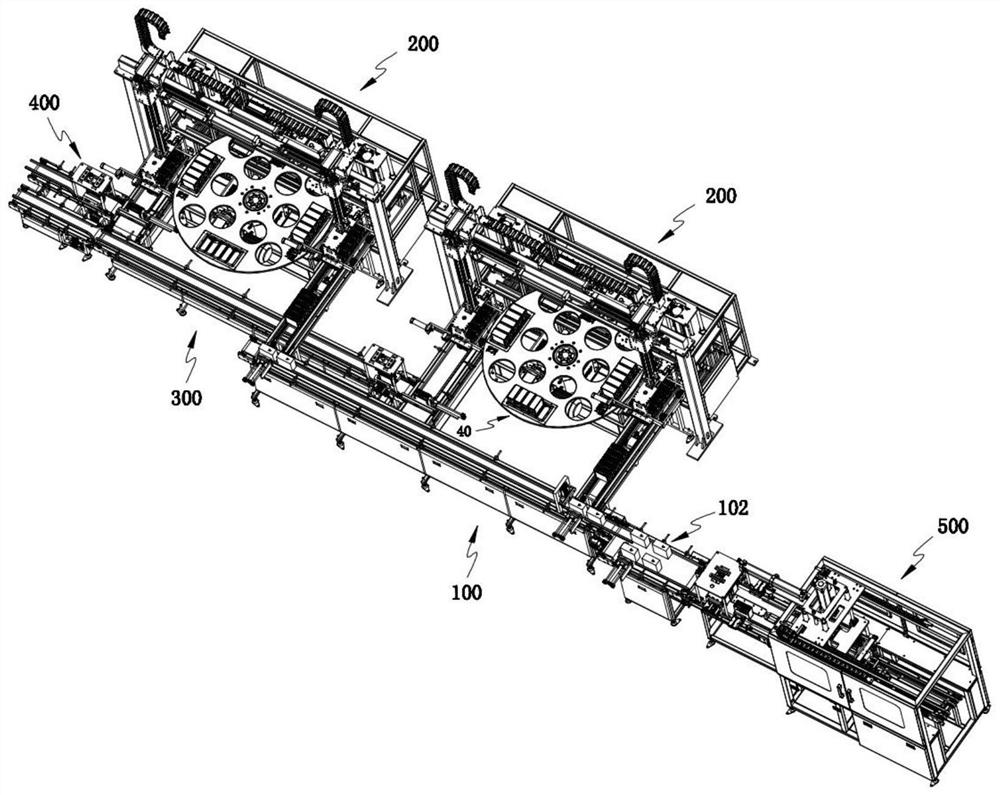

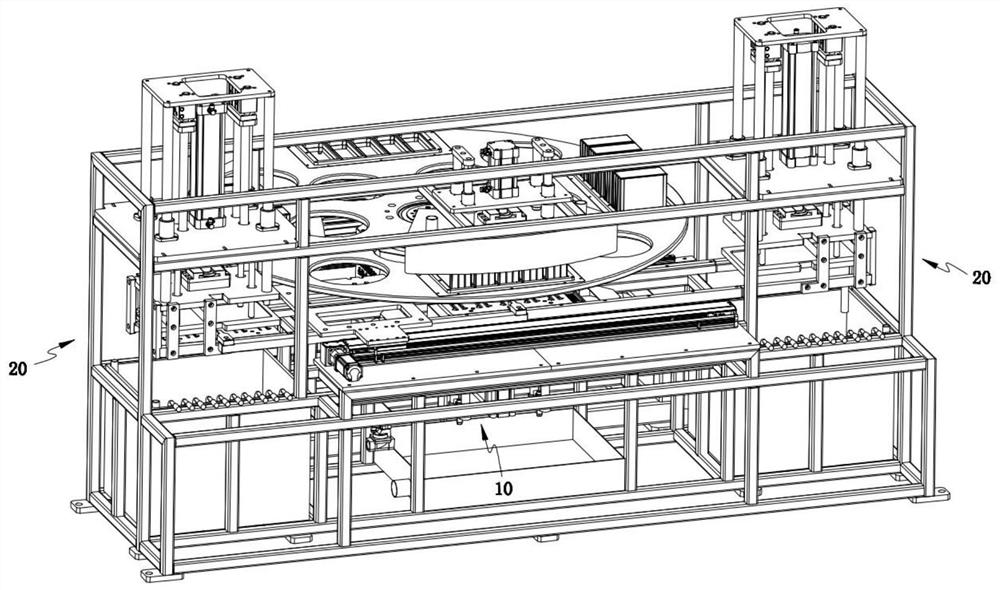

Efficient lead-acid storage battery cast-welding production process

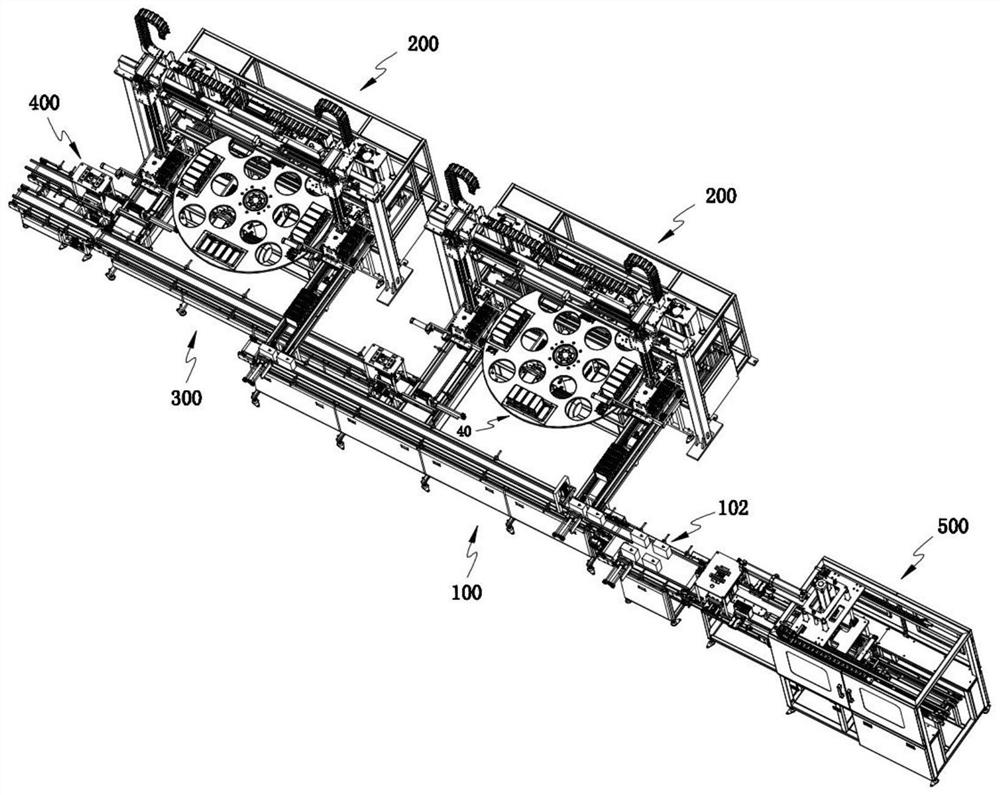

ActiveCN112756588ARealize flow operationShorten production timeCasting plantsFinal product manufactureEngineeringProcess engineering

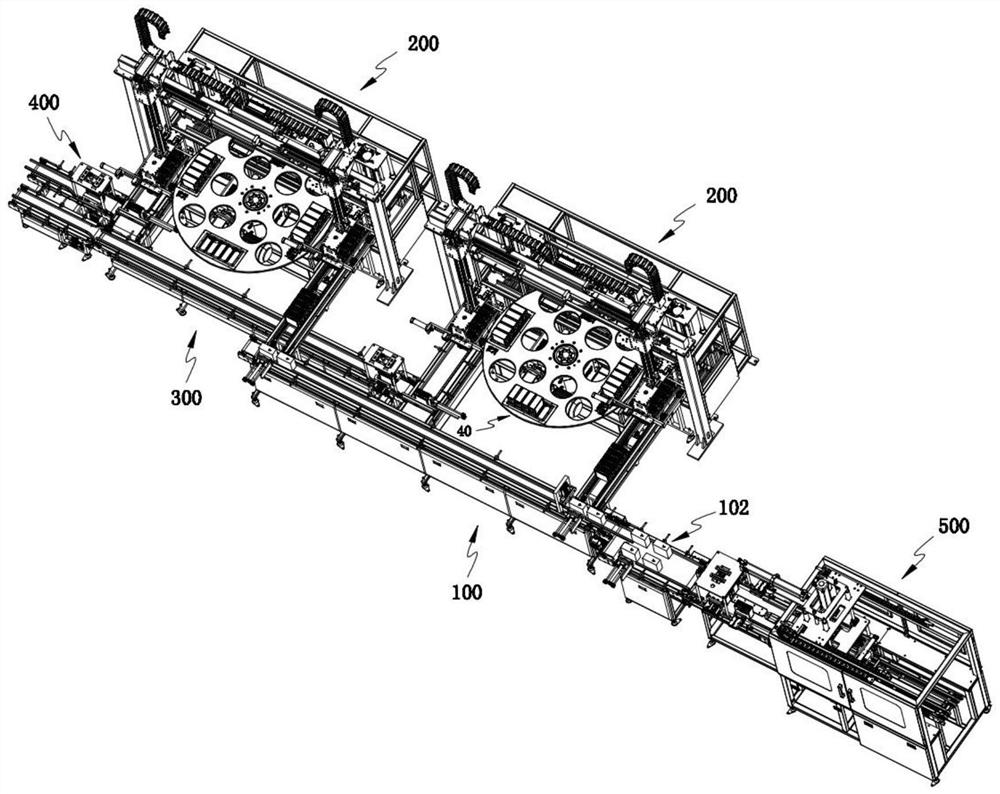

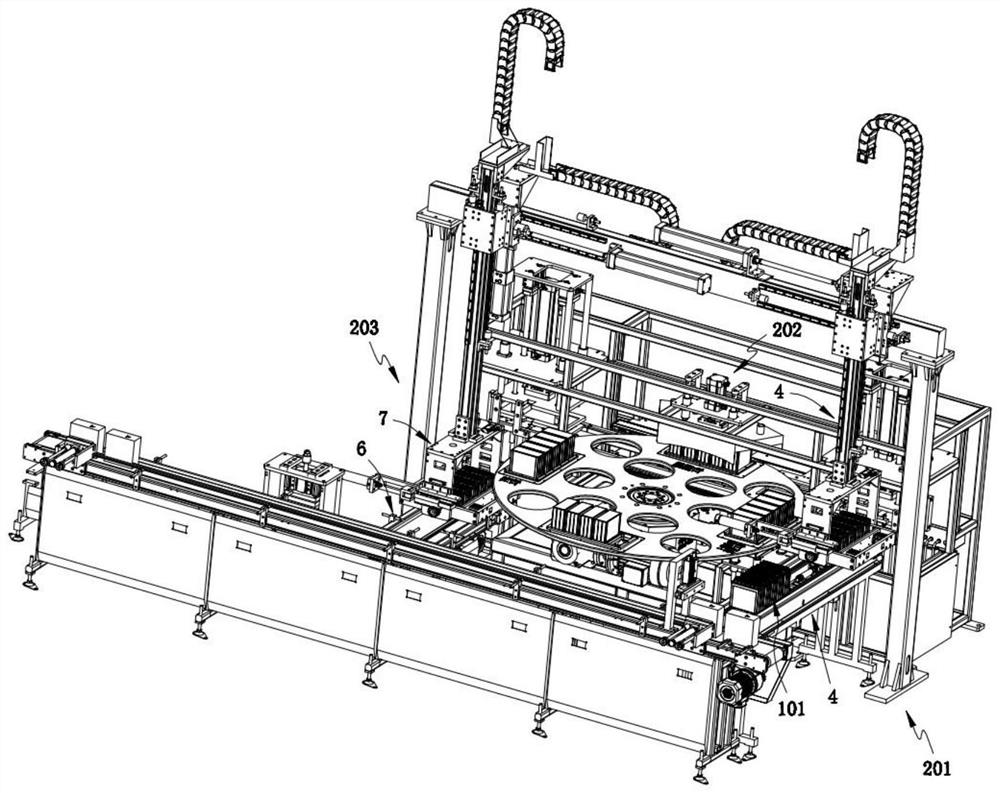

The invention relates to the technical field of storage battery production equipment, in particular to an efficient lead-acid storage battery cast-welding production process which is characterized by comprising the following steps: S1, a shunting procedure: a storage battery is automatically conveyed forwards by a feeding conveying system, and a plurality of cast-welding production systems are arranged on the side of the feeding conveying system; and S2, a cast-welding alternating procedure: each cast-welding production system comprises a cast-welding mechanism, a plurality of sets of lead dipping mechanisms and cast-welding molds which are arranged in one-to-one correspondence with the lead dipping mechanisms and can be conveyed and transferred between the cast-welding mechanism and the corresponding lead dipping mechanisms, the cast-welding mechanisms bear storage battery packs conveyed by a shunting mechanism in a shunting mode, the cast-welding molds obtain molten lead liquid from the lead dipping mechanisms to the cast-welding mechanisms to be subjected to cast-welding work with the storage battery packs, and the multiple cast-welding molds alternately change the cast-welding mechanisms to convey the lead liquid needed by cast-welding. Cast-welding flow production of the storage battery is achieved, the cast-welding molds are matched to alternately conduct cast-welding on the cast-welding mechanisms, and the production time is shortened.

Owner:长兴金润科技有限公司

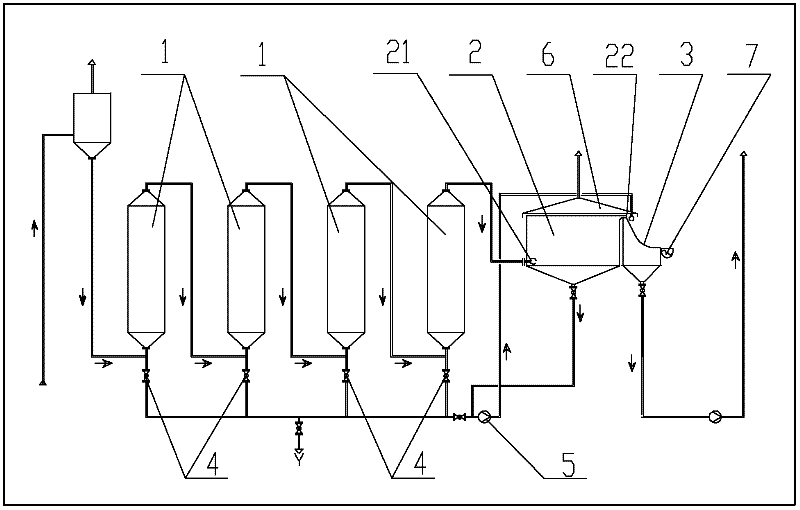

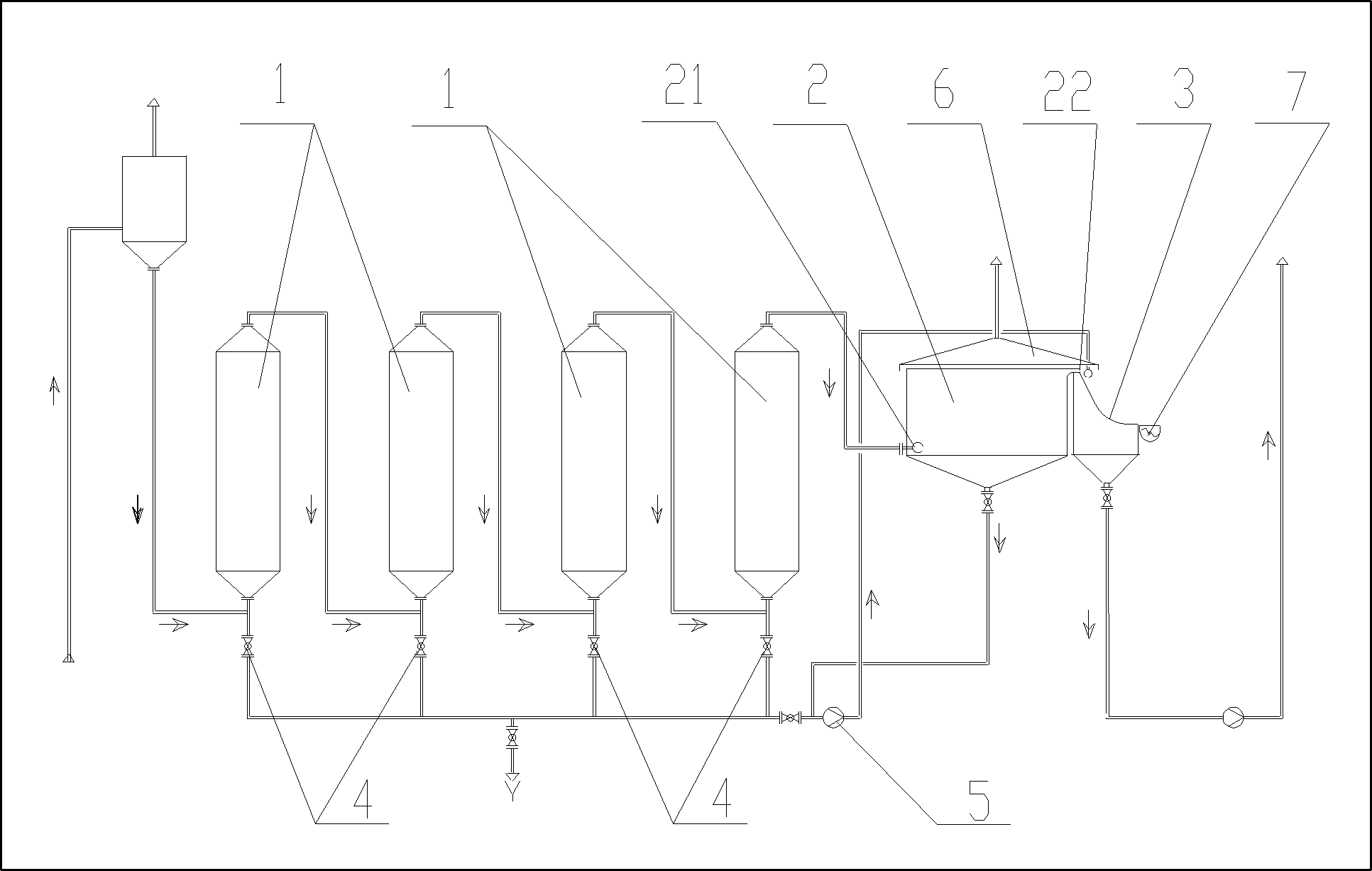

Separation method and equipment of protein from starch sugar liquefied solution

ActiveCN102516354AEfficient separationAvoid damagePeptide preparation methodsPlant peptidesStarch gelatinizationEngineering

