Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Increase the lattice constant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum based alloy

InactiveUS20060093512A1Improve mechanical propertiesIncrease the lattice constantSolid solutionAluminium alloy

An aluminum alloy comprising Al, Sc, Gd, Zr, and optionally Mg. The aluminum alloy is strengthened by an aluminum solid solution matrix and a dispersion of Al3X precipitate having an L12 structure where X comprises Sc, Gd and Zr. Mg is a preferred addition to the alloy containing Gd and Zr. The alloying additions control strengthening and coarsening kinetics of the alloy through control of diffusivity in the aluminum matrix and coherency strain of the Al3X precipitate.

Owner:RAYTHEON TECH CORP

Multi-wall carbon nano-tube carried core-shell silver-platinum cathode catalyst and preparation method

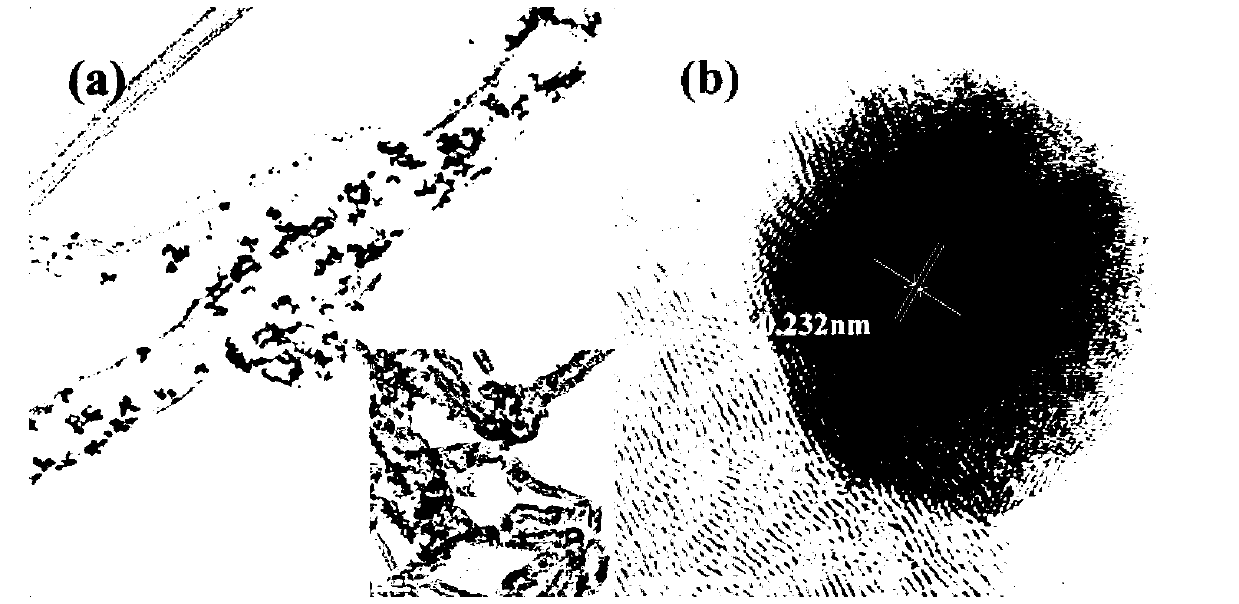

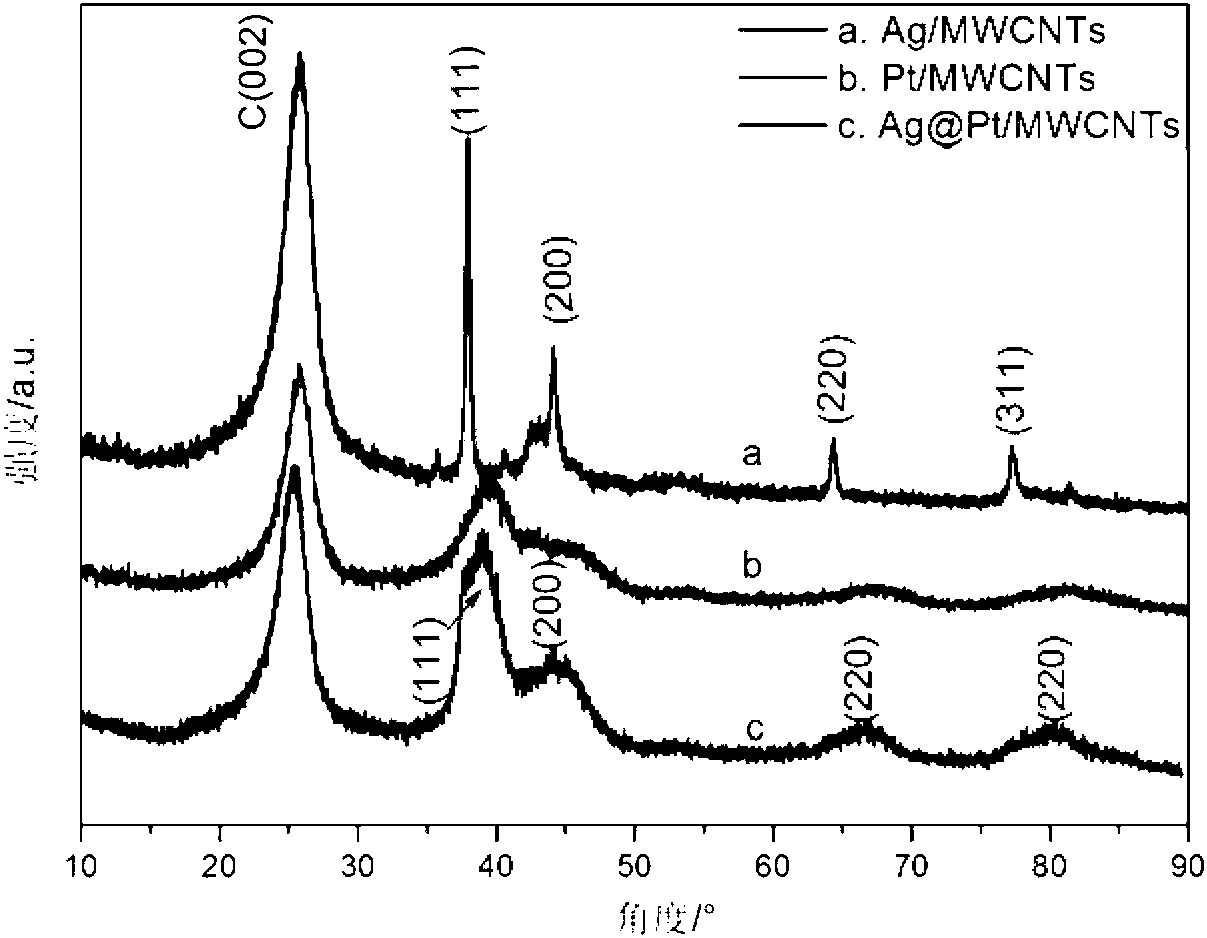

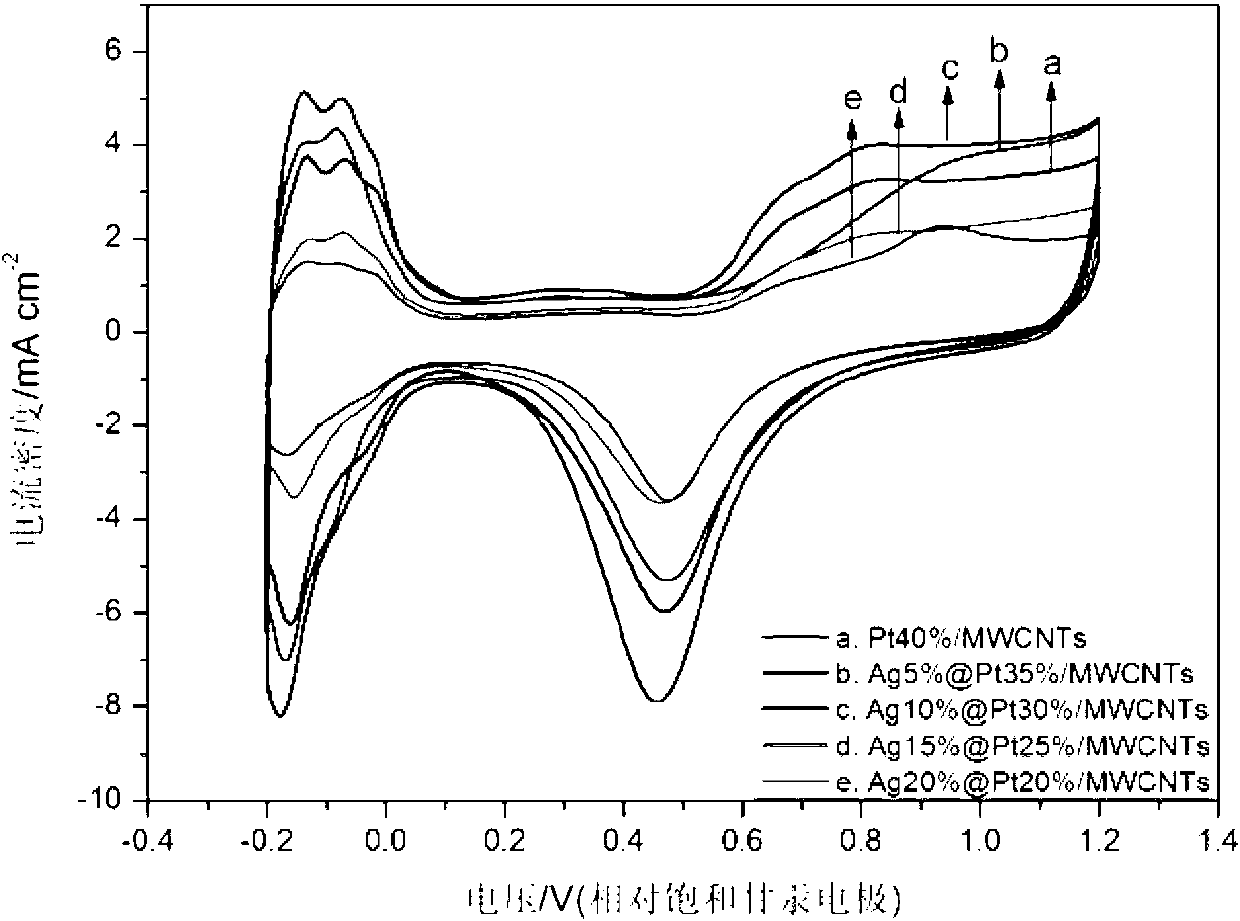

InactiveCN102723504AHigh catalytic efficiencyConducive to loadCell electrodesMetal/metal-oxides/metal-hydroxide catalystsCarbon nanotubeOxygen

The invention relates to a multi-wall carbon nano-tube carried core-shell silver-platinum cathode catalyst and a preparation method, which belongs to the fuel cell catalyst technical field. According to the invention, the multi-wall carbon nano-tube is taken as a carrier, a core-shell structure which is characterized in that an active metal component is taken as a core, platinum which is taken as a shell layer is grown on the surface of the multi-wall carbon nano-tube. The preparation method employs sodium borohydride and glycol as a solvent and a reducing agent, a two-step reduction method is used, silver is reduced firstly to obtain the multi-wall carbon nano-tube silver-carrying particles; then platinum is reduced, the temperature and pH value of the reaction can be controlled, thereby the platinum is deposited on the surface of silver, so that the core-shell catalyst is prepared. According to the invention, the catalysis efficiency of the catalyst and the utilization rate of precious metals can be substantially increased, the oxygen reduction capability can be enhanced and the development of the fuel battery can be promoted.

