Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

280 results about "O-Cresol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ortho-Cresol, also 2-methylphenol, is an organic compound with the formula CH₃C₆H₄(OH). It is a colourless solid that is widely used intermediate in the production of other chemicals. It is a derivative of phenol and is an isomer of p-cresol and m-cresol.

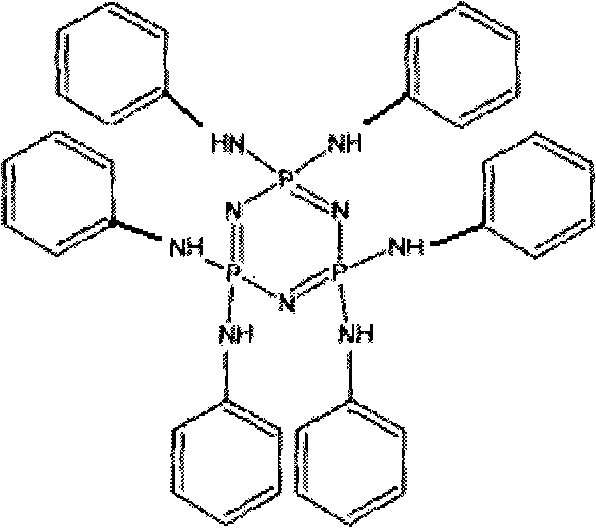

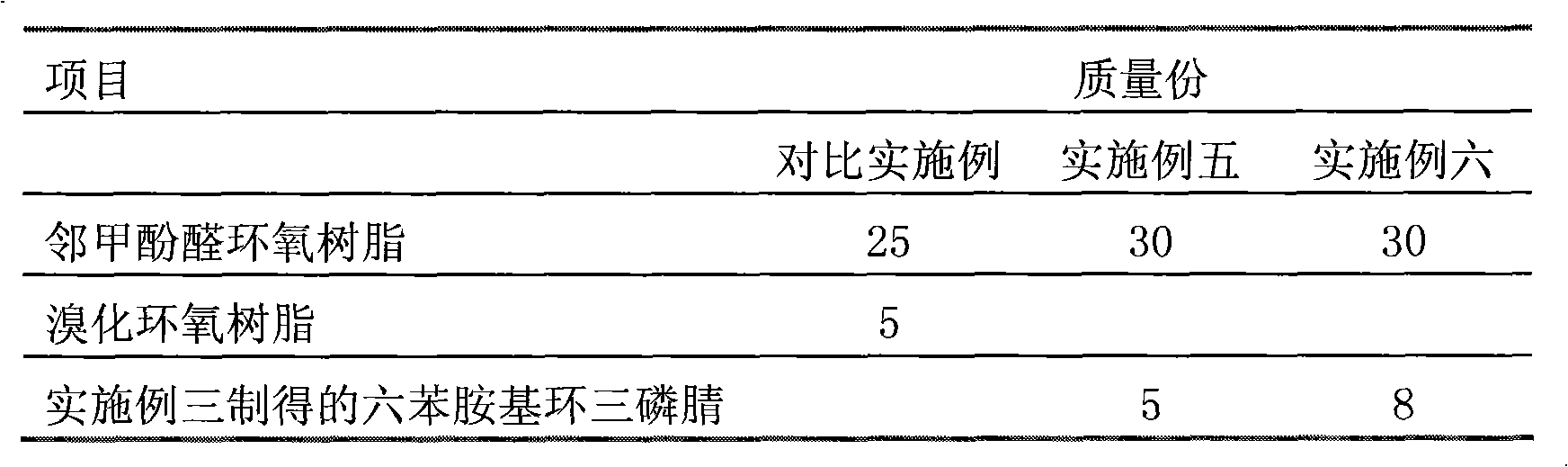

Preparation method of hexaaniline cyclotriphosphazene and non-halogen flame retardant epoxy resin composition

InactiveCN101597308AImprove performanceImprove flame retardant performanceGroup 5/15 element organic compoundsEpoxyPolymer science

The invention discloses a preparation method of hexaaniline cyclotriphosphazene and non-halogen flame retardant epoxy resin composition. The preparation method of hexaaniline cyclotriphosphazene comprises the following steps: adding solvent, hexachlorocyclotriphosphazene, aniline and acid-binding agent into a reaction device, stirring and introducing nitrogen for protection, heating the mixture to 50-120 DEG C, adding catalyst into the reaction device, reacting for 5-16h and cooling to room temperature, filtering, carrying out reduced pressure distillation on the filtrate, carrying out evaporation to remove solvent to obtain brown thick product, placing the product in a drying oven, drying for 8h in vacuum at 40-70 DEG C, crushing to obtain powder product, namely the hexaaniline cyclotriphosphazene. The non-halogen flame retardant epoxy resin composition applied to large-scale and very-large-scale integrated circuits encapsulation is prepared by mixing the prepared hexaaniline cyclotriphosphazene with o-cresol formaldehyde epoxy resin, microsilica, curing catalyst, silane coupling agent, lubricant, flexibilizer and stearic acid, milling, crashing and demagnetizing.

Owner:GUANGDONG RONGTAI IND +1

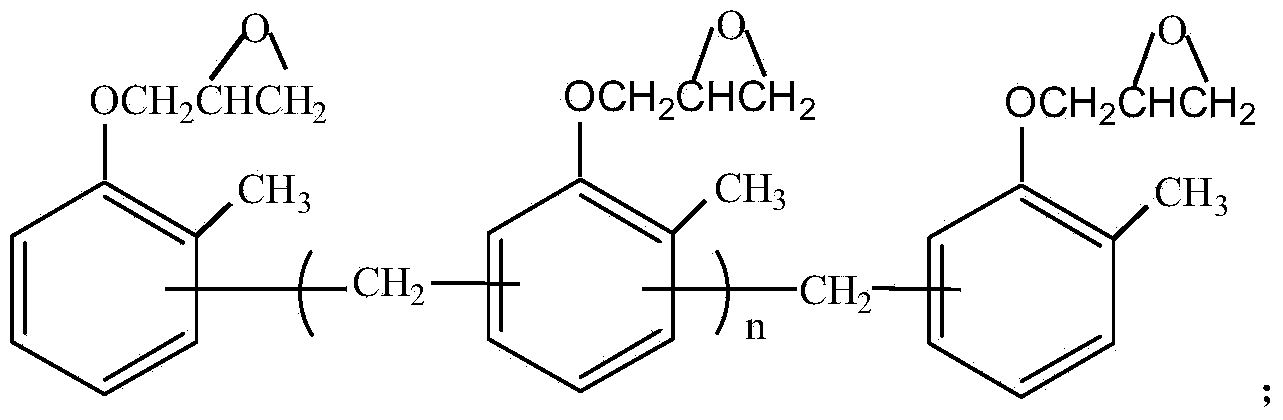

Modified epoxy resin and modified epoxy resin composition

InactiveCN104497271AHigh glass transition temperatureImprove impact toughnessGlass transitionBisphenol A

The application belongs to the field of synthetic resin and particularly relates to modified epoxy resin and a modified epoxy resin composition. The modified epoxy resin composition provided by the invention comprises the following components in parts by weight: 50-60 parts of modified epoxy resin, 10-30 parts of polyfunctional epoxy resin, 20-30 parts of a phosphorus-containing curing agent, 1-5 parts of a nitrogen-containing curing agent and 0.1-1 part of a curing accelerator, wherein the polyfunctional epoxy resin is one or more of o-cresol formaldehyde epoxy resin, phenol phenolic aldehyde epoxy resin, bisphenol A formaldehyde phenolic aldehyde epoxy resin, biphenyl type epoxy resin, triphenol hydroxyl methane phenolic aldehyde epoxy resin, tetraphenol hydroxyl methane phenolic aldehyde epoxy resin, tetraphenol ethane epoxy resin and phenoxy resin. Experimental results show that the modified epoxy resin composition provided by the invention has a glass-transition temperature higher than 165 DEG C and good impact toughness and meanwhile, UL-94 V0 level halogen-free flame retardancy is achieved.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Preparing methods of liquid crystal epoxy resin oligomer and epoxy resin composition

InactiveCN101585821AReduce melt viscositySmall coefficient of linear expansionOrganic chemistryEpoxySide chain

The invention discloses a preparing method of liquid crystal epoxy resin oligomer and epoxy resin composition. The method comprises that: p-phenylphenol, epoxy chloropropane, phase transfer catalyst, sodium hydroxide and distilled water as raw materials are reacted to prepare the liquid crystal epoxy resin oligomer. The epoxy resin composition comprises: mixing the prepared liquid crystal epoxy resin oligomer and other raw materials based on weight proportionality: 10-30 parts of liquid crystal epoxy resin oligomers by weight, 10-30 parts of o-cresol-formaldehyde epoxy resins by weight, 5-25 parts of melamine modified linear phenol aldehyde resins by weight, 60-150 parts of spherical silicon micronized quartz powders by weight, 0.1-2 parts of curing accelerators by weight, 2-10 parts of flexibilizers by weight, 0.6-5 parts of resin acceptors by weight and 0.5-5 parts of lubricants by weight, which are mixed for smelting, crushed and demagnetizing to prepare the epoxy resin composition comprising side chain liquid crystal structure. The epoxy composition has good heat-resistant property and good physical mechanical property, is suitable for the encapsulations of large scale and grand scale integrated circuits.