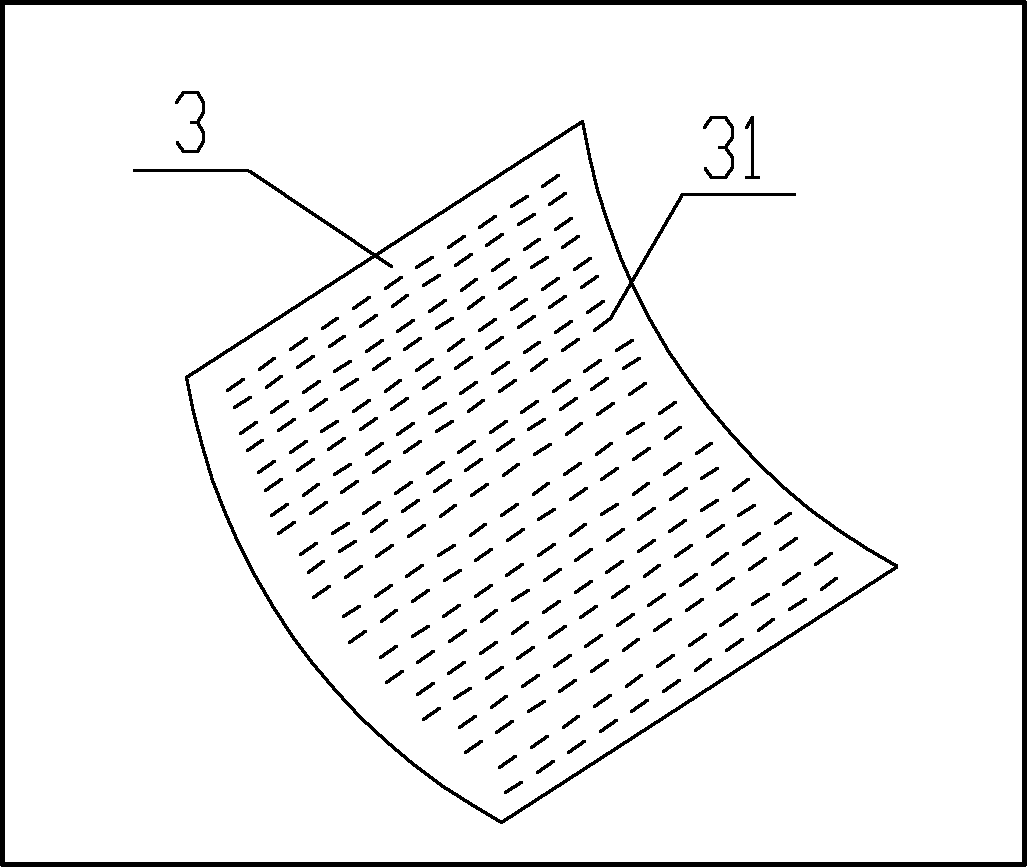

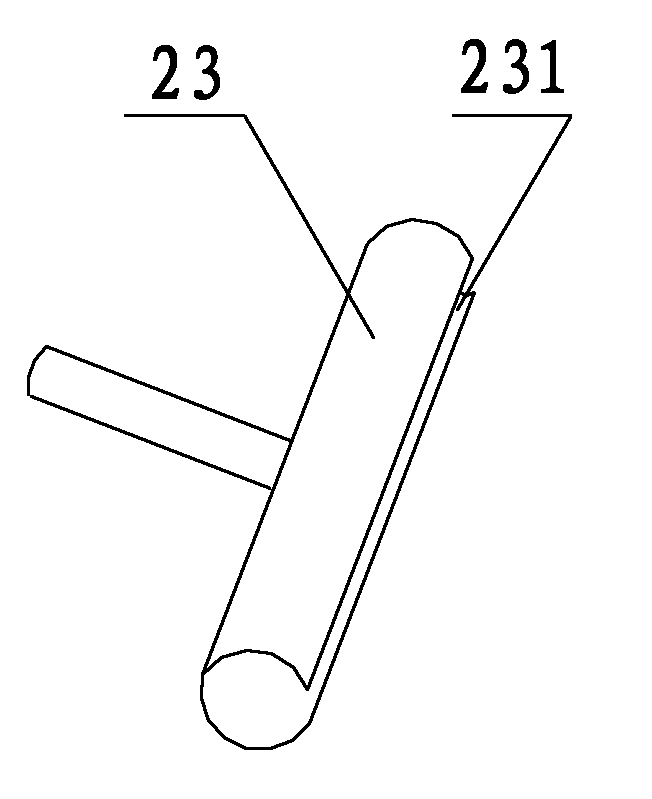

The invention discloses separation equipment of protein from a starch sugar liquefied solution, which structurally comprises a laminar flow tank system, a protein separation storage tank, and a protein separation sieve which are sequentially connected, wherein the laminar flow tank system comprises 2-6 laminar flow tanks connected in series, and the laminar flow tank at the end is connected with a feed port at the bottom end of the protein separation storage tank through a pipeline; and an overflow port is arranged at the top of the protein separation storage tank, and the protein separation sieve is arranged below the overflow port. The method for separating the protein from the starch sugar liquefied solution by utilizing the equipment comprises the following steps of: preparing a starch pasting liquid; B, treating the starch pasting liquid by the laminar flow tank system to obtain a primary liquefied solution; C, the primary liquefied solution being overflowed from the laminar flow tanks into the protein separation storage tank for layering; and D, the primary liquefied solution being overflowed from the protein separation storage tank to the surface of the protein separation sieve for protein separation. According to the method, a series of targeted treatment of the starch sugar liquefied solution is conducted, and the efficient separation of the protein from the starch sugar liquefied solution is realized by reasonably setting the sieve mesh size and the sieve mesh density of the protein separation sieve.