Owner:BEIJING UNIV OF CHEM TECH

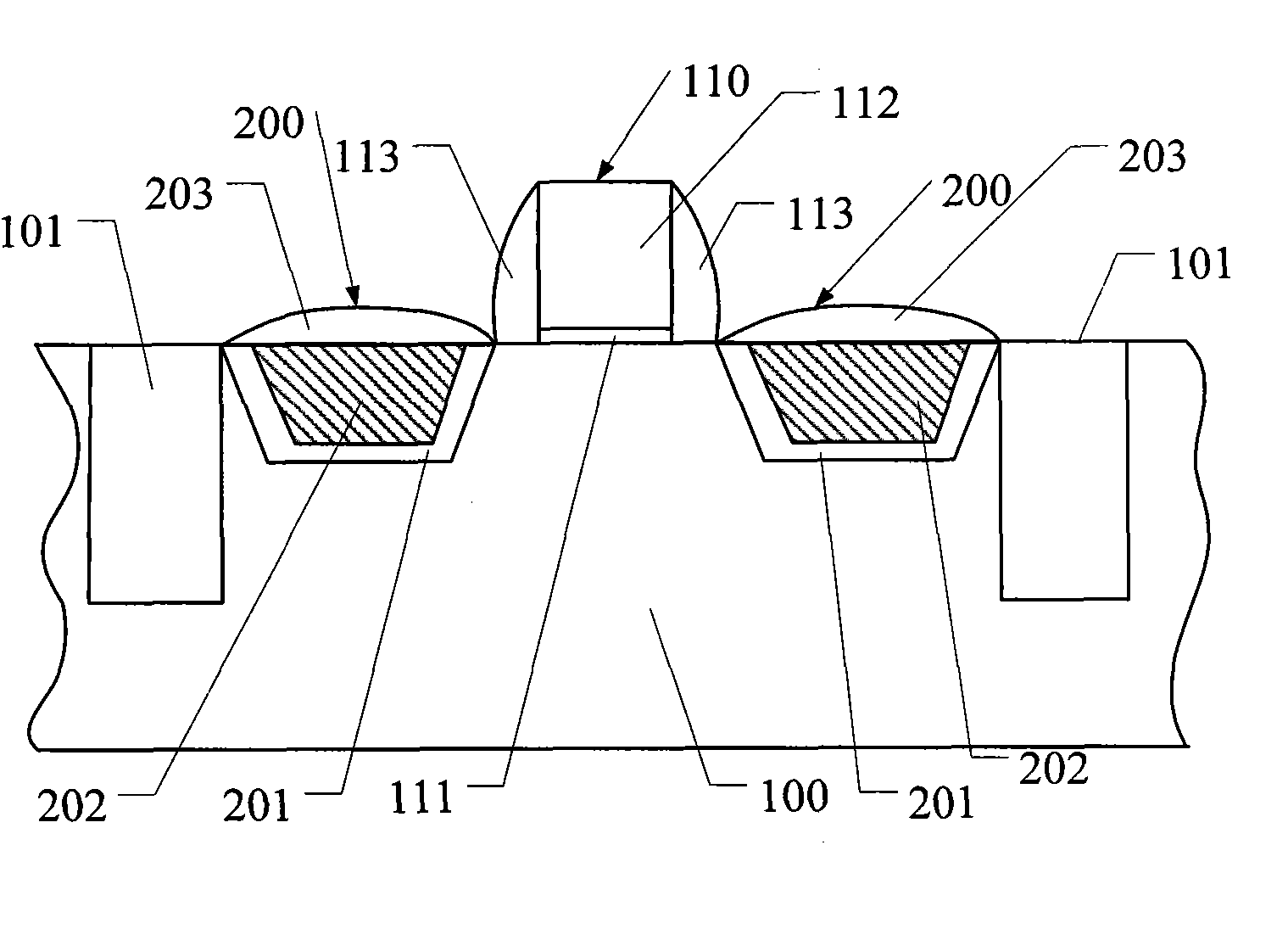

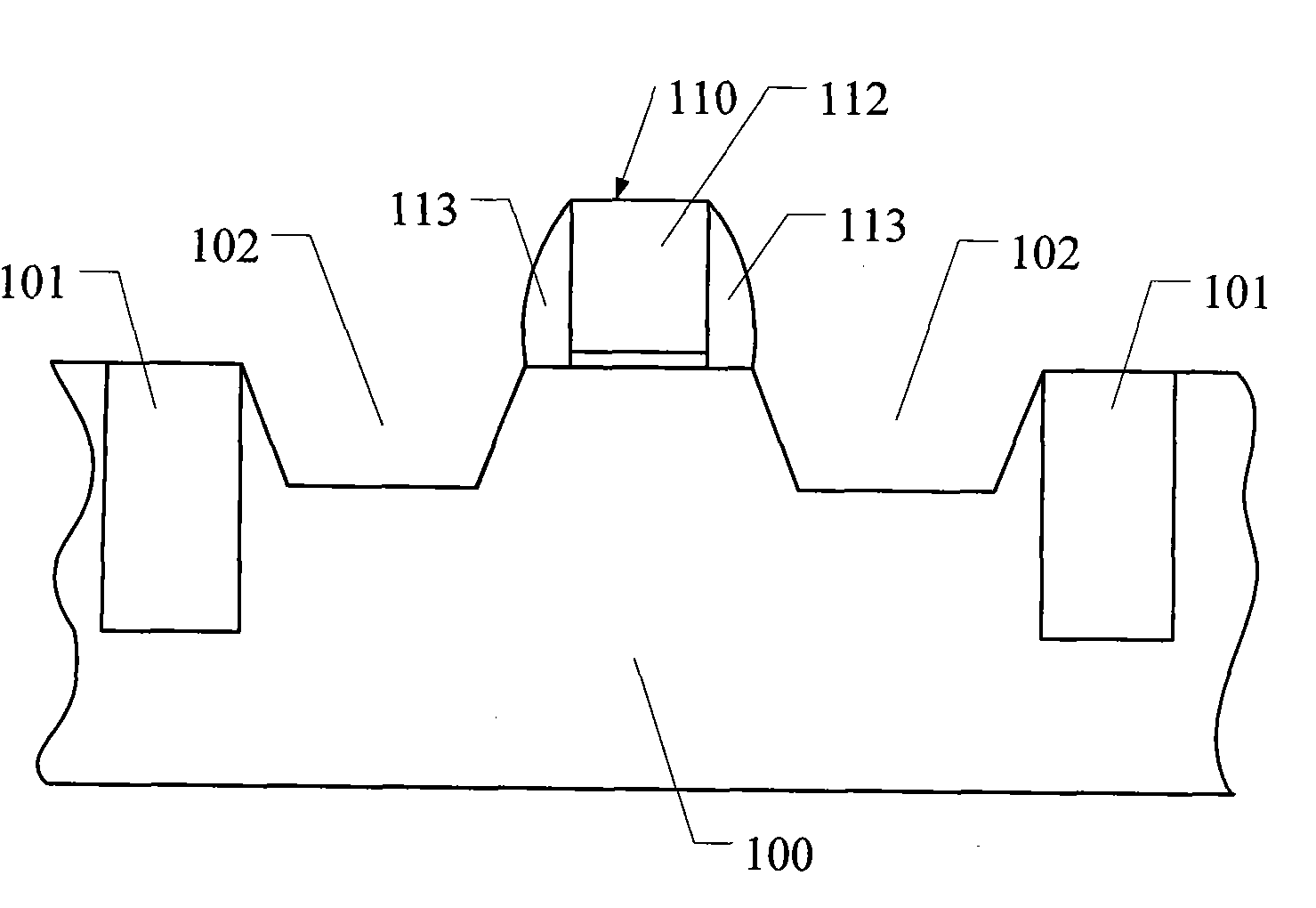

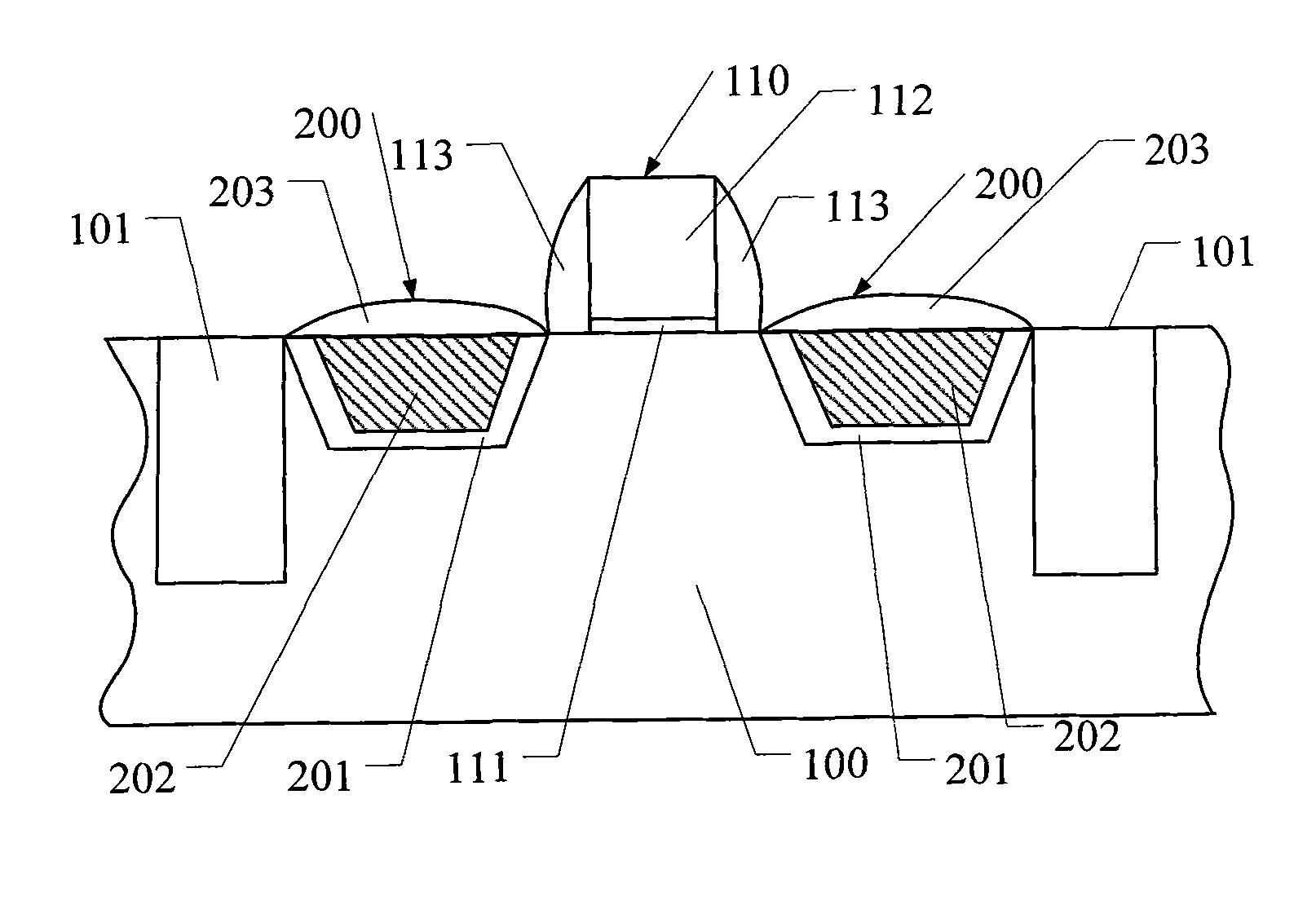

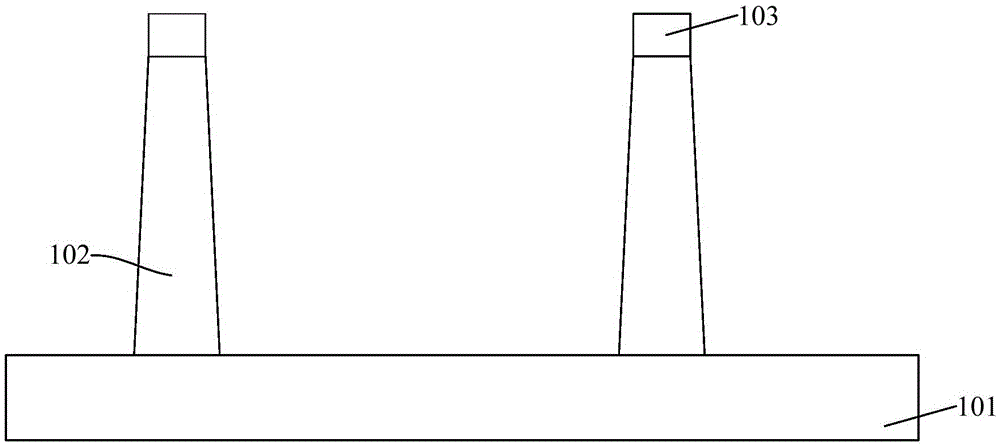

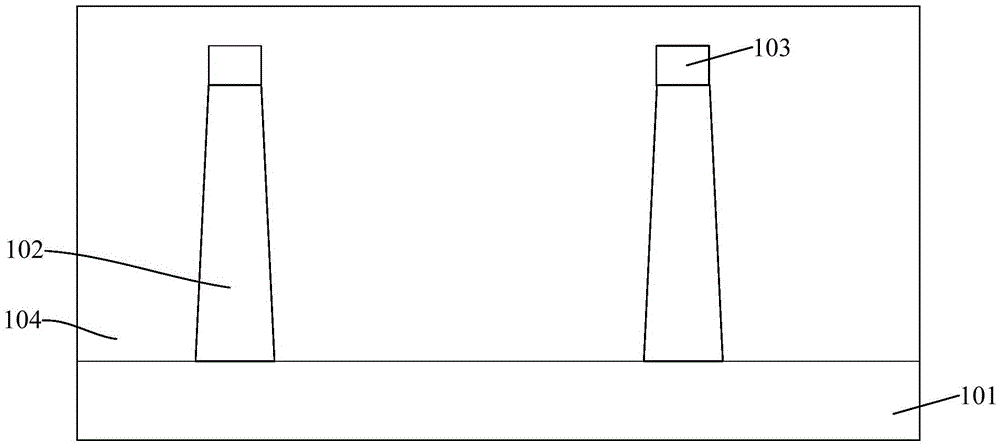

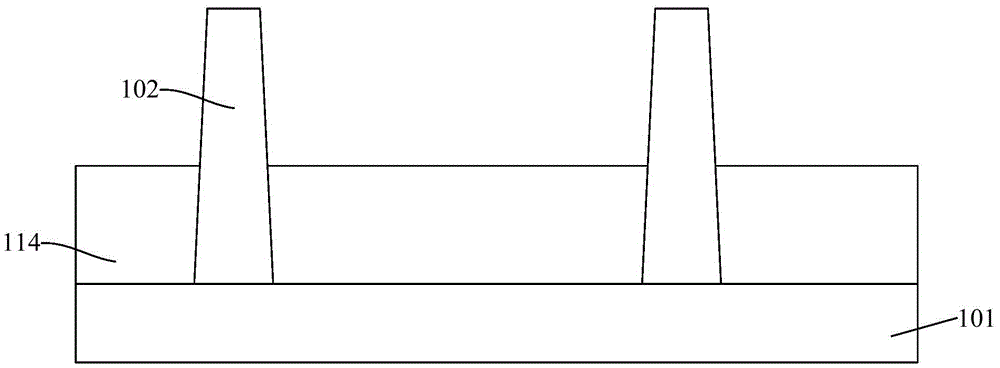

Transistor epitaxially growing source/drain region and manufacturing method thereof

InactiveCN102104067APromote growthIncrease the lattice constantSemiconductor/solid-state device manufacturingSemiconductor devicesStacking faultOptoelectronics

The invention provides a transistor epitaxially growing a source / drain region, comprising a substrate, a grid structure, a source region and a drain region, wherein the grid structure is positioned on the substrate; the source region and the drain region are formed in the substrate and positioned at both sides of the grid structure; the source region and the drain region comprise doped first homoepitaxial layers, doped heteroepitaxial layers and doped second homoepitaxial layers, wherein the doped heteroepitaxial layers are positioned on the doped first homoepitaxial layers, and the doped second homoepitaxial layers are positioned on the doped heteroepitaxial layers. The invention also provides a method for manufacturing the transistor. The transistor epitaxially growing the source / drain region can effectively reduce the defects of stacking faults and recesses.