Owner:GUANGDONG RONGTAI IND +1

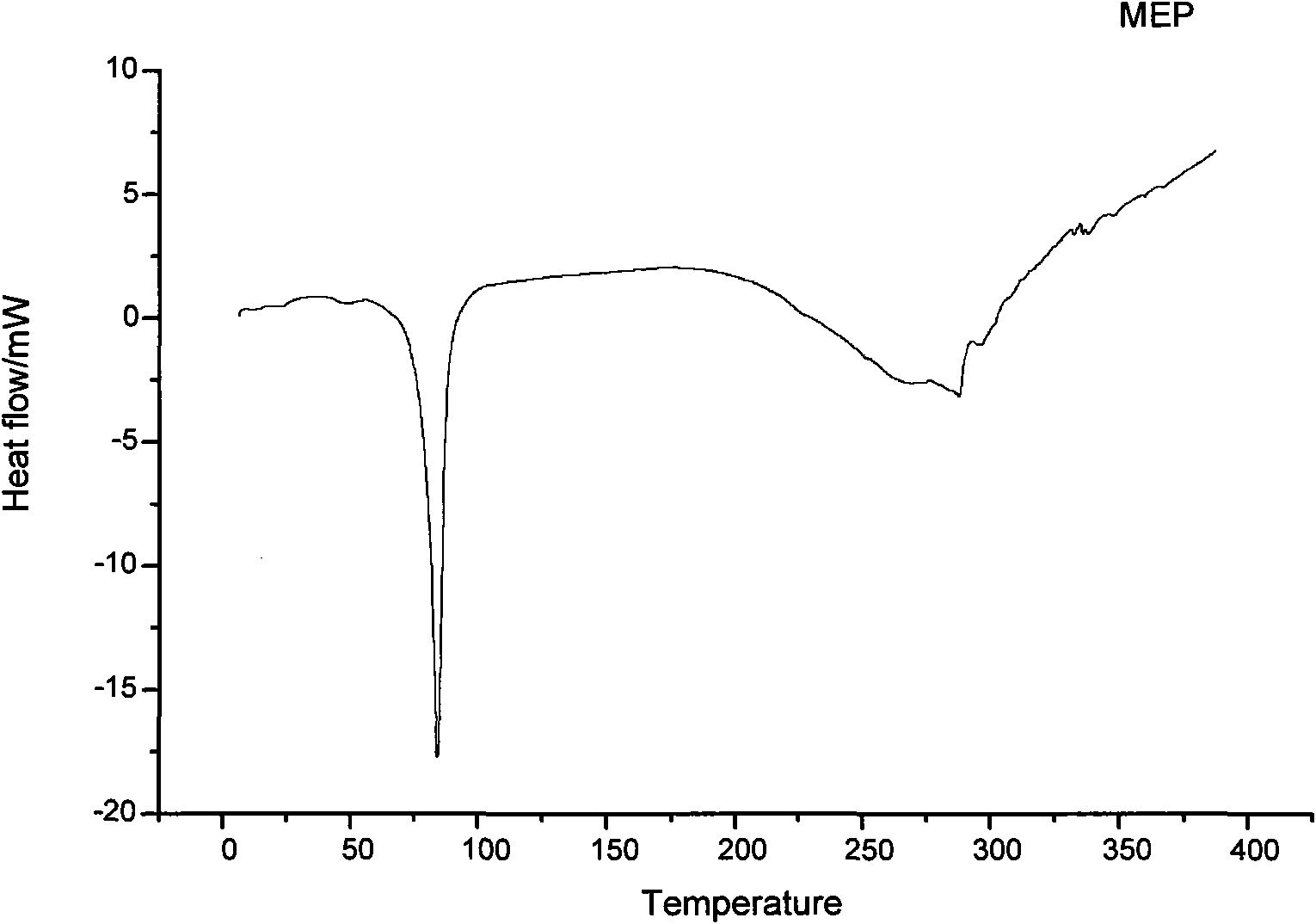

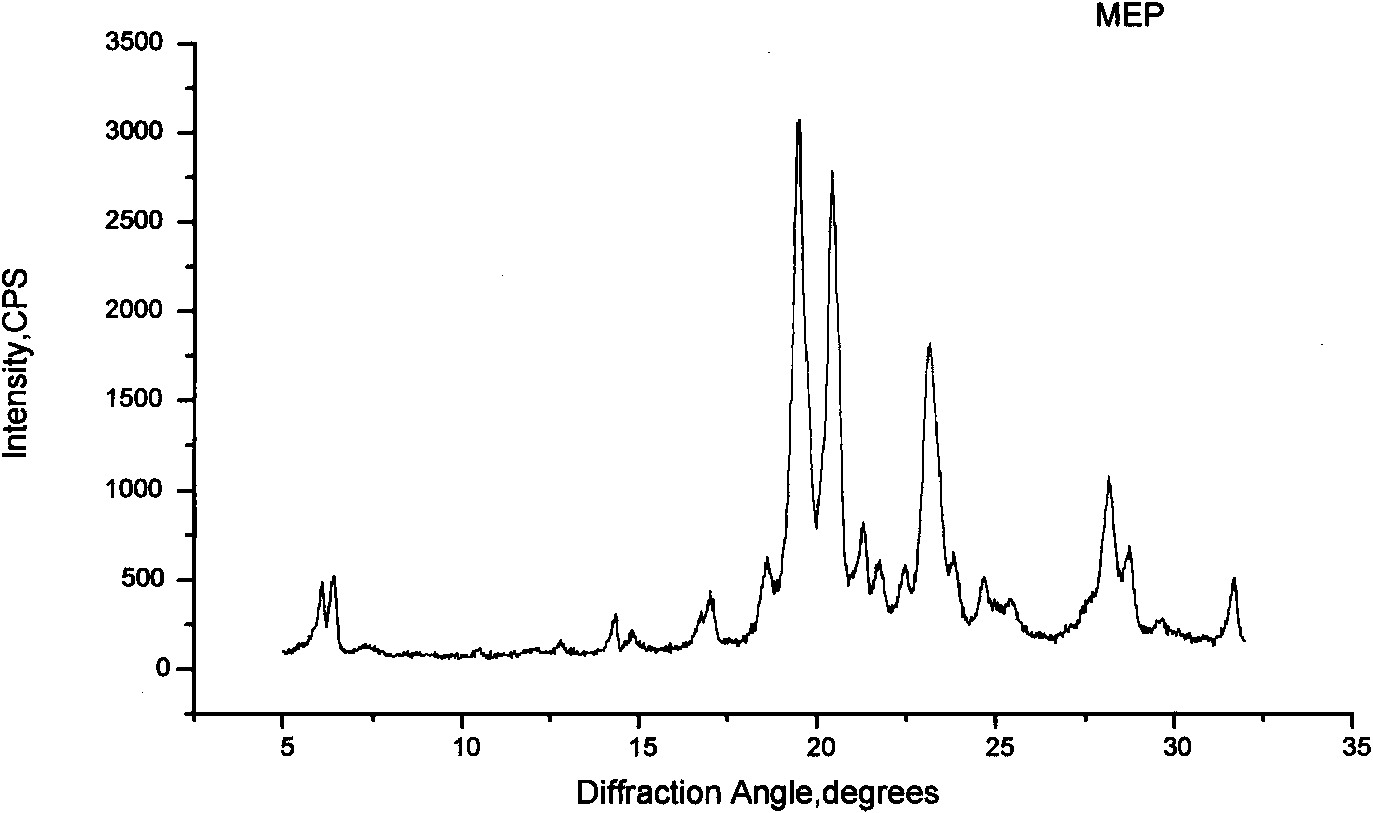

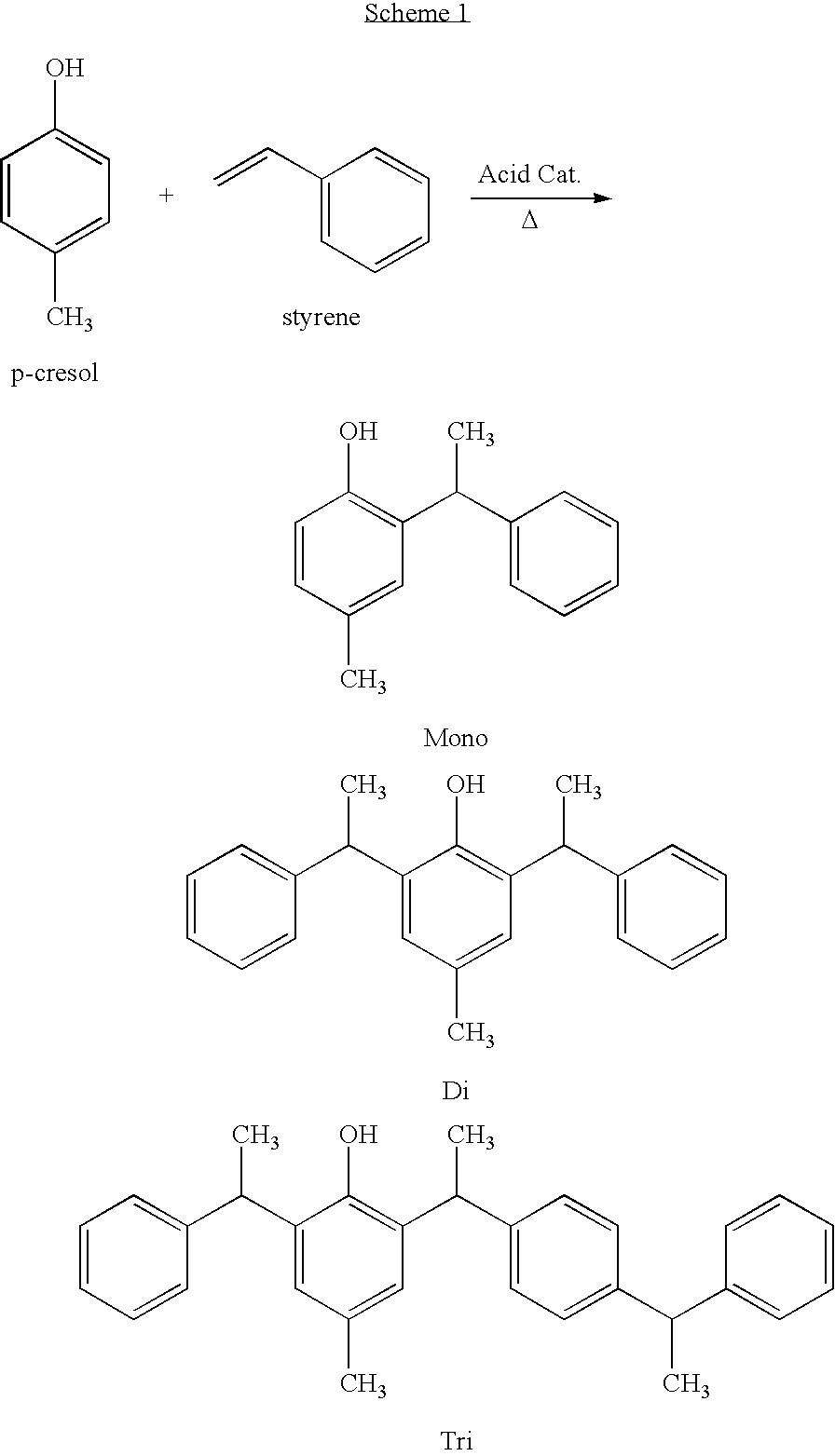

Liquid styrenated phenolic compositions and processes for forming same

Disclosed herein are highly stable styrenated phenolic compositions that are liquids at room temperature, and polymer articles and lubricant compositions containing such styrenated phenolic compositions. Also disclosed are processes for forming such styrenated phenolic compositions, which processes afford distyrenated phenolics assaying at 70% minimum by total GC area, comprising reacting styrene with one or more phenolics, e.g., at least one of phenol, p-cresol and / or o-cresol, in the presence of an acid catalyst, preferably a sulfonic acid catalyst, at elevated temperature, wherein the resulting product mixture comprises one or more monostyrenated phenolics, one or more distyrenated phenolics, and one or more tristyrenated phenolics.

Owner:SI GROUP INC

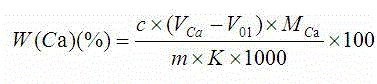

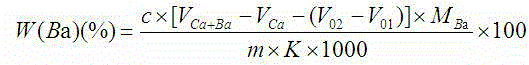

Indicator for simultaneous measurement of calcium, barium and magnesium in silicon-calcium-barium-magnesium by adopting EDTA titration method

InactiveCN104483311AColor SensitiveReduce mistakesMaterial analysis by observing effect on chemical indicatorAlizarinPhysical chemistry

Owner:INNER MONGOLIA BAOTOU STEEL UNION

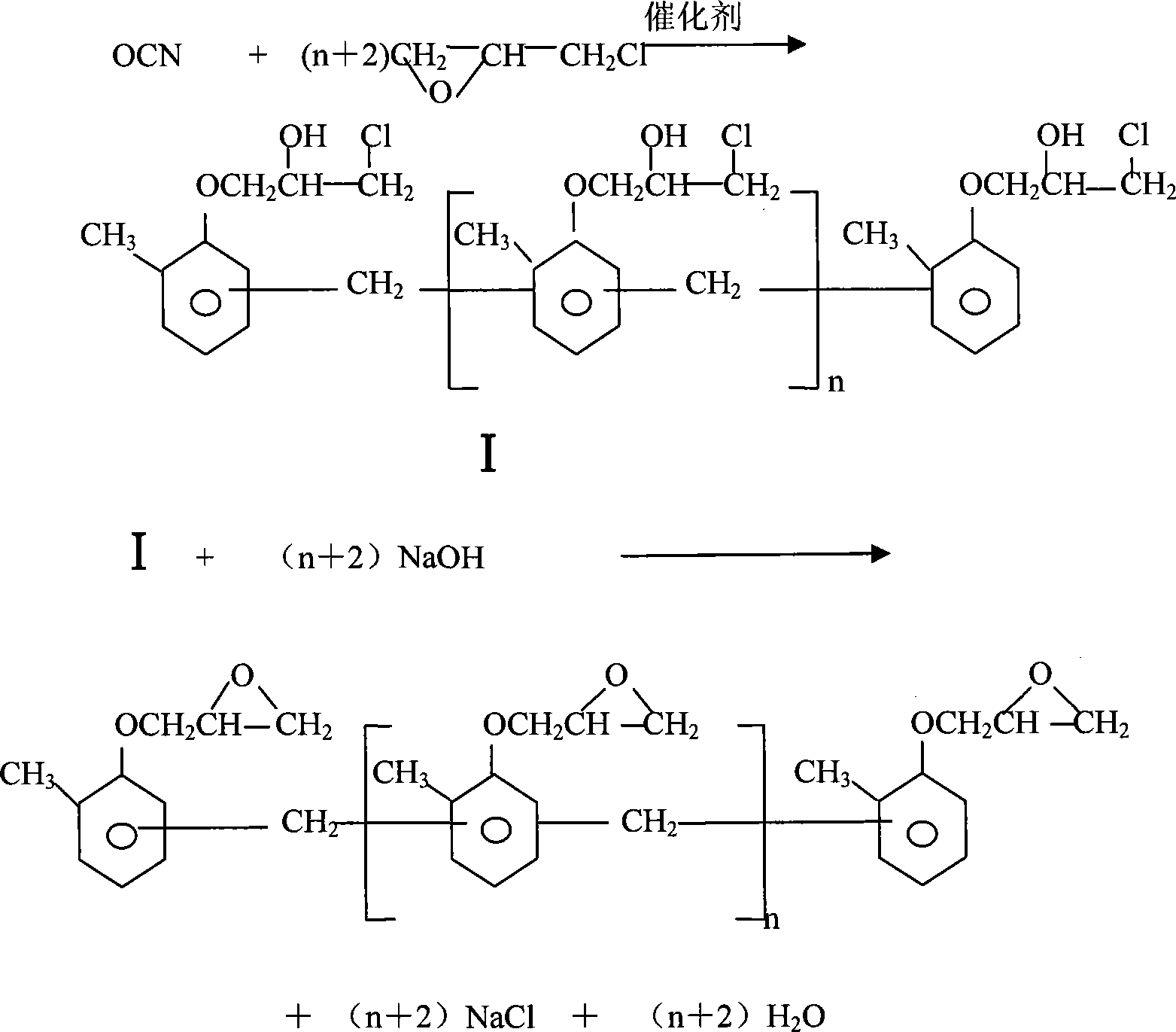

Synthesis of o-cresol formaldehyde epoxy resin

The invention provides a synthesis method of o-cresol formaldehyde epoxy resin, which comprises steps that: at 0.01-0.1Mpa vacuum degree, the o-cresol formaldehyde epoxy resin is dissolved by epichlorohydrin and a catalyzer is added for circumfluence and etherification reaction; at the 0.02-0.1Mpa vacuum degree, alkali is added for catalyzing cyclization reaction; the epichlorohydrin is recycled and processed after refining reaction. The o-cresol formaldehyde epoxy resin obtained by the synthesis method of the invention can reach a scheduled softening point and has high epoxy value and low content of easily saponifiable chlorine.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