Owner:玉锋实业集团有限公司

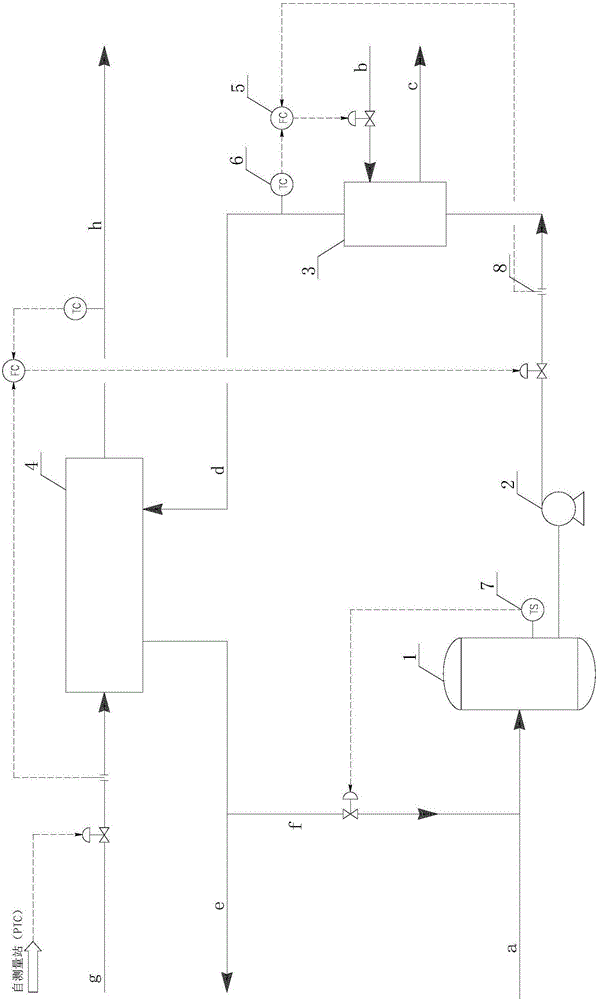

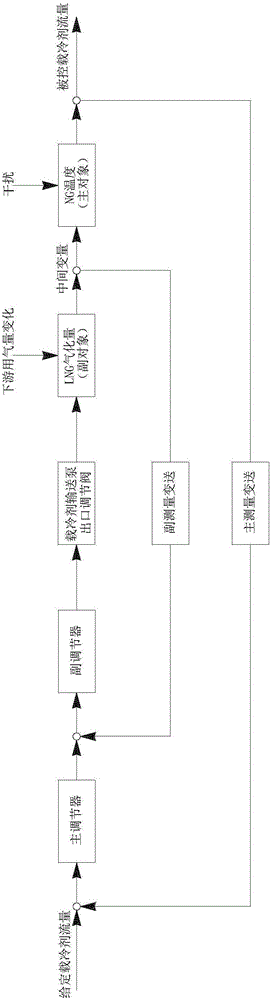

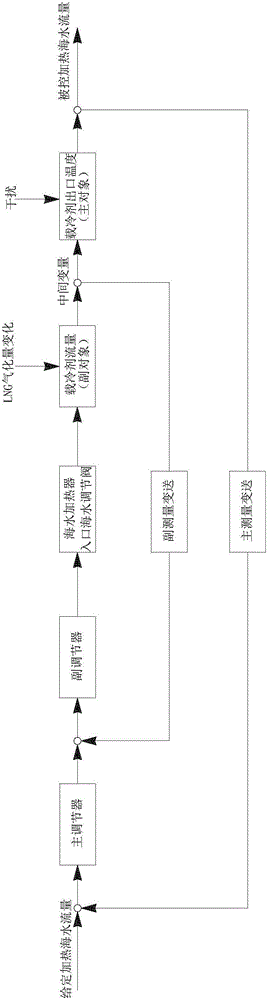

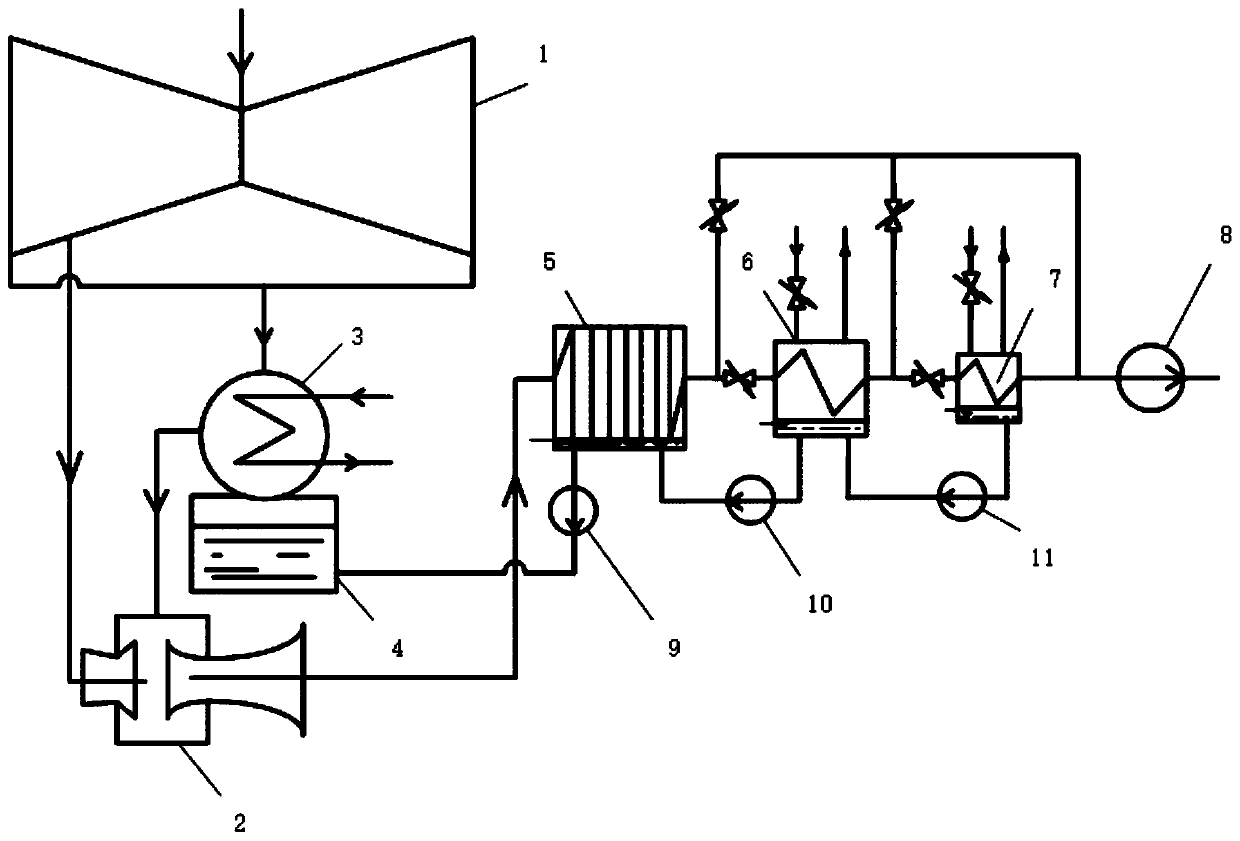

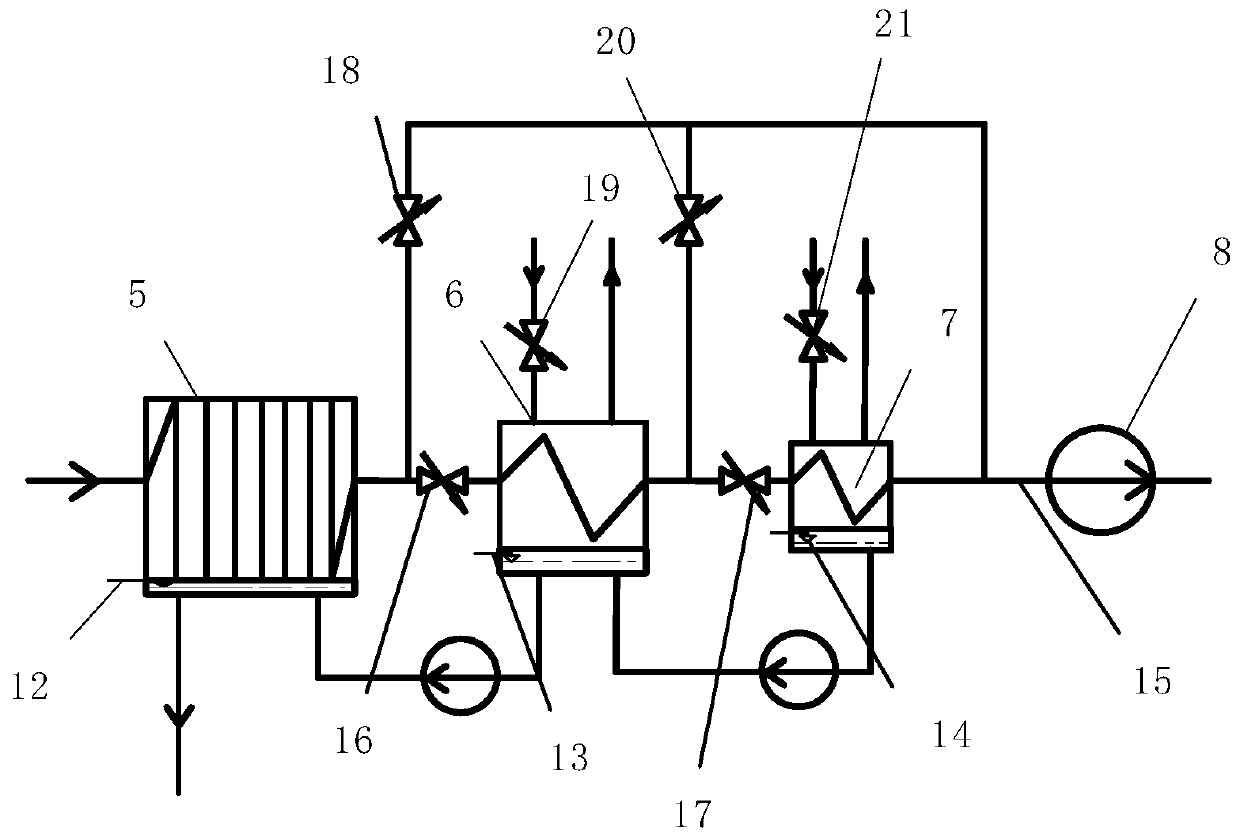

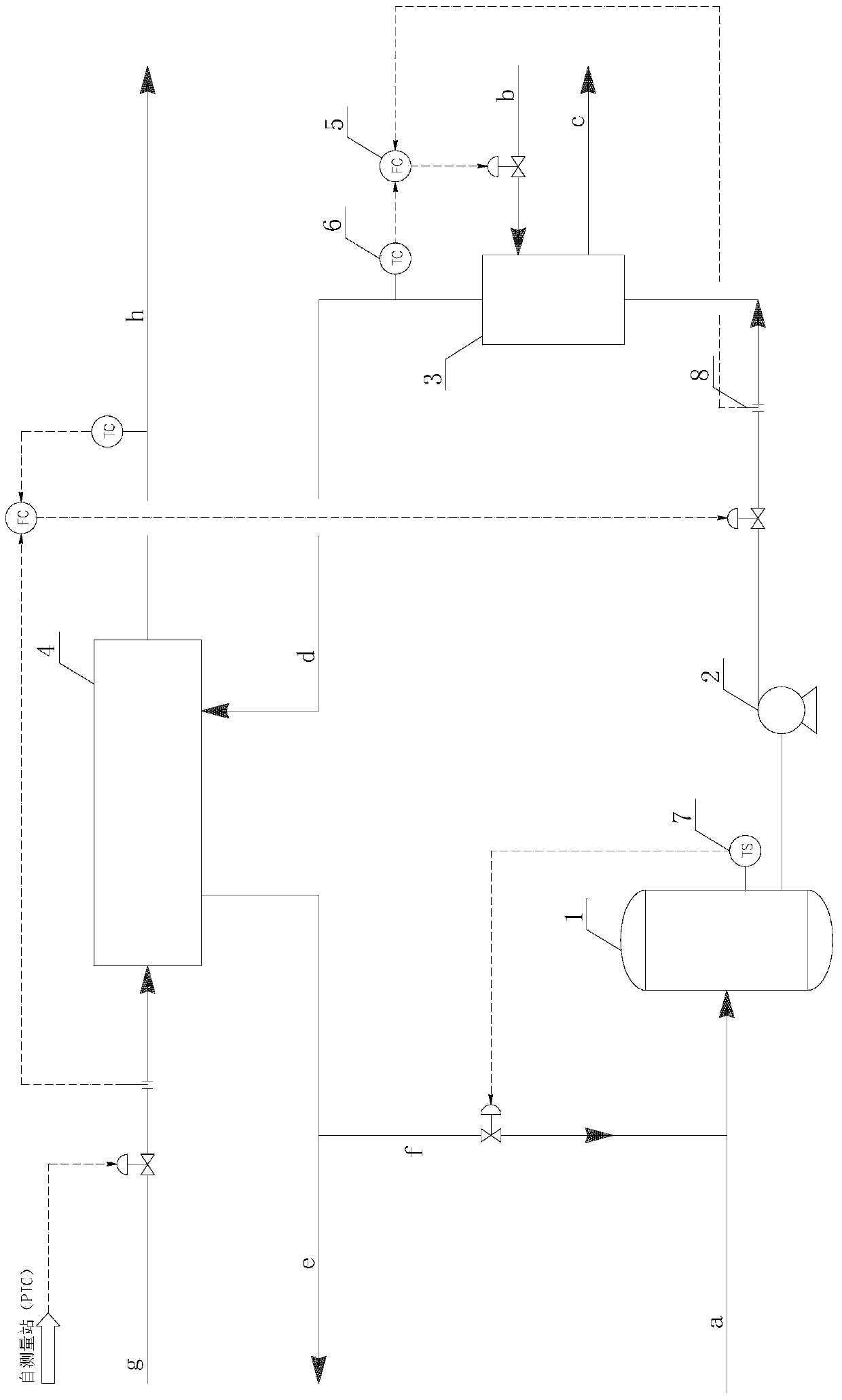

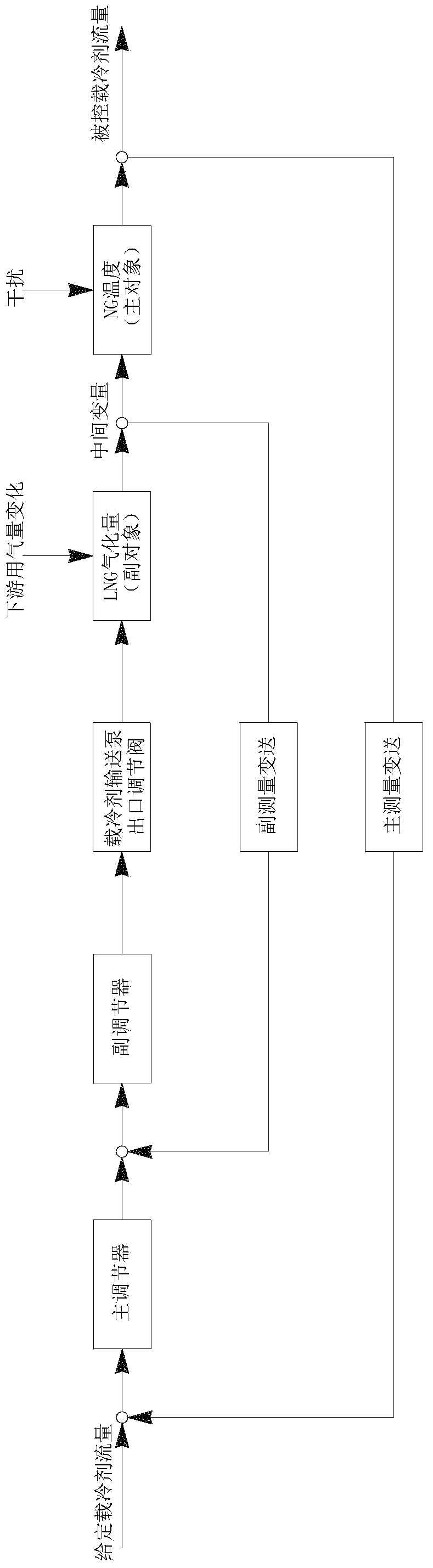

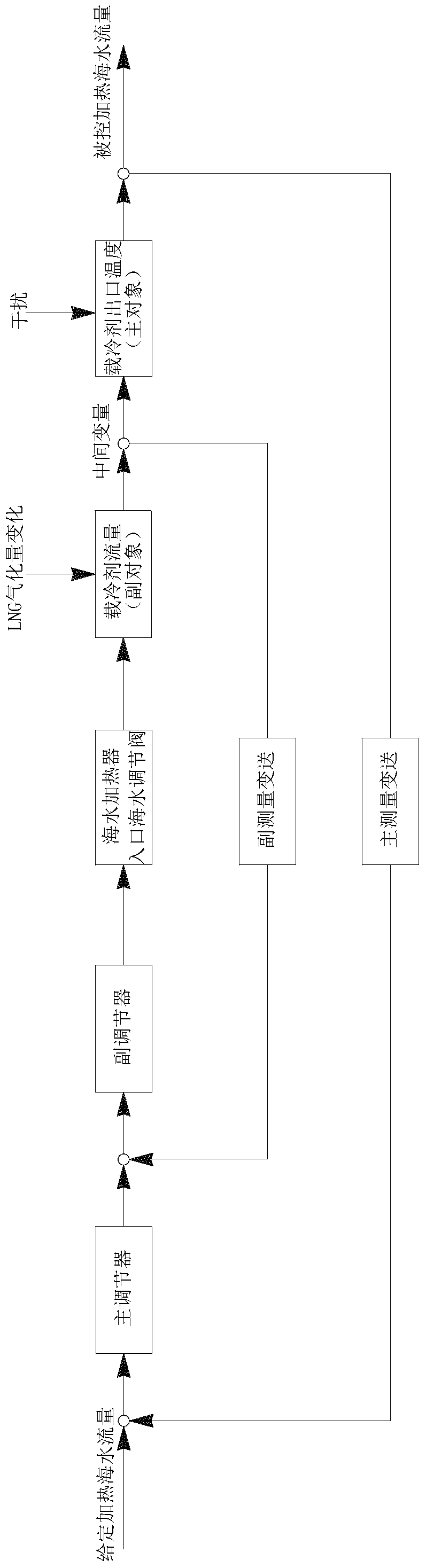

Control system and method for cold energy utilization in LNG gasification process

ActiveCN106122760ASafe and stable operationReduce the frequency of manual adjustmentsContainer filling methodsIndirect heat exchangersControl systemProcess engineering

The invention provides a control system and method for cold energy utilization in an LNG gasification process. The control system comprises a coolant storage tank, a coolant conveying pump, a seawater heater and an LNG gasifier. LNG is gasified through heat exchange of the LNG gasifier and coolant; the gasified natural gas is conveyed to downstream natural gas users; the coolant after heat exchange is conveyed to cool energy users for cooling; the coolant after being heated is conveyed to the coolant storage tank; and after being discharged from the coolant storage tank, the coolant is conveyed to the seawater heater through the coolant conveying pump, and the coolant enters the LNG gasifier after reaching the specified temperature. The control system for cold energy utilization in the LNG gasification process adopts cascade control, so that the phenomenon that the temperature of the natural gas can not be controlled timely due to flow variation of an LNG inlet is avoided; and the process of heating the coolant by seawater also adopts cascade control, so that the phenomenon that the temperature of a coolant outlet can not be controlled timely due to flow variation of a coolant inlet is avoided.

Owner:CHINA TIANCHEN ENG +1

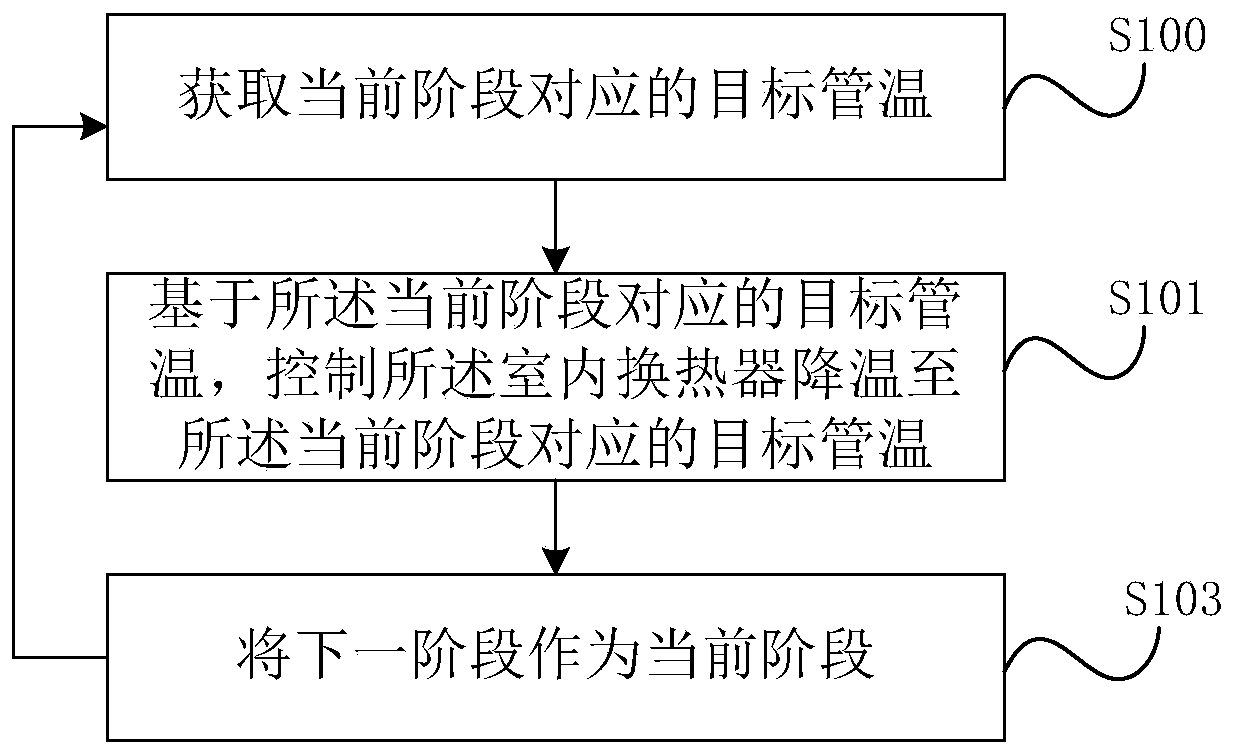

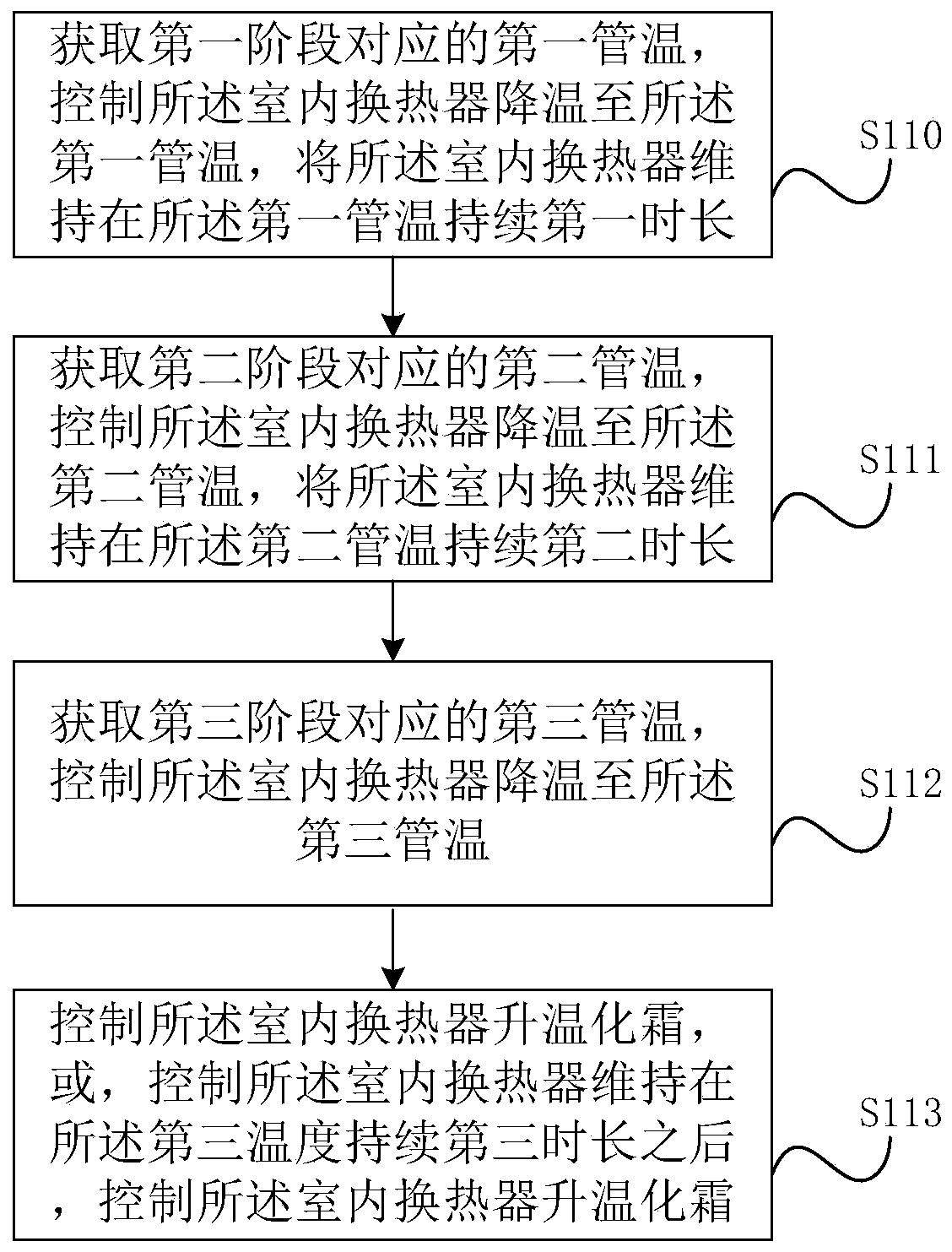

Air conditioner self-cleaning control method and device, air conditioner and storage medium

ActiveCN111442463ATube temperature dropTarget tube temperature dropMechanical apparatusNoise suppressionProcess engineeringControl room

The invention provides an air conditioner self-cleaning control method and device, an air conditioner and a storage medium. The air conditioner self-cleaning control method comprises the step that when the air conditioner is in a self-cleaning mode, an indoor heat exchanger is controlled to cool and frost stage by stage, wherein the operation of controlling the indoor heat exchanger to cool and frost stage by stage comprises the steps that target tube temperatures corresponding to all the stages are acquired sequentially, and the indoor heat exchanger is controlled to cool based on the targettube temperatures corresponding to all the stages. Through the method, cooling speed of the indoor heat exchanger can be reduced, and noise generated in the frosting process can be lowered.