Owner:SEMICON MFG INT (SHANGHAI) CORP

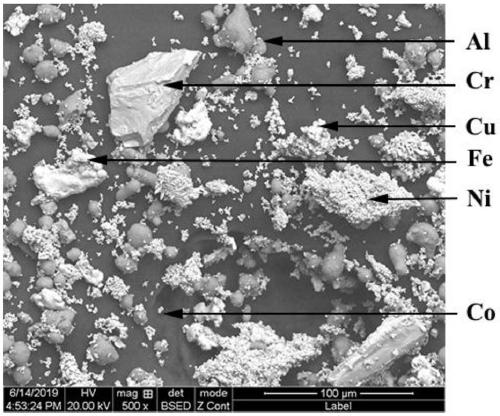

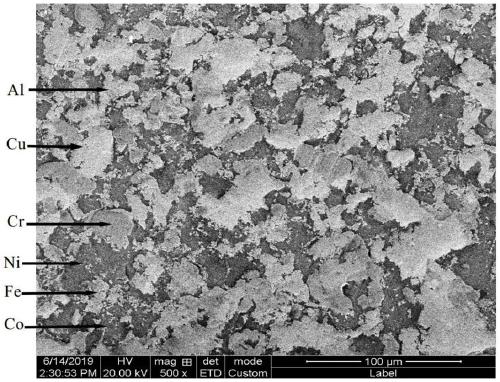

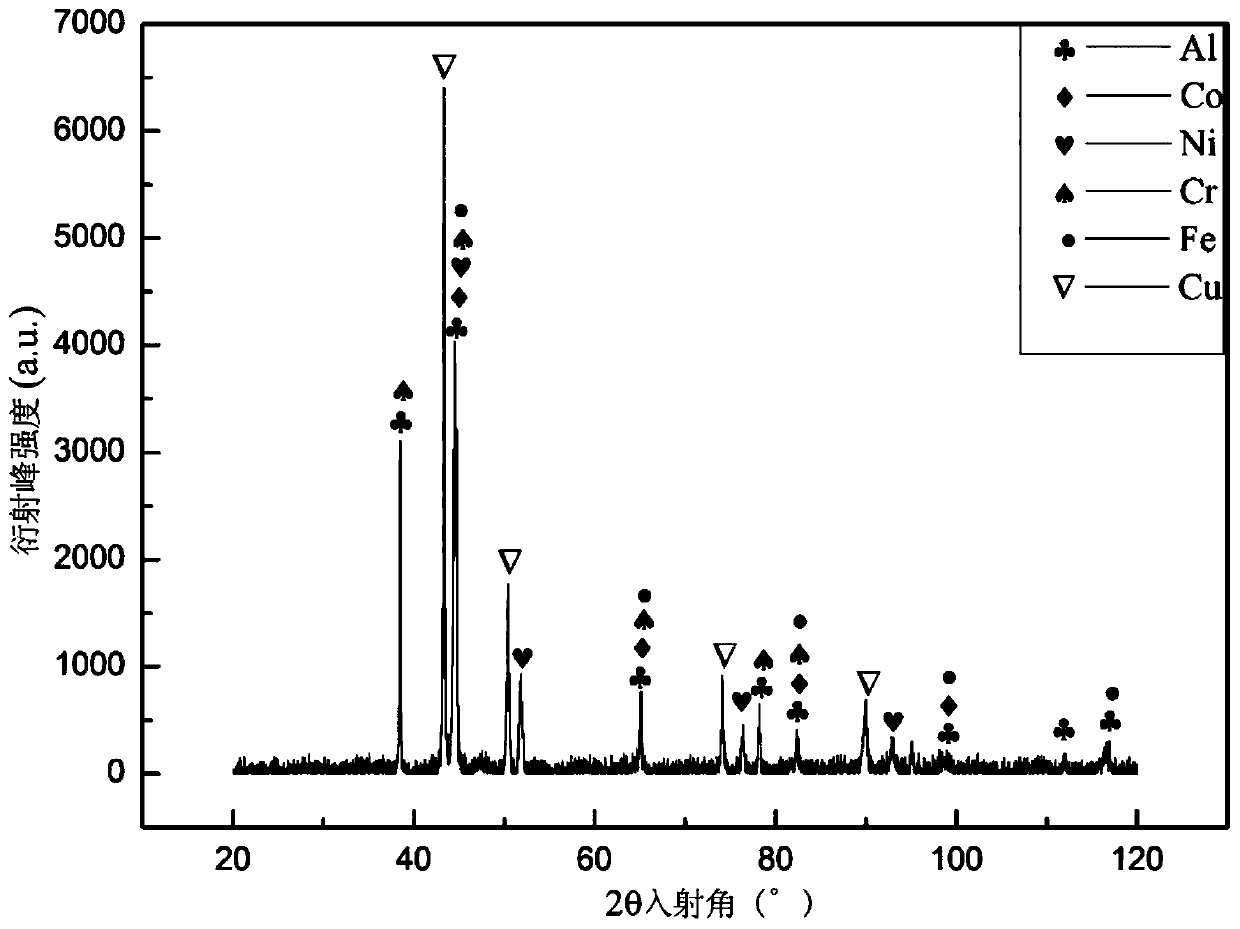

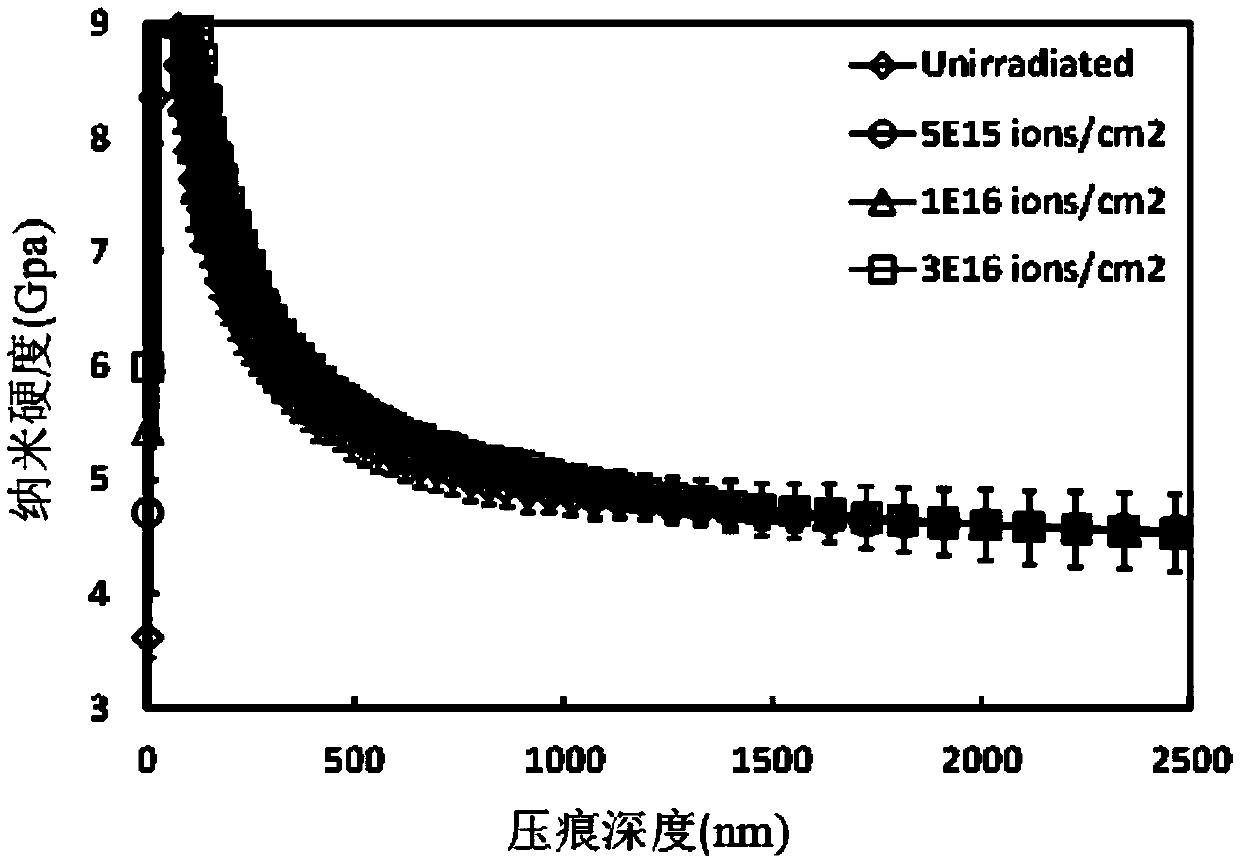

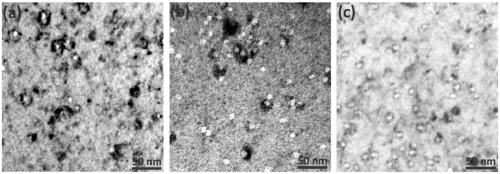

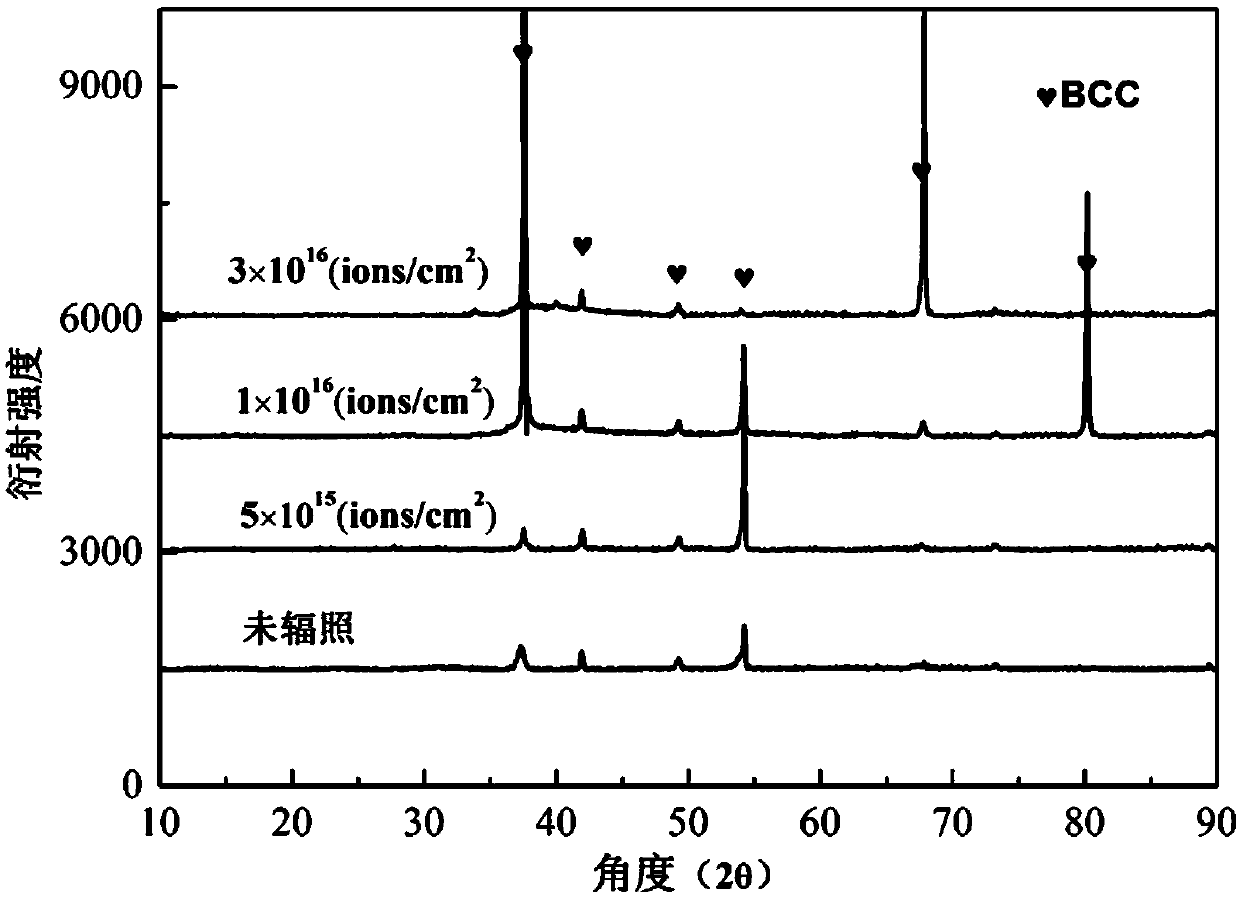

Preparation method of in-situ synthesis low-pressure cold spraying CuNiCoFeCrAl2.8 high-entropy alloy coating

The invention provides a preparation method of an in-situ synthesis low-pressure cold spraying CuNiCoFeCrAl2.8 high-entropy alloy coating. The method comprises the following steps that Cu powder, Ni powder, Co powder, Fe powder, Cr powder and Al powder are uniformly mixed to obtain powder for cold spraying, and then low-pressure cold spraying is carried out on the surface of a metal matrix so as to obtain a mixed powder coating, and then induction remelting in-situ synthesis is carried out to obtain the CuNiCoFeCrAl2.8 high-entropy alloy coating. According to the method, the low-pressure coldspraying technology is used, the cold spraying powder is subjected to low-pressure cold spraying on the matrix, the induction remelting in-situ synthesis is carried out, the CuNiCoFeCrAl2.8 high-entropy alloy coating is obtained, an alloying reaction is sufficient, the microstructure of a mixed powder coating forms a high-entropy alloy structure with a body-centered cubic structure from a pure metal in situ, the high-entropy alloy coating is formed, the structure is compact, the porosity is low, the high-entropy alloy structure is stable in structure, few in impurities, excellent in mechanicalperformance, high in strength and high in hardness, and good in wear resistance and corrosion resistance; and the thickness of the CuNiCoFeCrAl2.8 high-entropy alloy coating is 100 microns-3 millimeter, the preparation equipment is simple, and the process is convenient.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Irradiation-resistant high-entropy alloy and preparation method thereof

ActiveCN109666811AImprove high temperature performanceImprove corrosion resistanceOptical rangefindersNuclear energy generationHigh entropy alloysVolumetric Mass Density

The invention provides irradiation-resistant high-entropy alloy and a preparation method thereof. The general formula of the irradiation-resistant high-entropy alloy is TiZrHfVMoTaxNby, wherein X is no more than 0.25 and no less than 0.05, y is no more than 0.5 and no less than 0.05, and x and y are molar ratio. The preparation method of the irradiation-resistant high-entropy alloy comprises the following steps: sequentially mixing Ti, Zr, Hf, V, Mo, Ta and Nb, and then adopting vacuum electromagnetic suspension induction smelting or vacuum electric arc melting to obtain the irradiation-resistant high-entropy alloy. The irradiation-resistant high-entropy alloy is excellent in performance; helium ion simulated irradiation does not generate irradiation hardening damage; on the condition thatthe helium bubble size and traditional alloy size is equivalent, the bubble density is far lower than the density of the traditional alloy, and the lattice constant after irradiation is reduced abnormally; the irradiation resistance of the irradiation-resistant high-entropy alloy is far better than that of the traditional alloy; the irradiation-resistant high-entropy alloy has excellent strengthand plasticity; the compression yield strength of the irradiation-resistant high-entropy alloy under the cast condition is as high as 1.1 Gpa, and the compression ratio and elongation exceed 50%.

Owner:DALIAN UNIV OF TECH

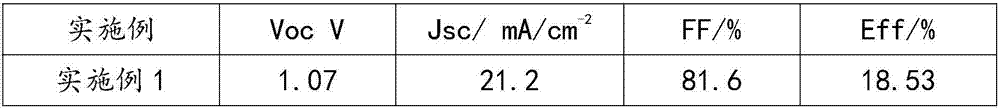

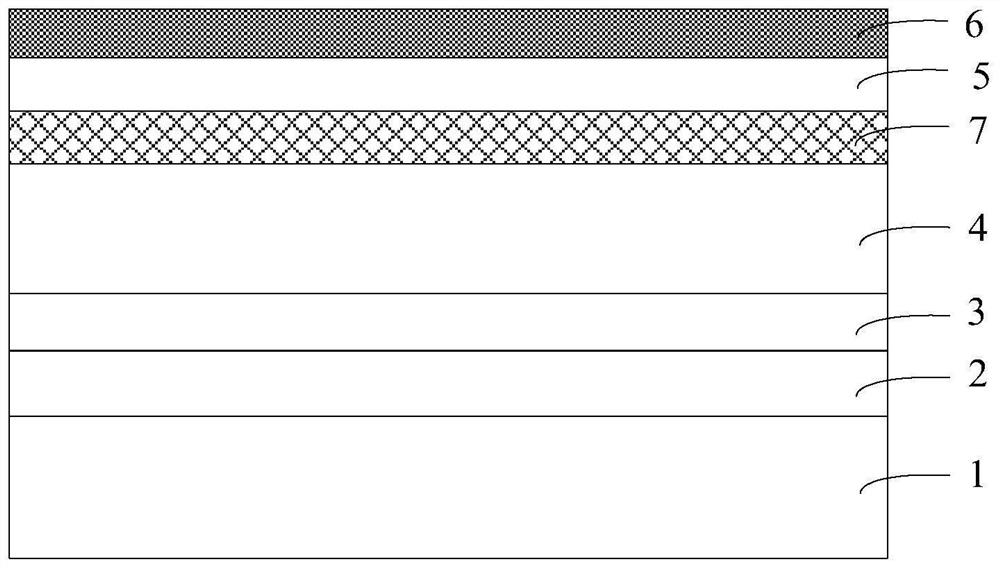

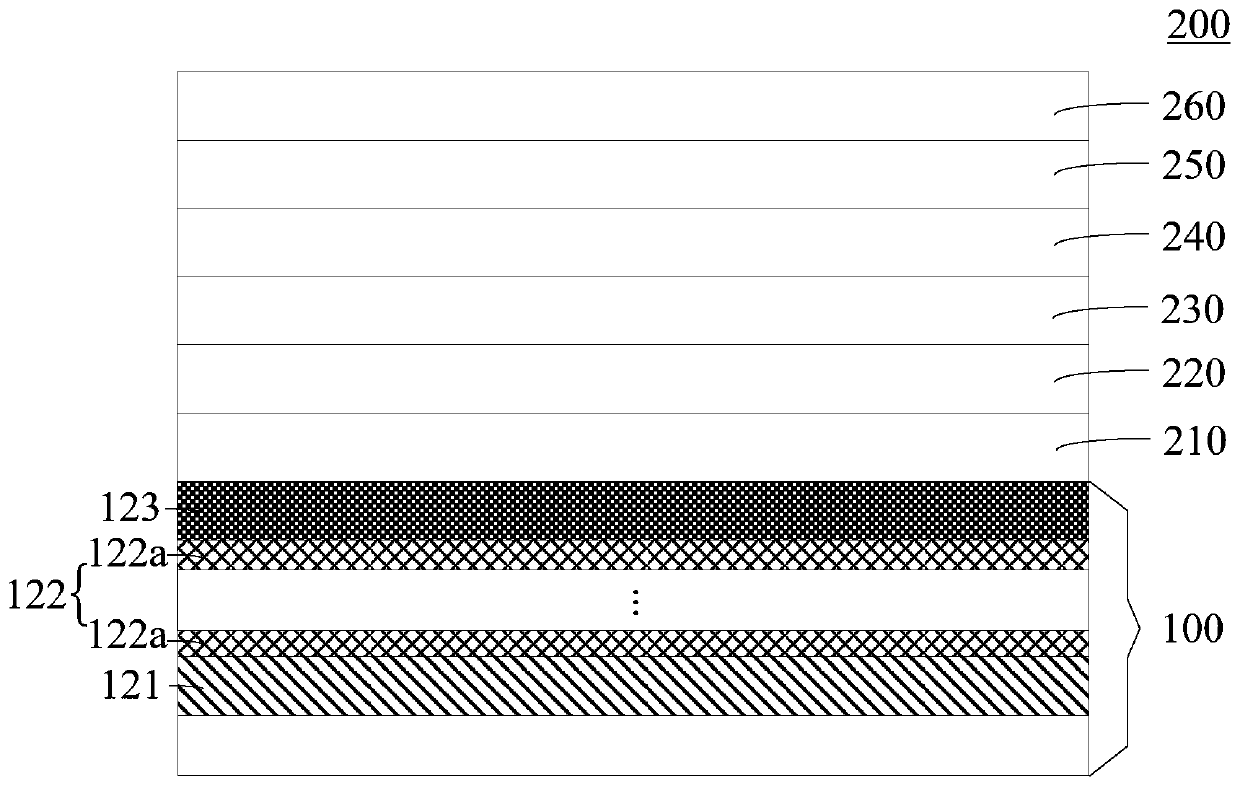

Perovskite solar cell and preparation method thereof

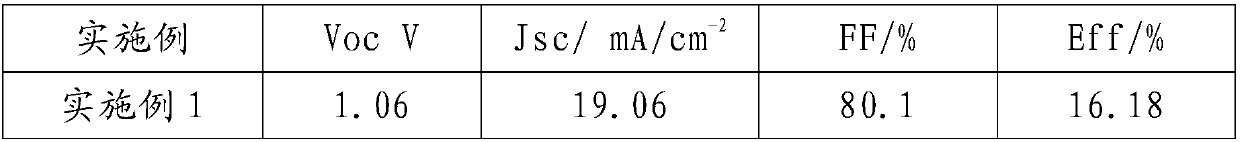

ActiveCN107482122AImprove conductivityIncrease the lattice constantSolid-state devicesSemiconductor/solid-state device manufacturingHysteresisPerovskite solar cell

The present invention belongs to the photovoltaic material field and relates to a perovskite solar cell and a preparation method thereof. The perovskite solar cell sequentially comprises a conductive glass substrate, a NiOx hole transporting layer, a perovskite absorption layer, an electron transport layer, a buffer layer and a metal electrode layer which are sequentially stacked from top to bottom, wherein each layer of the perovskite solar cell is made by means of a low-temperature solution method, and the NiOx hole transport layer is co-doped with Y3<+> and Mg<2+> / Cu<2+>. The preparation process of the perovskite solar cell of the present invention is simple; and the obtained perovskite solar cell has stable performance, small hysteresis effect and is suitable for industrialized production.

Owner:VALIANT CO LTD

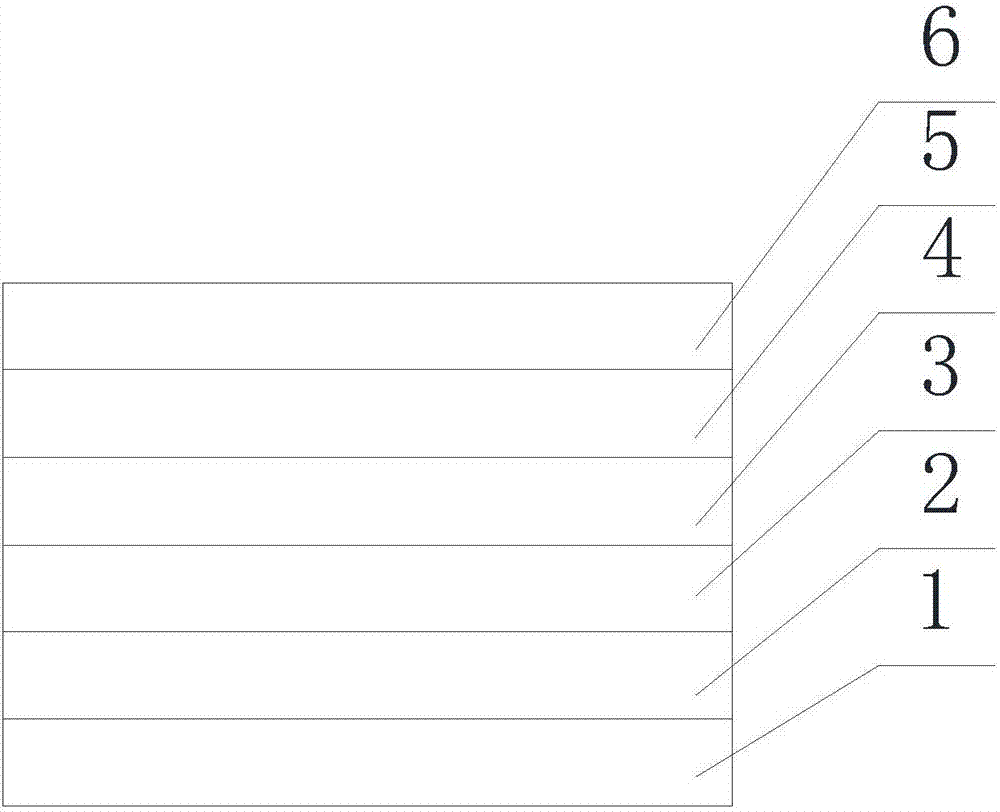

Gallium-nitride-based light emitting diode epitaxial wafer and manufacturing method thereof

ActiveCN108110098AIncrease the lattice constantReduced stress polarization effectsSemiconductor devicesQuantum wellLattice mismatch

The invention discloses a gallium-nitride-based light emitting diode epitaxial wafer and a manufacturing method thereof, belonging to the technical field of semiconductors. The gallium-nitride-based light emitting diode epitaxial wafer comprises a superlattice buffer layer, wherein the superlattice buffer layer is of a superlattice structure comprising N periods, and the superlattice structure ofeach period comprises a first sublayer, a second sublayer and a third sublayer which are laminated on a substrate. Through doping Al into the first sub-layer, the lattice mismatch between the substrate and a GaN layer can be alleviated, the defect density can be reduced, and the crystal quality of the entire epitaxial layer can be improved, thereby improving the anti-static capability of an LED. Through doping Mg into the second sublayer, a transition between the first sublayer and the second sublayer can be achieved. Through doping In into the third sublayer, the lattice constant of the thirdsublayer can be increased, thereby accelerating a stress release speed of an N-type layer, reducing the stress polarization effect of a multi-quantum well layer, and increasing the luminous efficiency of the LED.

Owner:HC SEMITEK ZHEJIANG CO LTD

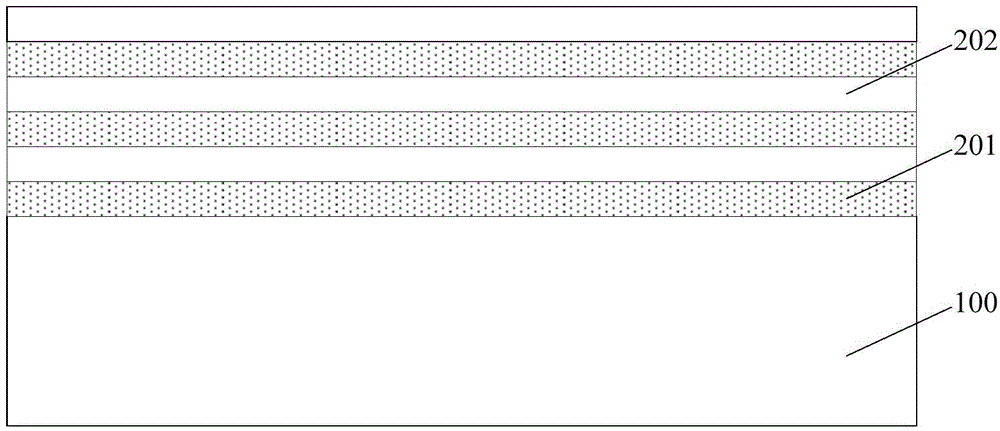

AlN template, preparation method of AlN template and semiconductor device on AlN template

ActiveCN105633233AIncrease the lattice constantThe lattice constant is close toSemiconductor devicesDevice materialSemiconductor technology

The invention discloses an AlN template, a preparation method of the AlN template and a semiconductor device on the AlN template, and belongs to the field of semiconductor technology. The AlN template comprises a substrate and an AlN thin film deposited on the substrate. The AlN thin film comprises a first AlN layer deposited on the substrate. The first AlN layer is mixed with oxygen. The content of the oxygen in the first AlN layer is gradually reduced from an interface of the first AlN layer and the substrate to the surface of the first AlN layer. The semiconductor device comprises the AlN template and a nitride semiconductor layer. The AlN template comprises the substrate and the AlN thin film deposited on the substrate. The nitride semiconductor layer is deposited on the AlN thin film. The AlN template is the aforesaid AlN template. The method comprises steps of providing the substrate; and depositing the AlN thin film on the substrate. The AlN thin film comprises a first AlN layer deposited on the substrate. The first AlN layer is mixed with oxygen. The content of the oxygen in the first AlN layer is gradually reduced from an interface of the first AlN layer and the substrate to the surface of the first AlN layer.