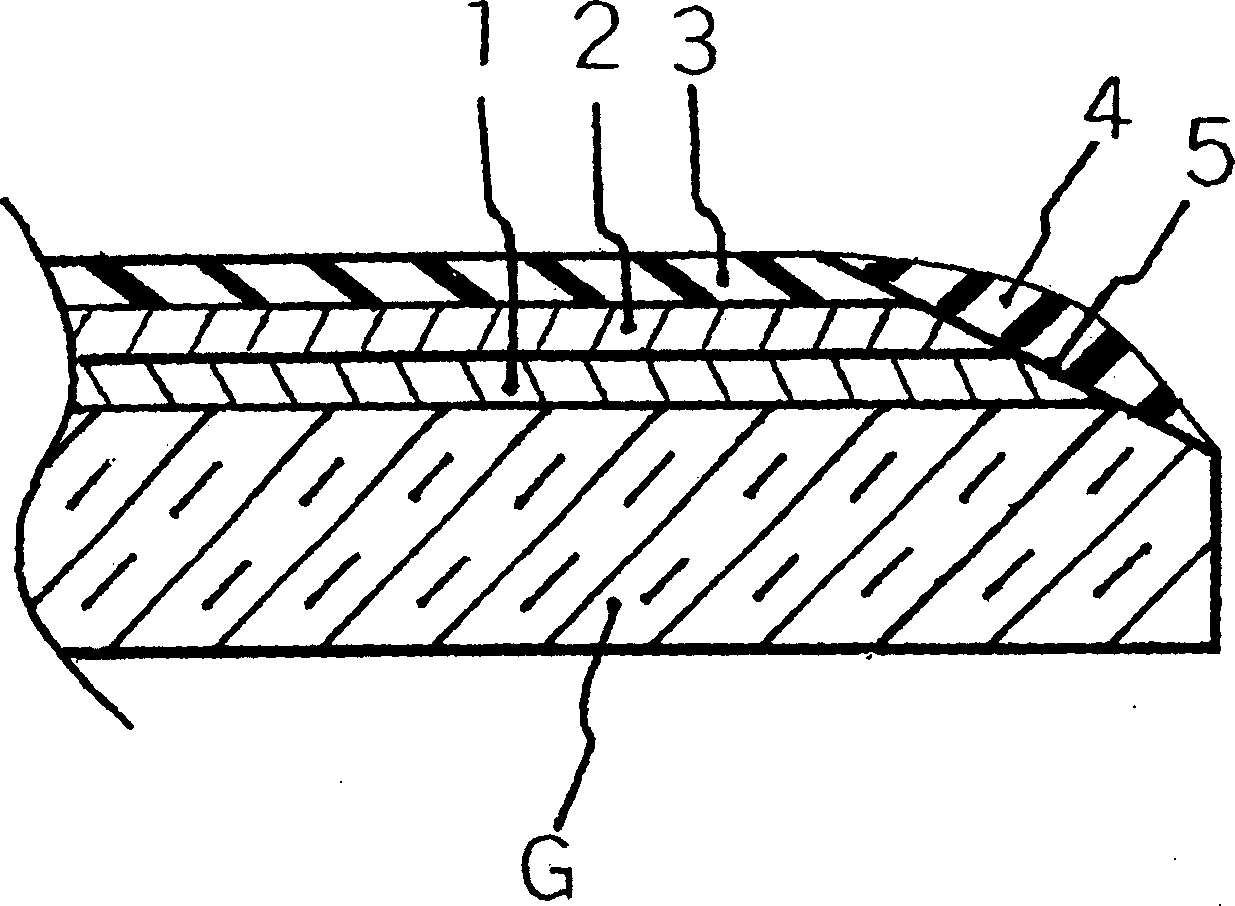

Coating material and mirror coated therewith

The invention provides an edge coating solution for a mirror, which comprises (A) a bisphenol-type liquid epoxy resin (having an epoxy equivalent of 150-300), (B) a bisphenol-type solid epoxy resin (having an epoxy equivalent of 450-3,300), (C) an o-cresol-novolak-type epoxy resin (having an epoxy equivalent of 180-300), (D) an epoxy curing agent, and (E) a silane coupling agent. The present invention relates to a water-based edge coating solution, which contains an acrylsilicone resin emulsion obtained by dispersing an acrylsilicone resin into water.

Owner:CENT GLASS CO LTD

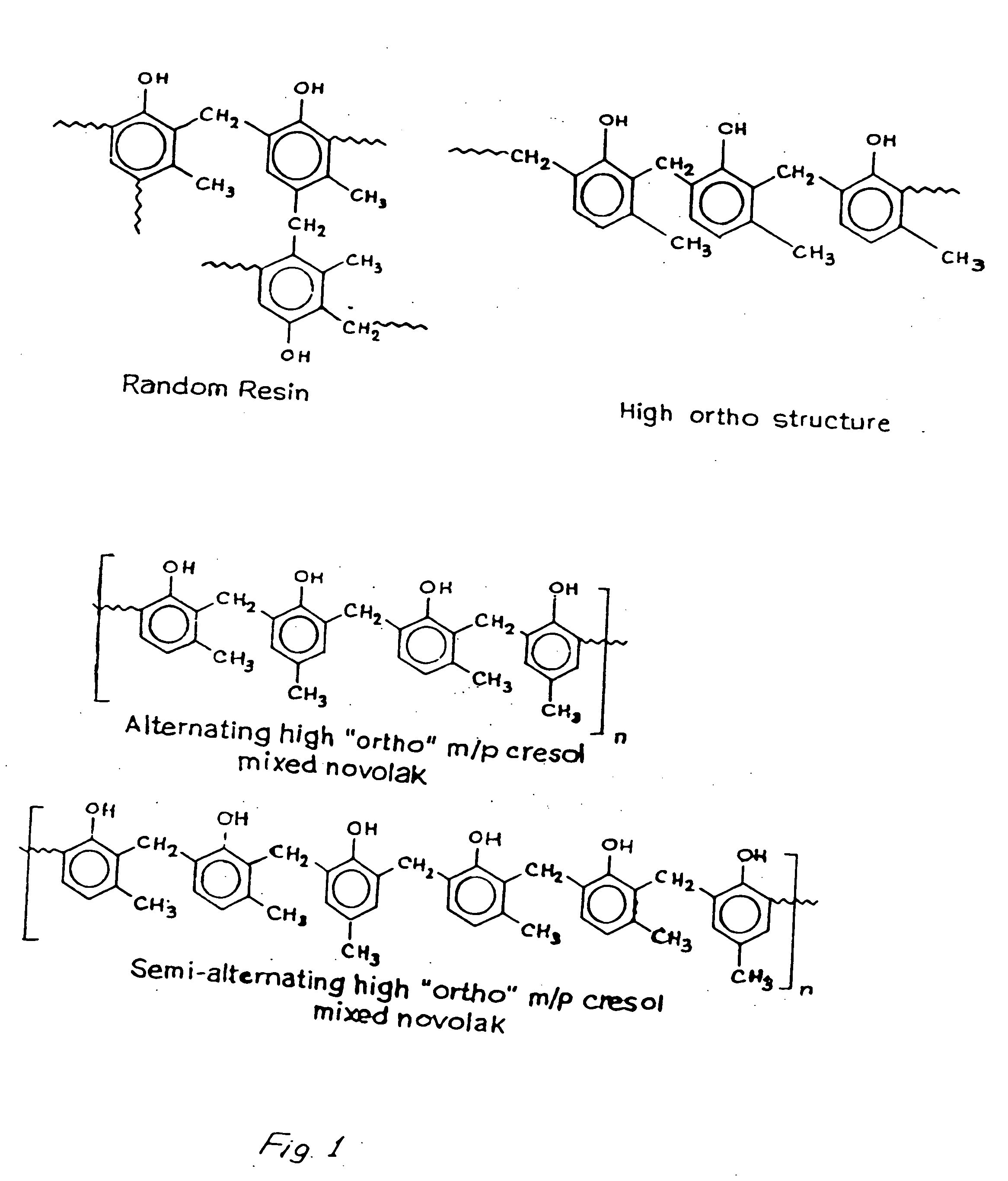

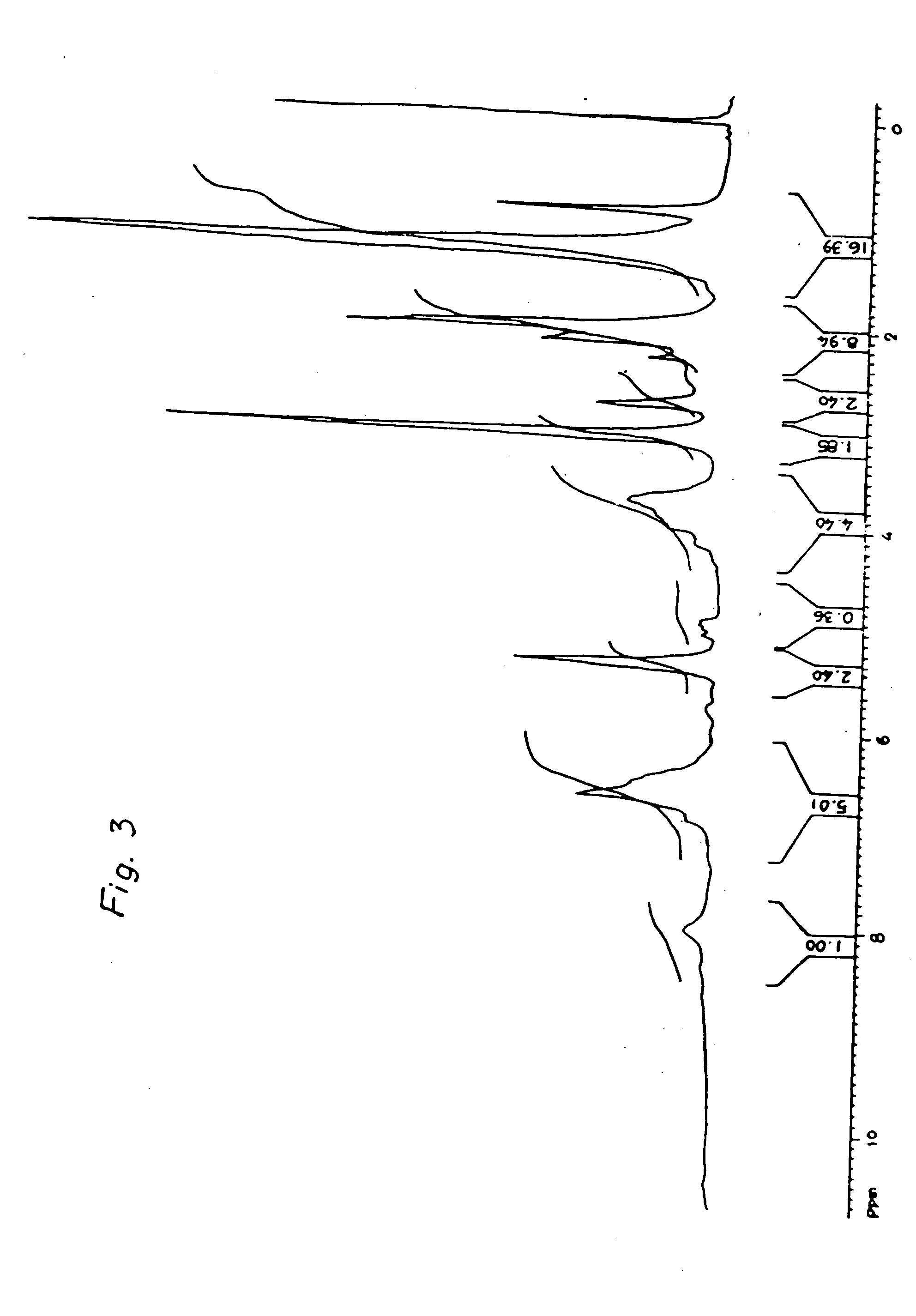

"High ortho" novolak copolymers and composition thereof

InactiveUS20050014086A1UsedPhotomechanical apparatusPhotosensitive material auxillary/base layersResistM-Cresol

A two step process for preparation of “high ortho” novolac resins. A first step involving reaction of phenolic component with formaldehyde carried out at room temperature, which ensures that all the formaldehyde used in the reaction is in liquid state, which almost completely reacts with phenolic compound, leaving no unreacted formaldehyde as effluents. The process uses CNSL or CNSL based phosphorylated prepolymer, or CNSL based monomeric Cardanol or hydrogenated Cardanol or vicinally hydroxylated Cardanol with formaldehyde and other phenolic compounds like m-cresol or p-cresol or o-cresol or 3.5-dimethylphenol or p-chlorophenol or resorcinol or t-butylphenol the positive and negative photoresists are made by mixing these polymers with appropriate photoactive components. For preparation of e-beam photoresist, these novolac resins are fist derivatised by t-BOC and then mixed with photoacid generator.

Owner:DEFENCE RES & DEV ORG GOVERNMENT OF INDIA

Method for preparing line-type o-cresol novolac epoxy resin

The invention provides a preparation method of the linear o-cresol-formaldehyde epoxy resin with the o-cresol-formaldehyde resin and epichlorohydrin as the raw materials; the polar additive is added; at the temperature between 40 and 120 Celsius system, the alkali catalyst is dropped; the material is decompressed, returned and reacted for 2 to 10 hours; the epichlorohydrin is decompressed and recycled; the solvent is added to dissolve and the alkali catalyst; the material is refined for 0.5 to 10 hours at the temperature between 40 and 100 Celsius system; the water is added until the Ph value is between 6 and 7; the solvent is decompressed and recycled; then the o-cresol-formaldehyde epoxy resin can be made. For the linear o-cresol-formaldehyde epoxy resin produced in the method, the epoxy value is above 0.50 eq per 100g; the content of the chlorine ion is below 150 ppm; the electronic components packaged with the resin can maintain the good electrical insulating properties even in the high-temperature, humid harsh environment.