Owner:NINGBO AUX ELECTRIC +1

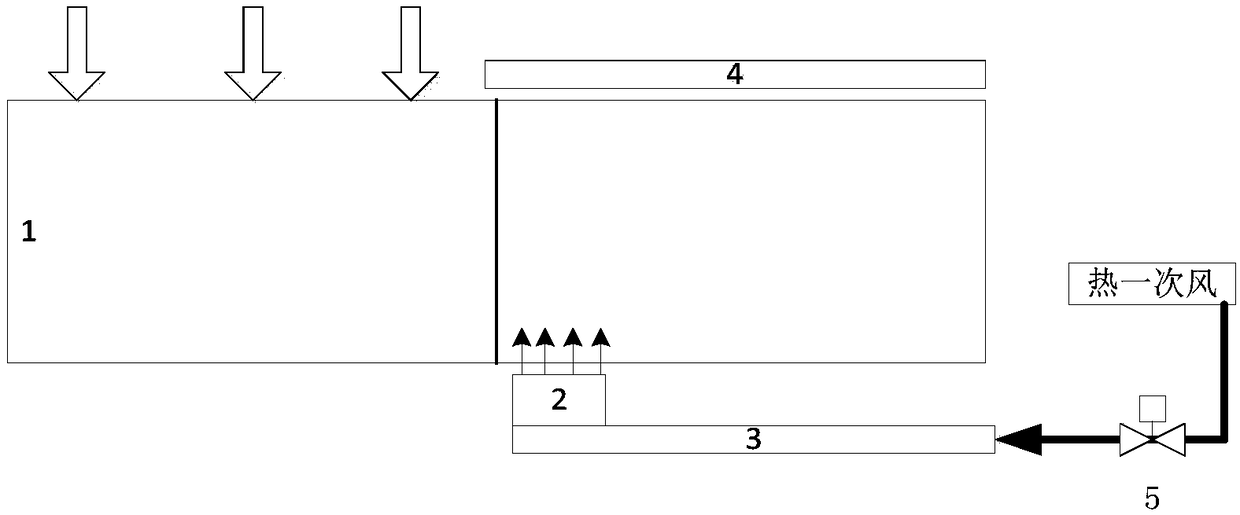

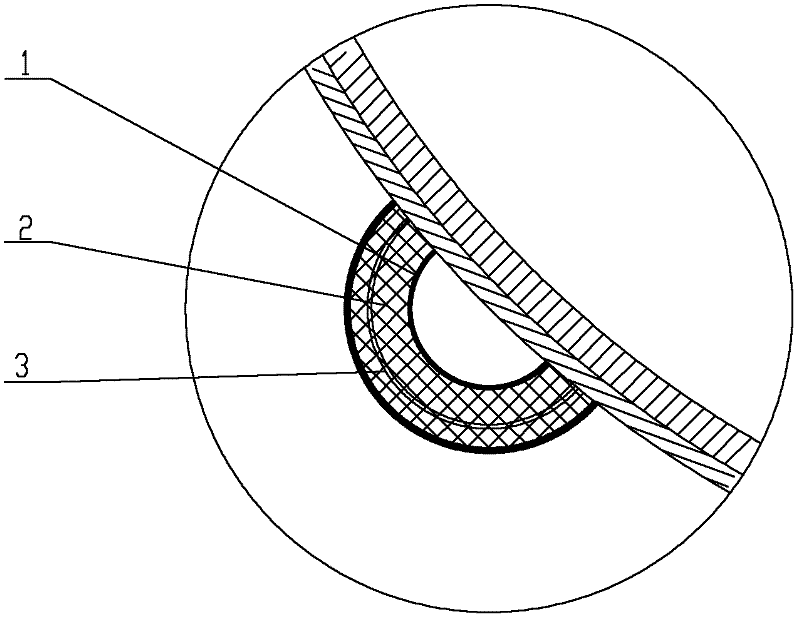

Rotation type air preheating system capable of achieving online cleaning and online cleaning method

PendingCN109373800AEasy to cleanImprove economySolid removalNon-rotary device cleaningAir preheaterSpray nozzle

The invention discloses a rotation type air preheating system capable of achieving online cleaning and an online cleaning method. The rotation type air preheating system comprises a rotation air preheater, a nozzle, a linear moving device and a flow shielding plate. The linear moving device is arranged at the smoke outlet end of a smoke channel of the rotation type air preheating system, the nozzle is arranged on the linear moving device, the nozzle is arranged towards the rotation air preheater, and the nozzle is connected with a hot primary air mother pipe through an air pipe. Hot primary air is guided out of the hot primary air mother pipe and sprayed towards a heat accumulation element of the rotation air preheater through the nozzle, and the flow shielding plate is arranged at the smoke inlet end of the smoke channel, corresponds to the motion area of the nozzle and is used for shielding smoke in the corresponding area from entering the rotation air preheater. By means of the rotation type air preheating system capable of achieving online cleaning and the online cleaning method, a cold end heat accumulation element of the rotation type air preheating system can be cleaned online, and the cleaning effect is better.

Owner:广东粤电靖海发电有限公司

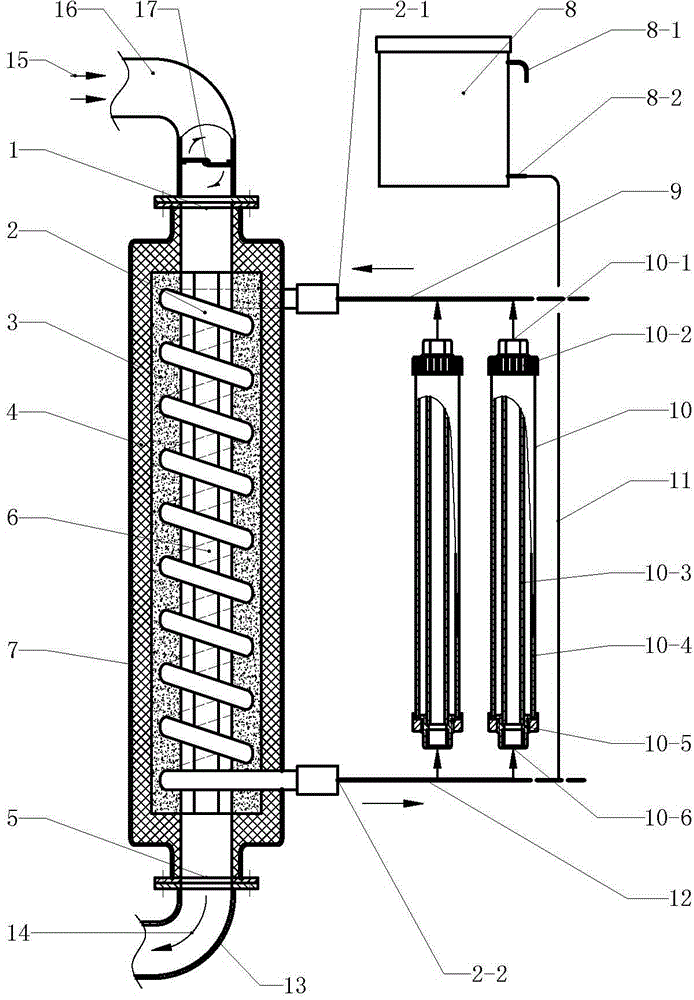

Temperature-difference regulating system for agricultural greenhouse

ActiveCN104488609AThe cooling rate is smallReduce the temperature difference between day and nightClimate change adaptationRenewable energy machinesHot blastCollector device

The invention provides a temperature-difference regulating system for an agricultural greenhouse, and relates to a temperature regulating device for an agricultural greenhouse. The temperature-difference regulating system for an agricultural greenhouse consists of a solar heat collector, a heat storage cylinder, a hot-oil circulating pipe, a return-oil circulating pipe, a warm-air pipe, a return-air pipe, a heat-storage oil tank and an oil circulating pump, wherein the hot-oil outlet of the solar heat collector is connected to a hot-oil inlet interface of a heat exchanging coil, and the return-oil outlet interface of the heat exchanging coil is connected to a return-oil inlet which is connected to the solar heat collector through the return-oil circulating pipe; the return-oil circulating outlet of the heat-storage oil tank is connected to the rear end of the return-oil circulating pipe, the hot-oil circulating inlet of the heat-storage oil tank is connected to the hot-oil circulating pipe, the heat-storage oil outlet interface of the heat-storage oil tank is connected to the inlet of the oil circulating pump, and the outlet of the oil circulating pump is connected to the front end of the return-oil circulating pipe; the warm-air pipe is mounted at the lower end of the heat storage cylinder, and the return-air pipe is mounted at the upper end of the heat storage cylinder. The temperature-difference regulating system for the agricultural greenhouse stores the heat of solar energy by utilizing the heat-storage oil tank with the heat storage cylinder, so that the time of heat emission of a heat-storage wall body is prolonged, and the temperature-difference regulating capability of the system is enhanced.

Owner:河南省李芳生态循环农业开发有限公司

Sensible heat recovery device with ash capture for preventing slag bonding and staining

ActiveCN102671410BWith anti-slagging abilityWide applicabilityVapor condensationCasings/liningsStainingSlag

Owner:SHANGHAI BOILER WORKS

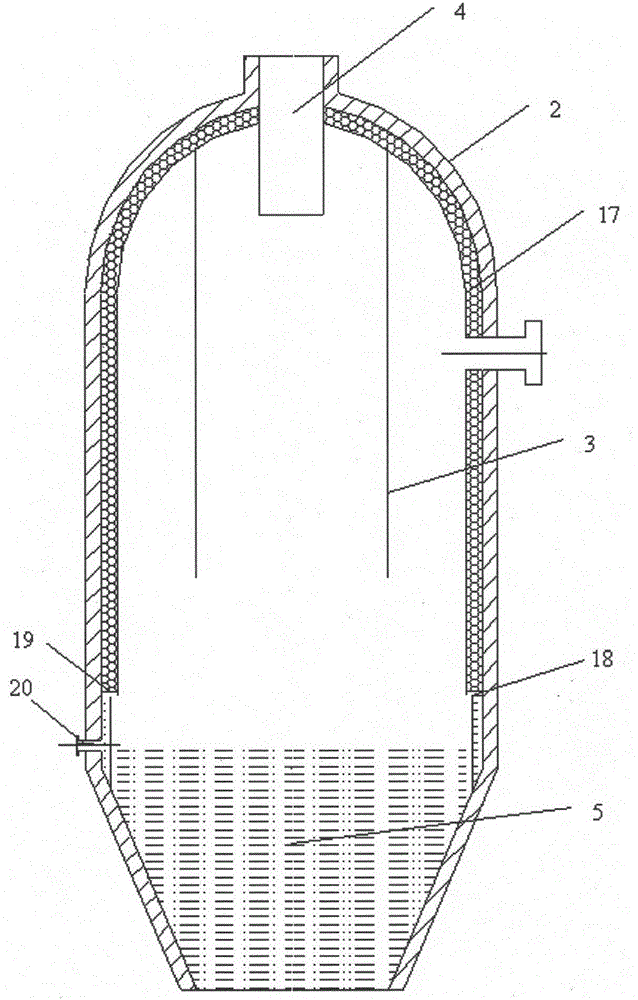

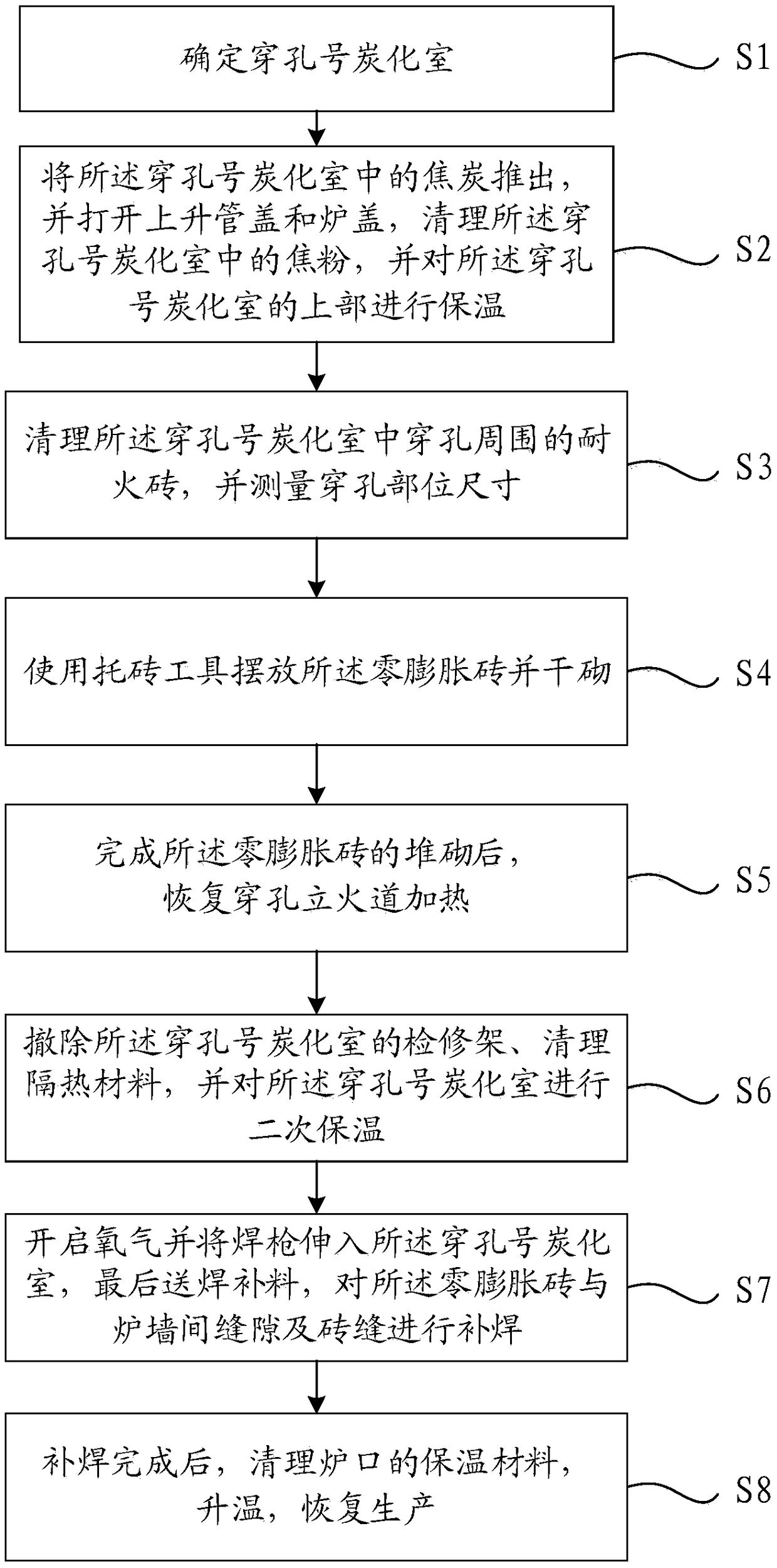

Quick repairing method for perforation of coke oven wall

InactiveCN109181716AHot repair cooling rate is lowThe cooling rate is smallBrickwork leakage repair/preventionBrickCarbonization

The invention discloses a quick repairing method for the perforation of a coke oven wall. The method comprises the following steps: determining a perforated carbonization chamber; pushing out coke inthe perforated carbonization chamber, opening a riser tube cap and an oven lid, cleaning the coke powder in the perforated carbonization chamber, and carrying out heat insulation on the upper part ofthe perforated carbonization chamber; measuring the size of the perforated part; placing zero-expansion bricks by using a brick holding tool, and carrying out dry building; restoring the heating of aperforated vertical flame path; carrying out secondary heat insulation on the perforated carbonization chamber; welding gaps between the zero-expansion bricks and the oven wall and gaps between bricks; and performing heating to restore production. The quick repairing method for the perforation of the coke oven wall has the advantages of effective prolongation of the service life of the coke oven,effective prevention of a repairing personnel from entering the carbonization chamber, avoiding of secondary damages caused by the temperature drop of the oven wall, effective improvement of the hot repairing efficiency of the coke oven, and great reduction of the labor intensity of the hot repairing personnel.

Owner:攀钢集团西昌钢钒有限公司

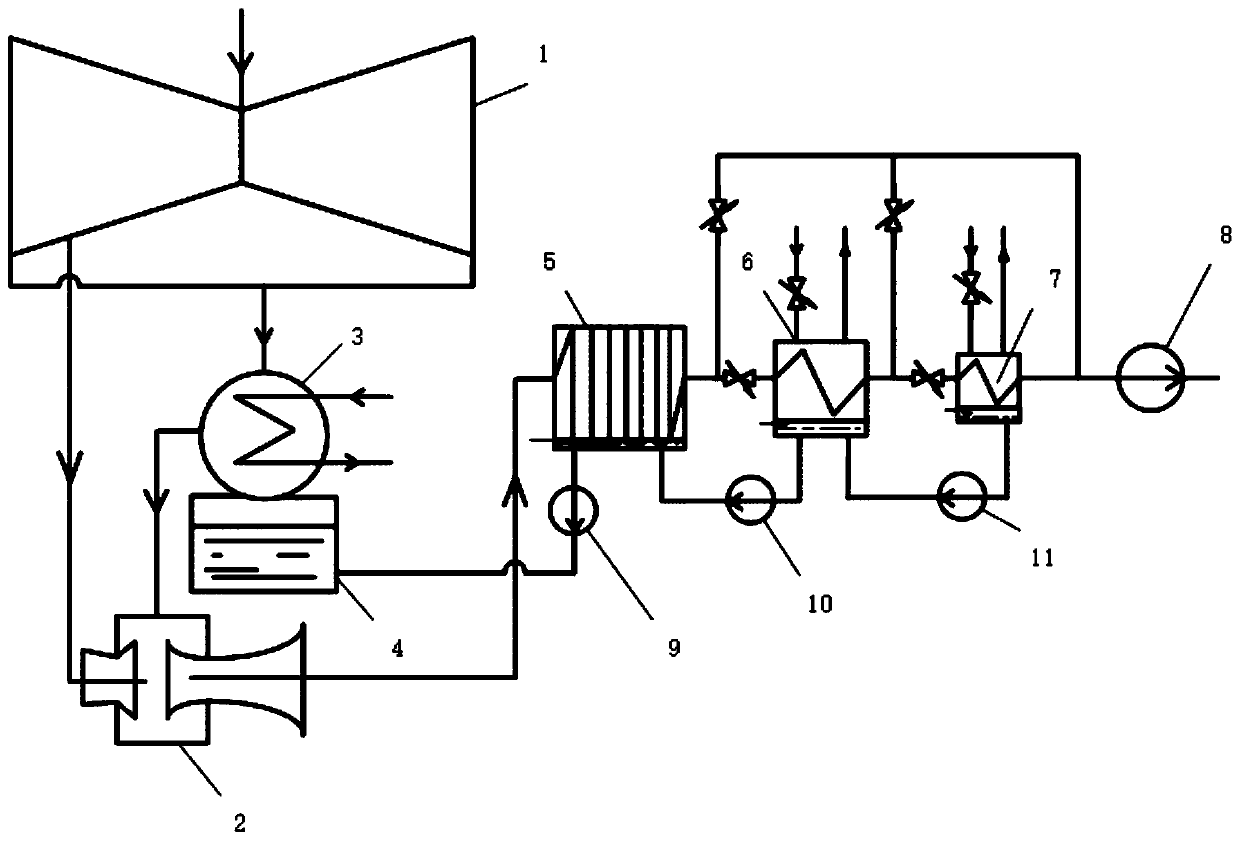

Turbine condenser vacuum-pumping system with coolers and control method

InactiveCN109708486ARequirements to achieve long-term design temperature operationExtended service lifeSteam/vapor condensersVacuum pumpingTurbine

The invention relates to a power generation assisting device, in particular to a turbine condenser vacuum-pumping system with coolers and a control method. Waste steam of a turbine is stored in a hotwell after being condensed in a condenser; non-condensable gas is introduced to a gas inlet of a steam-jet ejector; and exhaust air at the penultimate stage of the turbine is introduced to a jet portof the steam-jet ejector. The system comprises the air cooler, the cooling water cooler, the freezing water cooler and a vacuum pump which are sequentially connected to an air outlet of the steam-jetejector, wherein an air outlet of the air cooler is connected with an air inlet of the cooling water cooler through a first valve; an air outlet of the cooling water cooler is connected with an air inlet of the freezing water cooler through a second valve; the air outlet of the air cooler is connected with the vacuum pump through a first bypass with a third valve; and the air outlet of the coolingwater cooler is connected with the vacuum pump through a second bypass with a fourth valve.

