Preparation method of porous ceramics

A technology of porous ceramics and mixed powder, applied in the field of porous ceramic materials, can solve the problems of long time, difficult control of process conditions, cumbersome preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The porous ceramic material described in this embodiment is Sr doped with Cu at the Co site. 3 YCo 4 o 10.5 Porous ceramics, its preparation method comprises the steps:

[0021] (1) Weigh SrCO according to the molar ratio of Sr:Y:Co of 3:1:4 3 , Y 2 o 3 、Co 3 o 4 Mix it evenly and grind it for 2 hours to get the mixed powder;

[0022] (2) Compress the mixed powder obtained in step (1) into tablets. The conditions for tablet compression are as follows: increase the pressure of the tablet press from 0MPa to 20MPa, and keep the pressure for 2 minutes for each increase of 2MPa;

[0023] (3) The mixed powder after tableting is sintered in the air to obtain a porous ceramic material after sintering, wherein the sintering temperature is 1110° C. and the holding time is 24 hours.

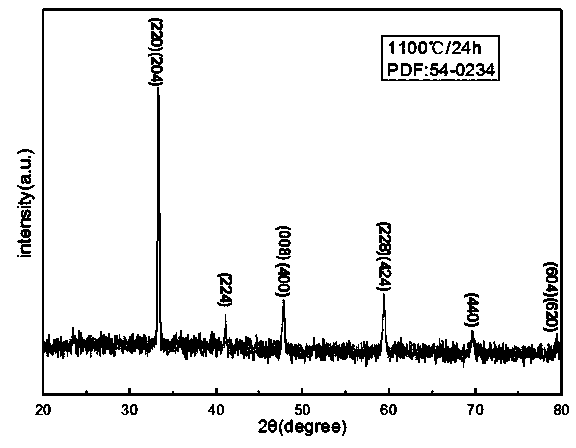

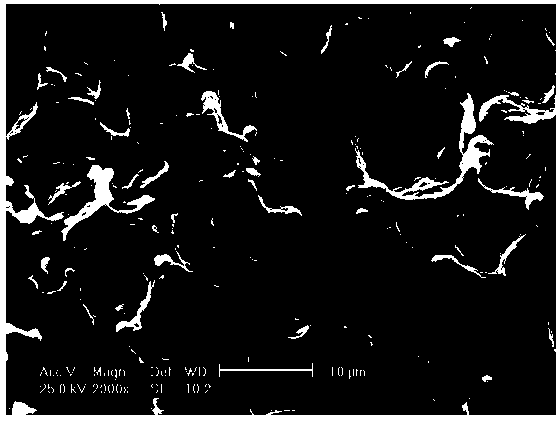

[0024] The Sr prepared in this example 3 YCo 4 o 10.5 Porous ceramic material, its XRD and SEM images are shown in figure 1 and figure 2 .

Embodiment 2

[0026] The porous ceramics described in this example are Sr doped with Cu at the Co site. 3 YCo 3.8 Cu 0.2 o 10.5 Porous ceramics, a preparation method thereof, comprising the steps of:

[0027] (1) Weigh SrCO according to the molar ratio of Sr:Y:Co:Cu: 3:1:3.8:0.2 3 , Y 2 o 3 、Co 3 o 4 , CuO to make it evenly mixed and then grind for 1h to obtain mixed powder;

[0028] (2) Compress the mixed powder obtained in step (1). The diameter of the tablet is 2cm and the thickness is 4mm. Press for 5 minutes;

[0029] (3) Sinter the mixed powder after tableting in the air, and get Sr after sintering 3 YCo 3.8 Cu 0.2 o 10.5 The porous ceramic material, wherein the sintering temperature is 1000° C., and the holding time is 24 hours.

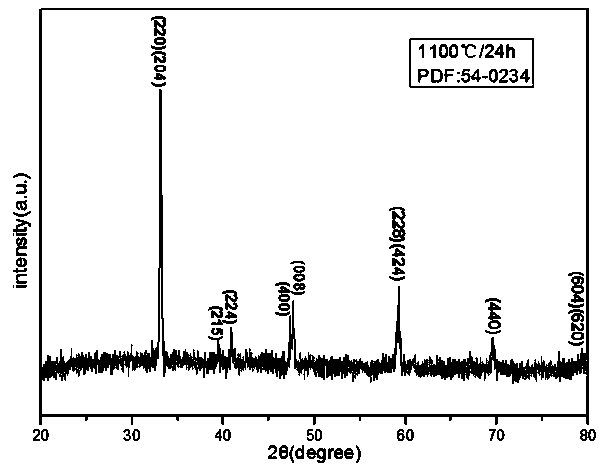

[0030] The Sr prepared in this embodiment 3 YCo 3.8 Cu 0.2 o 10.5 Porous ceramic material, its XRD and SEM images are shown in image 3 and Figure 4 .

Embodiment 3

[0032] The porous ceramics described in this example are Sr doped with Cu at the Co site. 3 YCo 3.6 Cu 0.4 o 10.5 Porous ceramics, its preparation method comprises the steps:

[0033] (1) Weigh SrCO according to the molar ratio of Sr:Y:Co:Cu: 3:1:3.6:0.4 3 , Y 2 o 3 、Co 3 o 4 , CuO to make it evenly mixed and then grind for 2 hours to obtain mixed powder;

[0034] (2) Compress the mixed powder obtained in step (1). The diameter of the tablet is 2cm and the thickness is 4mm. Press for 1min;

[0035] (3) Sinter the mixed powder after tableting in the air, and get Sr after sintering 3 YCo 3.6 Cu 0.4 o 10.5 Porous ceramics, wherein the sintering temperature is 1150° C., and the holding time is 15 hours.

[0036] The Sr prepared in this example 3 YCo 3.6 Cu 0.4 o 10.5 Porous ceramics, whose XRD and SEM images are shown in Figure 5 and Figure 6 .

[0037] From figure 1 ,3 In the XRD figure shown in , 5, it can be seen that the phase Sr prepared by the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com