Owner:HC SEMITEK SUZHOU

Method for preparing rare-earth-doped manganese-zinc ferrite material

InactiveCN109553408AChanging grain boundary compositionChange ionic valencePolyvinyl alcoholRare earth

The invention relates to the technical field of magnetic materials, and discloses a method for preparing a rare-earth-doped manganese-zinc ferrite material, comprising the steps of adding manganese oxide, zinc oxide and iron oxide as main components to a ball mill and conducting ball milling to obtain a mixture A; pre-firing the mixture A, and then conducting cooling to room temperature to obtaina pre-fired material; adding the pre-sintered material, vanadium oxide, niobium oxide, bismuth trioxide, molybdenum oxide, phosphorus pentoxide, copper oxide and a composite rare earth additive into aball mill, and conducting secondary ball milling and drying to obtain a mixture B, wherein the composite rare earth additive is composed of cerium oxide, yttrium oxide and lanthanum oxide; adding a polyvinyl alcohol solution to the mixture B, conducting mixing and granulation, and then conducting sieving by a sieve of 40-80 mesh, so as to obtain pellets; adding the pellets into a molding machinefor pressing, so as to obtain a blank; and sintering the blank and conducting cooling. The rare-earth-doped manganese-zinc ferrite material prepared by the method of the invention has high initial magnetic conductivity and saturation magnetic flux density.

Owner:ZHONGDE ELECTRONICS

Perovskite solar cell and preparation method thereof

ActiveCN107565023AIncrease the lattice constantImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingHysteresisPerovskite solar cell

The invention belongs to the field of photovoltaic materials and particularly relates to a perovskite solar cell and a preparation method thereof. The perovskite solar cell sequentially comprises a conductive glass substrate, a NiOx hole transport layer, a perovskite absorption layer, an electron transport layer, a buffer layer and a metal electrode layer which are sequentially stacked from bottomto top; and various layers in the perovskite solar cell all are prepared by adopting a low-temperature solution method, wherein the NiOx hole transport layer is doped with Y<3+>, Ni<+> and Li<+>. Thepreparation process is simple, and the obtained perovskite solar cell is stable in performance, small in hysteresis effect and suitable for industrial production.

Owner:VALIANT CO LTD

Nickel-based powder superalloy with high tensile strength

The invention discloses nickel-based powder superalloy with high tensile strength and belongs to the technical field of powder superalloy. The nickel-based powder superalloy comprises the following chemical components by mass percent: 0.03-0.07% of C, 16.0-17.5% of Co, 8.5-10.5% of Cr, 5.8-6.2% of W, 4.0-4.5% of Mo, 4.8-5.3% of Al, 1.6-2.0% of Ti, 2.4-2.8% of Nb, 0.1-0.4% of Hf, less than 0.02% of B, less than 0.02% of Zr, less than 0.01% of Mg, less than 0.01% of Ce and the balance of Ni. The nickel-based powder superalloy has the advantages that the tensile strength and high temperature lasting life of the nickel-based powder superalloy are superior to those of FGH97 alloy.

Owner:BEIJING CISRI GAONA TECH

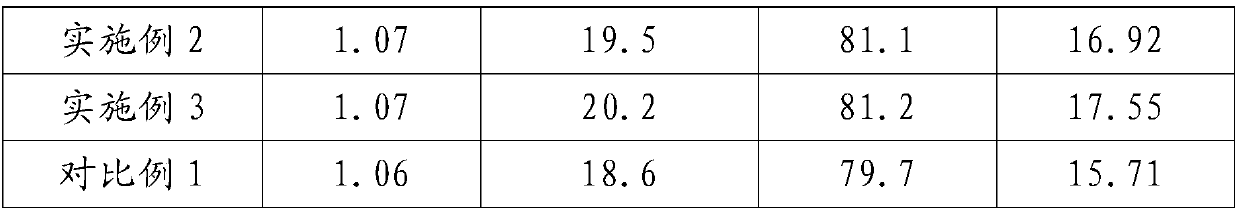

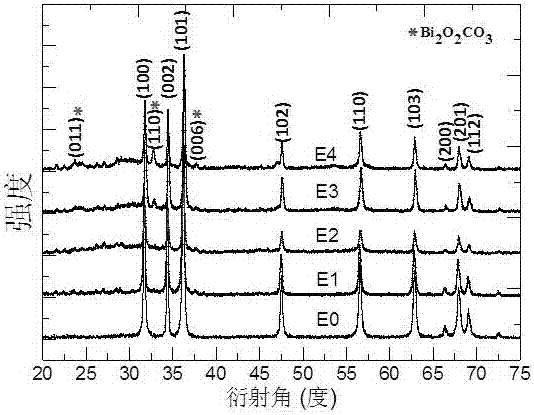

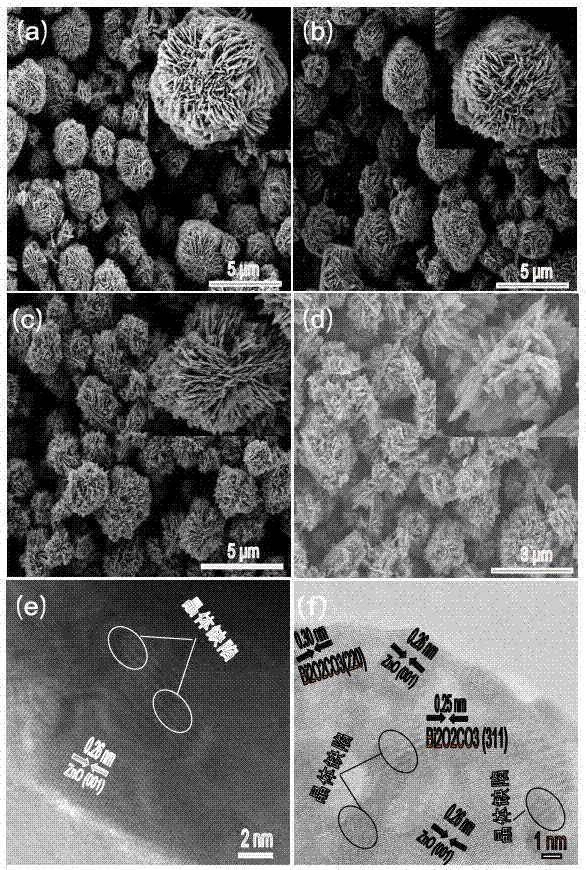

Bismuth-doped spherical zinc oxide gas sensing material and preparation method thereof

InactiveCN107572579AIncrease the lattice constantEasy transitionMaterial nanotechnologyZinc oxides/hydroxidesIonZinc Acetate Dihydrate

The invention discloses a bismuth-doped spherical zinc oxide gas sensing material and a preparation method thereof. The zinc oxide gas sensing material contains bismuth and zinc oxide, wherein bismuthis doped into a zinc oxide lattice in a doping mole ratio of (1-5.5) to 100. The preparation method comprises the following steps: (1) adding zinc acetate, sodium citrate and bismuth citrate into deionized water, and magnetically stirring for 20 minutes or longer until zinc acetate is completely dissolved into a solution; (2) slowly pouring a sodium hydroxide solution into the solution, and magnetically stirring for 30 minutes or longer; (3) transferring the solution into a reaction kettle, heating to 120-160 DEG C, maintaining the temperature for 10-30 hours, and after the reaction is finished, cooling to room temperature; and (4) carrying out solid-liquid separation on the obtained product, drying, and grinding, so as to obtain bismuth-doped spherical zinc oxide powder. The preparationmethod has the advantage that the gas sensing performance of the material is improved.

Owner:CHONGQING TECH & BUSINESS UNIV

Rare-earth type lithium iron phosphate serving as cathode material of lithium secondary battery and preparation method thereof

The invention relates to rare-earth type lithium iron phosphate serving as the cathode material of a lithium secondary battery and a preparation method thereof. The rare-earth type lithium iron phosphate contains 100 mole fractions of lithium iron phosphate, 3.9-7.8 mole fractions of rare-earth alloy and 1.1-2.2 mole fractions of cellulose acetate. The preparation method of the rare-earth type lithium iron phosphate comprises the following steps of: putting an iron source compound, a lithium source compound, a phosphorus source compound and a rare-earth material into a powder mixer for powder mixing; in the powder mixing process, gradually spraying cellulose acetate dissolved in acetone to the mixed powder so that cellulose acetate is uniformly stuck on the mixture particles of the four materials, and drying; pre-sintering the dried mixture particles in an atmosphere furnace under inert gas protection; and carrying out heat preservation on the pre-sintered powder in the atmosphere furnace under inert gas protection to obtain the rare-earth type lithium iron phosphate. The rare-earth type lithium iron phosphate provided by the invention has the advantages of good conductive performance, relatively short preparation time and the like.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Aluminum based alloy

An aluminum alloy comprising Al, Sc, Gd, Zr, and optionally Mg. The aluminum alloy is strengthened by an aluminum solid solution matrix and a dispersion of Al3X precipitate having an L12 structure where X comprises Sc, Gd and Zr. Mg is a preferred addition to the alloy containing Gd and Zr. The alloying additions control strengthening and coarsening kinetics of the alloy through control of diffusivity in the aluminum matrix and coherency strain of the Al3X precipitate.

Owner:RAYTHEON TECH CORP

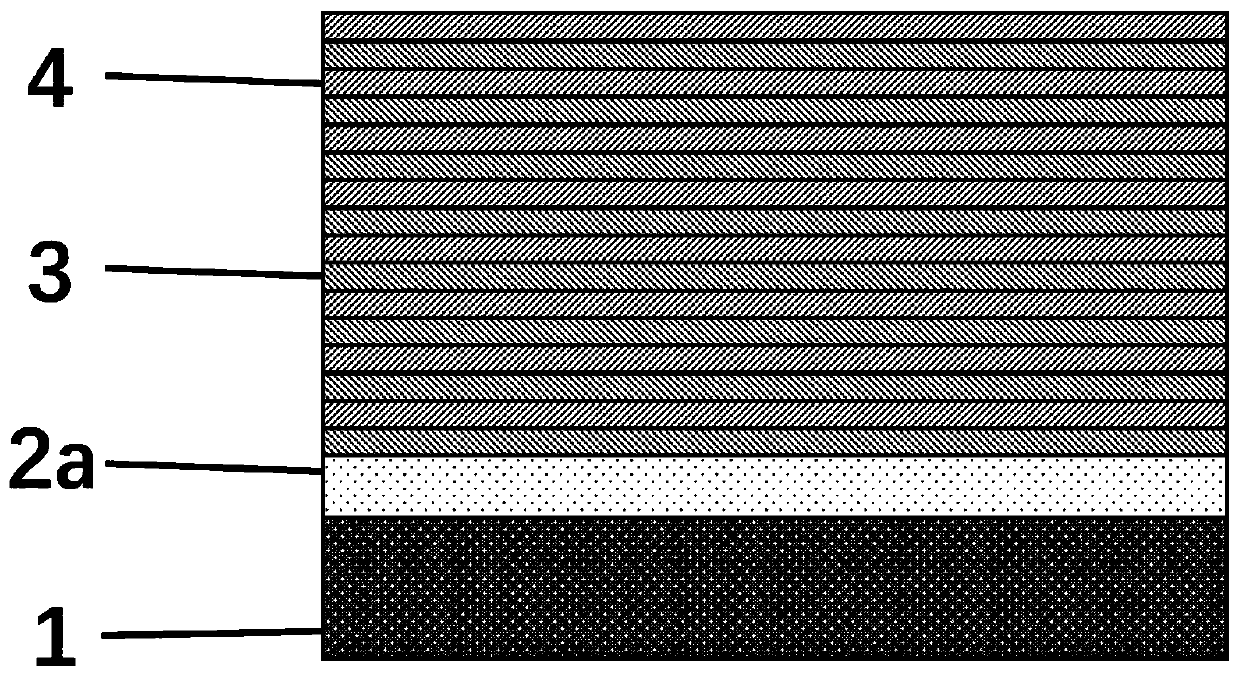

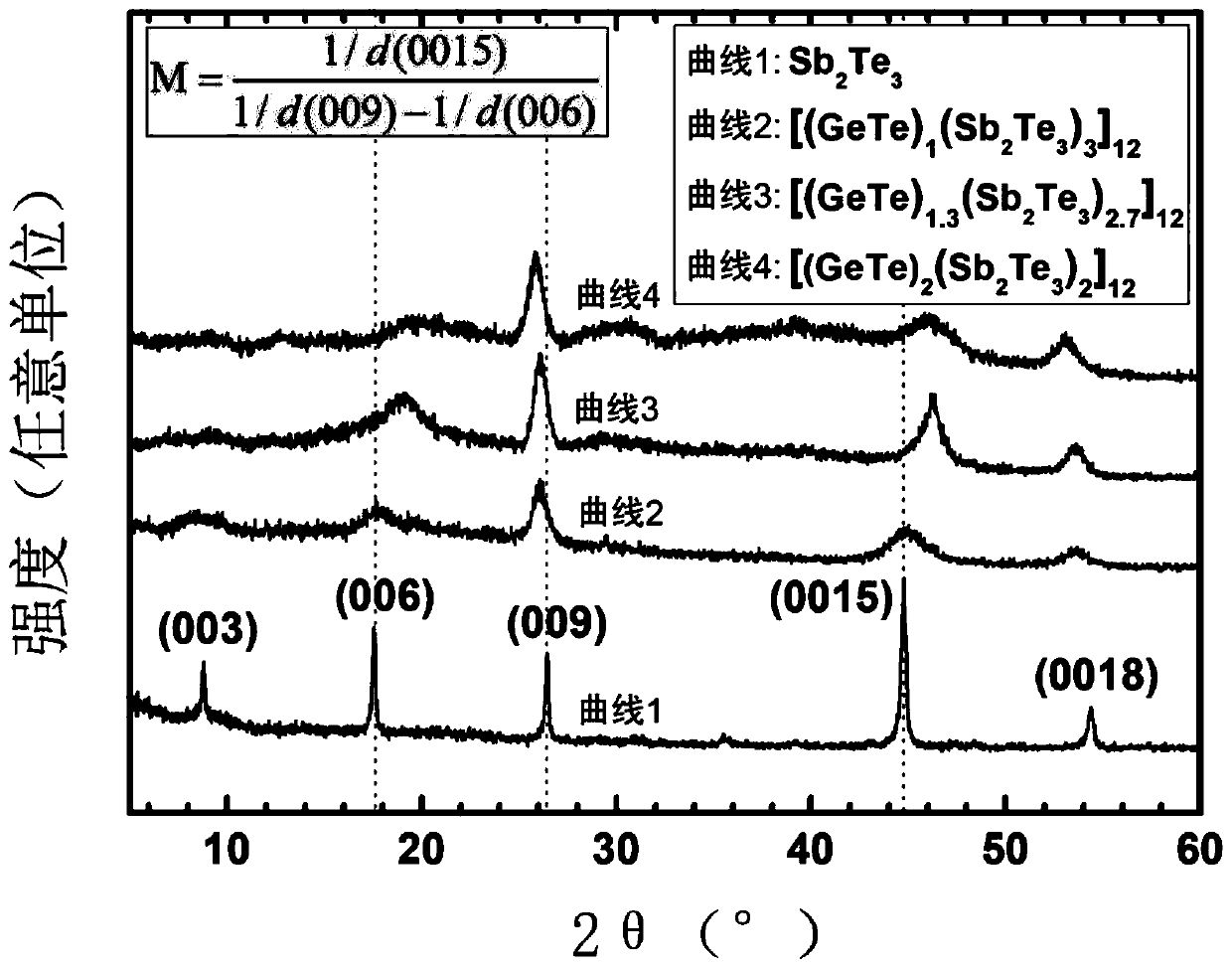

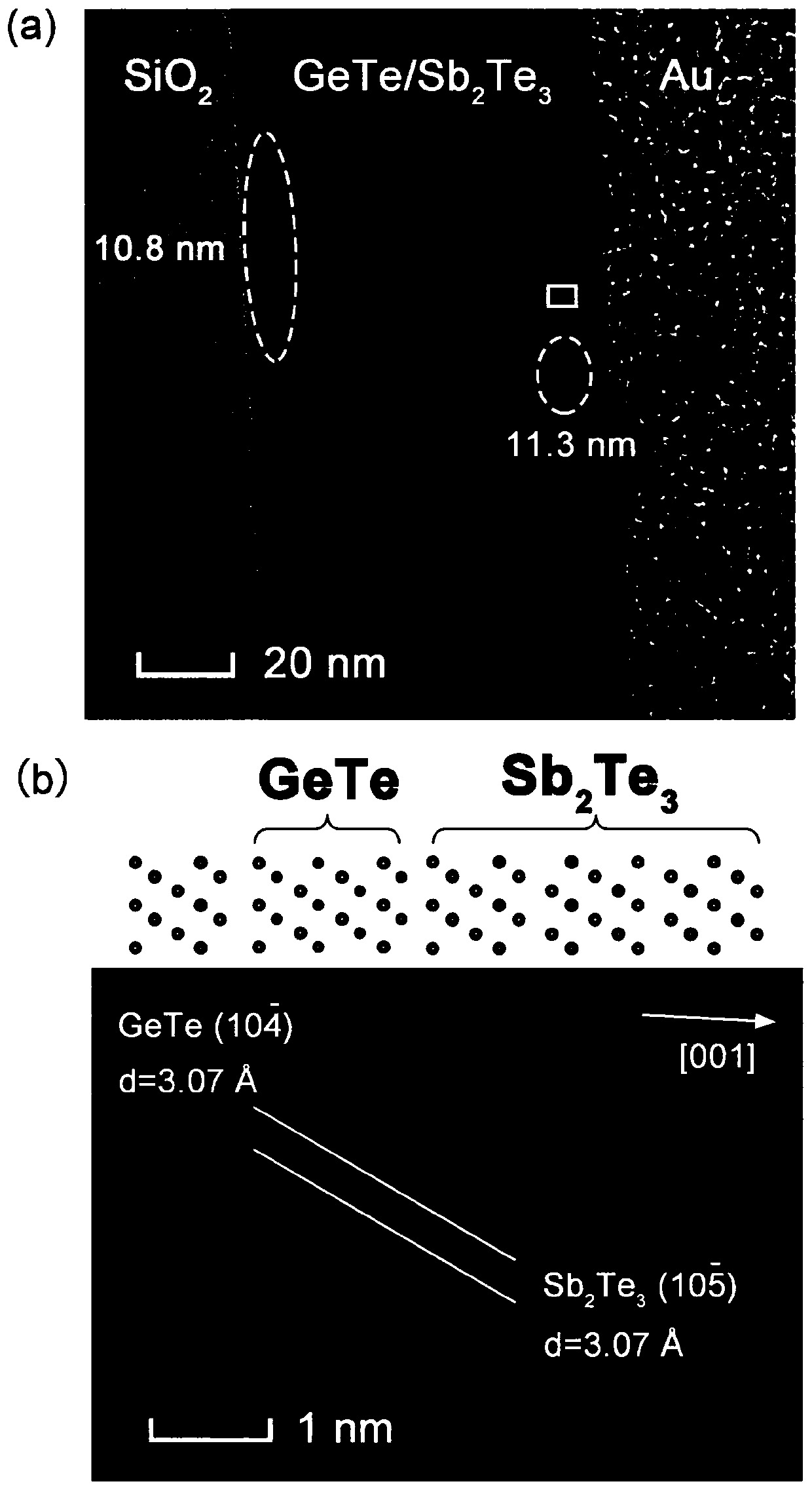

Method for regulating vacancy defect of material

ActiveCN109935685AStress regulationRegulating the concentration of vacancy defectsElectrical apparatusVacancy defectPhase-change memory

The invention discloses a method for regulating a vacancy defect of a material. The method, by inserting a stress applying material into a phase change functional material, regulates the vacancy defect concentration in the phase change functional material, and thus obtains a composite structure formed by the embedded growth of the phase change functional material and the stress applying material.The phase change property of the composite structure is mainly determined by the phase change functional material therein. By the regulation of the stress applying material, the phase change propertyof the composite structure varies on the basis of the phase change property of the phase change functional material crystal obtained by the pure phase change functional material, and the stress application material is specifically a material capable of forming a crystalline state. In particular by inserting the stress applying material having a slightly larger lattice constant into the phase change functional material having a slightly smaller lattice constant, the method can reduce the vacancy defect concentration of the phase change memory material, thereby lowering the threshold of the crystallization process and increasing the crystallization speed.