Owner:SHAANXI WEIHE POWER GENERATION CO LTD +1

Thermal insulating device for pavement asphalt mixture stirring cylinder

InactiveCN102345266AThe cooling rate is smallQuality assuranceRoads maintainenceProcess engineeringContinuous production

Relating to the field of road machineries, the invention provides a thermal insulating device for a pavement asphalt mixture stirring cylinder. An asphalt mixture can be stirred at a temperature of 160-180DEG C, below which the mixture quality can be affected. However, present stirring cylinders have no heating and thermal insulating device per se, and a hot material entering the cylinder can be cooled by a cold stirring cylinder. In order to avoid the disadvantage, the invention provides a technical scheme of sticking insulating pipes on the external wall of a stirring cylinder so as to realize preheating of a cold stirring cylinder or insulation during a continuous production process. The insulating pipes have a three-layer structure. The inner layer is a hot oil pipe layer, the middle layer is a rock wool insulating layer, and the outer layer is a cladding layer. The insulating pipes are arranged from the bottom to the top, then turned to one side and mounted from the top to the bottom, and then turned to the same side in order. And the hot oil pipe is loaded with heated heat conduction oil. The device of the invention has the advantages of high stirring efficiency, ensured asphalt mixture quality, compact equipment and low cost.

Owner:WUXI XUETAO GROUP

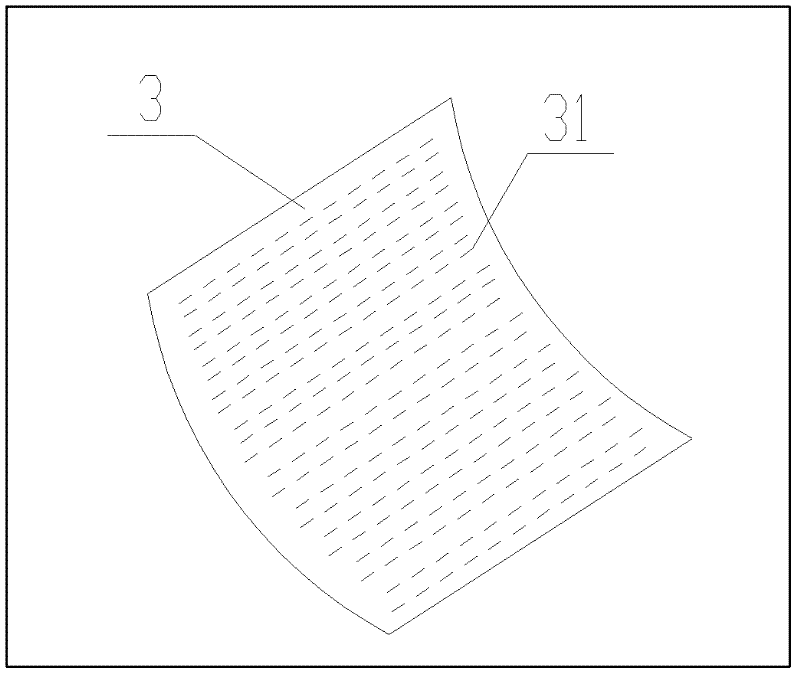

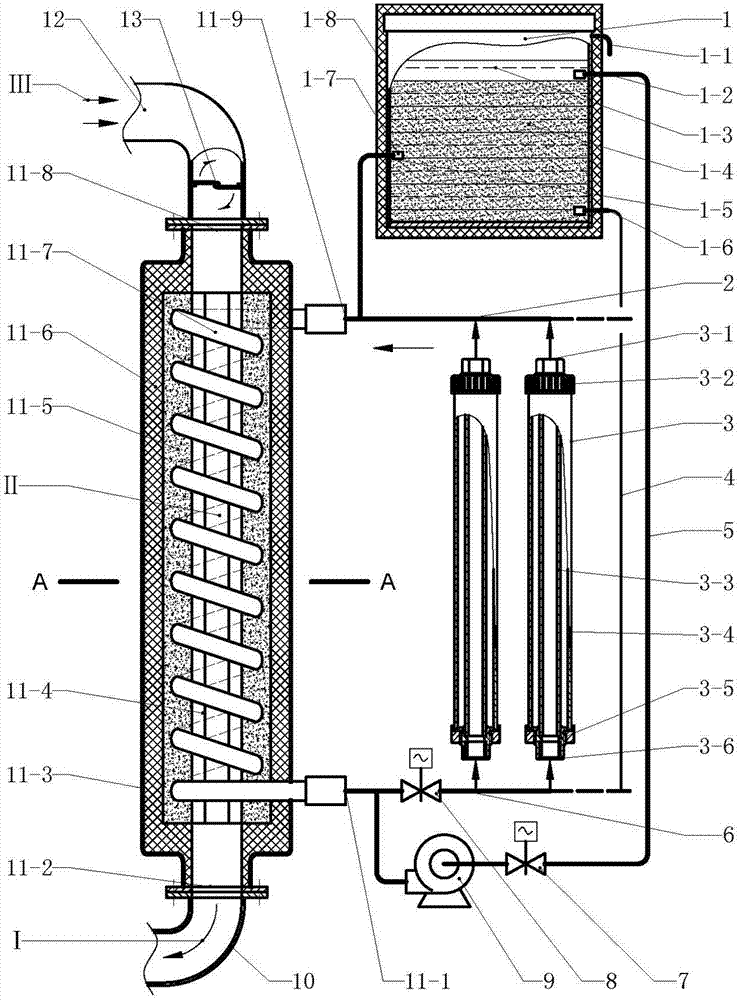

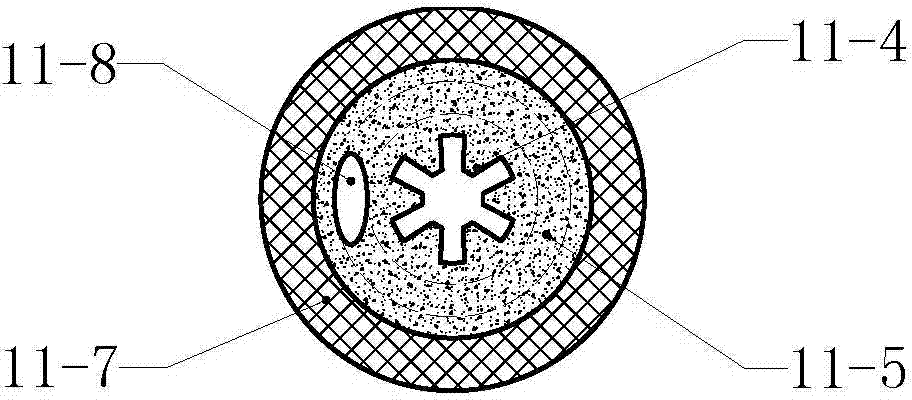

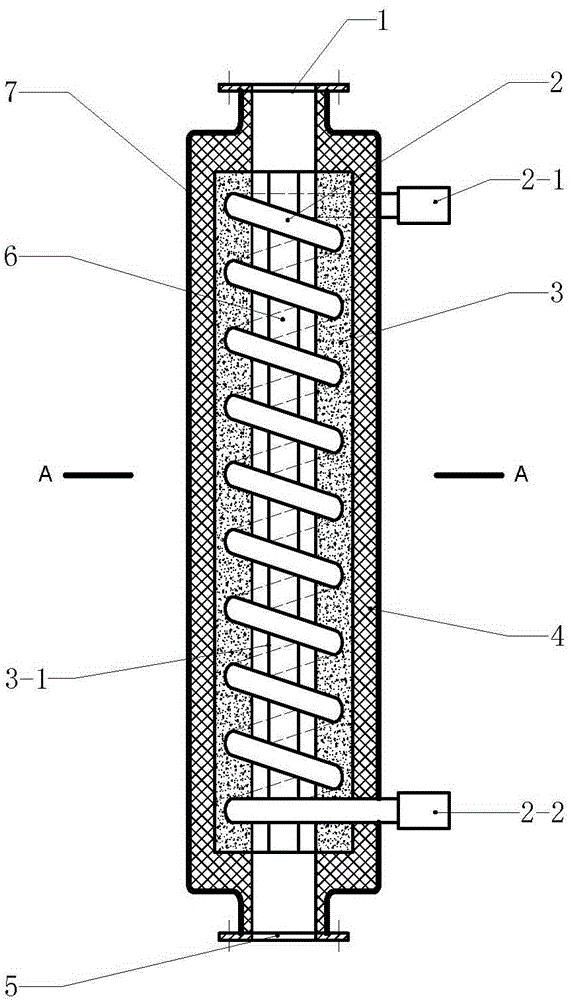

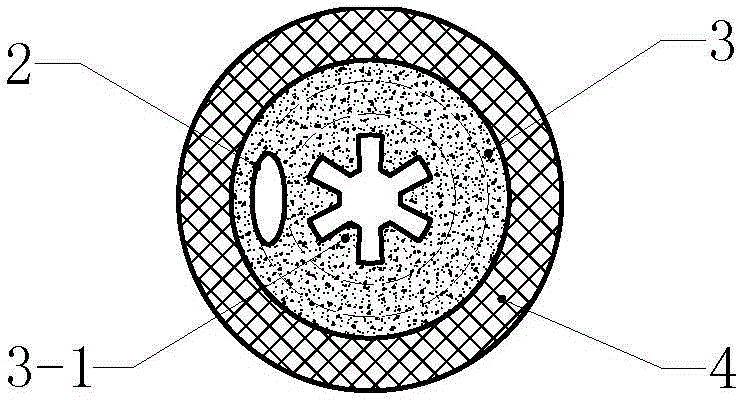

Solar heat accumulator used for regulating temperature difference of greenhouse

InactiveCN104429726AThe cooling rate is smallReduce the temperature difference between day and nightClimate change adaptationRenewable energy machinesThermodynamicsGreenhouse

The invention discloses a solar heat accumulator used for regulating the temperature difference of a greenhouse and relates to a temperature regulating device for agricultural greenhouses. The solar heat accumulator used for regulating the temperature difference of the greenhouse is characterized in that the solar heat accumulator is composed of a heat storage barrel, a heat exchanging coil and a heat preservation cotton-padded covering, wherein the wall of the heat storage barrel is of a cylindrical structure, the inner space of the heat storage barrel forms an air heat exchanging chamber, cooling ribs are arranged on the inner wall of the heat storage barrel and are annularly and evenly distributed in the air heat exchanging chamber, the heat exchanging coil is arranged in the wall of the heat storage barrel, a hot oil input port is formed in the upper end of the heat exchanging coil, an oil return output port is formed in the lower end of the heat exchanging coil, the heat preservation cotton-padded covering is mounted on the outer wall of the heat storage barrel, an air return input port is formed in the upper end of the solar heat accumulator, a hot air output port is formed in the lower end of the solar heat accumulator, and the air return input port is communicated with the hot air output port through the air heat exchanging chamber. According to the solar heat accumulator, solar energy is stored in the solar heat accumulator, when temperature in the greenhouse drops at night, heat is released gradually so that the diurnal temperature difference in the greenhouse is reduced.

