Bismuth-doped spherical zinc oxide gas sensing material and preparation method thereof

A gas sensing, zinc oxide technology, applied in chemical instruments and methods, zinc oxide/zinc hydroxide, bismuth compounds, etc., can solve problems such as high cost and complex synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

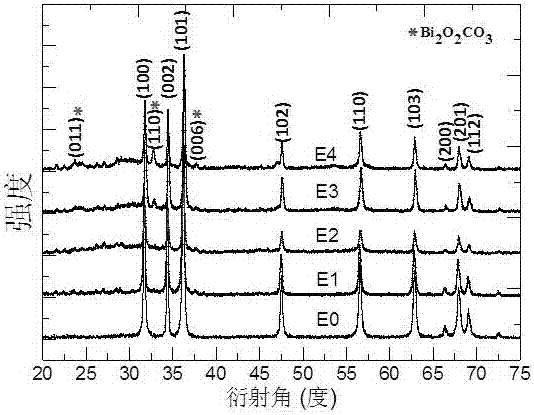

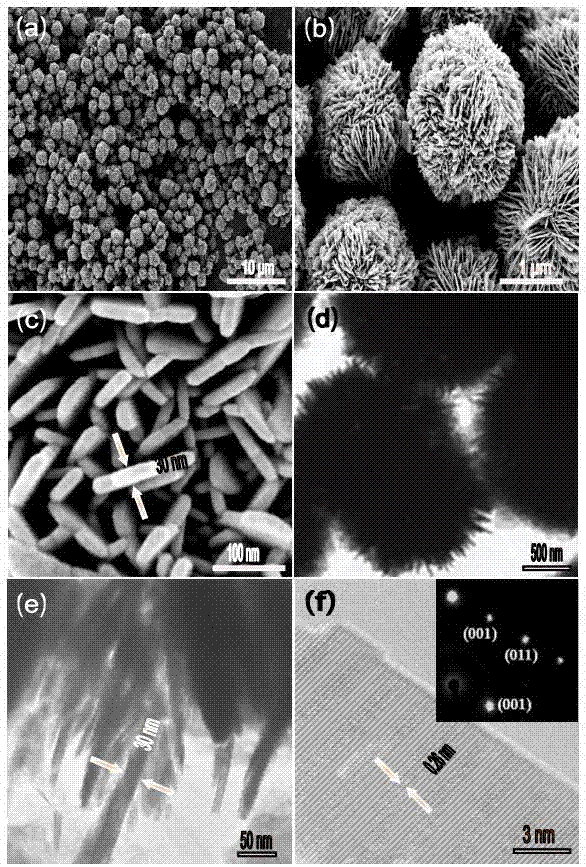

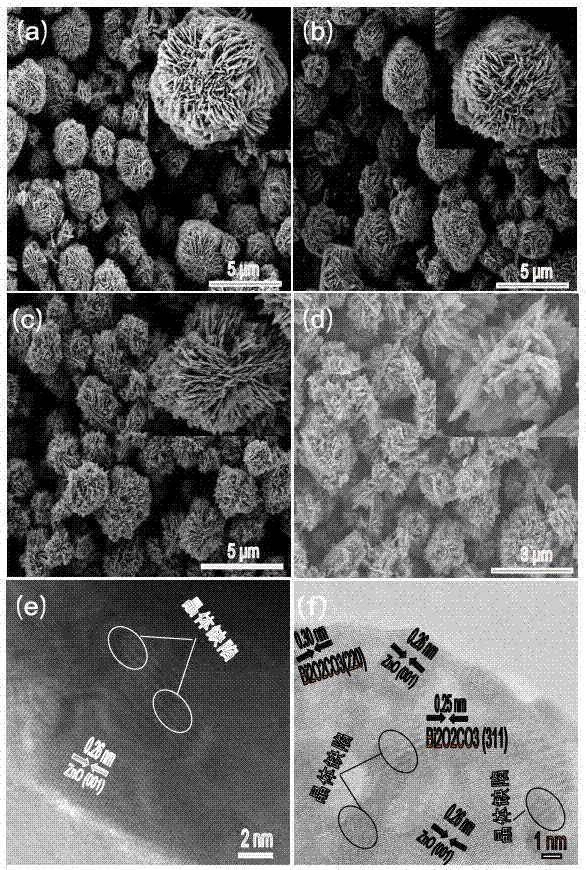

[0025] Add 1mmol of zinc acetate and 0.5 mmol of sodium citrate into 20ml of deionized water, and stir magnetically for more than 20 minutes; slowly pour 8mmol of sodium hydroxide into the solution, and stir magnetically for more than 30 minutes; transfer to a reaction kettle, and heat at 120°C Insulate for 30 hours, cool to room temperature, and undergo solid-liquid separation, drying, and grinding to obtain bismuth-doped spherical zinc oxide powder with a doping ratio of 0:100, denoted as E0.

Embodiment 2

[0027] Add 1 mmol of zinc acetate, 0.5 mmol of sodium citrate and 0.01 mmol of bismuth citrate into 20 ml of deionized water, and stir magnetically for more than 20 minutes; slowly pour 8 mmol of sodium hydroxide into the solution, and stir magnetically for more than 30 minutes; transfer to the reaction Kettle, heated at 120°C for 30 hours, cooled to room temperature, solid-liquid separation, drying, and grinding to obtain bismuth-doped spherical zinc oxide powder with a doping ratio of 1:100, denoted as E1.

Embodiment 3

[0029] Add 1 mmol of zinc acetate, 0.5 mmol of sodium citrate and 0.025 mmol of bismuth citrate into 20 ml of deionized water, and stir magnetically for more than 20 minutes; slowly pour 8 mmol of sodium hydroxide into the solution, and stir magnetically for more than 30 minutes; transfer to the reaction Kettle, heated at 160°C for 20 hours, cooled to room temperature, solid-liquid separation, drying, and grinding to obtain bismuth-doped spherical zinc oxide powder with a doping ratio of 2.5:100, denoted as E2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com