Owner:HUAZHONG UNIV OF SCI & TECH

Semiconductor structure and forming method thereof

ActiveCN105870183AImprove performanceUniform thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesNanowireElectrical conductor

A semiconductor structure and a method for forming the same, the method for forming the semiconductor structure includes: providing a substrate; sequentially forming a stack structure on the surface of the substrate, the stack structure including several sacrificial layers and several first semiconductor layers, the The surface of the substrate is a sacrificial layer, and the sacrificial layer and the first semiconductor layer are sequentially overlapped; the stacked structure is etched to form a groove on the surface of the substrate, and the first semiconductor line and the sacrificial layer on both sides of the groove line; remove the sacrificial line, so that the first semiconductor line is suspended above the substrate; perform annealing treatment on the first semiconductor line, so that the cross-section of the first semiconductor line is circular; adopt the epitaxial process, in the A second semiconductor layer is formed on the surface of the first semiconductor wire, and the carrier mobility of the second semiconductor layer is greater than that of the first semiconductor nanowire. The method can improve the performance of a gate-all-around field effect transistor formed on the first semiconductor nanowire.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Semiconductor device and method for improving semiconductor device performance

ActiveCN106847698AImprove performanceImprove mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceCharge carrier mobility

The invention discloses a semiconductor device and a method for improving semiconductor device performance. The method for improving semiconductor device performance comprises the following steps: an amorphousizing ion implantation is carried out on substrates on both sides of a gate structure to form amorphous layers, wherein the amorphous layers comprise first amorphous layers, second amorphous layers and third amorphous layers, and the first amorphous layers are located within a portion of the substrates below the gate structure; the second amorphous layers and the substrates with a second thickness located below the second amorphous layers are removed by etching, first grooves are formed in the amorphous layers, and second grooves and third grooves penetrating each other are formed below the first grooves; the third grooves are filled with an organic material layer; sidewalls of the second grooves are etched to form sigma-shaped dips; and the first grooves, the second grooves with the sigma-shaped dips and the third grooves are filled with a stress layer. According to the invention, the stress in the channel region is increased, the carrier mobility of the semiconductor device is improved and the electrical performance of the semiconductor device is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

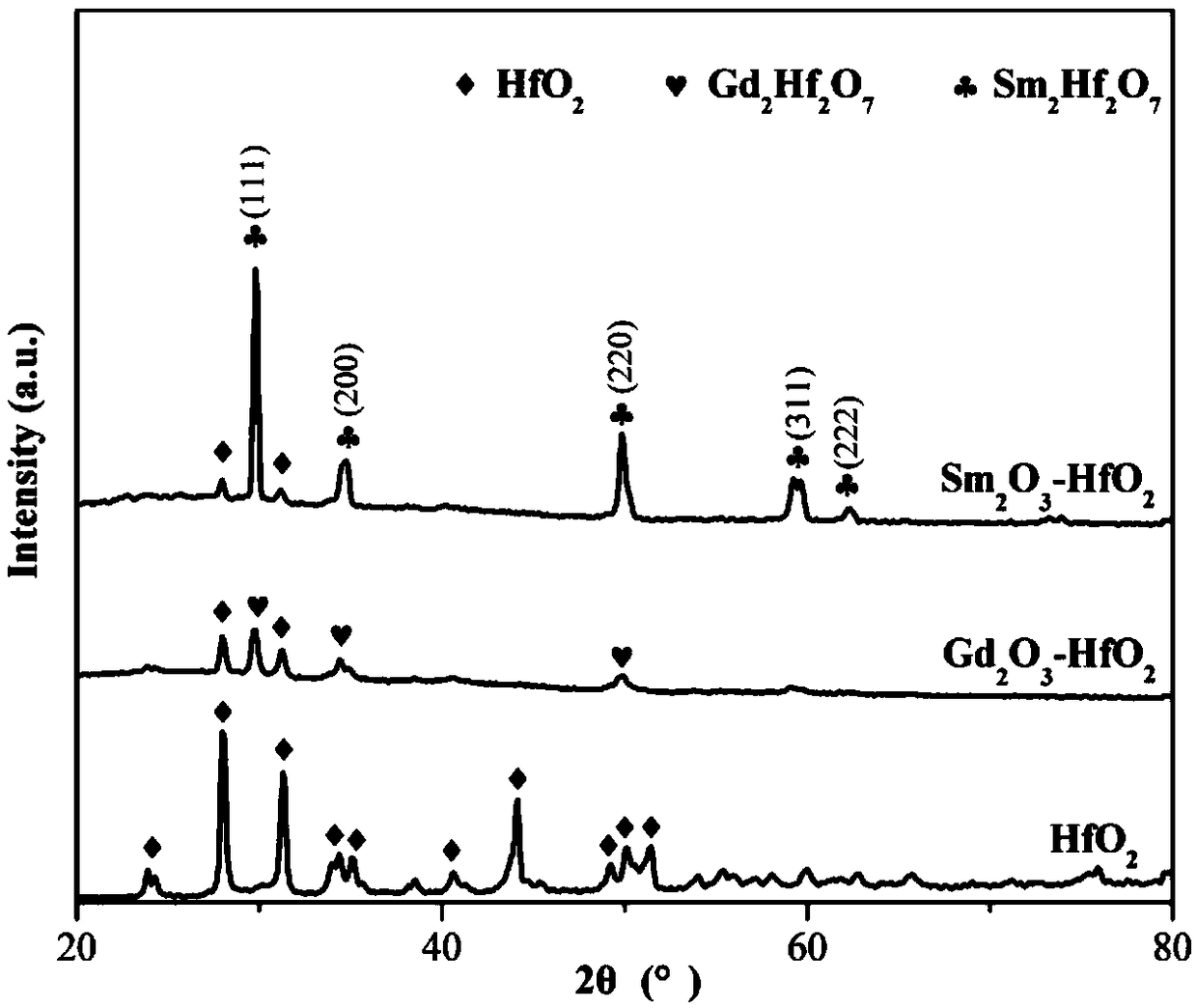

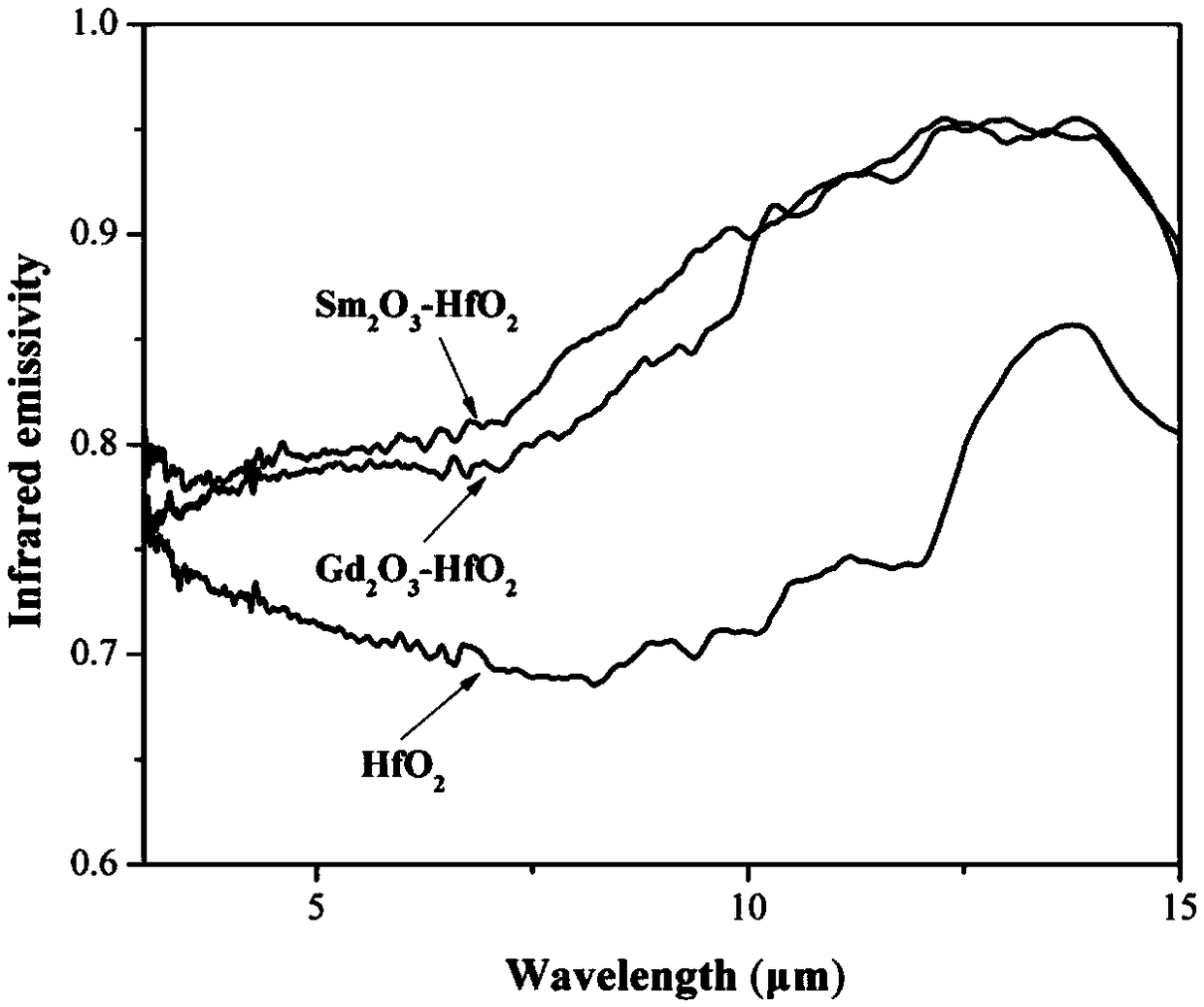

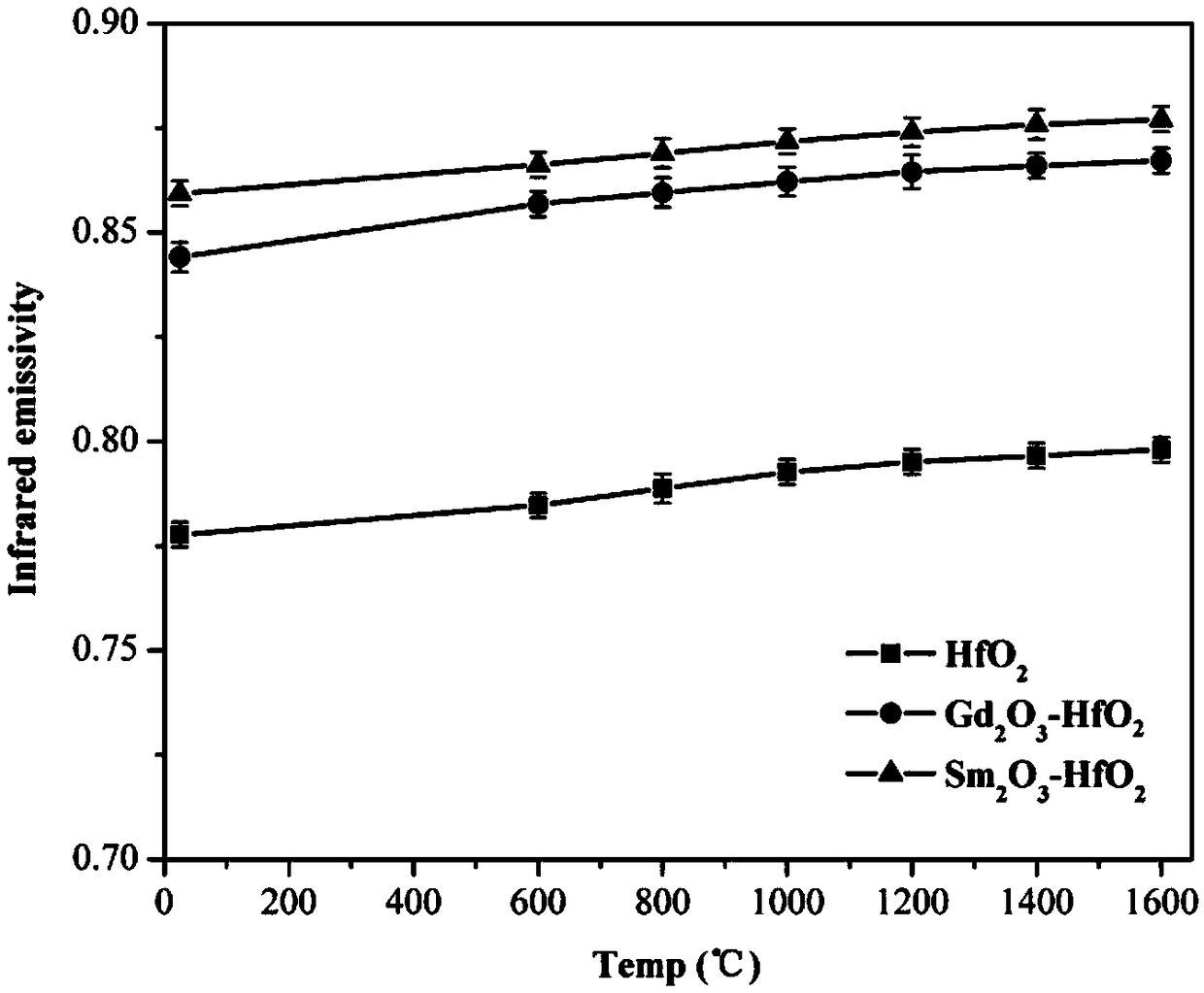

High-temperature and high-emissivity hafnium oxide base infrared radiating coating and preparing method thereof

The invention discloses a high-temperature and high-emissivity hafnium oxide base infrared radiating coating. According to the high-temperature and high-emissivity hafnium oxide base infrared radiating coating, HfO2 powder and rare earth oxide powder serve as main raw materials, water and a binding agent are added in the HfO2 powder and the rare earth oxide powder to prepare uniform slurry, and then the high-temperature and high-emissivity hafnium oxide base infrared radiating coating is formed sequentially through spray granulation, high-temperature roasting and heat spraying. According to the high-temperature and high-emissivity hafnium oxide base infrared radiating coating, compounding of HfO2 powder and Gd2O3 or Sm2O3 and other rare earth oxide is provided for the first time, the heatspraying technology is combined, the full-wave band normal integral emissivity of the obtained high infrared radiating coating at the normal temperature can reach 0.85 or above, the slow ascending tendency is achieved along with increasing of the high temperature, and good high temperature resisting performance and full-wave band infrared radiation performance can be combined; and the related preparing technology is simple, the synthesis time is short, energy consumption is low, and important study and popularization value is achieved.

Owner:WUHAN UNIV OF TECH

Soft magnetic material and preparation method thereof

InactiveCN103515043AImprove communication distanceImpede movementInorganic material magnetismSuperexchangeOctahedron

The invention provides a soft magnetic material which is large in magnetic conductivity and low in magnetic loss and a preparation method thereof. The soft magnetic material comprises main components, auxiliary components and a sintering aid, wherein the main components relate to Fe2O3, NiO, ZnO and CuO, and the auxiliary components relate to Gd2O3 and B2O3; with the total molar weight of the soft magnetic material as the basic standard, the content of the Fe2O3 is 46-53mol%, the content of the NiO is 11-19mol%, the content of the ZnO is 22-27mol%, the content of the CuO is 6-11mol%, the content of the Gd2O3 is 0.1-1mol%, the content of the B2O3 is 0.1-2mol%, and the content of the sintering aid is 0.4-2mol%. According to the soft magnetic material and the preparation method thereof, the magnetic performance of products is improved, the products can have higher magnetic conductivity and low magnetic loss under the 13.56MHz condition, and then the communication distance of an NFC system of a mobile phone is improved; the Gd2O3 can increase the lattice constant, prevent domain wall movement, reduce superexchange interaction between ions on the A phase of a tetrahedron and ions on the B phase of an octahedron, improve cut-off frequency and reduce the magnetic loss, the B2O3 can form liquid-phase sintering, promote grain growth, make tissue compacter, and reduce internal and external air hole rates of a grain, and coercivity can be reduced and initial magnetic conductivity can be improved if a proper amount of B2O3 is added.