Owner:徐州好嗨哟农业科技有限公司

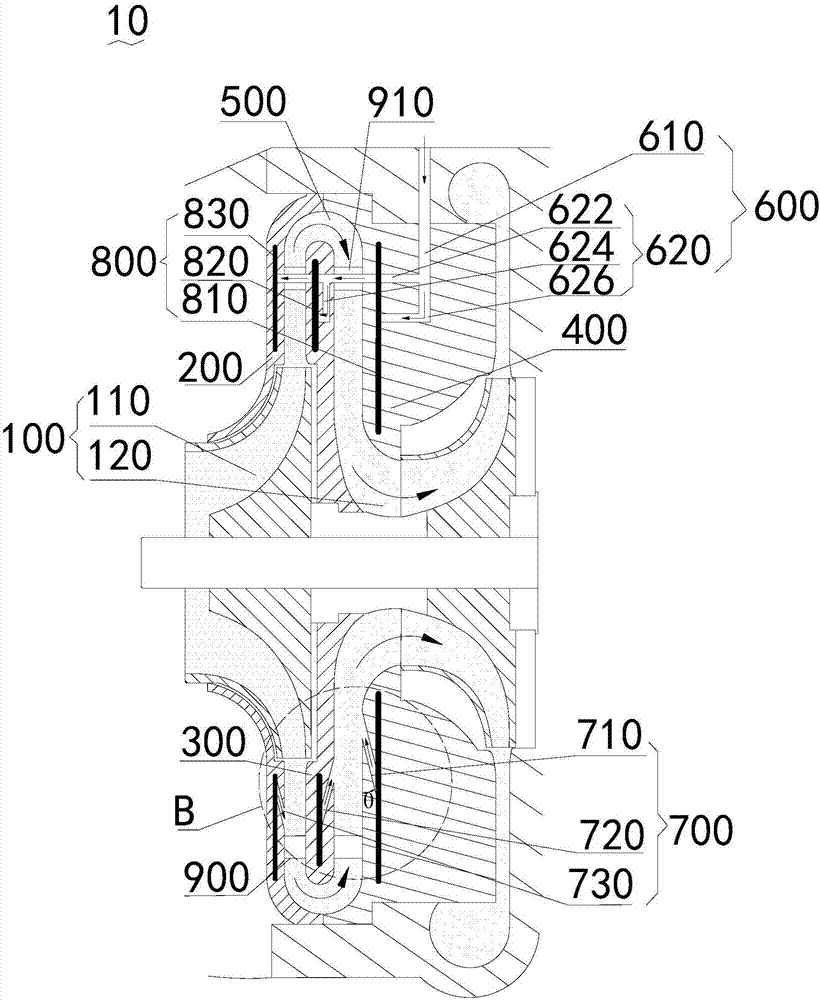

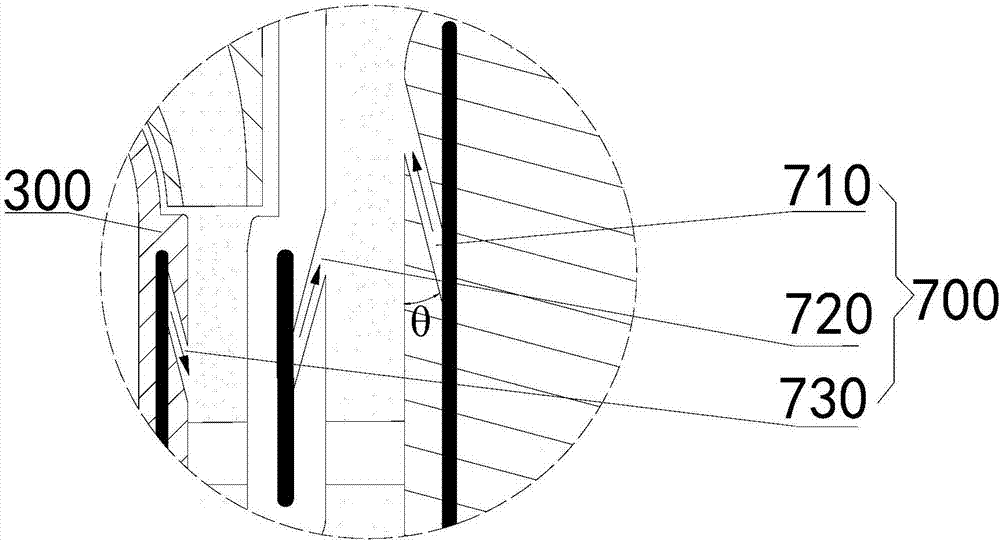

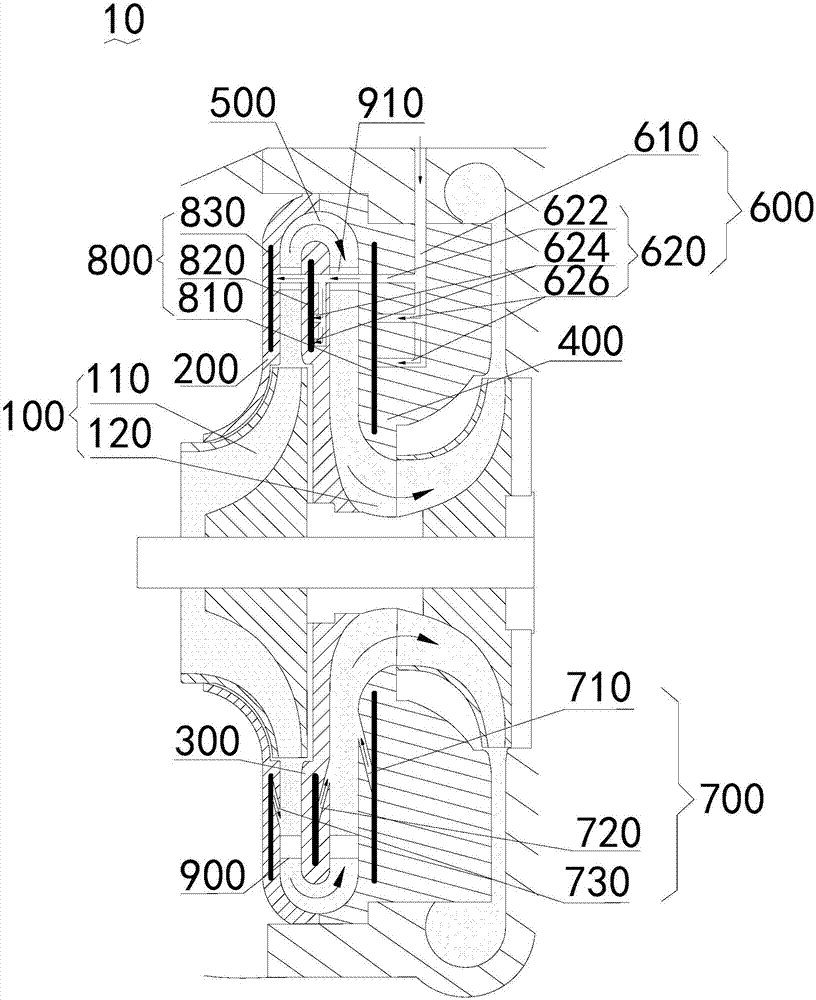

Centrifugal compressor

PendingCN107542674AThe cooling rate is smallReduce energy consumptionPump componentsRadial flow pumpsEngineeringGas supply

The invention provides a centrifugal compressor, which comprises at least two stages of impellers, a pressure expander, a return channel transition plate and a return channel. The pressure expander, the return channel transition plate and the return channel form a stage runner for communicating the two stages of impellers. The centrifugal compressor further comprises a gas supply channel, which comprises a gas supply port, a gas outlet and a cooling channel. The cooling channel is arranged in at least one of the pressure expander, the return channel transition plate and the return channel; thegas outlet communicates with the stage runner; and a replenishing medium enters from the gas supply port, flows through the cooling runner, flows out from the gas outlet, enters the stage runner, andis mixed with gas in the stage runner.

Owner:GREE ELECTRIC APPLIANCES INC

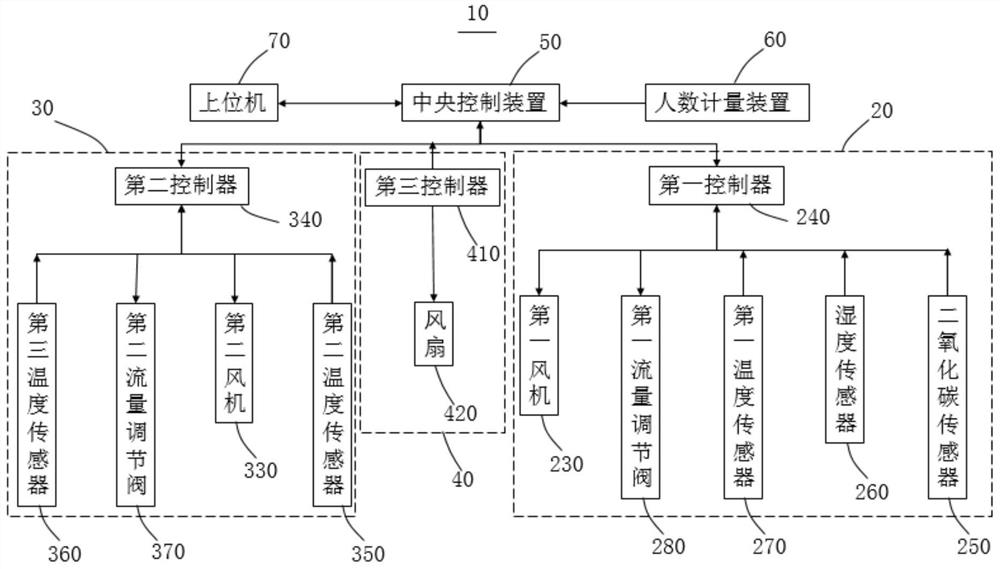

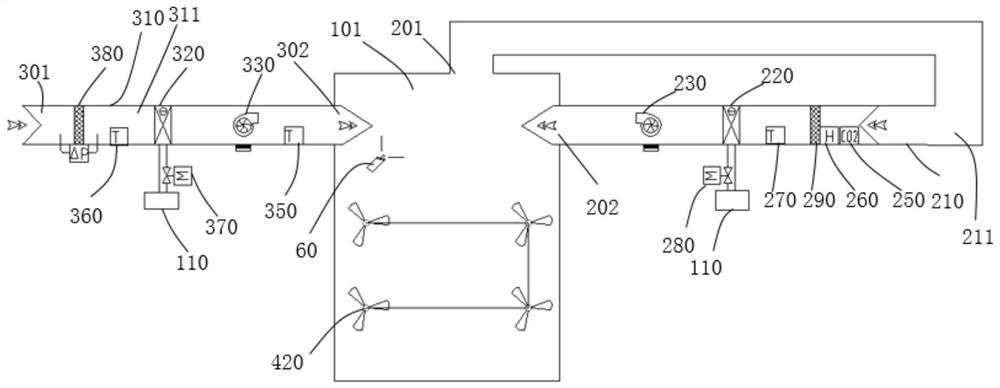

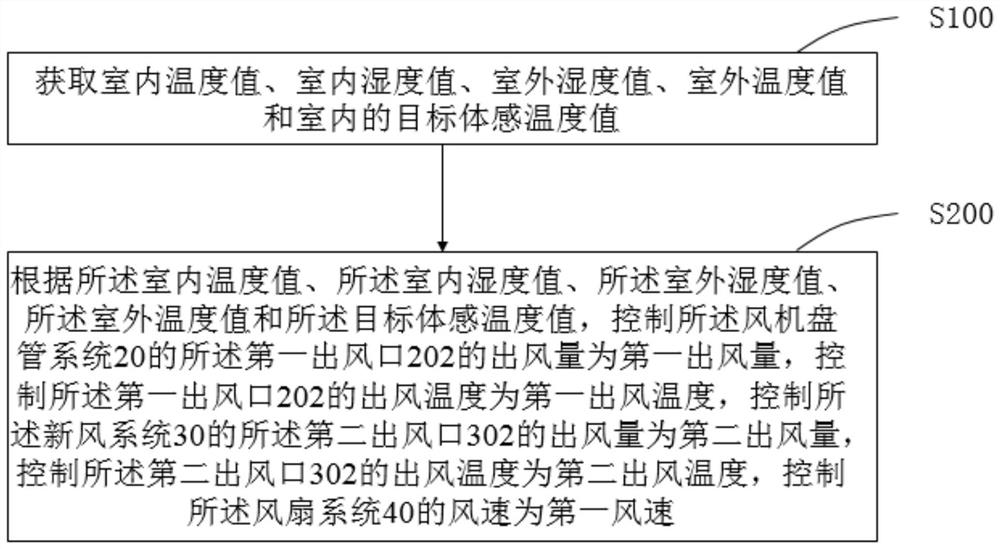

Indoor air conditioning system and control method thereof

PendingCN111853943AReduce energy consumptionSpeed up the flowMechanical apparatusSpace heating and ventilation safety systemsOutdoor temperatureIndoor air

The invention relates to an indoor air conditioning system and a control method thereof. The indoor air conditioning system comprises a fan coil system, a ventilation system, a fan system and a central control device. A first air inlet and a first air outlet of the fan coil system are used for communicating with an indoor space. A second air inlet of the ventilation system is used for communicating with the external environment. A second air outlet is used for communicating with the indoor space. The fan system is arranged in the indoor space. The central control device is used for obtaining an indoor temperature value, an indoor humidity value, an outdoor humidity value, an outdoor temperature value and an indoor target somatosensory temperature value and controlling operation of the fancoil system, the ventilation system and the fan system according to the indoor temperature value, the indoor humidity value, the outdoor humidity value, the outdoor temperature value and the indoor target somatosensory temperature value. According to the indoor air conditioning system, the indoor temperature value is reduced through the fan coil system and the ventilation system, a flowing speed of air in the indoor space is increased through the fan system, the somatosensory temperature of a human body is reduced, and the overall energy consumption of the indoor air conditioning system is reduced.

Owner:广州市设计院集团有限公司 +1

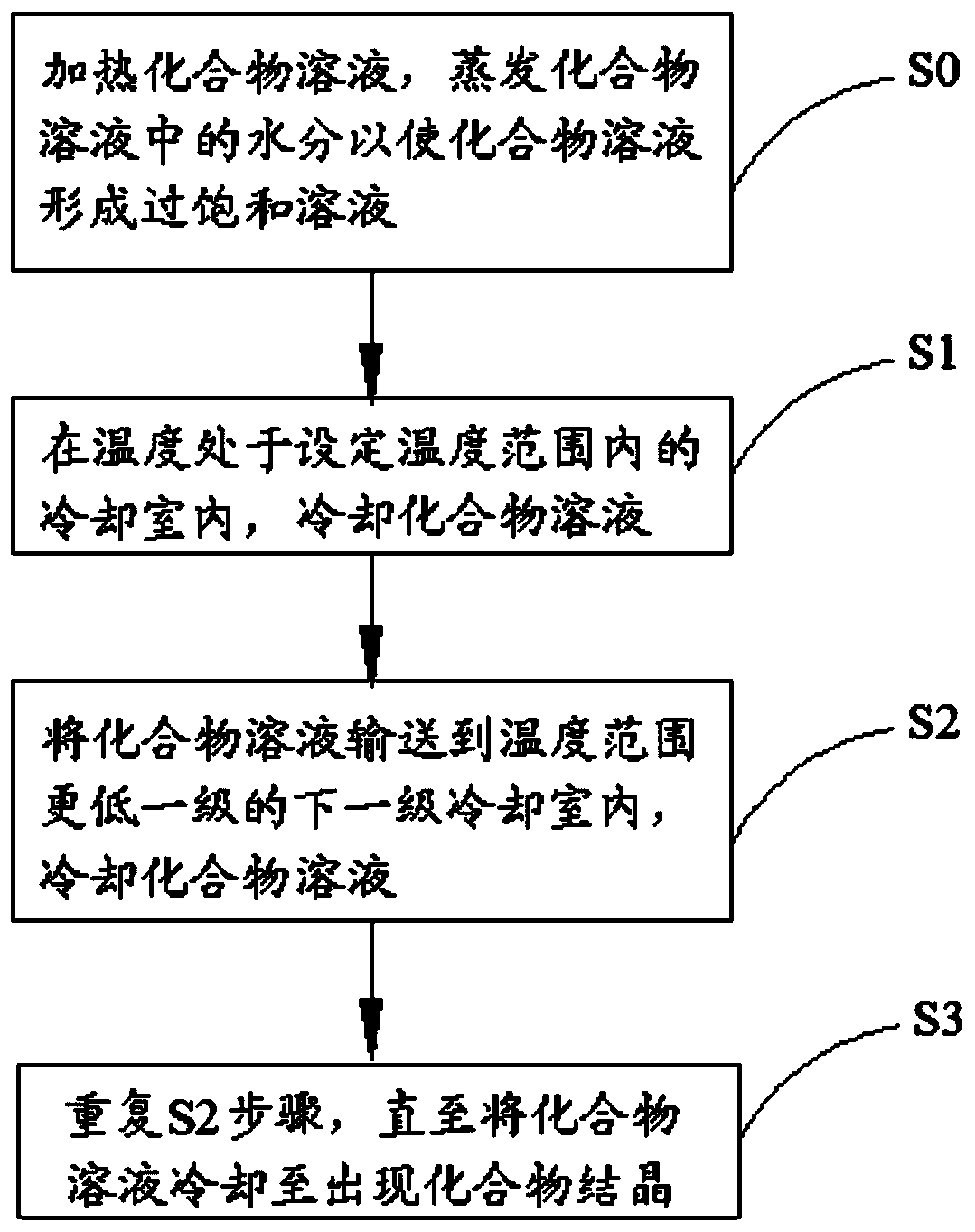

Compound crystallization device, compound preparation system and compound crystallization process

PendingCN110755874AReduce the deviation of crystal grain sizeImprove finished product qualitySolution crystallizationCrystallization plant arrangementsCooling chamberProcess engineering

The invention provides a compound crystallization device, a compound preparation system and a compound crystallization process, and relates to the technical field of compound preparation. The compoundcrystallization device comprises multi-stage cooling units; the cooling units comprise cooling chambers; refrigeration modules are arranged in the cooling chambers; multi-stage cooling chambers communicate with one another sequentially; and in the two adjacent stages of cooling units, the next stage of refrigeration module is used for enabling the temperature of the cooling chamber of the stage of the cooling unit to be less than the temperature of the cooling chamber of the previous stage of cooling unit. The compound preparation system comprises a solution concentration device and the compound crystallization device. The technical problems in the prior art that when the temperature of compound clear liquid needs to be reduced from high temperature to a certain temperature range in the process of crystallizing the compound by a biological fermentation method, the heat release duration time of the compound clear liquid is too long, heat release at each position is too non-uniform, thecondition that local crystallization is too fast or too slow is liable to occur, the crystal granularity deviation is too large and the quality of the compound finished product is seriously influenced are solved.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