Owner:CHINA PETROCHEMICAL CORP +1

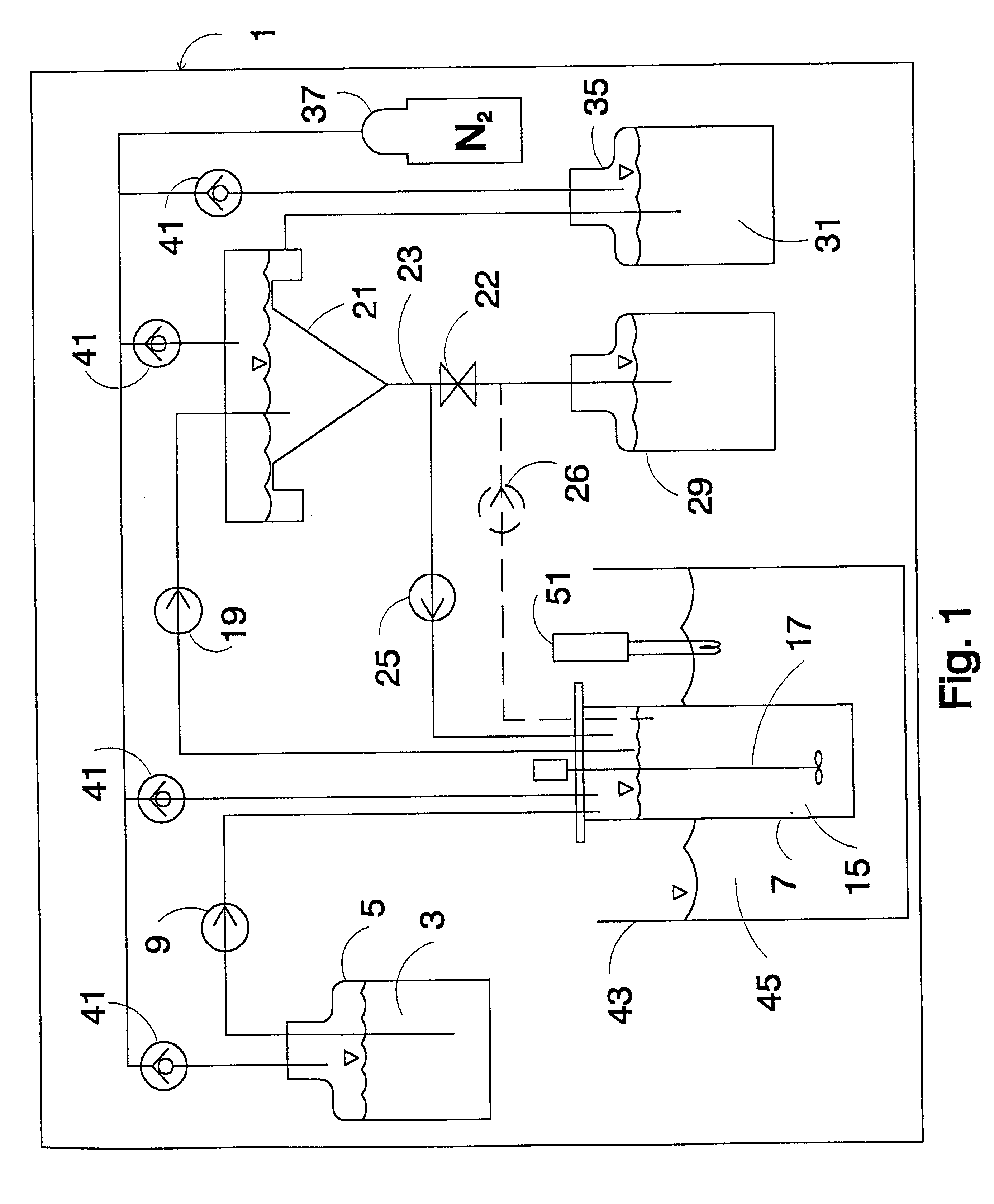

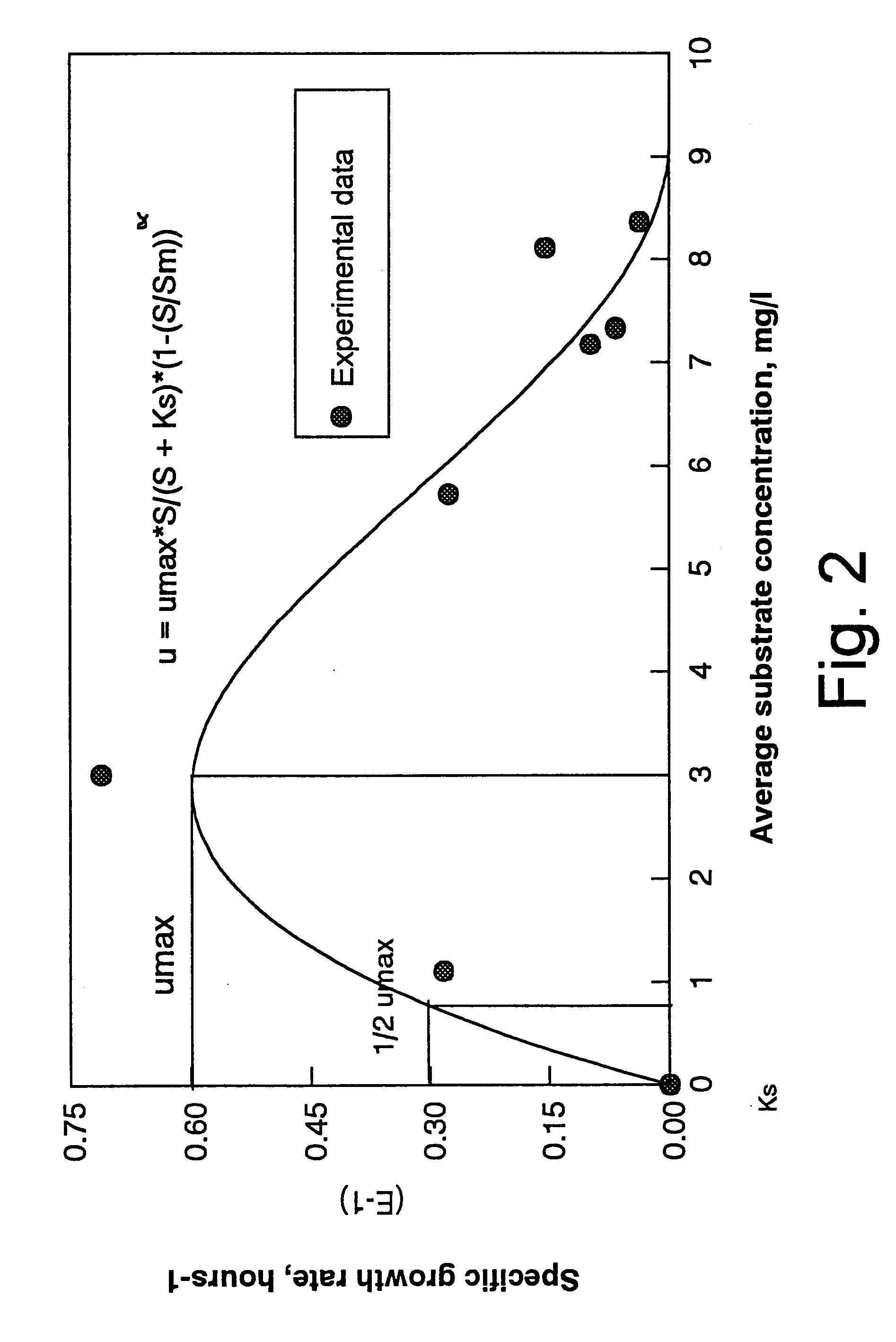

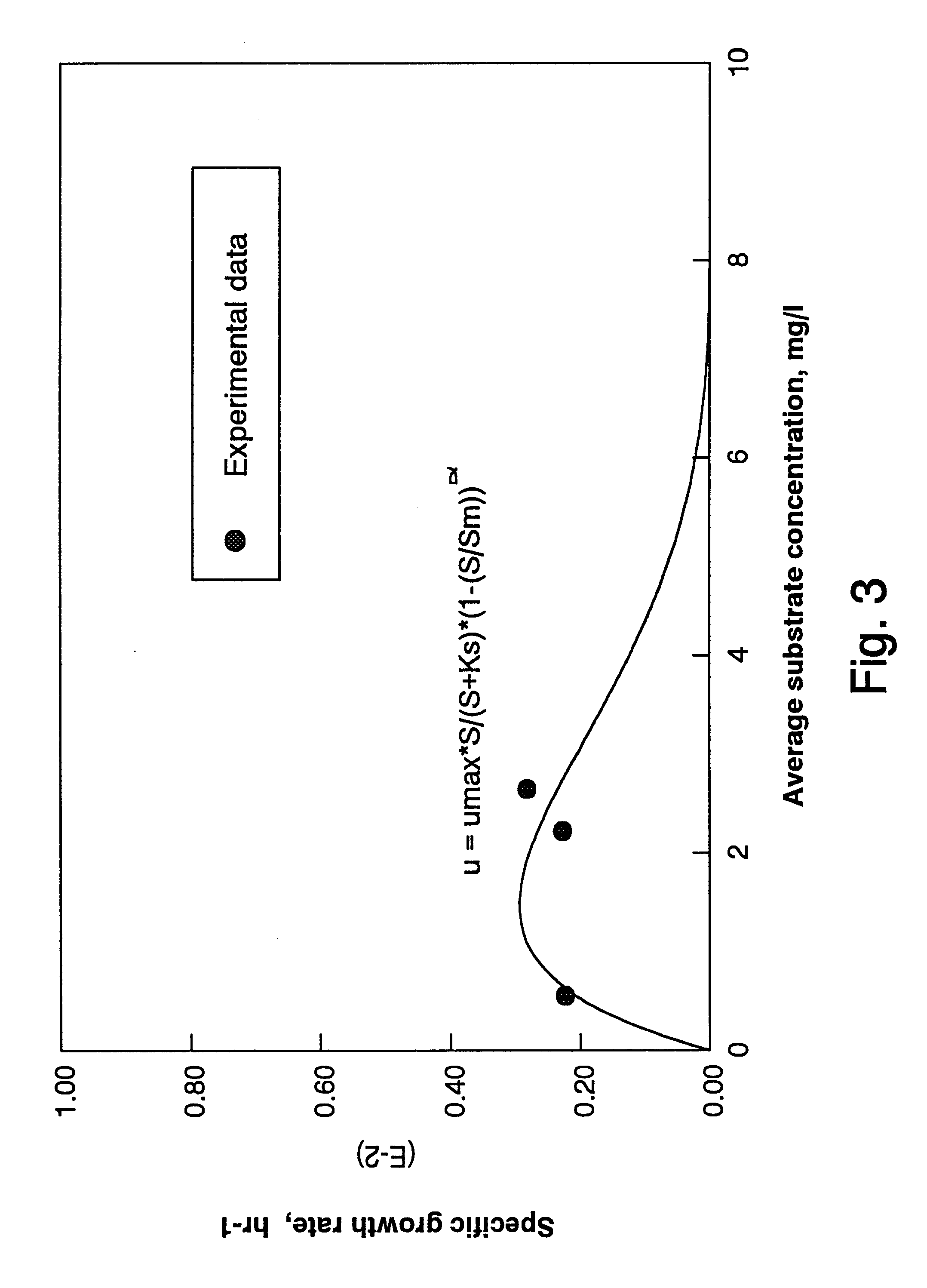

Anaerobic biodegradation of unsaturated, saturated, aromatic and halogenated hydrocarbons

An apparatus and method for anaerobic biodegradation, bioremediation or bioprocessing of hydrocarbons dissolved in an aqueous matrix, such as wastewater, groundwater, or slurry. Dissolved alkanes (saturated hydrocarbons), alkenes (unsaturated hydrocarbons), aromatic hydrocarbons and / or halogenated hydrocarbons are metabolized or cometabolized. In one form, the invention involves introducing an aqueous stream comprising at least one dissolved aromatic hydrocarbon (such as benzene, toluene, ethylbenzene, o-xylene, m-xylene, p-xylene, phenol, o-cresol, m-cresol, or p-cresol) and a dissolved oxide of nitrogen [such as nitrate (NO3-), nitrite (NO2-), nitric oxide (NO) and nitrous oxide (N2O)] to a reactor, and operating said reactor under conditions that support denitrification of the aromatic hydrocarbon. Alternatively, the aqueous stream may comprise at least one alkane (such as ethane) and / or at least one alkene (such as ethene or ethylene) and biodegradation of these compounds is accomplished. In a preferred form, the aqueous stream also comprises at least one dissolved halogenated hydrocarbon (such as tetrachloroethylene, trichloroethylene, or 1,1,1-trichloroethane) and dehalogenation of the halogenated hydrocarbon is accomplished. The reactor may be a continuous stirred tank reactor, a batch (or sequencing batch) reactor, a plug-flow reactor, a fixed-film reactor, or a pore space in an underground aquifer in situ. The reactor is operated in such a way that molecular oxygen is excluded from the space or zone in which the biodegradation is occurring and the other requirements of denitrifying bacteria are met. In some implementations, kinetic control (control of mean cell residence time) is used to enrich a denitrifying culture in the reactor.