Owner:BYD CO LTD

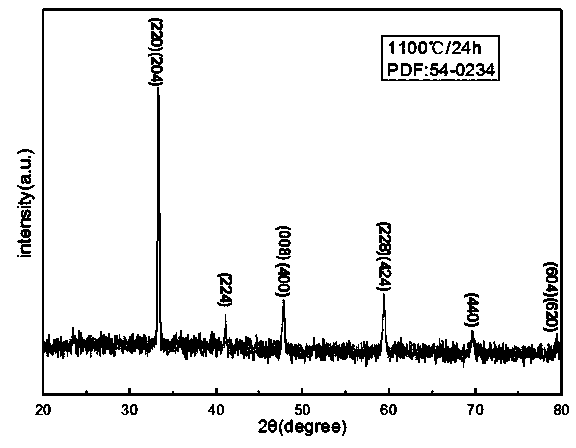

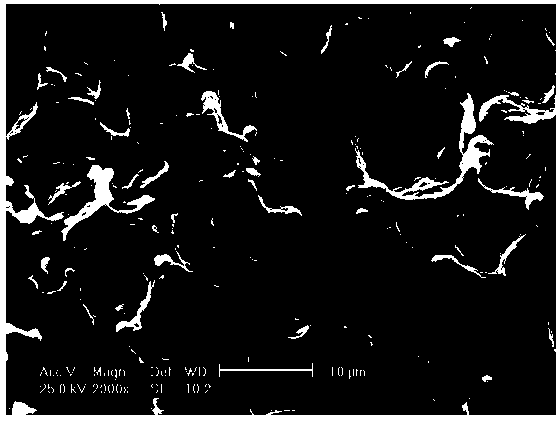

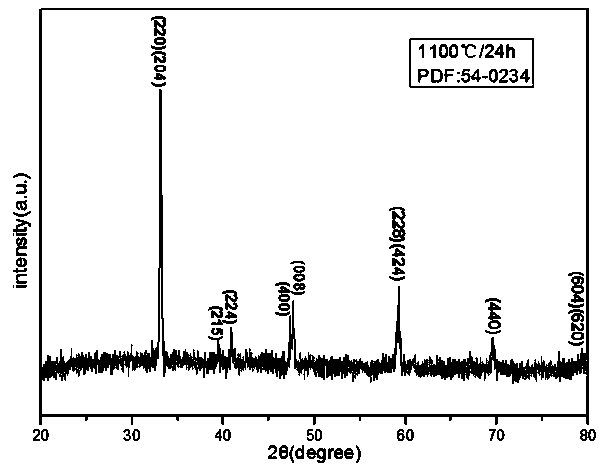

Preparation method of porous ceramics

The invention discloses a preparation method of porous ceramics. The method is realized through the following technical scheme: SrCO3, Y2O3, Co3O4 and CuO are adopted as raw materials, the raw materials are calculated and measured in a molar ratio of Sr: Y: Co: Cu of 3: 1: (4-x): x, and the raw materials are mixed, ground, tabletted and sintered to obtain the Sr3YCo[4-x]CuxO10.5 porous ceramic material, wherein when x is equal to 0 to 0.4, the synthesized Sr3YCo[4-x]CuxO10.5 is a single phase. By utilizing the method, under the situation that the Sr3YCo[4-x]CuxO10.5 is determined as a single phase, the porous structure can be varied regularly. The method is simple and easy and low in cost.

Owner:KUNMING UNIV OF SCI & TECH

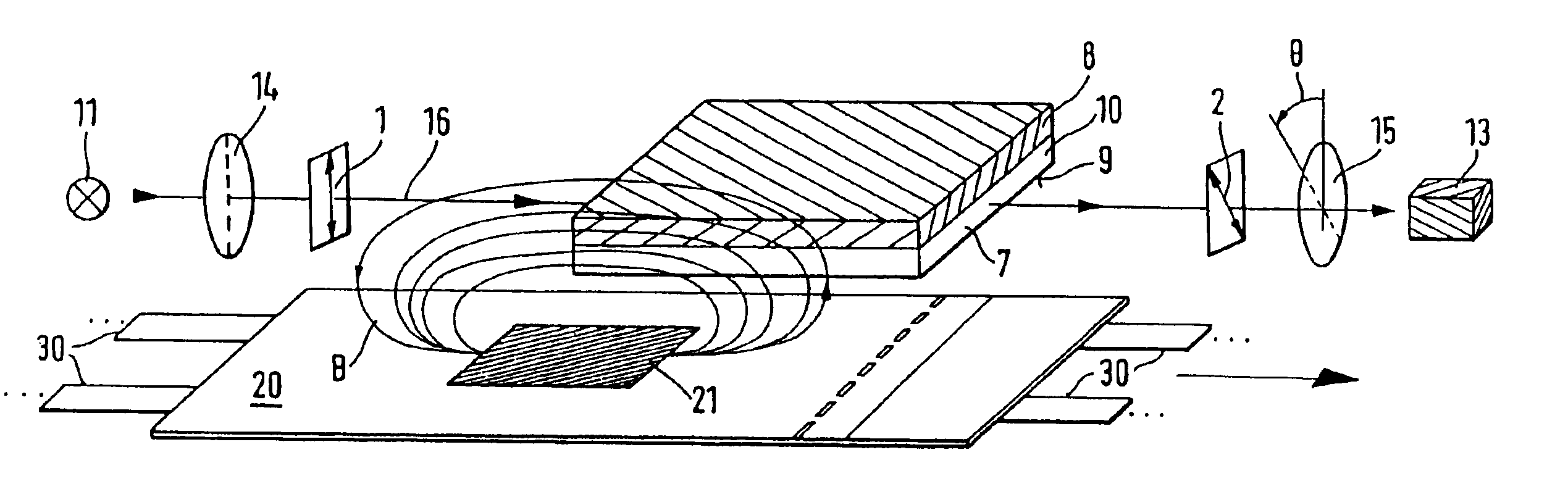

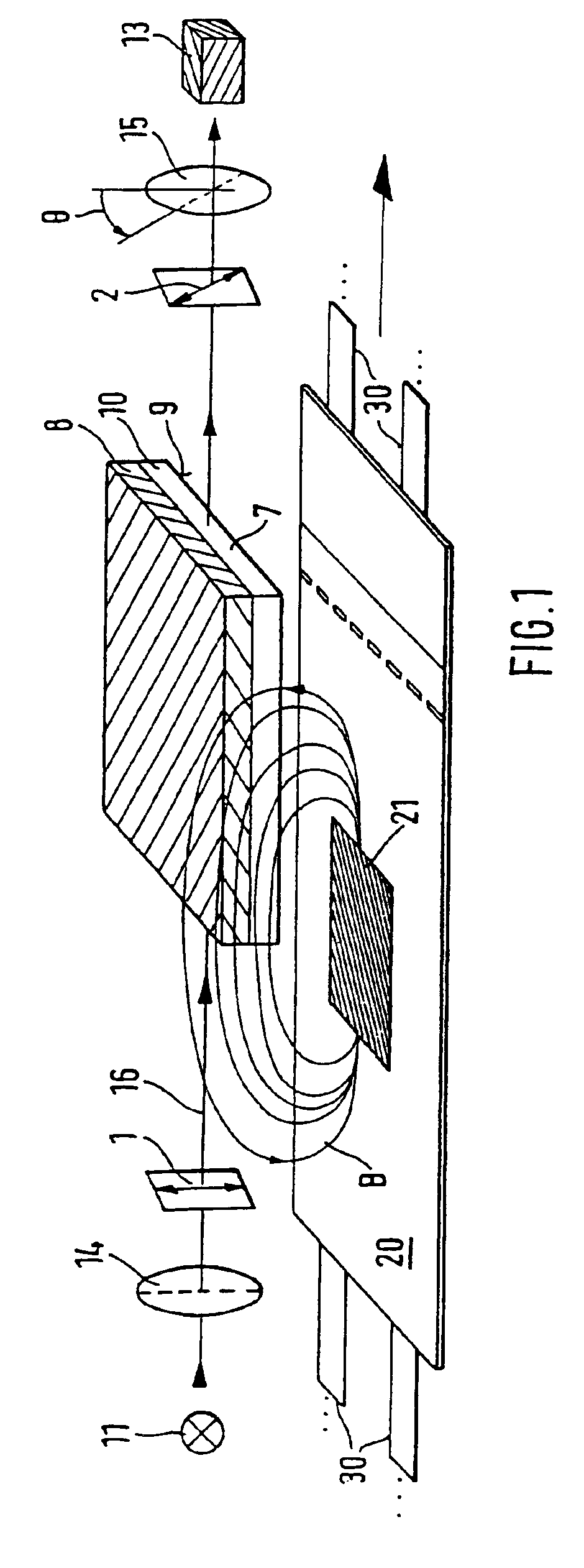

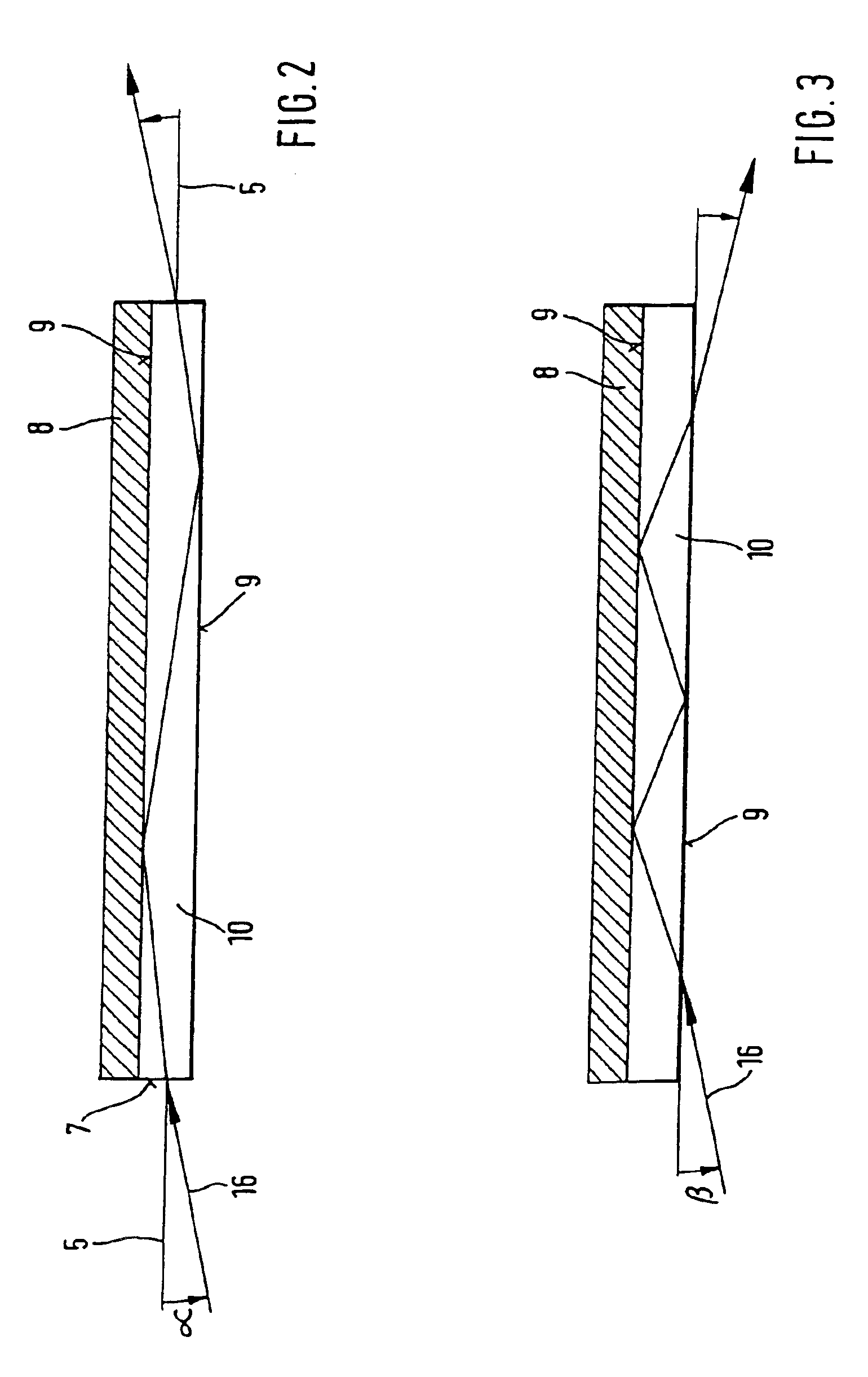

Apparatus for examining properties of objects

InactiveUS6927571B2High sensitivityIncrease changePaper-money testing devicesMagnetic field measurement using magneto-optic devicesOptical propertyOptic layer

The invention relates to apparatus for examining magnetic properties of objects, in particular sheet material, such as bank notes (20). The apparatus comprises a magneto-optic layer (10) whose optical properties are influenceable by the magnetic properties of the sheet material (20), a light source (11) for producing light that is coupled into the magneto-optic layer (10), and a detector (13) for detecting light that is transmitted and / or reflected by the magneto-optic layer (10). For reliable examination of the magnetic properties of sheet material it is provided that the direction of propagation of the coupled-in light extends parallel to a base surface (9) of the magneto-optic layer (10). The invention permits the magnetic properties in particular of sheet material with areas emitting very weak magnetic fields to be examined with very high sensitivity and reliability.

