Environment-friendly slag heat insulating agent for high and medium furnace ironmaking and preparation method thereof

A technology of heat preservation agent and adhesive, which is used in medium furnace ironmaking or slag heat preservation agent for ladle. It can solve the problems of low utilization rate of equipment and achieve the effect of prolonging service life, reducing cost and reducing erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

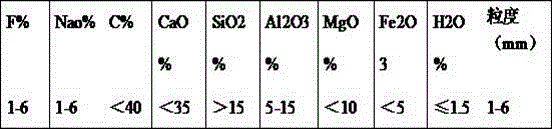

Embodiment 1

[0022] A defoaming slag heat preservation agent for blast furnace ironmaking, prepared from the following raw materials: flue ash 35-45kg, fluorosodium carbon 15-25kg, vermiculite soil 20-30kg, graphite 2-6kg, silica fume Stone 8-12kg, adhesive 1-3kg. Among them, the graphite is acidified graphite, the binder is a water-soluble binder, and the main component is starch; the main component of the flue ash is coal ash or cinder, and the content of C is 20-30%, SiO 2 , the content is 20%-35%; the main components of fluorosodium carbon are F ≥ 30%, Na ≥ 18% and C ≥ 30%; the main component of vermiculite soil is vermiculite soil raw ore, of which SiO 2 ≥40%, Al 2 o 3 ≥10-15%, expansion multiple 2-5 times.

[0023] Its preparation method is as follows: firstly make powder of each raw material, the particle size of the powder is 20-100 mesh, stir and mix for 7min-15min, then spray 7%-13% of the total raw material mass with water, continue stirring for 7min-15min, and then granulate...

Embodiment 2

[0025] A defoaming slag heat preservation agent for blast furnace ironmaking, prepared from the following raw materials: 35kg of flue ash, 15kg of fluorosodium carbon, 30kg of vermiculite soil, 5kg of graphite, 12kg of wollastonite, and 3kg of adhesive. Among them, the graphite is acidified graphite, the binder is a water-soluble binder, and the main component is starch; the main component of the flue ash is coal ash or cinder, and the content of C is 30%, SiO 2 , the content is 25%; the main components of fluorosodium carbon are F ≥ 30%, Na ≥ 18% and C ≥ 30%; the main component of vermiculite soil is vermiculite soil raw ore, of which SiO 2 ≥40%, Al 2 o 3 ≥10%, the expansion multiple is 2-5 times.

[0026] Its preparation method is as follows: firstly make powder of each raw material, the particle size of the powder is 20 mesh, stir and mix for 7 minutes, then spray 7% water of the total raw material mass, continue stirring for 7-15 minutes, then granulate, and finally dry ...

Embodiment 3

[0028] A defoaming slag heat preservation agent for blast furnace ironmaking, prepared from the following raw materials: 37kg of flue ash, 21kg of sodium fluoride carbon, 24kg of vermiculite soil, 5kg of graphite, 10kg of wollastonite, and 3kg of adhesive. The graphite is acidified graphite, the binder is a water-soluble binder, and the main component is starch; the main component of the flue ash is coal ash or cinder, in which the C content is 28%, SiO 2 , the content is 27%; the main components of fluorosodium carbon are F ≥ 30%, Na ≥ 18% and C ≥ 30%; the main component of vermiculite soil is vermiculite soil raw ore, of which SiO 2 ≥40%, Al 2 o 3 ≥10-15%, expansion multiple 2-5 times.

[0029] Its preparation method is as follows: first, each raw material is powdered, the particle size of the powder is 50 mesh, stirred and mixed for 10 minutes, then sprayed with 9% water of the total raw material mass, continued to stir for 9 minutes, then granulated, and finally dried at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com