Owner:YESTECH

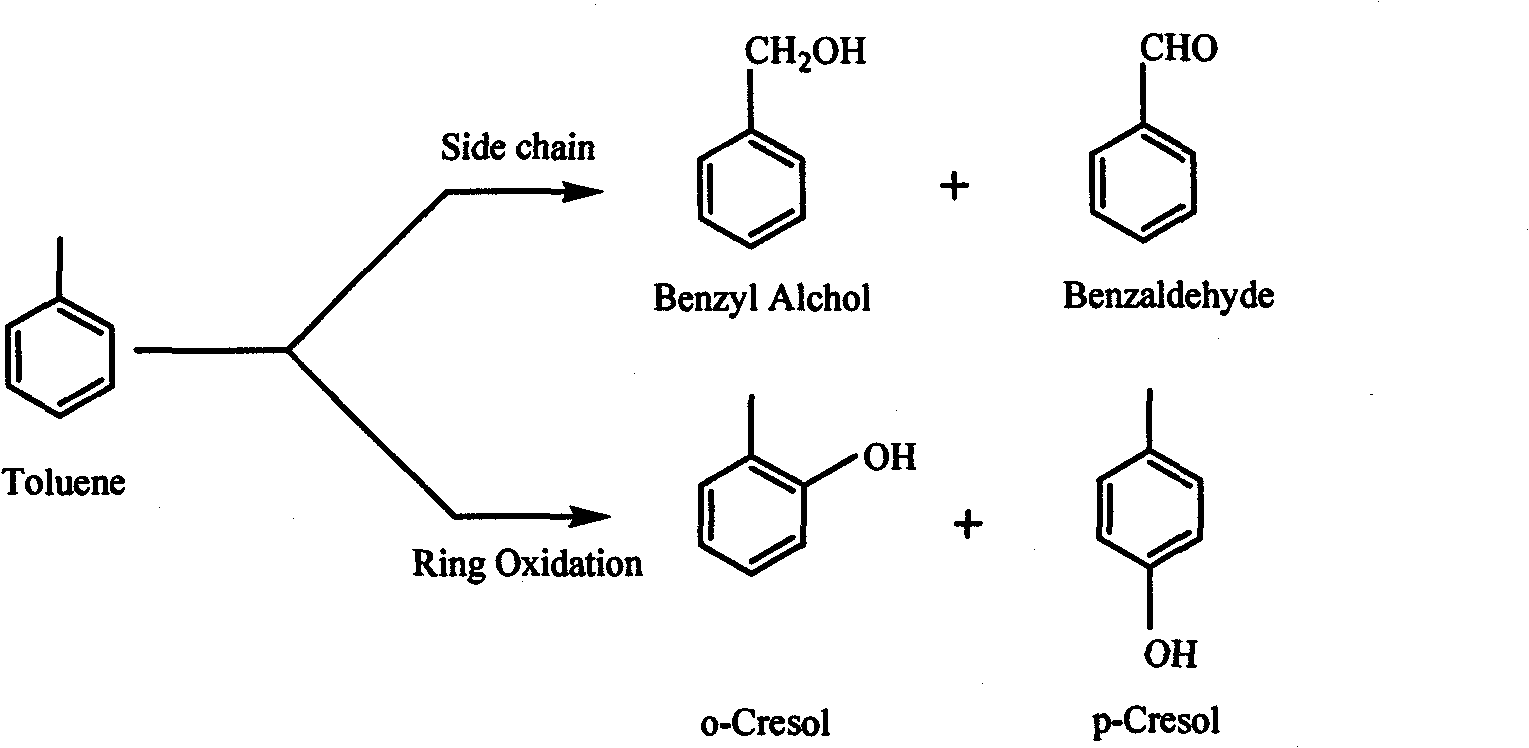

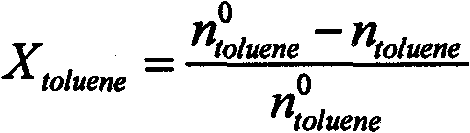

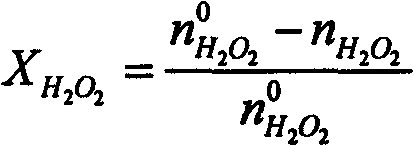

Catalytic synthesis method for preparing cresol by toluene one-step hydroxylation reaction

InactiveCN101786943AImprove effective utilizationIncreased o-cresol concentrationOrganic chemistryMolecular sieve catalystsRare-earth elementSynthesis methods

The invention discloses a catalytic synthesis method for preparing cresol by toluene one-step hydroxylation reaction, which is characterized in that: composite catalyst consisting of titanium silicalites and kieselguhr is adopted, the hydrogen peroxide is used as oxidant and the acetone is used as solvent, a continuous fixed-bed catalytic reaction system is adopted, and the reaction is carried out in solid-liquid two phases. The titanium silicalite in the composite catalyst has a MFI structure, and the kieselguhr is subjected to modification by a specific chemical method; and meanwhile, rare-earth elements are used to carry out modification on the catalyst, so that the catalyst has higher catalytic performance for the cresol-prepared toluene one-step hydroxylation reaction. The reaction process has the characteristics of high selectivity of cresol product, high effective utilization ratio of hydrogen peroxide, molar ratio of o-cresol to p-cresol in the cresol products of 1.3 to 1.4, mild reaction condition, simple and safe technological process, environmental protection and the like; therefore, the invention provides an economic and ecological method for preparing cresol.

Owner:EAST CHINA UNIV OF SCI & TECH

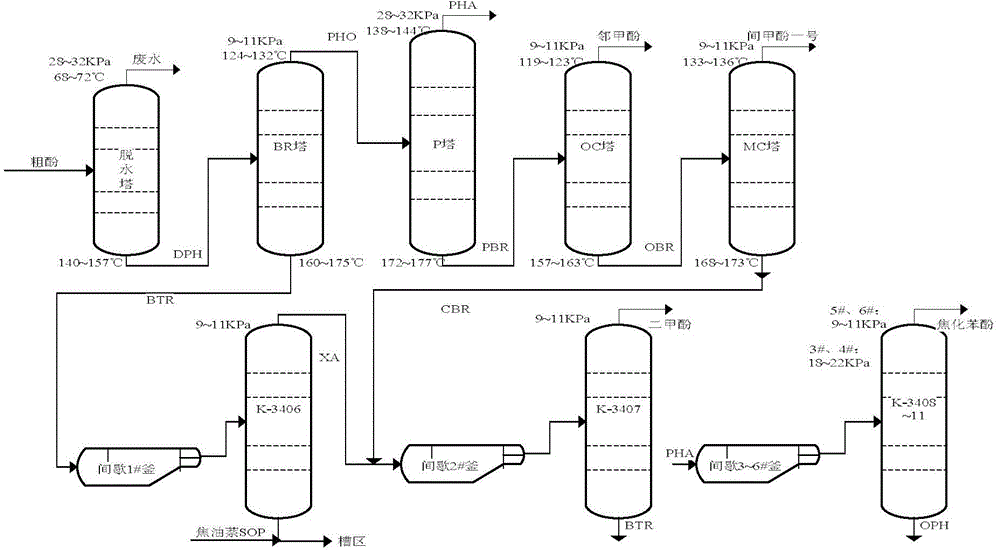

Production process of phenol products

InactiveCN1974517ALess investmentSmall footprintOrganic chemistryOrganic compound preparationTheoretical plateSlag

The present invention relates to coal chemical technology, and is especially process of producing phenol products. By using crude phenol after dewaterig and eliminating slag as material and through once intermittent rectifying process in a rectifying tower with theoretical plate number of 60-90, phenol, o-cresol fraction, m, p-cresol and industrial xylenol are obtained, with the o-cresol fraction is intermittently decompression rectified to obtain o-cresol product. Compared with tower type process, the present invention has low cost, small area and low power consumption.

Owner:ANGANG STEEL CO LTD

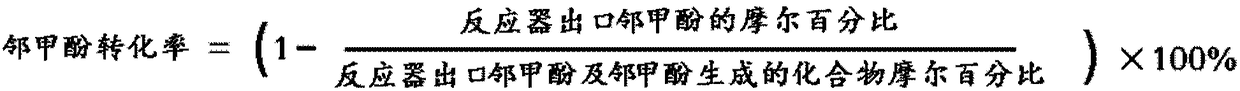

Preparation method of o-methylcyclohexanol

The invention discloses a preparation method of o-methylcyclohexanol. A hydrogenation raw material contacts with hydrogen in a hydrogenation reactor under the action of a catalyst and reaction, so as to obtain an o-methylcyclohexanol product. The method has the advantages of simple technological process, high catalyst activity, and high in o-cresol conversion rate and o-methylcyclohexanol yield; the activity selectivity after the catalyst continuously runs for 2500 hours is not obviously reduced; and the method is suitable for continuous and large-scale production of o-methylcyclohexanol.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Plant growth nutrient solution

The invention relates to a plant growth nutrient solution which is prepared from the following raw materials in parts by weight: 1.5 parts of zinc sulfate, 0.75 part of boric acid, 9 parts of urea, 7 parts of monopotassium phosphate, 2 parts of triacontanol, 14 parts of methyl alcohol, 1.5 parts of aspirin, 5 parts of potassium permanganate, 0.5 part of polyoxyethylene sorbitan glyceryl monooleate, 0.7 part of fenvalerate, 0.5 part of o-cresol, 3 parts of nicotinamide, 4 parts of ethylene oxide, 14 parts of ethylene, 2 parts of vitamin B6, 3 parts of sodium selenite, 5 parts of ammonium dihydrogen phosphate, 5 parts of sodium benzoate, 2 parts of sodium dodecyl benzene sulfonate, 1.5 parts of heteroauxin, 1.5 parts of gibberellin, 1.5 parts of cytokinin, 4 parts of garlic and 450 parts of deionized water. The plant growth nutrient solution has the beneficial effects that the rapid growth of plants is promoted, the mature periods of melons and fruits are earlier than planned within more than 10 days, the yields of melons and fruits are increased by more than 60%, and insect pests in each stage of the plants can be prevented and controlled.

Owner:尹红

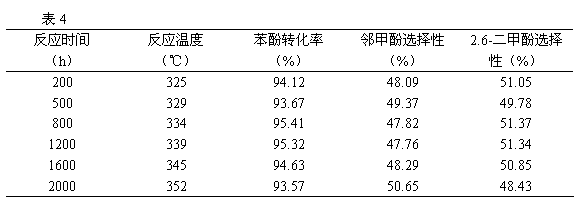

Method for preparing ortho-cresol and 2,6-dimethylphenol

InactiveCN102826960AAdjustable pHHigh activityOrganic chemistryOrganic compound preparationPtru catalystOrtho position

The invention discloses a method for preparing ortho-cresol and 2,6-dimethylphenol and is characterized in that a reaction mixed liquid at the mole ratio of phenol to methanol to water being 1: (2-5): (1-3) is pumped the into a reactor by the use of a pump at the feeding space velocity of 0.5-2 hr<-1>; N2 with the flow velocity of 10-25 mL / min is used as a carrier gas; and a vapor-phase alkylation reaction is carried out at the reaction pressure of normal pressure to 0.5 MPa at the reaction temperature of 320-380 DEG C and under the condition of an alkaline Fe / Mg / Sb composite oxide used as a catalyst. The method provided by the invention has advantages as follows: high average conversion rate of phenol, long one-way service life of the catalyst, high ortho-selectivity, and no generation of impurities m.p-cresol and anisole. In addition, the process is simple, and the method is suitable for continuous large-scale production of ortho-cresol, or reallocation of 2,6-dimethylphenol, or co-production of ortho-cresol and 2,6-dimethylphenol.