Owner:GIESECKE & DEVRIENT GMBH

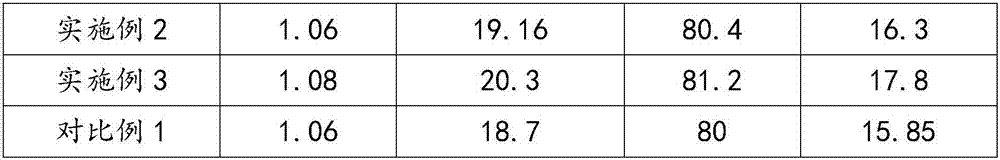

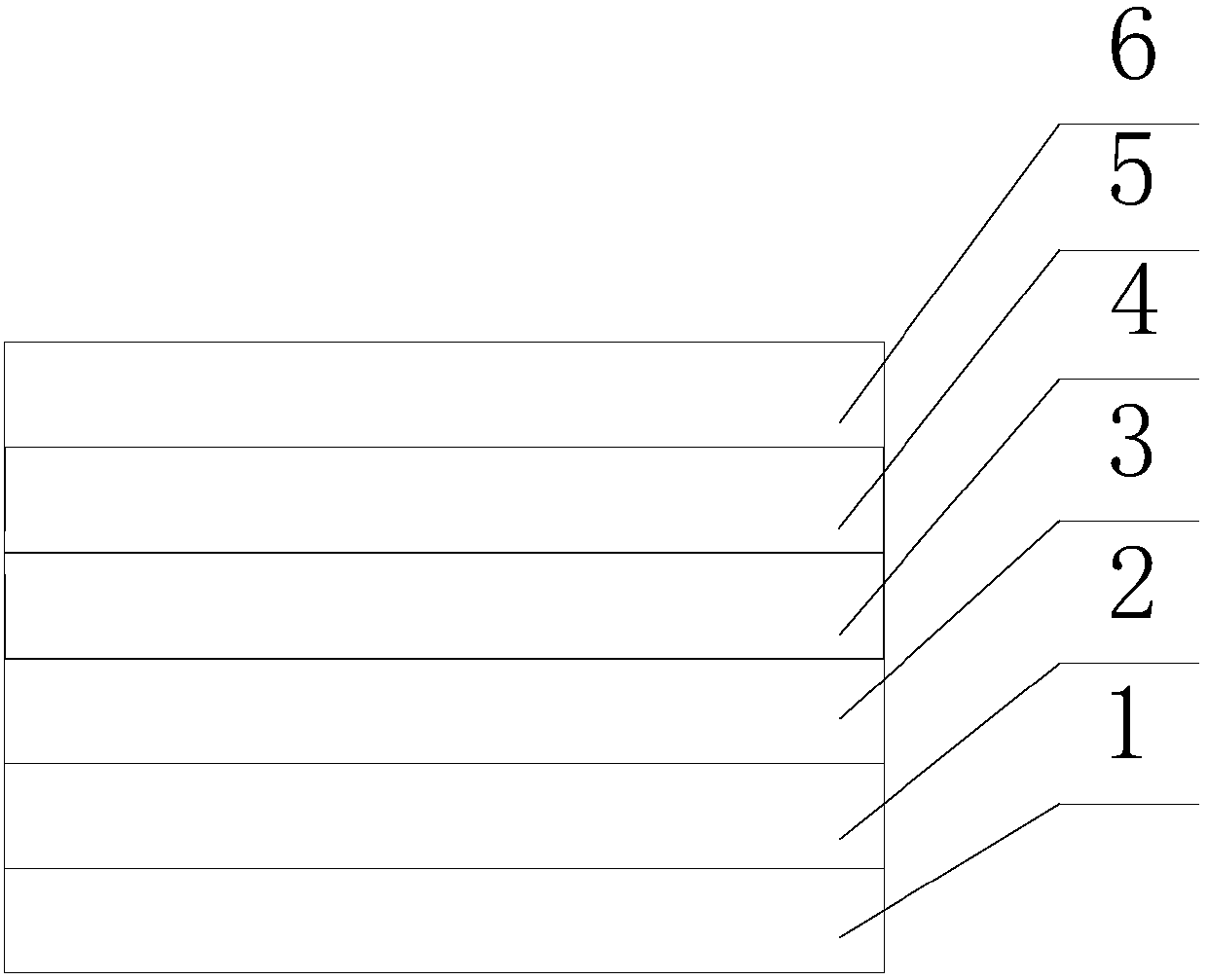

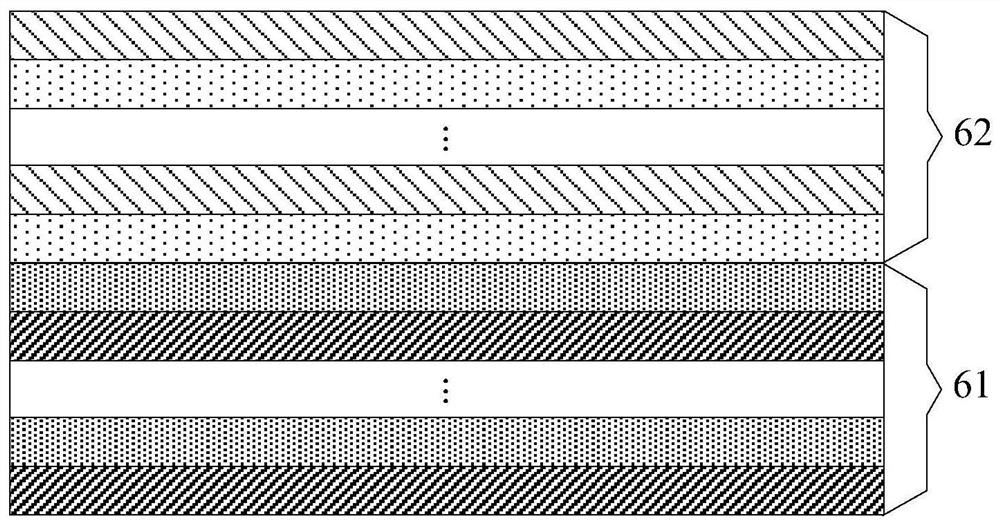

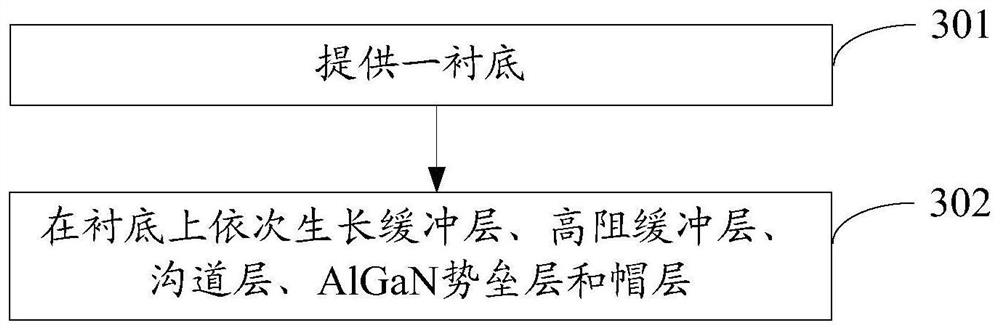

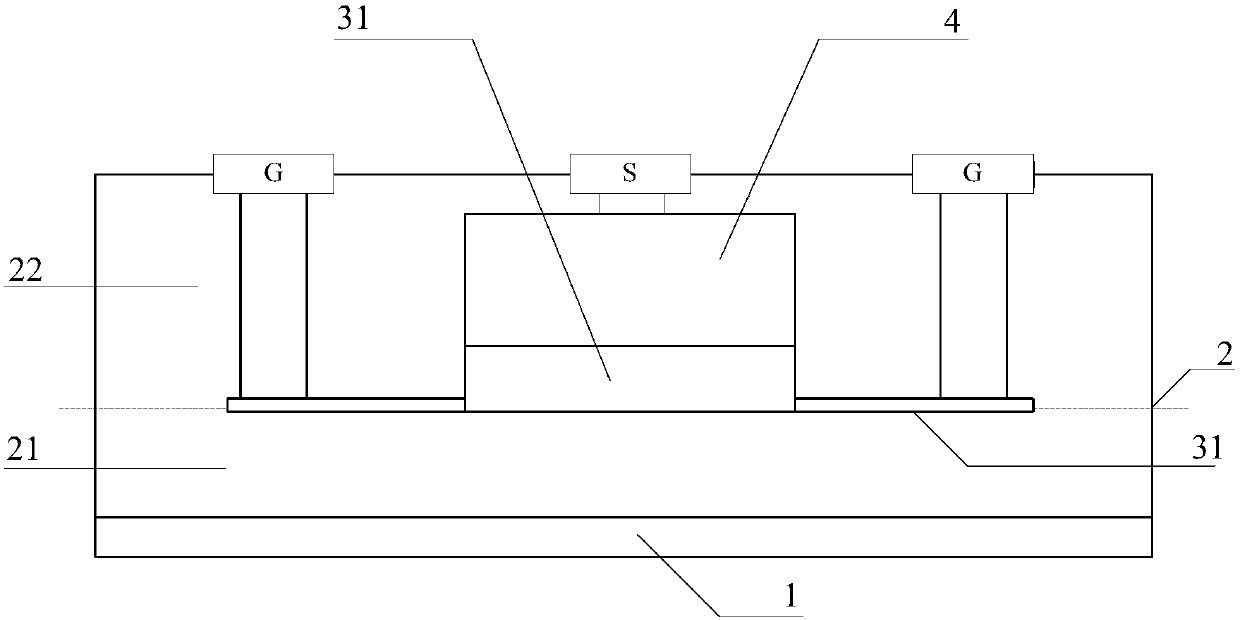

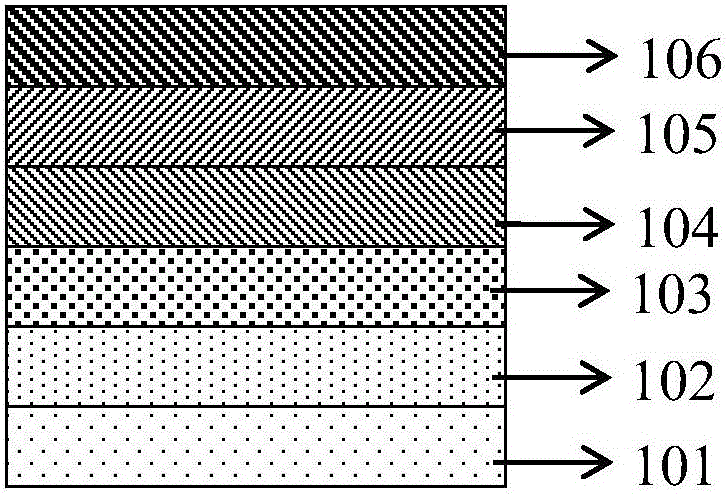

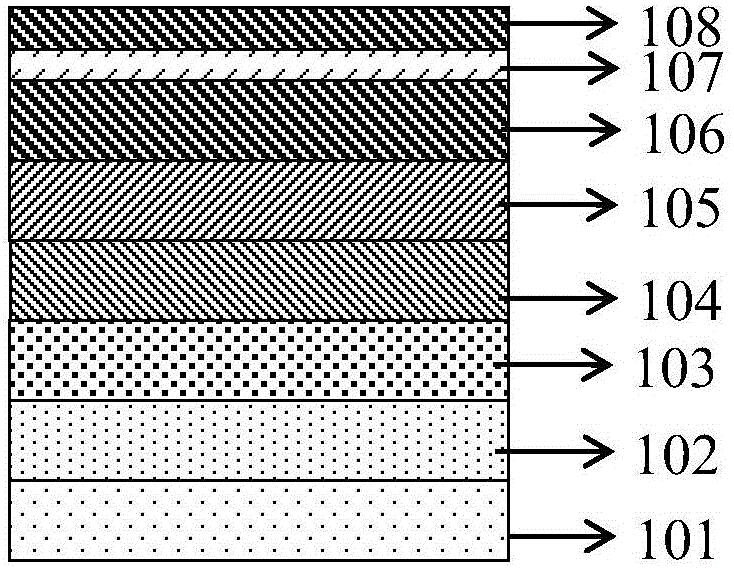

GaN-based high-electron-mobility transistor epitaxial wafer and preparation method thereof

ActiveCN112701160AIncrease the doping concentrationEasy to dopeSemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideHigh-electron-mobility transistor

The invention provides a GaN-based high-electron-mobility transistor epitaxial wafer and a preparation method thereof, and belongs to the technical field of semiconductors. The GaN-based high-electron-mobility transistor epitaxial wafer comprises a substrate, a buffer layer, a high-resistance buffer layer, a channel layer, an AlGaN barrier layer and a cap layer, wherein the buffer layer, the high-resistance buffer layer, the channel layer, the AlGaN barrier layer and the cap layer are stacked on the substrate; the cap layer comprises a first semiconductor layer and a second semiconductor layer which are stacked in sequence; the first semiconductor layer is of a P-type doped InxGa1-xN / MgN superlattice structure, wherein x is larger than 0 and is smaller than 1; the second semiconductor layer is of a P-type doped AlyGa1-yN / InzGa1zN superlattice structure, wherein y is larger than 0 and smaller than 1, and z is larger than 0 and smaller than 1. According to the epitaxial wafer, the doping concentration of Mg in the cap layer can be improved, an enhanced HEMT is formed, and meanwhile, the crystal quality of the enhanced HEMT epitaxial wafer is improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

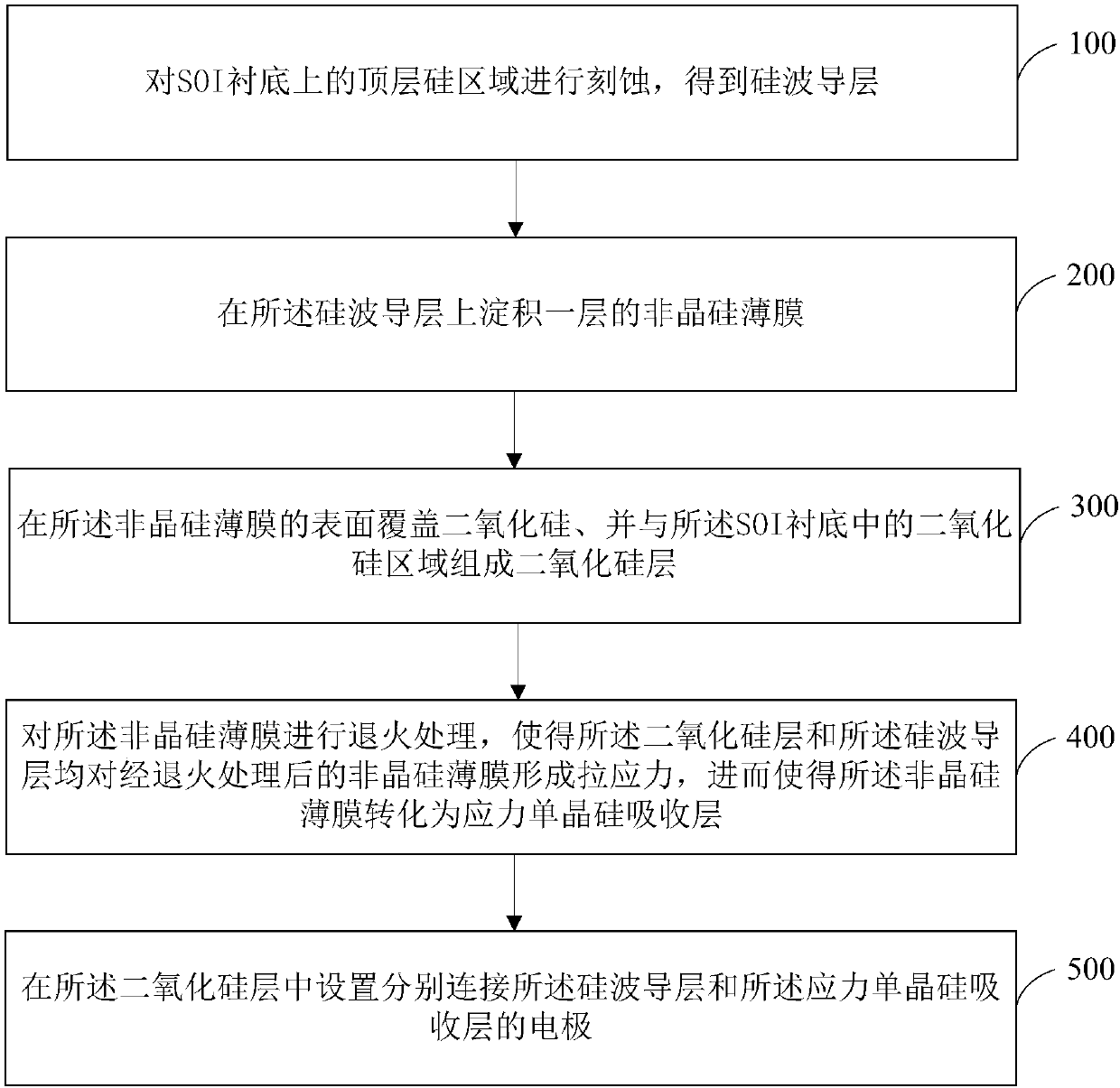

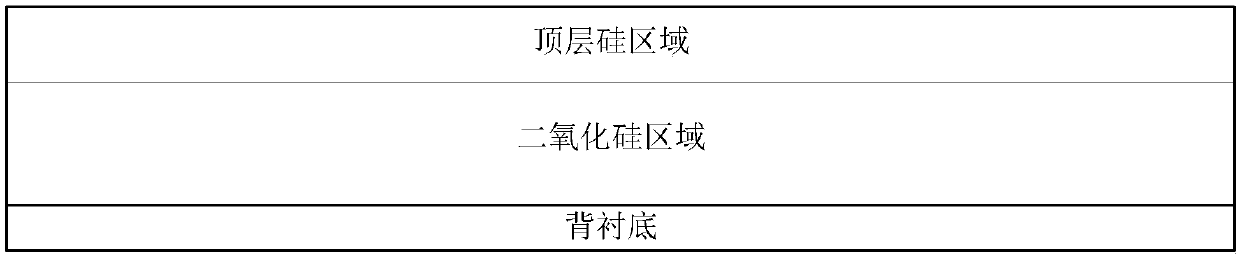

Stress silicon detector for C band and making method thereof

ActiveCN108039377AIncrease the lattice constantIncrease the absorption limitFinal product manufactureSemiconductor devicesC bandingAmorphous silicon

The invention provides a stress silicon detector for the C band and a making method thereof. The stress silicon detector includes a silicon dioxide layer arranged on a back substrate, and a stress mono-crystalline silicon absorption layer and a silicon waveguide layer arranged in the silicon dioxide layer. The stress mono-crystalline silicon absorption layer is connected to the upper end of the silicon waveguide layer. The stress mono-crystalline silicon absorption layer is formed by applying a tensile stress to an amorphous silicon film through the silicon waveguide layer and the silicon dioxide layer. The silicon waveguide layer and the stress mono-crystalline silicon absorption layer are respectively connected with electrodes. The lattice constant of silicon can be accurately and effectively increased, and the band gap can be reduced. Therefore, the absorption limit of silicon can be increased reliably, and the silicon detector can work in the C band or even in a greater wavelengthrange.

Owner:联泰集群(北京)科技有限责任公司

High-power nickel-zinc soft magnetic ferrite material and preparation method thereof

InactiveCN111099890AReduce dosageEnhanced interactionInorganic material magnetismSpray GranulationCompression molding

The invention discloses a high-power nickel-zinc soft magnetic ferrite material and a preparation method thereof. The preparation method comprises the following steps: mixing S1, Fe2O3, NiO and ZnO tobe uniform to obtain a main material, carrying out primary ball milling and drying on the main material, and obtaining a pre-sintered material through pre-sintering treatment and crushing; S2, uniformly mixing CuO, V205, MoO3, CoC2O4 and Gd2O3 to obtain an auxiliary material, uniformly mixing the auxiliary material with the pre-sintered material, and carrying out secondary ball milling and dryingto obtain a mixture; S3, uniformly mixing the mixture with a polyvinyl alcohol aqueous solution to obtain mixed slurry; S4, performing stirring treatment on the mixed slurry under a microwave condition, and then performing spray granulation to obtain a granular material; and S5, carrying out compression molding on the granular material, then carrying out high-temperature sintering, and performingcooling to obtain the ferrite material. The nickel-zinc soft magnetic ferrite material prepared by the invention has high saturation flux density and low power loss, and is suitable for being appliedin a high-frequency high-power state.

Owner:ZHONGDE ELECTRONICS

Mg(1-x)Ca(x)B2 (0<x<0.07) series compounds and preparation method thereof

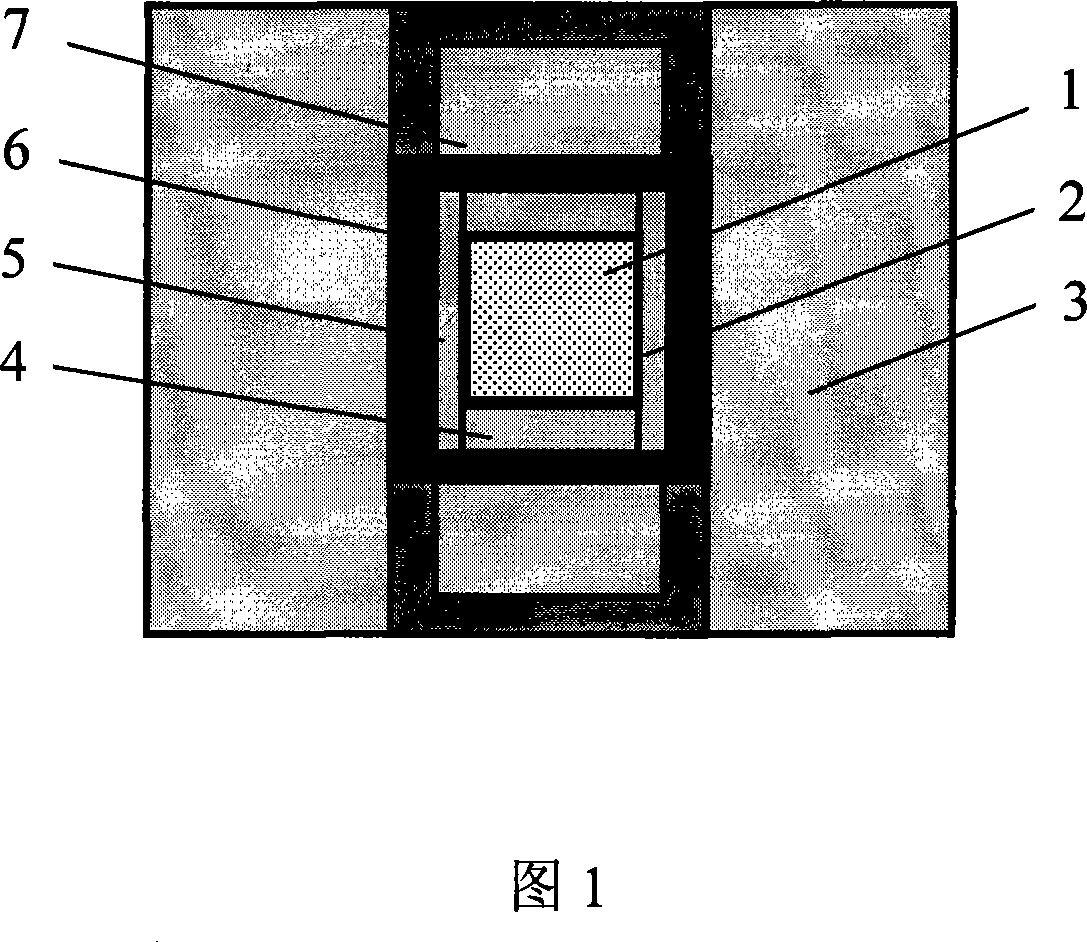

InactiveCN101100385AIncrease the lattice constantReduce monotonySuperconductors/hyperconductorsUltra-high pressure processesRoom temperatureGraphite

This invention relates to a group of series compounds (Mg1-xCaxB2, wherein 0<x<0.07). Its characteristics are: having the hexagonal structure same as that as MgB2, the lattice constants a and c values being monotone increased as the content of Ca being increased; and the superconducting transition temperature being monotone decreasing as the content of Ca being increased. The production procedures are: the raw materials Mg, B and Ca3B2N4 (as calcium source) are proportionally mixed, then pressed into sheets (1), being enclosed by tantalum sheets (2), then placed in graphite heating tubes (5) which being then placed in high pressure chamber, increasing the pressure to 4-5 GPa, then increasing the temperature to 1000-1200deg.C, keeping the same for 0.5-1hrs, lowing to room temperature, then decreasing the pressure to obtain the inventive product.

