Epoxy resin system and preparation method thereof

An epoxy resin system and epoxy resin technology, applied in the chemical and material fields, can solve the problems of reducing the manufacturing cost of the mold production industry, the overall cracking of the mold, and the easy occurrence of dry spots, so as to avoid mold cracking, and the curing degree is uniform and good. The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

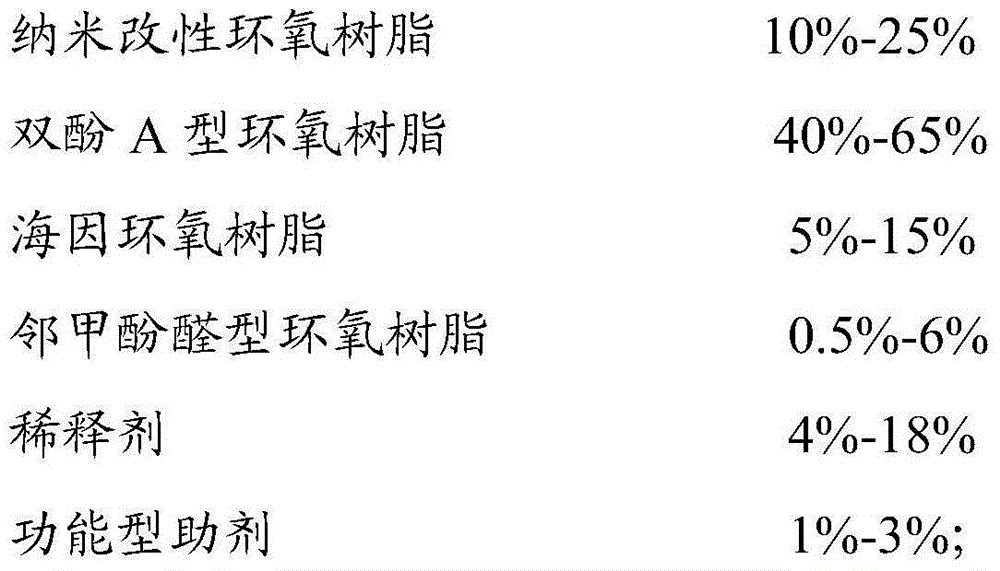

Method used

Image

Examples

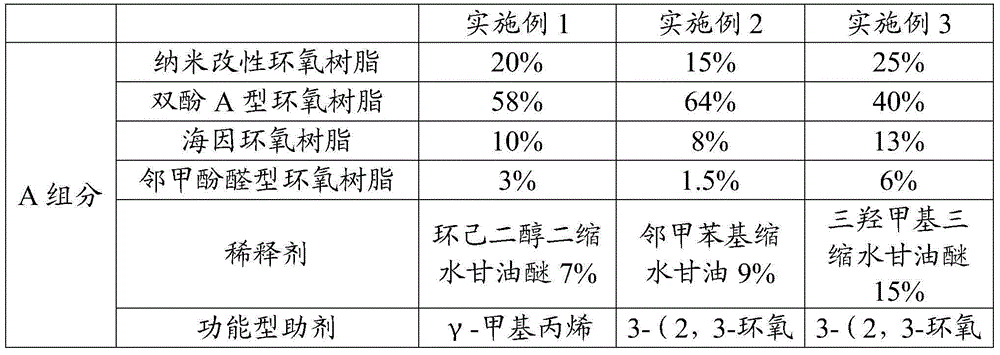

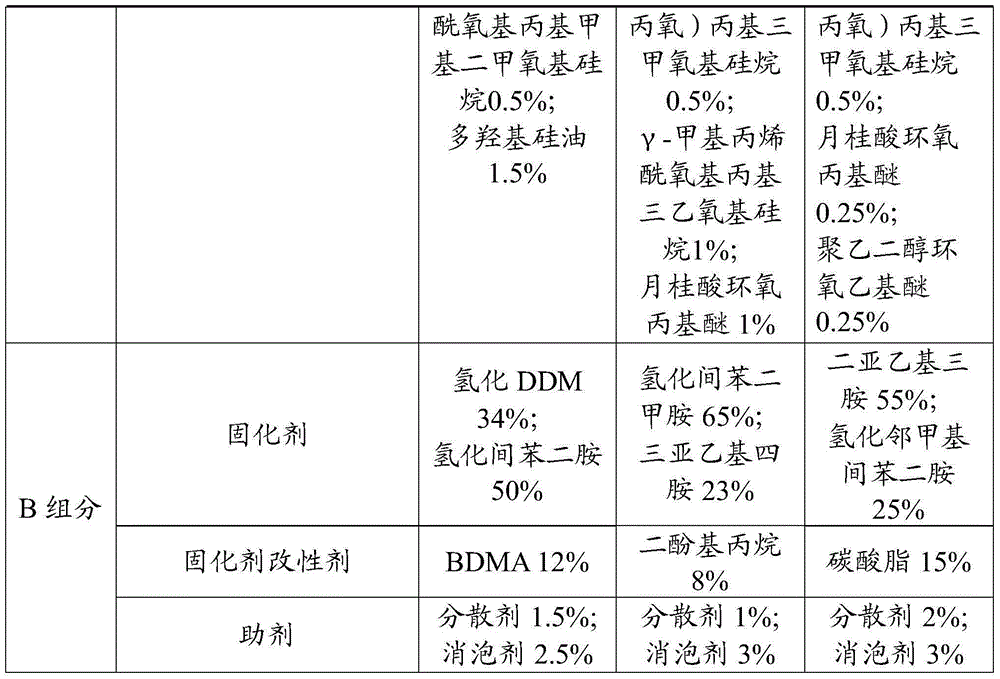

Embodiment 1

[0057] The preparation method of epoxy resin system described in embodiment 1 may further comprise the steps:

[0058] The bisphenol A type epoxy resin, hydantoin epoxy resin, o-cresol novolac type epoxy resin, and diluent are put into the reaction kettle according to the set mass ratio, and the vacuum pumping device is opened to set the vacuum degree to be 220-350mmHg, and at the same time Turn on the heating device to heat up to 50°C, stir with the mixer at a speed of 200R / min, mix for 2 hours, then add functional additives dropwise, then lower the temperature to 40-45°C, and drop the nano-modified ring at a uniform speed Oxygen resin, then continue to stir for 2 hours, filter, and discharge to obtain component A, with a viscosity of 1250mpa.s (25°C), an epoxy value of 0.71, and a light yellow transparent liquid;

[0059] Add the curing agent to the reaction kettle, vacuumize to 300-400mmHg, then close the vacuum equipment and keep the equipment sealed, start the mixer to st...

Embodiment 2

[0062] The preparation method of epoxy resin system described in embodiment 2 may further comprise the steps:

[0063] The bisphenol A type epoxy resin, hydantoin epoxy resin, o-cresol novolac type epoxy resin, and diluent are put into the reaction kettle according to the set mass ratio, and the vacuum pumping device is opened to set the vacuum degree to be 220-350mmHg, and at the same time Turn on the heating device to heat up to 45°C, stir with the mixer at a speed of 100R / min, mix for 1 hour, then add functional additives dropwise, then lower the temperature to 40-45°C, and drop the nano-modified ring at a uniform speed Oxygen resin, then continue to stir for 1 hour, filter, and discharge to obtain component A, with a viscosity of 1070mpa.s (25°C), an epoxy value of 0.75, and a colorless transparent liquid;

[0064] Add the curing agent to the reaction kettle, evacuate to 300-400mmHg, then close the vacuum equipment and keep the equipment sealed, start the mixer to stir at ...

Embodiment 3

[0067] The preparation method of epoxy resin system described in embodiment 3 may further comprise the steps:

[0068] The bisphenol A type epoxy resin, hydantoin epoxy resin, o-cresol novolac type epoxy resin, and diluent are put into the reaction kettle according to the set mass ratio, and the vacuum pumping device is opened to set the vacuum degree to be 220-350mmHg, and at the same time Turn on the heating device to heat up to 65°C, stir with the mixer at a speed of 300R / min, mix for 3 hours, then add functional additives dropwise, then lower the temperature to 40-45°C, and drop the nano-modified ring at a uniform speed Oxygen resin, then continue to stir for 3 hours, filter, and discharge to obtain component A with a viscosity of 900mpa.s (25°C) and an epoxy value of 0.54;

[0069] Add the curing agent to the reaction kettle, vacuumize to 300-400mmHg, then close the vacuum equipment and keep the equipment sealed, start the mixer to stir at a stirring speed of 200R / min, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com