Owner:HUNAN XINLING CHEM CO LTD

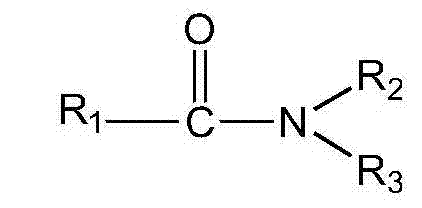

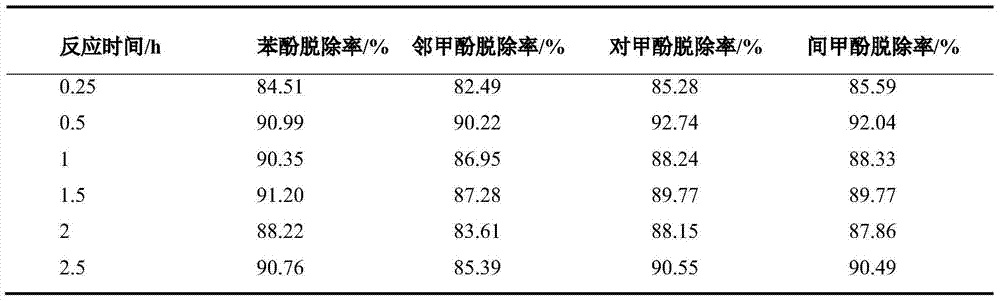

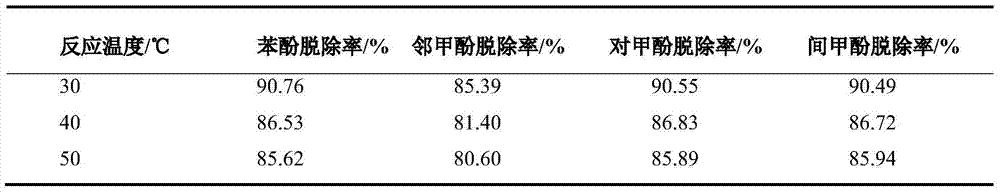

Method for directly separating phenols from coal pyrolytic oil

InactiveCN104324519ASimple processMild conditionsOrganic chemistryOrganic compound preparationEtherOil phase

The invention discloses a method for directly separating phenols from coal pyrolytic oil. Amide compounds are taken as extracting agents and form eutectic solvent solvents or solid complexes insoluble in the oil phases with phenols in oil, and therefore, the phenols are separated from the oil phases. Ether compounds are adopted to recycle the extracting agents by virtue of reverse extraction; the recycled extracting agents can be continuously applied to the extraction process. The phenols can be one or more of phenol, o-cresol, p-cresol, m-cresol, ethyl phenol, naphthol, butyl phenol, propyl phenol, dihydroxyl phenol and polyhydroxyl phenol; the oil includes model oil and pyrolytic oil; the concentration range of the phenols is 10-400g / L; the molar ratio of the amide compounds to the phenols is within the range of 0.1-2.0; the separation temperature ranges from 0 to 100 DEG C and the separation time ranges from 1 to 100 minutes. The removal rate of the phenols under appropriate reaction conditions is above 90%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method for high softening point o-cresol formaldehyde epoxy resin

InactiveCN102838727AImprove insulation performanceHigh softening pointInksThermal dilatationPolymer science

The present invention provides a preparation method for a high softening point o-cresol formaldehyde epoxy resin. The preparation method comprises the following steps: adopting o-cresol and paraformaldehyde as raw materials, carrying out a reaction for 3-5 hours under a catalysis effect of a catalyst, and carrying out a post-treatment to obtain a high softening point o-cresol formaldehyde resin; mixing the synthesized linear high softening point o-cresol formaldehyde resin and epichlorohydrin according to a mass ratio of 1:3-1:10; adding an auxiliary agent; carrying out an etherification reaction at a temperature of 30-100 DEG C; adding an alkali to catalyze a ring closing reaction under a vacuum degree of 0.01-0.1 MPa; recovering the epichlorohydrin; and carrying out a refinement reaction and a post-treatment. The o-cresol formaldehyde epoxy resin prepared by adopting the preparation method of the present invention has the following characteristics that: high softening point of 80-95 DEG C can be achieved; epoxy equivalent is low; hydrolyzable chlorine content is low; and a high yield can be achieved. In addition, the o-cresol formaldehyde epoxy resin of the present invention is a special function type epoxy resin focused for green electronics encapsulation, IC packaging and circuit board (green oil), wherein the o-cresol formaldehyde epoxy resin has characteristics of high heat resistance, low moisture absorption, and low thermal expansion coefficient.

Owner:CHINA PETROCHEMICAL CORP

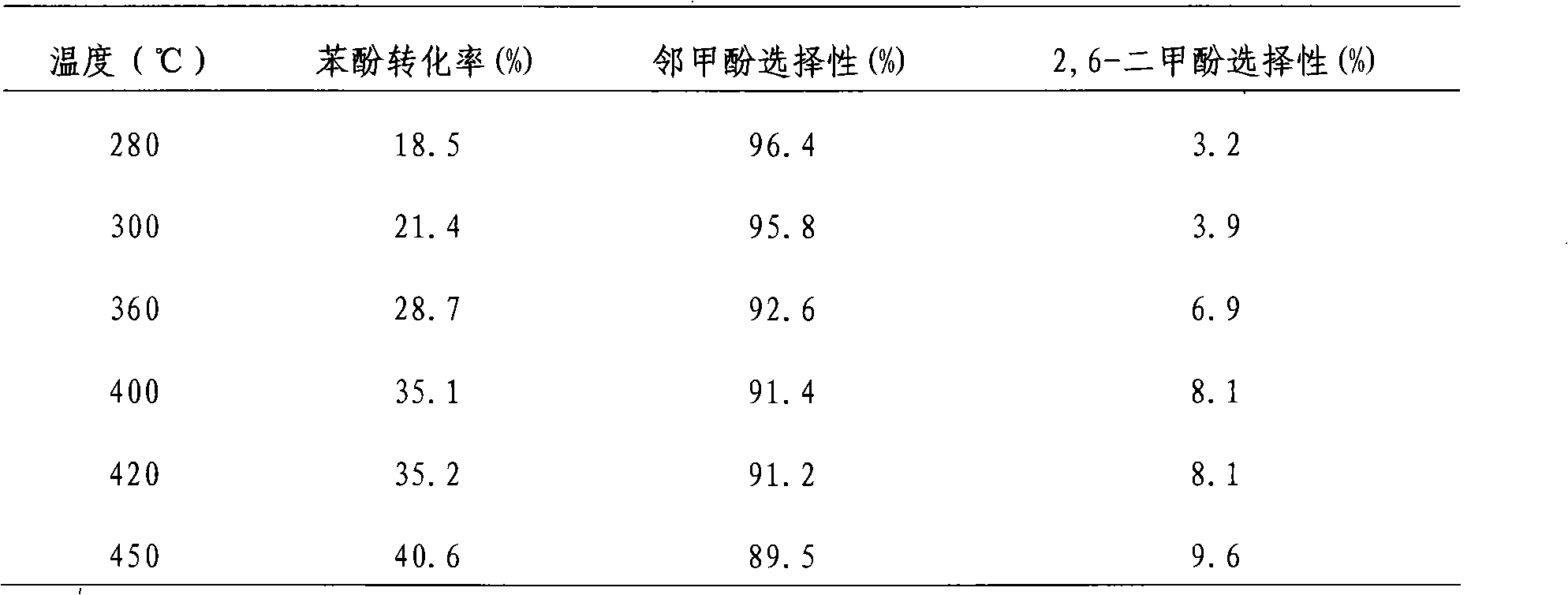

Method for preparing o-cresol

ActiveCN101514145AHigh selectivityLow selectivityOrganic chemistryOrganic compound preparationReaction temperatureP-Cresol

The invention discloses a method for preparing o-cresol, which is characterized by comprising the following steps: uniformly mixing phenol with methanol by a mass ratio 1: (0.5-4), and then pumping the mixture into a reaction tube containing alkylate catalyst, introducing inert carrier gas into the reaction tube, and obtaining o-cresol after condensing and recycling the reaction product. The reaction conditions comprise normal atmosphere, reaction temperature of 280 to 450 DEG C, and the airspeed of incoming stock of 0.8-1.8h. The method has advantages of simple technical process, high selectivity of o-cresol, no generation of by-products such as meta-cresol, p-cresol and anisole relatively low selectivity of 2, 6-dimethyl phenol and long service life of the catalyst.

Owner:HUNAN XINLING CHEM CO LTD

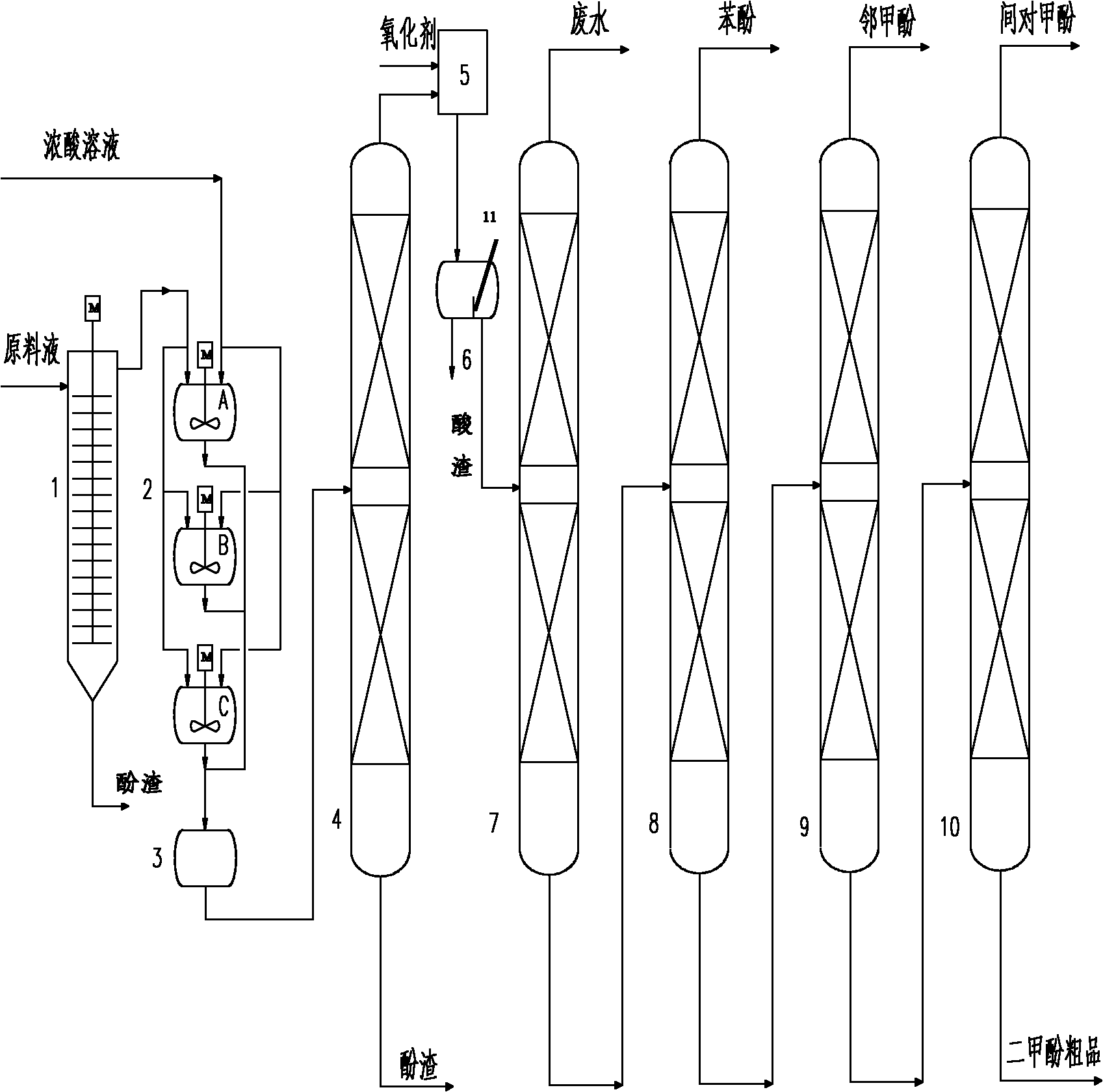

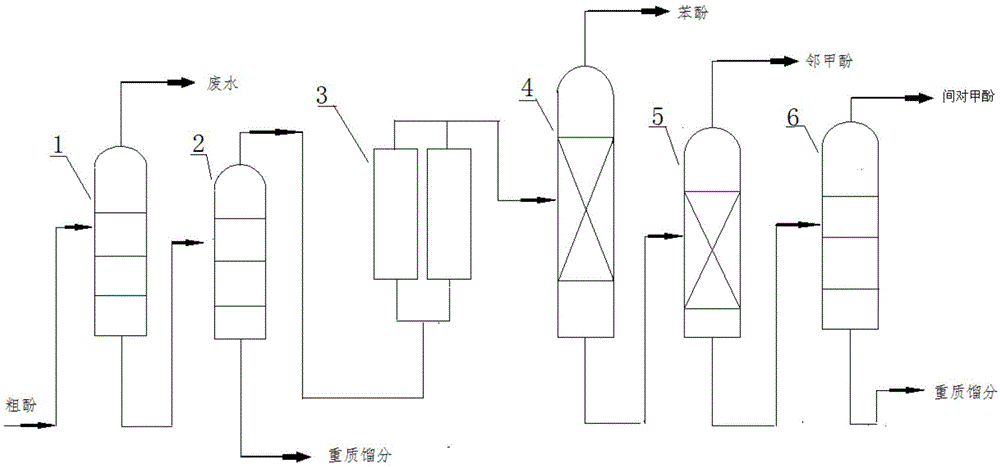

Continuous refining separation device and method for coal gasification crude phenol

ActiveCN102153449ASolve corrosion resistanceQuality assuranceOrganic chemistryOrganic compound preparationP-CresolImpurity

The invention discloses a continuous rectification separation device and a continuous rectification separation method for coal gasification crude phenol. The device comprises a first-level pretreatment acidifying unit consisting of a film scraping evaporator, a primary acid regulating tank group and a buffer tank, a second-level pretreatment oxidizing unit consisting of a static mixer and a secondary acid regulating tank and a rectifying tower system consisting of a deslagging tower, a dehydrating tower, a phenol refining tower, an o-cresol refining tower and a m, p-cresol refining tower, wherein the first-level pretreatment acidifying unit is connected with the phenol deslagging tower; and the phenol deslagging tower is connected with the second-level pretreatment oxidizing unit and is connected with each rectifying tower system respectively. By the device and the method, the raw material of the coal gasification crude phenol is subjected to decoloration, deodorization, desulfuration, impurity removal and the like effectively, so that products of high-purity phenol with the purity of more than 99.5 weight percent, high-purity o-cresol with the purity of more than 96.0 weight percent, high-purity m, p-cresol with the purity of more than 99.0 weight percent, mixed xylenol and phenol residual oil can be obtained. The method has the characteristics of reasonable process, high automaticity, low process energy consumption, high quality of products, high stability and the like, and is an efficient and feasible continuous rectification separation process for the coal gasification crude phenol.