Owner:YANSHAN UNIV

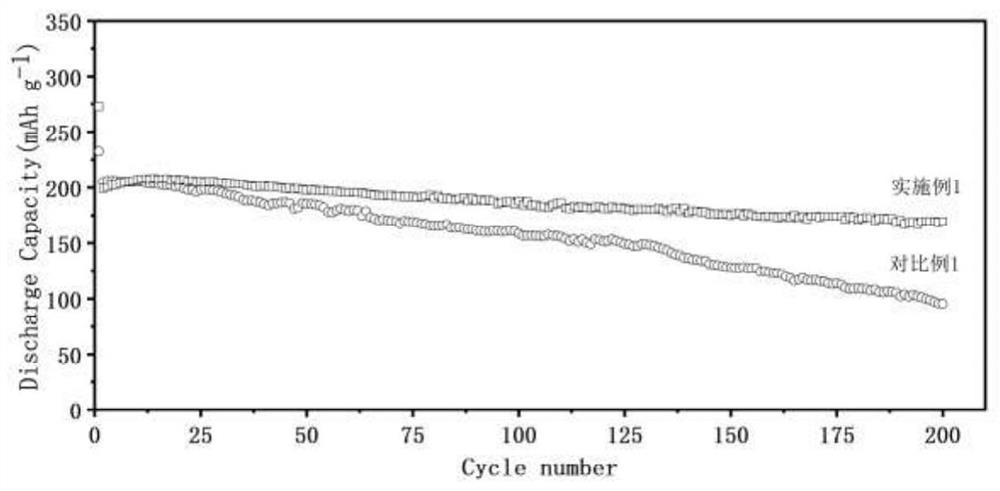

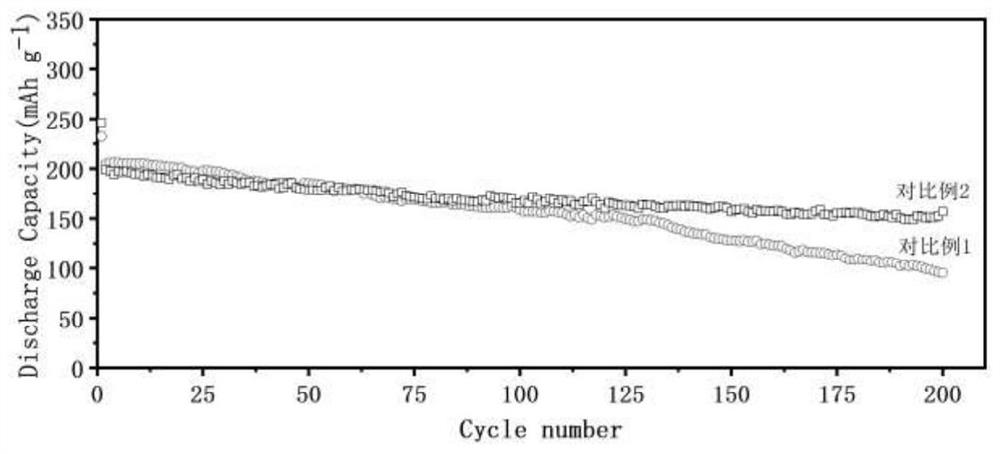

Anion-cation co-doped lithium-rich manganese-based positive electrode material as well as preparation method and application thereof

PendingCN112072114AIncrease the lattice constantReduce polarizationSecondary cellsPositive electrodesManganesePhysical chemistry

The invention provides a preparation method and application of an anion-cation co-doped lithium-rich manganese-based positive electrode material, which comprises the following steps: uniformly mixingprecursor powder, lithium-containing compound powder, a certain amount of alkali metal M1-containing compound powder and a certain amount of negative valence M2-containing compound powder, carrying out heat treatment at 300-600 DEG C for 3-7 hours, heating to 700-1000 DEG C, and carrying out heat treatment for 8-20 hours. The element M1 replaces Li to inhibit migration of transition metal ions tothe lithium layer so as to stabilize the structure; the element M2 replaces O, so that the release of oxygen can be inhibited. According to the anion-cation co-doped lithium-rich manganese-based positive electrode material, the interlayer spacing is enlarged, the lithium ion migration rate is increased, the structure is stable, the average working voltage is relatively high, and the rate capability and the cycle performance are good.

Owner:CENT SOUTH UNIV

Light-emitting diode epitaxy structure with hole energy adjustment layer

ActiveCN105742425AImprove hole injection efficiencyImprove internal quantum efficiencySemiconductor devicesSemiconductor materialsSurface barrier

The invention provides a light-emitting diode epitaxy structure with a hole energy adjustment layer, and relates to a semiconductor device which has at least one potential jump barrier or surface barrier and is especially suitable for light emission. A P-type semiconductor material hole energy adjustment layer with a low barrier layer is inserted into a P-type semiconductor material transport layer of the LED epitaxy structure; the material is Al<x1>In<y1>Ga<1-x1-y1>N; in the formula, x1 is smaller than or equal to 1 and greater than or equal to 0; y1 is smaller than or equal to 1 and greater than or equal to 0; 1-x1-y1 is greater than or equal to 0; the thickness is 1-300nm; the lattice constant of the hole energy adjustment layer is greater than those of a P-type semiconductor material transport layer I and a P-type semiconductor material transport layer II; and the forbidden bandwidth is smaller than those of the P-type semiconductor material transport layer I and the P-type semiconductor material transport layer II. The hole energy is increased by a polarization electric field to improve the hole injection efficiency; a hole barrier is not increased; and the defects of low hole injection efficiency and low internal quantum efficiency in the prior art are overcome.

Owner:ZHIXIN SEMICON (HANGZHOU) CO LTD

Preparation method of glass ceramic with good thermal conductivity

PendingCN110436785AHigh thermal conductivityLow thermal conductivityGlass shaping apparatusEpoxyFiber

The invention relates to a preparation method of glass ceramic with good thermal conductivity, and belongs to the technical field of glass ceramic materials. According to the invention, waste glass powder and silicon dioxide are used as raw materials, alumina fiber toughening-modified epoxy resin is used as a binder, and aluminum nitride, diamond, copper powder and waste ceramic powder with high thermal conductivity are used as fillers, and the glass ceramic with good thermal conductivity is prepared by doping rare earth lanthanum oxide through low-temperature co-firing. The diamond has high thermal conductivity, low dielectric constant, high resistivity and high breakdown field intensity; the aluminum nitride has excellent electrical properties and thermal properties, is a good thermal shock resistant material, has strong molten metal erosion resistance, is also an electrical insulator, and has good dielectric properties. By means of the low-temperature co-firing process, the preparation method is low in sintering temperature, low in dielectric constant and short in signal delay time; the glass serves as a fluxing agent to promote densification of the glass-ceramic composite material; in addition, the ceramic filler is used for improving the mechanical strength and insulativity of the substrate and preventing warping caused by the surface tension of the glass during sintering.

Owner:黄兰英

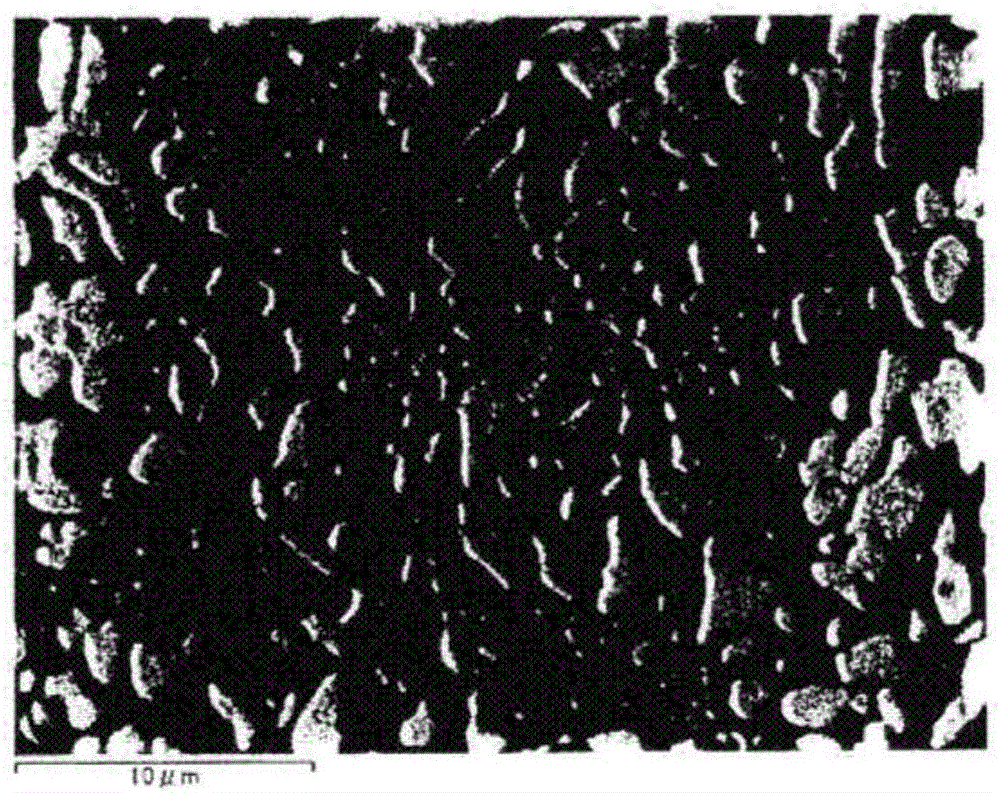

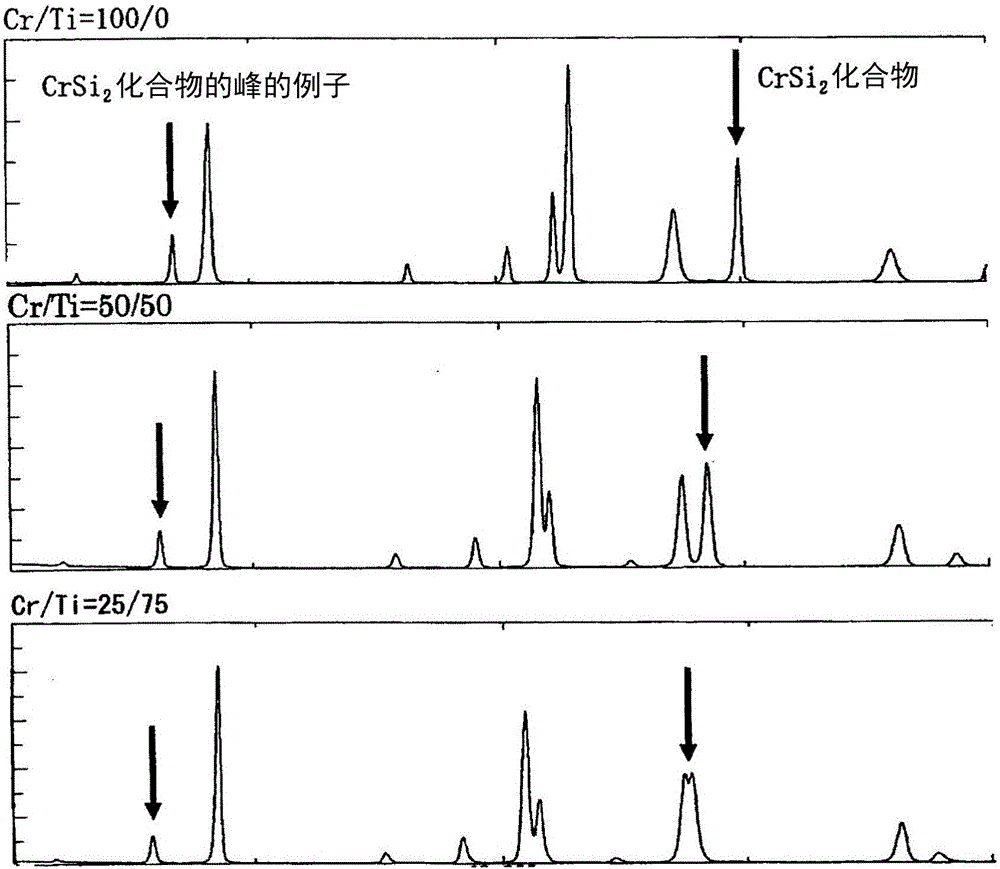

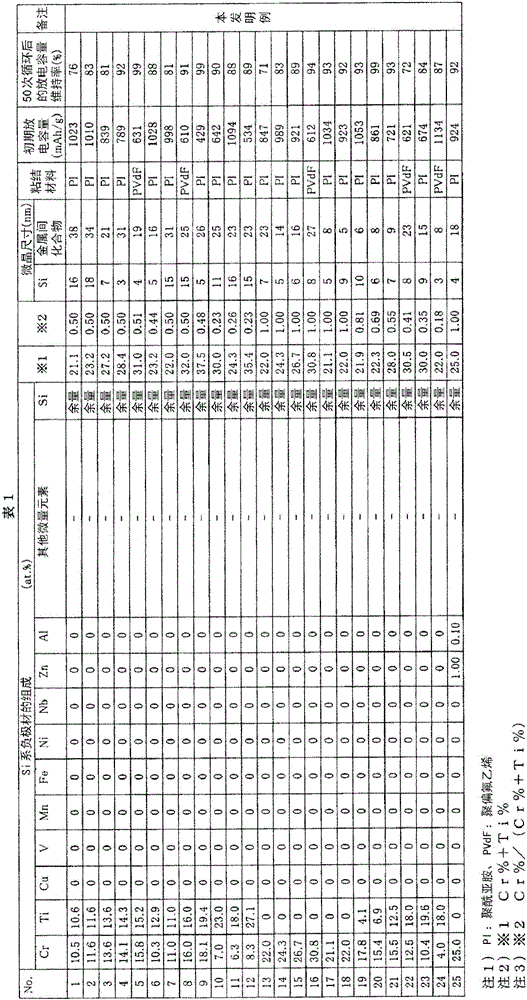

Si-based alloy negative electrode material for electricity storage devices and electrode using same

InactiveCN106605322AThe role of preventing electrical isolationImprove conduction abilityHybrid capacitor electrodesCell electrodesLithiumElectricity

The present invention provides: an Si-based alloy negative electrode material which enables the achievement of excellent battery characteristics; and an electrode. This negative electrode material is a negative electrode material which is formed of an Si-based alloy and is for use in electricity storage devices wherein lithium ions move during charging and discharging. The negative electrode material which is formed of an Si-based alloy has an Si main phase that is composed of Si and a compound phase that is composed of Si and one or more elements other than Si. The compound phase comprises a phase containing a phase composed of Si and Cr or a phase composed of Si, Cr and Ti. The Si crystallite size in the Si main phase is 30 nm or less, and the crystallite size in the compound phase composed of Si and Cr or in the compound phase composed of Si, Cr and Ti is 40 nm or less. The total content of Cr and Ti is 21.1-40 at.%, and the ratio of Cr to Ti, specifically Cr% / (Cr% + Ti%) is within the range of 0.15-1.00.

Owner:SANYO SPECIAL STEEL COMPANY

AlN template, light-emitting diode epitaxial wafer and production method thereof

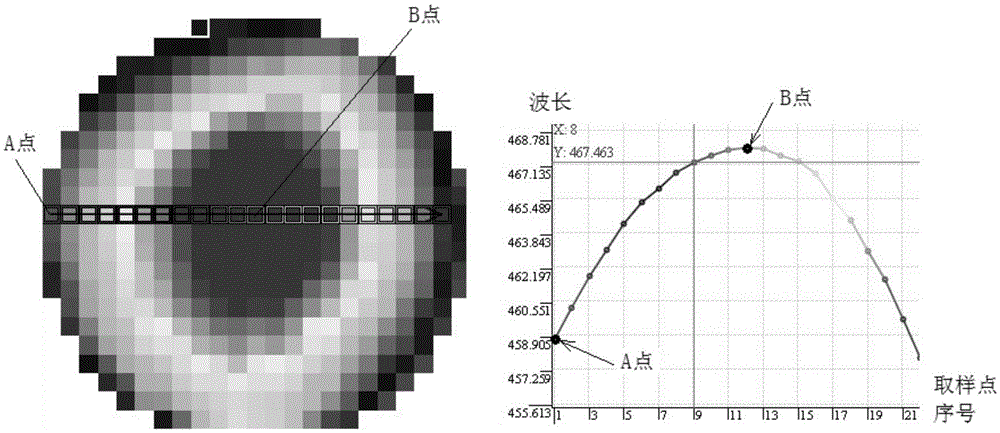

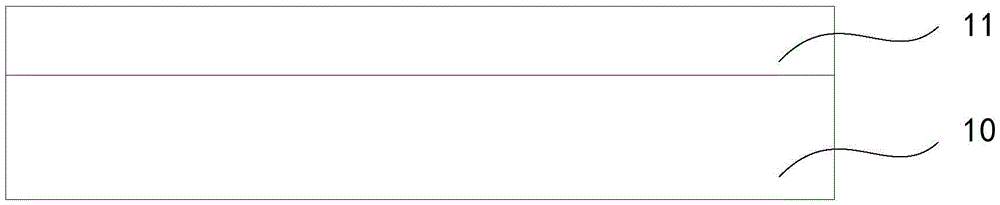

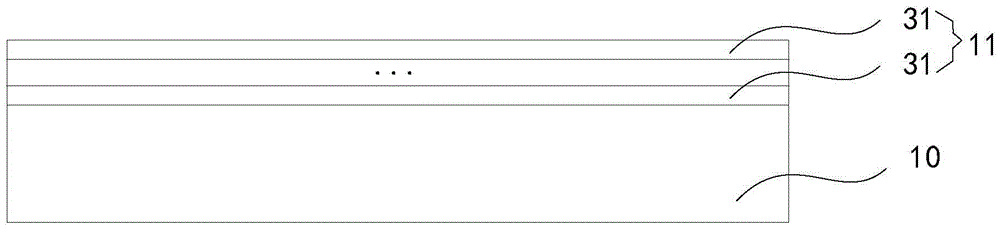

InactiveCN109888070AIncrease the lattice constantImprove wavelength uniformitySemiconductor devicesOxygen contentLength wave

The invention discloses an AlN template, a light-emitting diode epitaxial wafer and a production method thereof and belongs to the field of semiconductor technologies. The AlN template comprises a substrate and an AlN thin film deposited on the substrate, wherein the AlN thin film comprises a first AlN thin film part, an inserted layer and a second AlN thin film part which are sequentially stacked, the inserted layer comprises multiple AlNO sub-layers, and oxygen content in the multiple AlNO sub-layers is increased layer by layer and then decreased layer by layer along the stacking direction of the multiple AlNO sub-layers. A part of O atoms in the AlNO sub-layers can replace N atoms, the other part of O atoms can form gap-filling atoms, both the replacing O atoms and the gap-filling O atoms can make AlN lattices distort to a certain extent, therefore, the lattice constant of the AlN thin film is increased, the lattice constant of the AlN thin film is more approximate to the lattice constant of a subsequent GaN epitaxial thin film, pressing stress in a GaN material can be reduced beneficially, warping of the epitaxial wafer is relieved, and then wavelength uniformity of an epitaxial layer is improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com