A low-water consumption, low-discharge and fat-releasing processing method

A processing method and low-emission technology, which is applied in the field of rosin processing, can solve environmental pollution and other problems, and achieve the effects of low water consumption, low energy loss, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

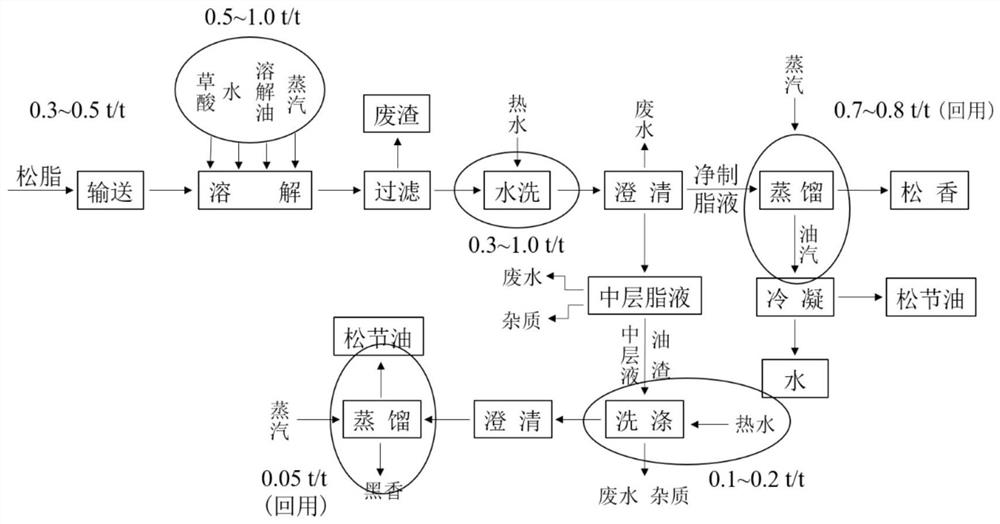

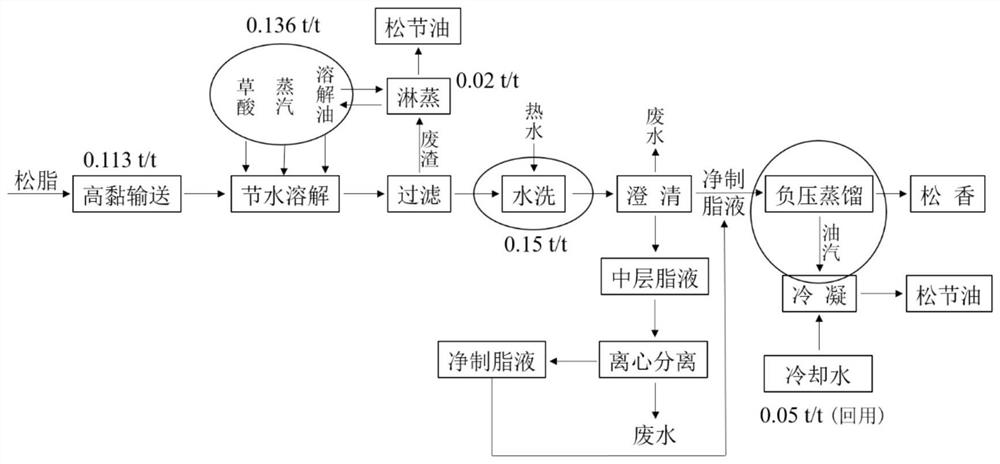

Method used

Image

Examples

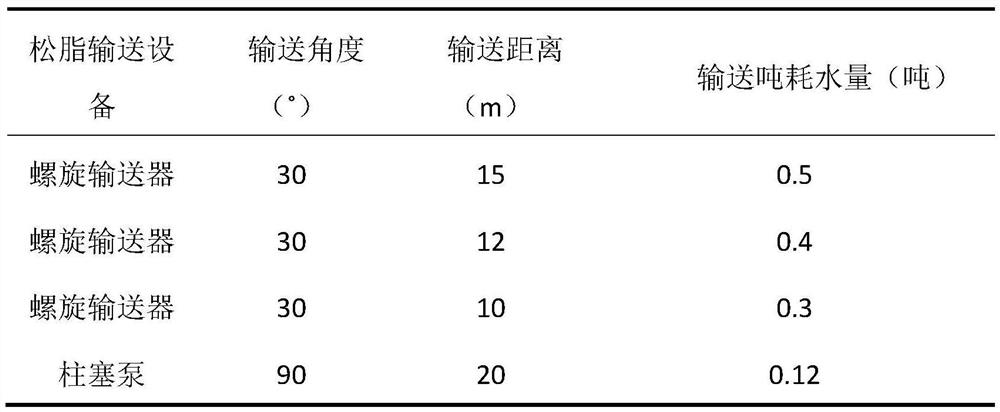

Embodiment 1

[0048] Under normal temperature conditions, the viscosity of rosin with a moisture content of 6% is greater than 10,000 mPa·s. With the increase of water content, the viscosity of rosin decreases. In industry, before conveying rosin, a certain amount of water will be added to the rosin to reduce the viscosity of rosin, so as to meet the conditions of rosin transportation, which are transported by screw conveyor and plunger pump respectively Rosin, each conveying equipment conveys rosin with different moisture content at different conveying angles, the maximum conveying distance of the conveying equipment and the water consumption per ton of rosin (that is, the water consumption of adding water to the rosin by the screw conveyor to reduce the viscosity or when the rosin is conveyed by the plunger pump. The data of pump head jacket cooling water consumption) are shown in Table 1:

[0049] Table 1. Conveying angle, conveying distance and water consumption per ton of rosin conveye...

Embodiment 2

[0053] The rosin is continuously put into the spray vertical continuous dissolver, and liquid water is not added to the rosin during the rosin dissolving process. The process of adding water, heating, gasification, boiling, stirring and melting during the rosin dissolving process is eliminated. The oil-vapor mixture is dissolved in turpentine, the dissolved oil is preheated to 130 ℃, and then mixed with high-temperature water vapor to obtain the oil-vapor mixture. The oil-vapor mixture enters tangentially from the bottom of the rosin vertical continuous dissolver, and rotates and mixes with the rosin in the dissolver. The amount of dissolved oil added is: according to the level of oil content in the raw material, adjust the oil content of turpentine after dissolving to 40%. The amount of water required to dissolve the steam consumed by the rosin, that is, the water consumption, is 0.14 t / t. The water consumption of dissolving rosin in the traditional process is more than 0.5 ...

Embodiment 3

[0055] Example 2 The heavier mechanical impurities in the rosin in the melter sink, and are discharged from the lower slag discharge port after being cooled by the water vapor in the melter and the water layer formed by the sinking in the rosin; The impurities overflow to the continuous slag removal filter outside the outlet. After slag removal and filtration, the obtained fat liquid is sent to the next process, and the waste residue is recovered. The melted oil is recovered by drying in the slag steaming equipment. The amount of melted oil used for rinsing the waste residue is 20% of the mass fraction of the waste residue. The temperature of the melted oil is 90°C, the distillation time of the waste residue is 0.5h, and the steam consumption is about 0.02 ton / ton. Pine resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com