Owner:天津美科泰化工科技有限公司

Method for producing m-cresol

The invention relates to a method for converting o-cresol or p-cresol into m-cresol with high productivity. The method at least comprises the following steps: during a technology of extracting m-cresol from m-cresol and p-cresol mixture complexation, after a complexing crystallizing method is adopted to isolate partial m-cresol, the residual m-cresol and p-cresol mixture with m-cresol content less than 50% is regarded as raw material solution, and isomerization is carried out to raw material solution again.

Owner:BEIJING RISUN TECH CO LTD

Novel heat-resistant corrosion-resistant coating as well as preparation and application method thereof

InactiveCN106010229AEvenly paintedStable performanceFireproof paintsAnti-corrosive paintsCorrosion resistantChemistry

The invention provides a novel heat-resistant corrosion-resistant coating as well as a preparation and application method of the novel heat-resistant corrosion-resistant coating, wherein the novel heat-resistant corrosion-resistant coating comprises ethyl silicate, methyl triethoxysilane, triethylamine, ethyl alcohol, hydrochloric acid, o-cresol formaldehyde epoxy resin, dimethylbenzene, diatomite, silica, zinc oxide, zoelite powder, mica, a butyl cellosolve solvent and butyl alcohol. The novel heat-resistant corrosion-resistant coating is reasonable in components, the stability, the corrosion resistance and the heat resistance of a product are good, and the stability is high. The preparation method of the novel heat-resistant corrosion-resistant coating is simple and feasible in process, high in production efficiency and low in application cost, the operation is easy and simple to implement, the quality of a produced product is stable, and the popularization and application values are relatively high.

Owner:SUZHOU TIANJIANHENG ELECTRONICS INFORMATION TECH CO LTD

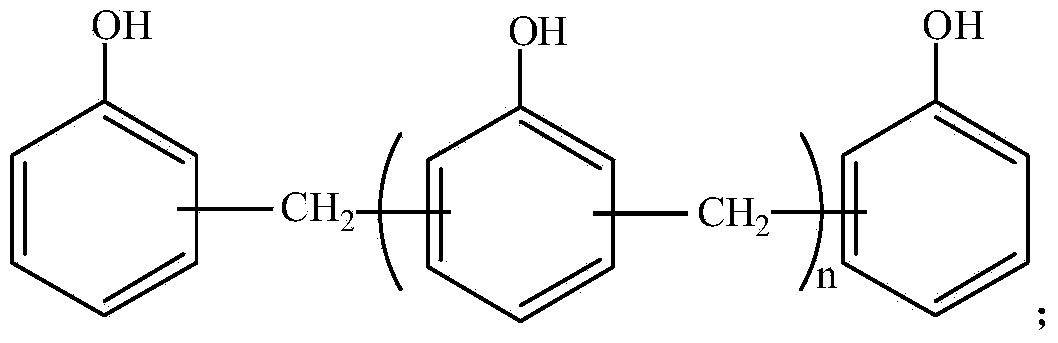

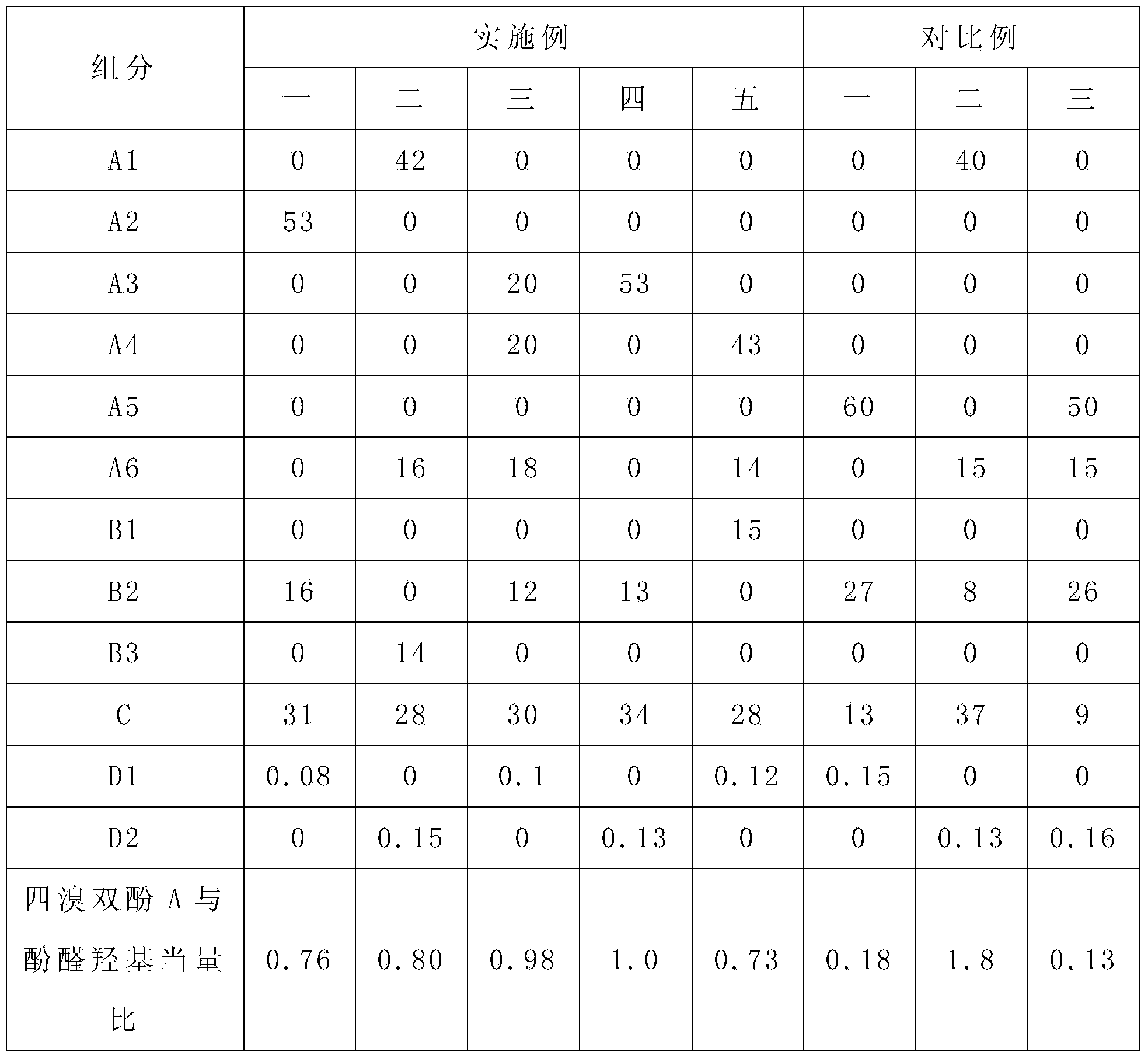

Thermosetting resin composition and prepreg and laminated board prepared therefrom

ActiveCN103897350AImprove toughnessNo crackingSynthetic resin layered productsMetal layered productsTetrabromobisphenol APrinted circuit board

The invention discloses a thermosetting resin composition, comprises the following components in solid weight: (a) 50-95 parts of o-cresol phenolic epoxy resin; (b) 5-32 parts of linear phenolic resin; (c) 2-42 parts of tetrabromo bisphenol A; and (d) 0.01-0.5 part of accelerator, wherein the hydroxyl equivalent ratio of the tetrabromo bisphenol A to the linear phenolic resin is 0.4-1.2. The laminated board prepared from the thermosetting resin composition is good in toughness and free from punching / rotating hole quality problem and cracking in the subsequent PCB (printed circuit board) manufacture process, the circuit board machining requirement can be well satisfied, and the thermosetting resin composition has positive practical significance.

Owner:SHENGYI TECH SUZHOU

Method for preparing etherification catalyst and method for producing o-methylanisole

InactiveCN109277115AImprove performanceImprove stabilityMolecular sieve catalystsCatalyst activation/preparationMolecular sieveWater vapor

The invention provides a method for preparing an etherification catalyst. The method includes the following steps: a) molecular sieve and a binder are mixed and molded, and are calcinated at 500-700 DEG C for 4-10 hours; c) oxidate modification is performed on a product obtained in the last step, and the product is calcinated at 550-700 DEG C for 3-10 hours, wherein an oxide is selected from one or more of an alkaline earth metal oxide and a rare-earth metal oxide; and d) steam treatment is performed on the product obtained in the last step at 300-800 DEG C for 0.5-10 hours, wherein an order of implementation of the step c) and the step d) can be interchanged. The invention also provides a method for producing o-methylanisole by an etherification reaction, by using o-cresol and methanol asraw materials, and by using the etherification catalyst. According to the method, the catalyst is good in stability, does not produce equipment corrosion during a production process, is an environmentally friendly catalyst, and has good industrial application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

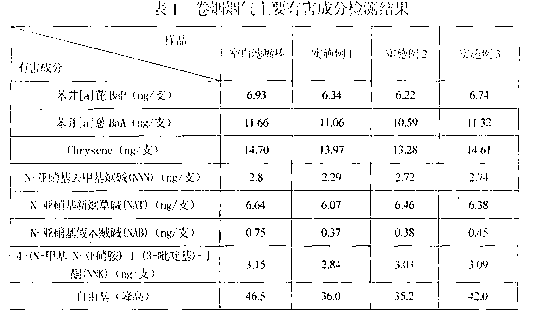

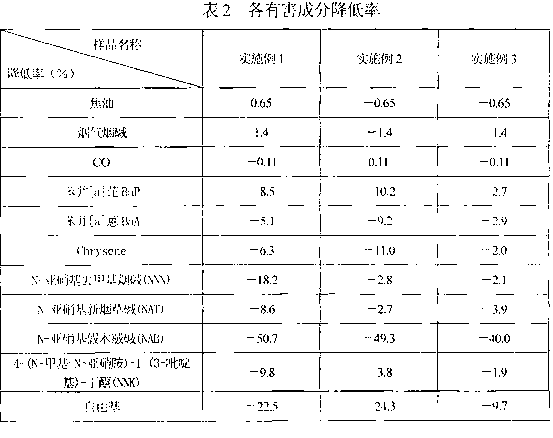

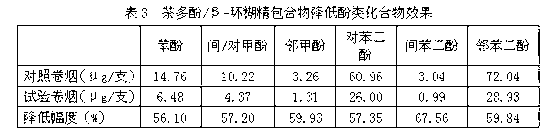

Applications of tea polyphenol/beta-cyclodextrin inclusion compound taken as cigarette filter additive in reduction of cigarette smoke phenolic compound

The invention provides applications of a tea polyphenol / beta-cyclodextrin inclusion compound taken as a cigarette filter additive in reduction of a cigarette smoke phenolic compound. The tea polyphenol / beta-cyclodextrin inclusion compound takes a beta-cyclodextrin inclusion compound as a host molecule, and takes tea polyphenol as a guest molecule. According to the applications, as the host molecule of the inclusion compound has acting forces of van der waals' force, hydrophobic effect, hydrogen bonding and the like, and the guest molecule of the inclusion compound has the antioxidation function, the inclusion compound can be combined with phenolic compounds in the cigarette smoke selectively to play a selectively filtering role and alleviate the danger of the cigarette. The tea polyphenol / beta-cyclodextrin inclusion compound has the following technical effects that 1) under the premise of not changing the original smoking smell of the cigarette basically, the contents of main phenolic compounds such as phenol, m-phenol / p-phenol, o-cresol and resorcinol can be reduced greatly; and 2) the tea polyphenol / beta-cyclodextrin inclusion compound is few in addition amount, simple in addition mode, and can be added in the production process of a filter rod, and the operation is convenient and easy to implement.