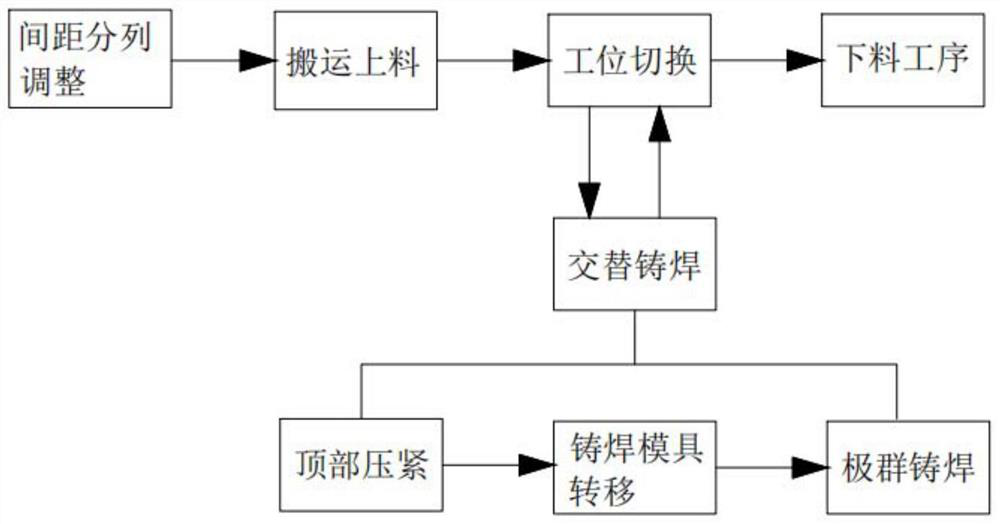

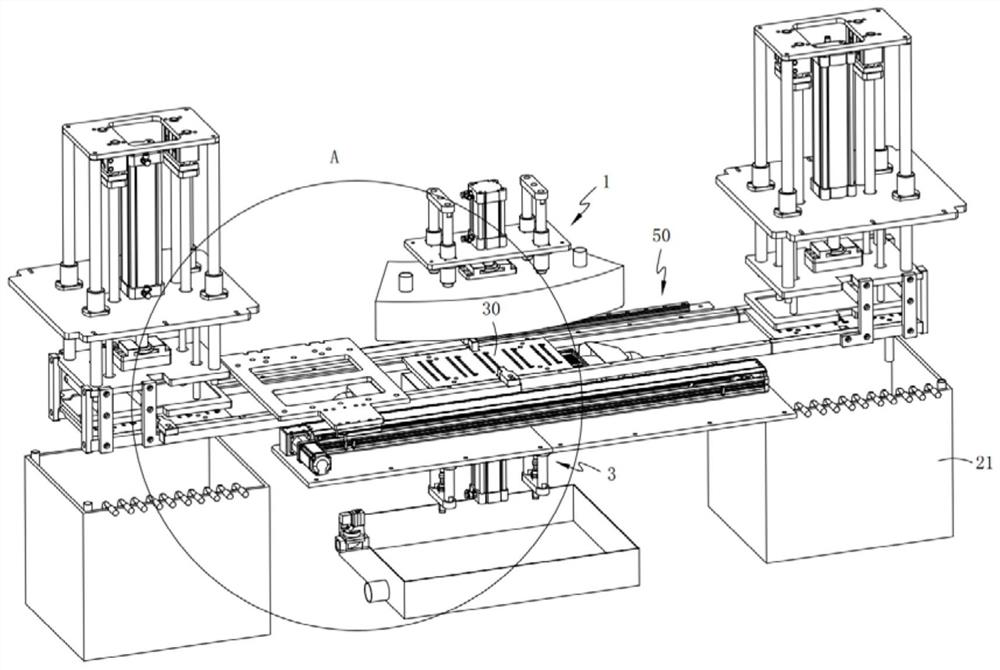

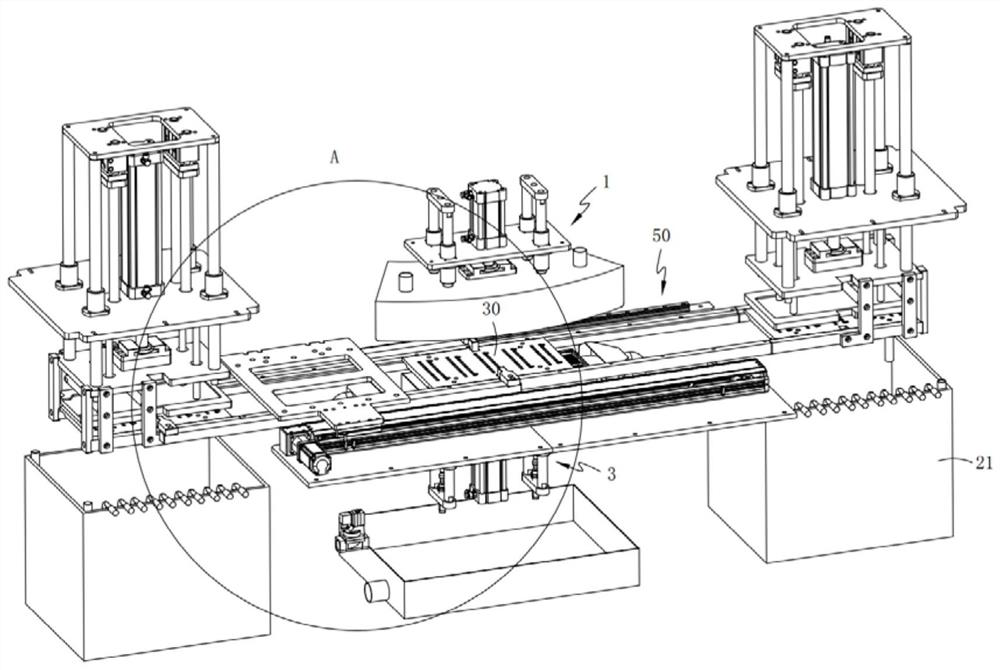

Double-station alternate cast-welding production process

ActiveCN112705685AShorten production hoursThe cooling rate is smallManufacturing engineeringMaterials science

The invention provides a double-station alternate cast-welding production process. The double-station alternate cast-welding production process is characterized by comprising the following step of S1, alternate cast-welding. A cast-welding system arranged in a cast-welding area comprises a cast-welding unit, a plurality of sets of lead immersion units and cast-welding molds arranged in one-to-one correspondence with the lead immersion units, the cast-welding unit bears a storage battery pack, and the cast-welding molds obtain molten lead from the lead immersion units to the cast-welding unit to be subjected to cast-welding work together with the storage battery pack; and the multiple cast-welding molds alternately convey the molten lead needed by cast-welding to the cast-welding unit. When one set of mold performs cast-welding work at a cast-welding station, another set of cast-welding mold synchronously completes lead immersion in another lead immersion mechanism and waits for conveying, and the cast-welding is performed by alternately advancing in this way, so that the production time is greatly saved.

Owner:长兴金润科技有限公司

Sea water desalination device and method

ActiveCN101935078BIncrease water productionSimple structureGeneral water supply conservationSeawater treatmentWater desalinationWater storage tank

Owner:广州金抡电器有限公司

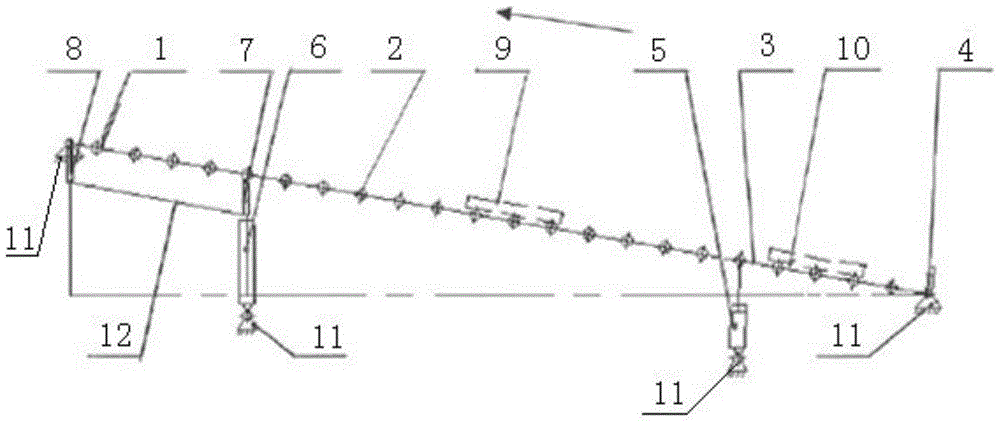

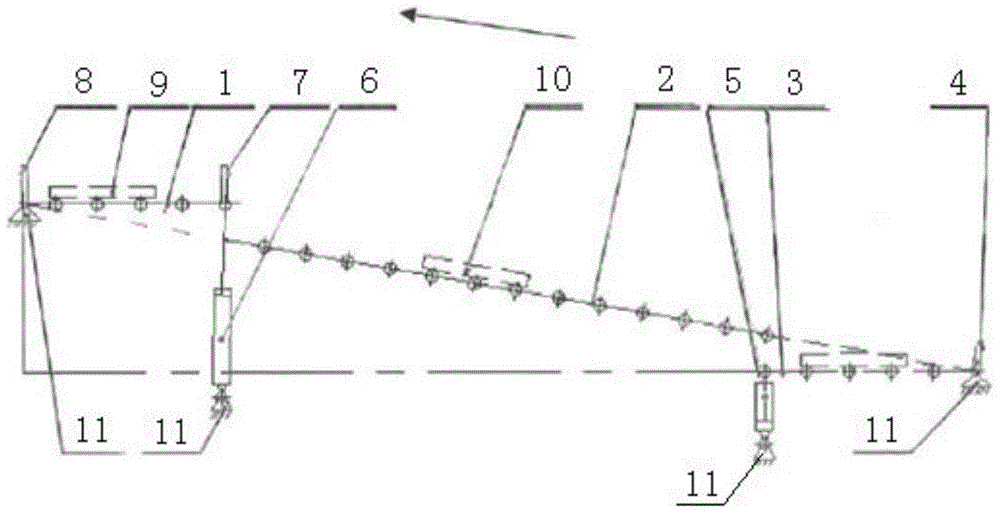

Slab conveying device with variable track

ActiveCN104801686BThe cooling rate is smallReduce the delivery linkEngineeringMechanical engineering

The invention discloses a slab conveying device with a variable track. The slab conveying device comprises a fixedly arranged middle-end conveying track, wherein the middle-end conveying track is inclined; the front end and the rear end of the middle-end conveying track are respectively connected with a front-end conveying track and a rear-end conveying track; the front end of the front-end conveying track is fixed on a stander; the lower side at the rear end of the front-end conveying track is connected with a second push cylinder; when the second push cylinder is in a contraction state, the rear end of the front-end conveying track is butted with the front end of the middle-end conveying track to form a plane; the rear end of the rear-end conveying track is fixed on the stander; the lower side of the rear-end conveying track is connected with a first push cylinder; when the first push cylinder is in an extending state, the front end of the rear-end conveying track is butted with the rear end of the middle-end conveying track to form a plane; oil cylinders are used for pushing the conveying tracks, so that the conveying tracks can be freely converted between a horizontal state and an inclined state; the number of the conveying steps is small; lifting and conveying can be synchronously realized; the conveying time is effectively shortened; the slab conveying device has the characteristics of low cost, energy conservation and high efficiency.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Controlled rolling and controlled cooling system for bars

InactiveCN103551403BPrevent "overcooling"Large temperature difference in the axial directionTemperature control deviceWork treatment devicesProduction lineEngineering

A controlled rolling and controlled cooling system for bars comprises a first cooling section at the position of an outlet of an intermediate mill group, a machine cooling section of a finishing mill group, a second cooling section between the finishing mill group and a third flying shear, a third cooling section between the third flying shear and a cooling bed, a sensor module and a central control unit. The first cooling section, the second cooling section and the third cooling section respectively comprise one or a plurality of cooling lines arranged on a horizontal moving trolley and a bypass roll table, one cooling line or the bypass roll table can be selectively connected to a production line by horizontally moving the horizontal moving trolley, and every production line comprises one or a plurality of series connection coolers. Every cooler is connected to a water supply main pipe through one water supply branched pipe, control valves are arranged in the water supply branched pipes, and the coolers connected to the production lines are selected and used by opening and closing of the control valves. According to the controlled rolling and controlled cooling system, a plurality of cooling sections can be selected flexibly, the coolers in every cooling section can also be selectively used simultaneously, and accordingly the system not only is good in applicability, but also improves bar finished product performances.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

A control system and control method for cold energy utilization in lng gasification process

ActiveCN106122760BSafe and stable operationReduce the frequency of manual adjustmentsContainer filling methodsIndirect heat exchangersControl systemProcess engineering

The invention provides a control system and method for cold energy utilization in an LNG gasification process. The control system comprises a coolant storage tank, a coolant conveying pump, a seawater heater and an LNG gasifier. LNG is gasified through heat exchange of the LNG gasifier and coolant; the gasified natural gas is conveyed to downstream natural gas users; the coolant after heat exchange is conveyed to cool energy users for cooling; the coolant after being heated is conveyed to the coolant storage tank; and after being discharged from the coolant storage tank, the coolant is conveyed to the seawater heater through the coolant conveying pump, and the coolant enters the LNG gasifier after reaching the specified temperature. The control system for cold energy utilization in the LNG gasification process adopts cascade control, so that the phenomenon that the temperature of the natural gas can not be controlled timely due to flow variation of an LNG inlet is avoided; and the process of heating the coolant by seawater also adopts cascade control, so that the phenomenon that the temperature of a coolant outlet can not be controlled timely due to flow variation of a coolant inlet is avoided.

Owner:CHINA TIANCHEN ENG +1

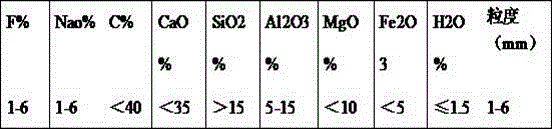

Defoaming and slagging heat insulation agent for blast furnace ironmaking and preparation method thereof

InactiveCN102417940BAnti-oxidation functionImprove liquidityBlast furnace detailsRecycling and recovery technologiesSlagGraphite

The invention discloses a defoaming and slagging heat insulation agent for blast furnace ironmaking. The heat insulation agent comprises the following raw materials in parts by weight: 15-20 parts of portland cement clinker, 25-30 parts of graphite, 12-18 parts of fly ash, 20-25 parts of vermiculite, 15-18 parts of sodium carbonate and 1-3 parts of acidized graphite. The defoaming and slagging heat insulation agent has the functions of slagging, defoaming, keeping the temperature, absorbing the inclusions of molten steel and preventing the oxidation of molten steel. After the product is added, the liquidity of iron slag is good, the slag-iron separation effect is good, the recovery rate of molten steel is high and molten steel can not stick to the ladle and wall and can not crust.

Owner:ZHENGZHOU DONGSHENG METALLURGY NEW MATERIAL

A double-station alternate casting and welding production process

The present invention provides a dual-station alternate casting and welding production process, which is characterized by comprising the following steps: a dual-station alternate casting and welding production process, characterized in that it includes the following steps: S1, alternate casting and welding, and in the casting process The casting and welding system provided at the welding area includes a casting and welding unit, a plurality of groups of lead immersion units, and casting and welding molds arranged in a one-to-one correspondence with the lead soaking units. The molten lead obtained from the lead unit is sent to the casting and welding unit and the battery pack for casting and welding. Multiple casting and welding molds alternately transport the lead liquid required for casting and welding to the casting and welding unit. When one group of molds is cast and welded at the casting and welding station, the other group of molds is dipped in lead synchronously in another lead-dipping mechanism and waits to be transported, so alternately travel for casting and welding, which greatly saves production time.

Owner:长兴金润科技有限公司

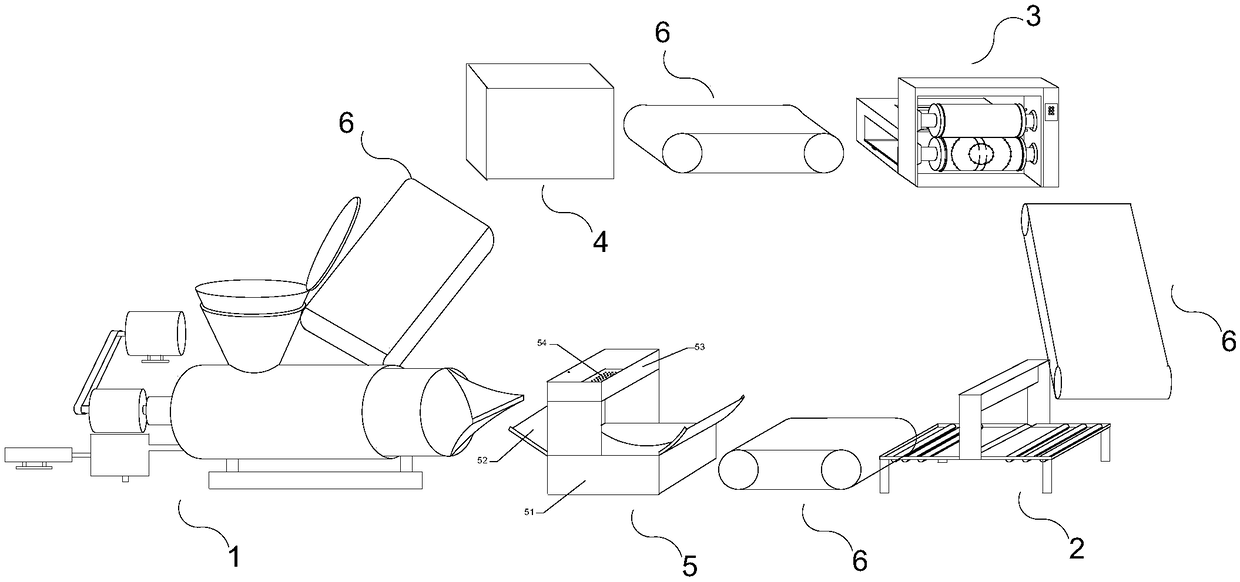

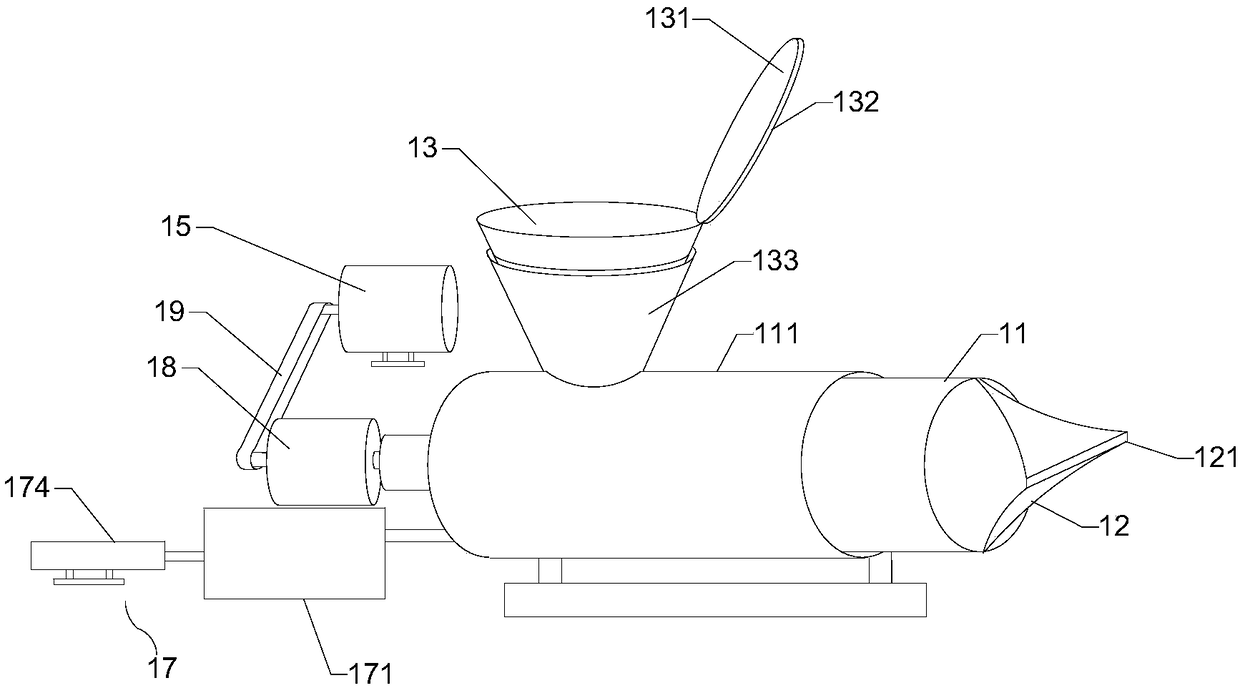

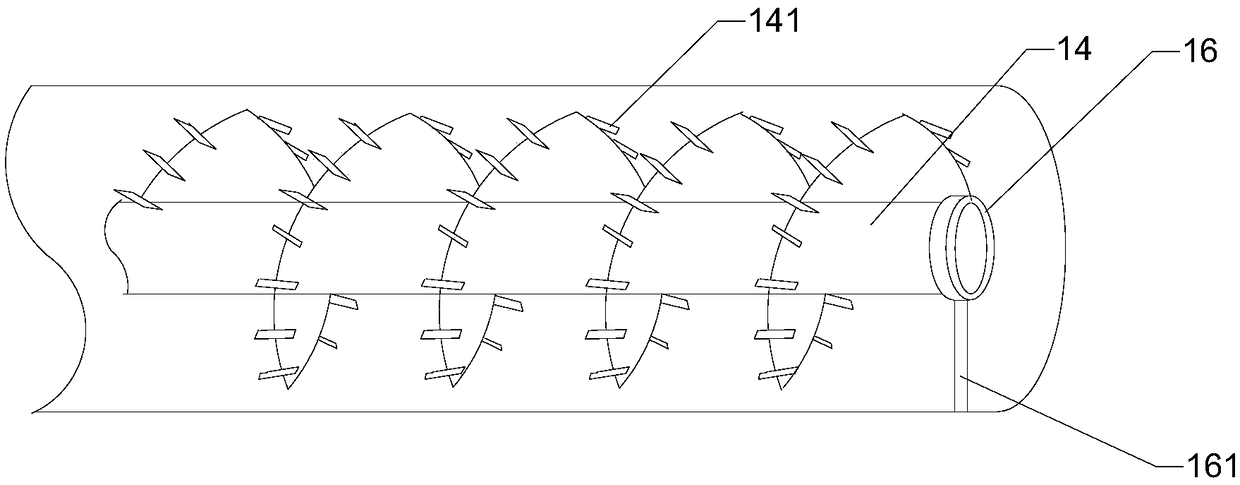

Steel coil end plate production line

ActiveCN108838686ASave spaceImprove thermal conductivityOther manufacturing equipments/toolsProduction lineEngineering

