A converter gas dry dust removal fine ash pneumatic conveying system

A pneumatic conveying system and dry dedusting technology, applied to conveyors, mechanical conveyors, conveying bulk materials, etc., can solve problems such as high investment costs, dust jams, and easy damage to equipment, so as to reduce transportation links and reduce failure rates , reduce the effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

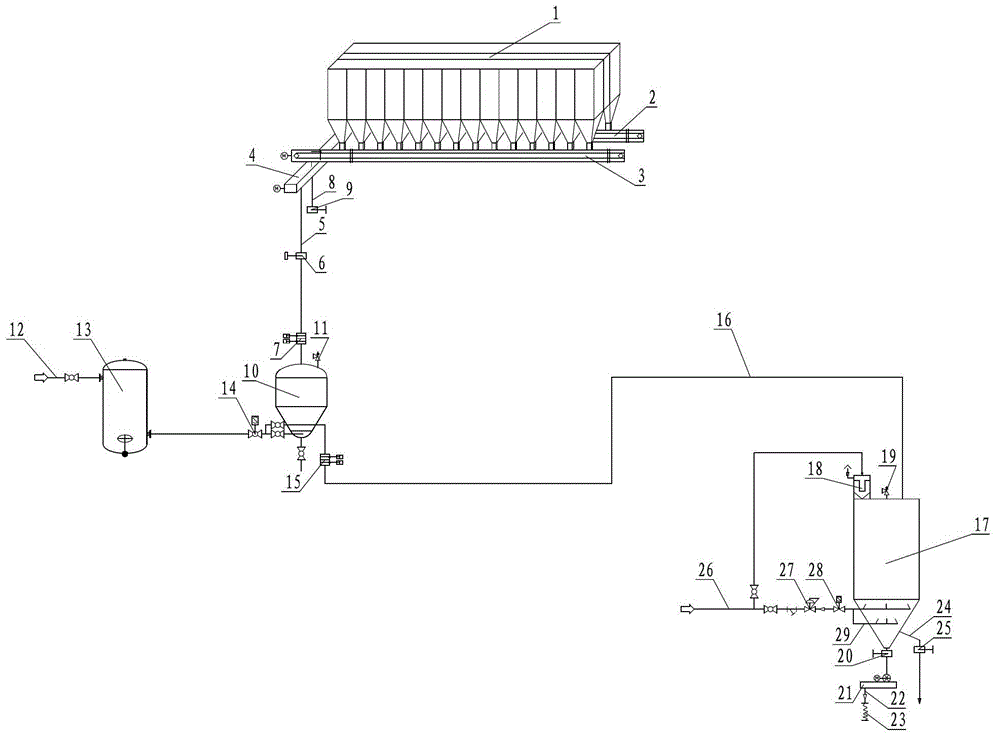

[0024] Such as figure 1 As shown, the converter gas dry dust removal fine ash pneumatic conveying system of the present invention includes a dry filter bag dust collector 1, a first horizontal chain conveyor 2, a second horizontal chain conveyor 3, and a cut-out chain conveyor 4 , Ash unloading pipe 5, warehouse pump 10, pneumatic conveying pipe 16 and fine ash bin 17.

[0025] The horizontal chain conveyor 2 and the second horizontal chain conveyor 3 are horizontally arranged under the dry filter bag filter 1, and the cut-out chain conveyor 4 is horizontally arranged on the first horizontal chain conveyor 2 and the second horizontal chain Below the type conveyor 3, the storehouse pump 10 is installed below the cut-out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com