Owner:CHINA TOBACCO JIANGSU INDAL

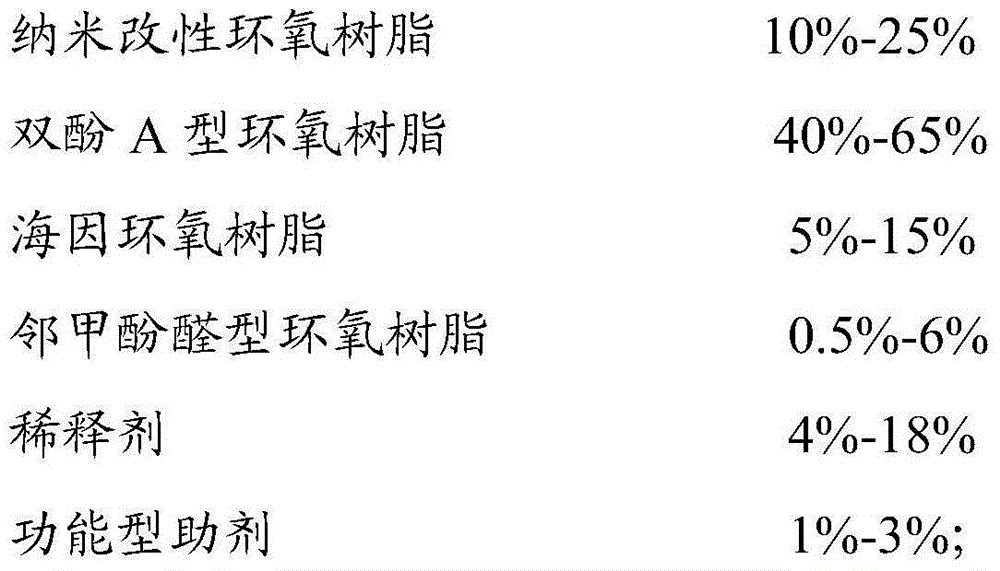

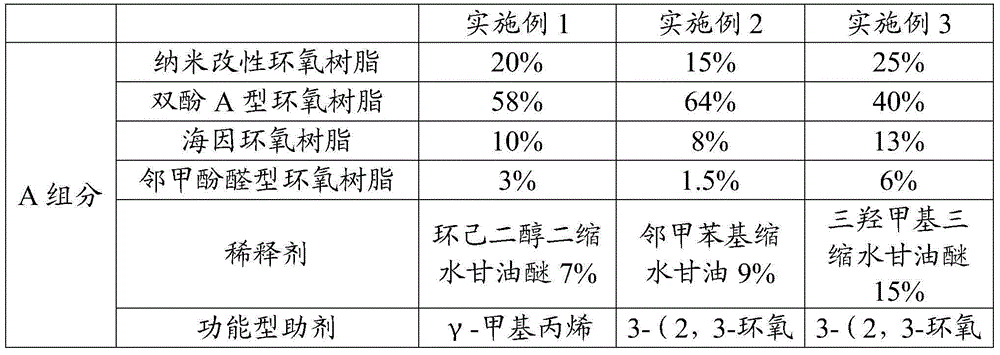

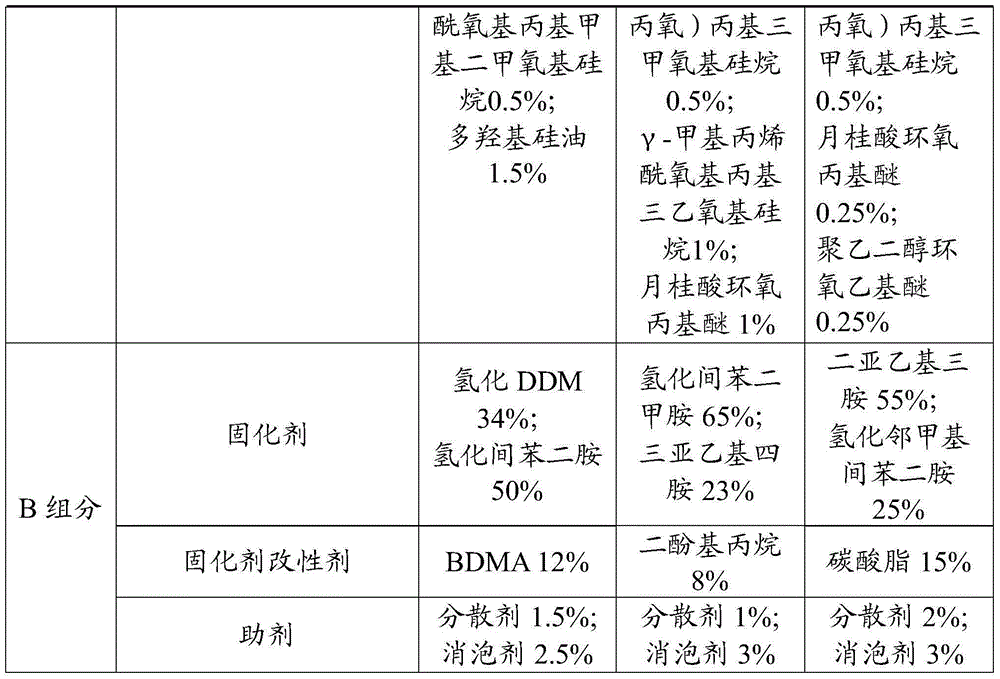

Epoxy resin system and preparation method thereof

The invention relates to an epoxy resin system and a preparation method thereof. The epoxy resin system comprises a component A and a component B, wherein the component A comprises 10-25% of nano modified epoxy resin, 40-65% of bisphenol A type epoxy resin, 5-15% of hydantoin epoxy resin, 0.5-6% of o-cresol formaldehyde type epoxy resin, 4-18% of diluent and 1-3% of a functional auxiliary; the component B comprises 80-90% of a curing agent, 5-15% of a curing agent modifying agent and 3-5% of auxiliaries. The epoxy resin system has low viscosity applicable to a vacuum pouring technology and also has high heat resistance and excellent mechanical properties through coordination of all the components, has good wettability on carbon fibers and glass fibers and can react rapidly at a low temperature for realizing a certain curing degree, and the curing degrees of all the parts are uniform; meanwhile, the requirement of a composite material mould on resin properties is met, and the cost is low.

Owner:GUANGZHOU POCHELY NEW MATERIAL TECH CO LTD

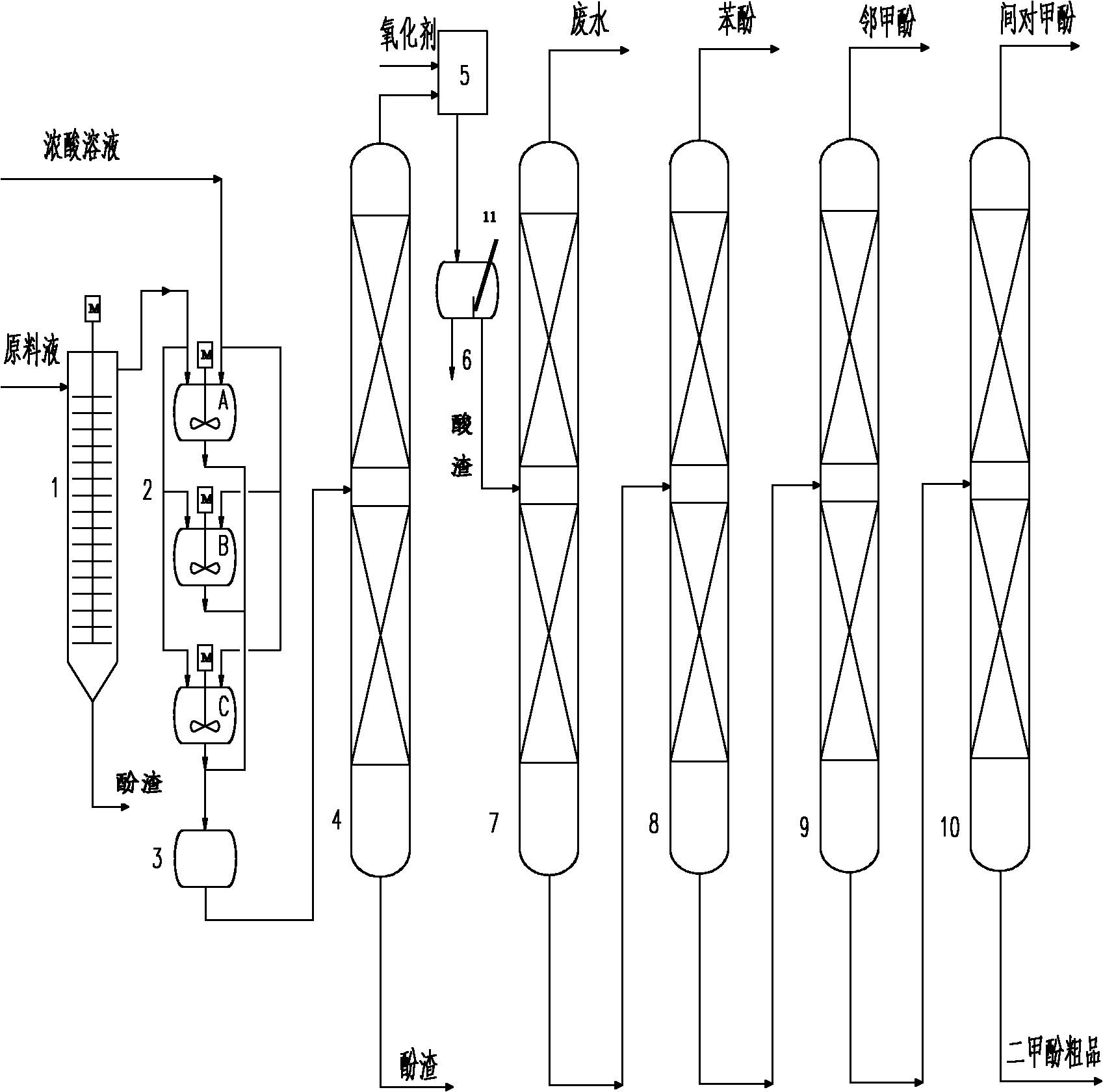

Coked crude phenol refining device and method

InactiveCN105198711AAvoid joiningEasy to operate and controlOrganic chemistryOrganic compound preparationDistillationP-Cresol

The invention provides a coked crude phenol refining device. The device adopts the scheme that a crude phenol pre-distillation system, an impurity conversion system and a refining distillation system are sequentially connected through pipelines, wherein the crude phenol pre-distillation system is composed of a dehydration tower and a de-heavy tower, which are connected; the impurity conversion system is composed of a middle tank and an adsorption reaction tower, which are connected; the refining distillation system is composed of a phenol tower, an o-cresol tower and a m-cresol and p-cresol tower, which are connected in sequence. According to the invention, the problem of impurity removal in the adsorption reaction tower is solved through a sweetening catalyst, so that the fact that a liquid oxidizing agent is added into raw material crude phenol is avoided and the operation and control are simpler and more convenient; the conventional intermittent distillation process of phenol fractions is eliminated, so that the whole crude phenol refining process becomes very refined and the processing cost of products is reduced greatly; the whole production process flow is reasonable, the device is high in automation degree, the product quality is high and the energy consumption is low.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

Process for synthesizing o-cresol formaldehyde epoxy resin with low chlorine content

InactiveCN102181039AReaction conditions are easy to controlHigh epoxy valueOther chemical processesEpoxyMethyl group

Owner:ZHUHAI CHANGXIAN CHEM TECH

Phosphorus-containing/nitrogen-containing phenolic resin and preparation method thereof

ActiveCN103254379AWide range of usesEasy to realize industrial productionAldehyde/ketone condensation polymer adhesivesEpoxyAdhesive

The invention relates to phosphorus-containing / nitrogen-containing phenolic resin and a preparation method thereof, and belongs to the technical field of flame retardant curing agents and package materials. By a method for easily realizing industrial production by fully adjusting the ratios of phenol or alkylphenol / phenylamine or alkylaniline / a phosphorus-containing compound or a nitrogen-containing compound, phenolic resin with different types of phosphorus-containing / nitrogen-containing content is obtained; and therefore, a composition consisting of the prepared phosphorus-containing / nitrogen-containing phenolic resin, phosphorus-containing epoxy resin and o-cresol formaldehyde epoxy resin has wider application range; and the phosphorus-containing / nitrogen-containing phenolic resin / epoxy resin composition can be applied to laminated material adhesives and electronic package materials (EMC).

Owner:江苏文昌电子科技有限公司

Method for preparing line-type o-cresol novolac resin

The invention provides a manufacturing method of the linear o-cresol-formaldehyde resin with the o-cresol and formaldehyde as the raw materials; the acidic catalyst is added in batches; the water is added to adjust the pH value of the reaction system to be between 3 and 5; at the temperature of 60 to 120 Celsius system, the reaction is kept for 4 to 10 hours; the solvent is added to dissolve; the water is added until the ph value is between 6 and 7; the solvent is decompressed and recycled; then the linear o-cresol-formaldehyde resin can be made. For linear o-cresol-formaldehyde resin produced in the method, the molecular weight distribution Mw per Mn is less than 4.

Owner:CHINA PETROCHEMICAL CORP +1

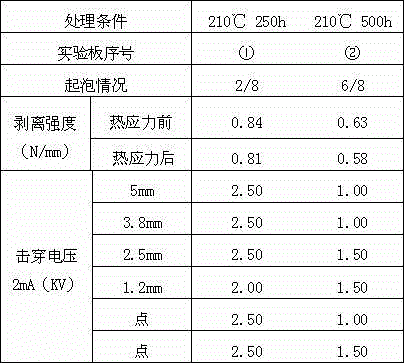

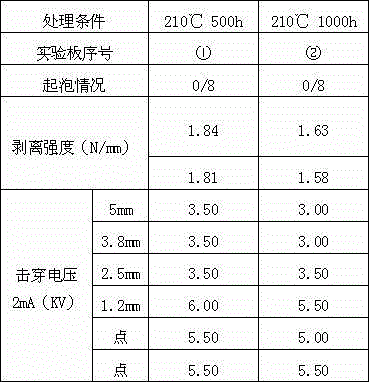

High-temperature-resistant and aging-resistant substrate and production method thereof

InactiveCN104610708AExcellent pyrolysis resistanceReduce liquidityNon-macromolecular adhesive additivesLaminationPolymer scienceInsulation layer

The invention provides a high-temperature-resistant and aging-resistant substrate. The substrate comprises an insulation layer which comprises substances in parts by weight as follows: 1-10 parts of o-cresol formaldehyde epoxy resin, 10-20 parts of phenoxy resin, 20-30 parts of bisphenol A type epoxy resin, 1-10 parts of nitrile butadiene rubber and 30-70 parts of filler. The substrate selects the resin adopting special structures, has excellent high-temperature decomposition resistance, can still keep good mechanical strength and electric strength after treated at the temperature of 210 DEG C for 1000 h and can be adapted to complex using environments such as high-temperature environments and the like.

Owner:广东全宝科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com