The invention belongs to the technical field of end plate manufacturing and provides a steel coil end plate production line. The steel coil end plate production line comprises an extrusion device, a cooling device, a trimming device, a forming device and a recovering device which are successively arranged. The extrusion device comprises a horizontally arranged charging barrel, an aluminum foil sheet coats the outer wall of the charging barrel, one end of the charging barrel is closed while an extrusion die is arranged at the other end of the charging barrel, an extrusion port is formed in theend part of the extrusion die, and the extrusion port is strip-shaped; a feed inlet is formed in the charging barrel, a screw is axially arranged in the charging barrel, one end of the screw penetrates the closed end of the charging barrel and is connected to a rotating motor while the other end of the charging barrel is connected to the peripheral inner wall of the charging barrel through a bearing and a connecting rod, and a blade is fixedly arranged on the screw. The steel coil end plate production line provided by the invention solves the technical problems that it is time- and labor-wasting to produce existing coil end plates, the cost is high, the coil end plates are not recovered, the quality of the panels is not high and the like.

Owner:HANDAN HANGANG AFFILIATED ENTERPRISE CO LTD

Environment-friendly slag heat insulating agent for high and medium furnace ironmaking and preparation method thereof

The invention discloses an environment-friendly slagging heat-preservation agent used for blast and medium-furnace iron making and a preparation method thereof. The environment-friendly slagging heat-preservation agent is prepared from the following raw materials in parts by weight: 35-45 parts of flue ashes, 15-25 parts of fluorine-sodium carbon, 20-30 parts of vermiculite soil, 2-6 parts of graphite, 8-12 parts of wollastonite and 1-3 parts of adhesive. The preparation method of the environment-friendly slagging heat-preservation agent comprises the following steps: firstly, preparing raw materials into powder with grain size of 20-100 meshes, stirring and mixing for 7-15 minutes, spraying water accounting for 7%-13% mass of the total raw materials, and continuously stirring for 7-15 minutes; then, pelletizing; and finally, drying at 30-40 DEG C to prepare the product. According to the environment-friendly slagging heat-preservation agent and the preparation method thereof disclosed by the invention, the adopted flue ashes, the fluorine-sodium carbon, the vermiculite soil, the graphite, the wollastonite and the adhesive are taken as the raw materials, so that in a manufacturing process, the flue ashes, the fluorine-sodium carbon, the vermiculite soil, the acidified graphite and the wollastonite can be sufficiently adhered by using the adhesive; on the other hand, in a using process, the raw materials of the product do not produce dust and smoke, so that the product is free of dust and smoke in the using process, and free of environmental pollution.

Owner:XIXIA JINYANG MINING & METALLURGY

A kind of high-efficiency lead-acid battery casting welding production process

ActiveCN112756588BRealize flow operationShorten production timeCasting plantsFinal product manufactureMaterials scienceIndustrial engineering

Owner:长兴金润科技有限公司

Separation method and equipment of protein from starch sugar liquefied solution

ActiveCN102516354BEfficient separationAvoid damagePeptide preparation methodsPlant peptidesStarch gelatinizationEngineering

Owner:玉锋实业集团有限公司

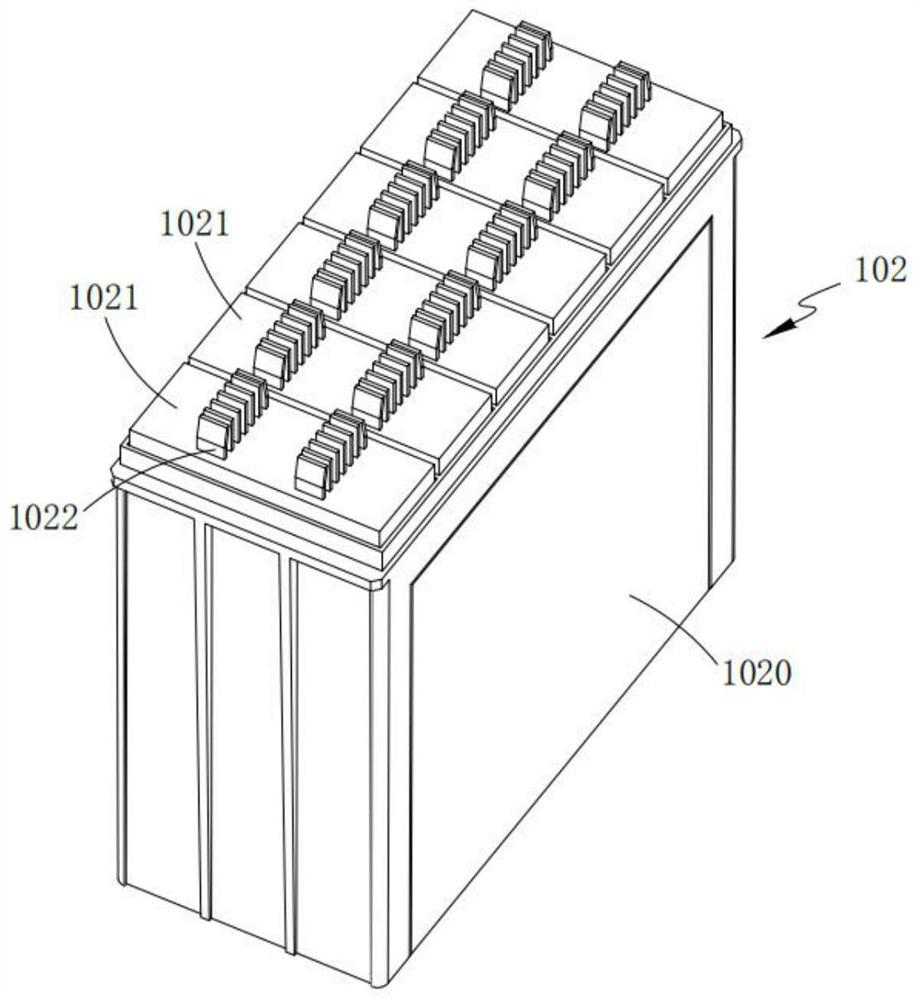

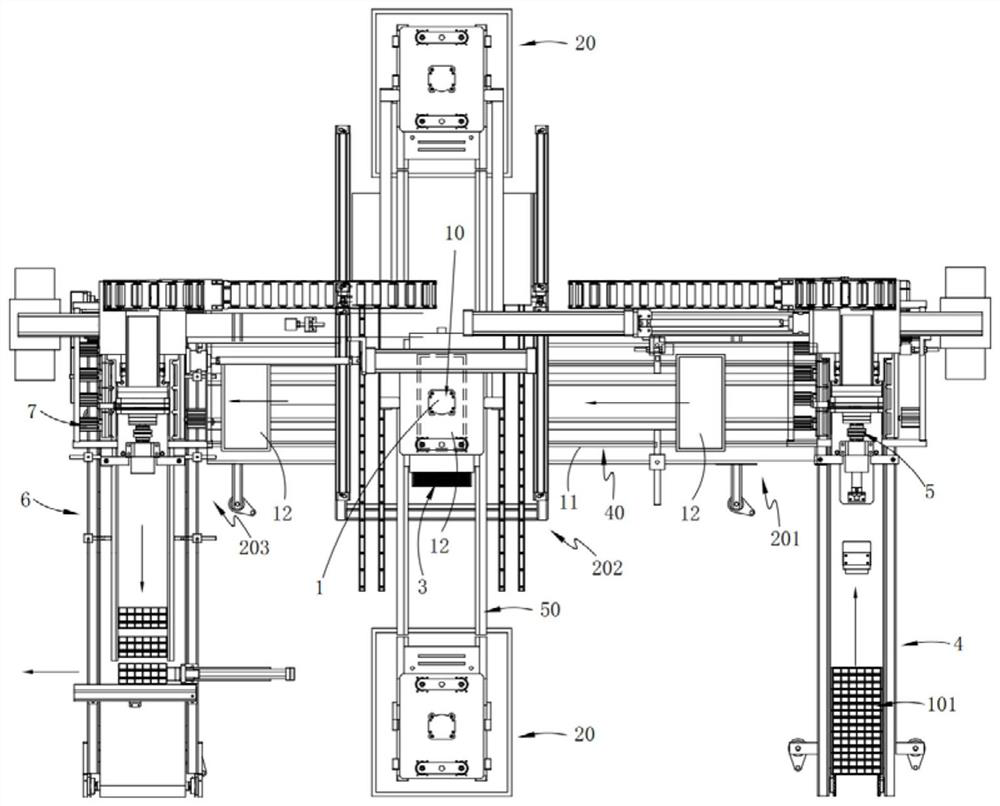

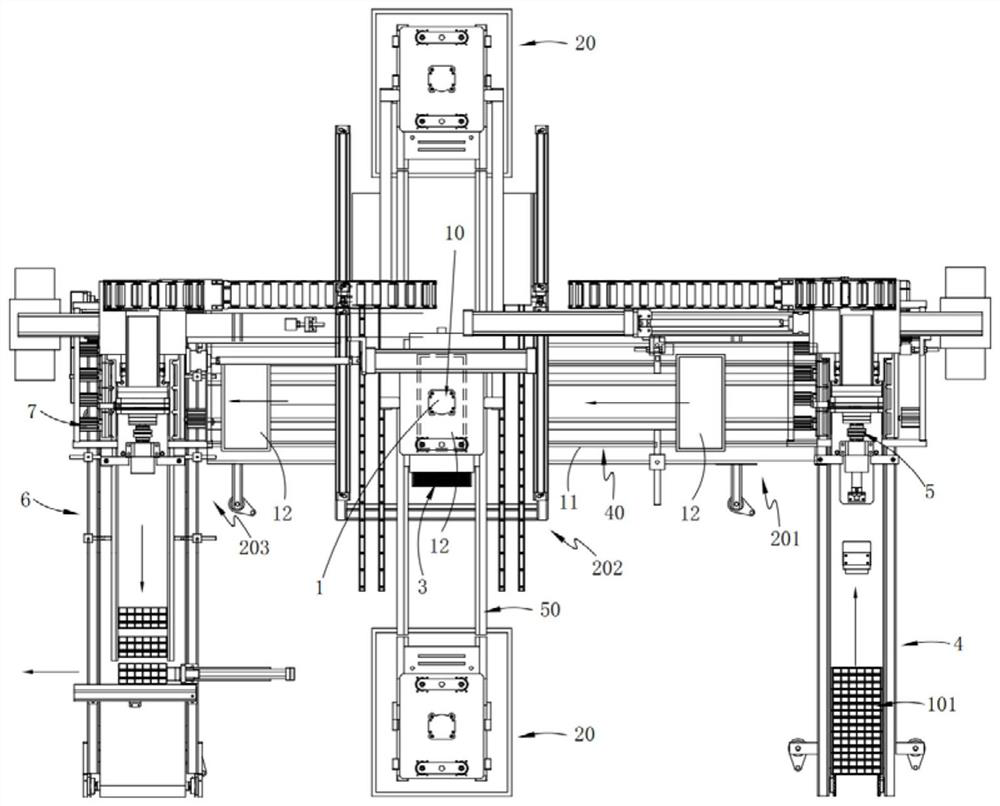

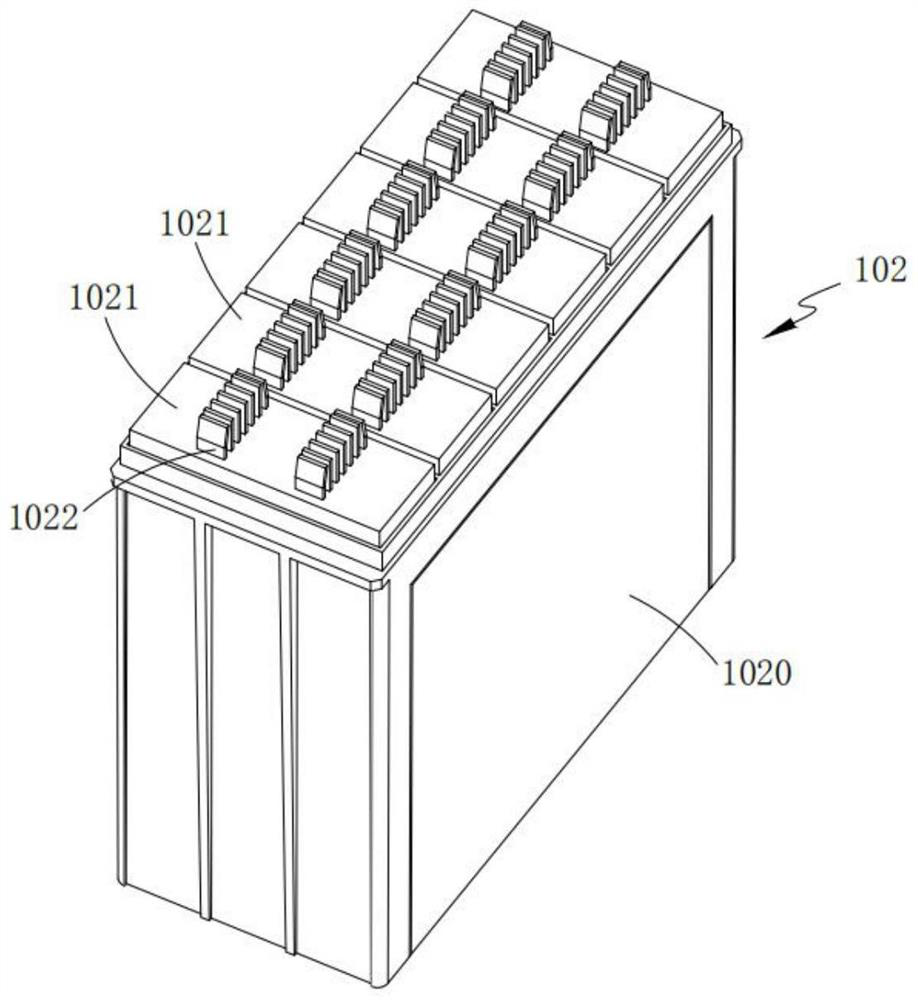

Lead-acid storage battery cast-weld production line

ActiveCN112792322AIncrease productivityThe cooling rate is smallCasting plantsFinal product manufactureProcess engineeringManufacturing line

The invention provides a lead-acid storage battery cast-weld production line. The lead-acid storage battery cast-weld production line comprises a feeding conveying system, at least one set of cast-weld production systems distributed in the conveying direction of the feeding conveying system, a discharging conveying system connected with the discharging ends of the cast-weld production systems, and a groove entering system arranged on a discharging path. The feeding conveying system and the multiple sets of cast-weld production systems distributed corresponding to the feeding conveying system are arranged, multiple sets of lead dipping units and cast-weld molds corresponding to cast-weld units are arranged in the cast-weld production systems, the feeding conveying system automatically conveys and distributes storage batteries to all the cast-weld production systems, then the multiple sets of cast-weld molds are alternately matched with the cast-weld units for cast-weld operation, and therefore the multiple sets of cast-weld production systems can work simultaneously under one production line, and all the procedure structures in all the sets of cast-weld production systems are in close fit to complete continuous cast-weld.

Owner:长兴金润科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com