Thermosetting resin composition and prepreg and laminated board prepared therefrom

A technology of resin composition and prepreg, which is applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., which can solve the problem of insufficient CAF resistance of plates, affecting product quality and reliability, and slag dropping from plate punching/drilling and other problems, to achieve the effect of low peel strength, meet the needs of mechanical processing, and balance heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment and

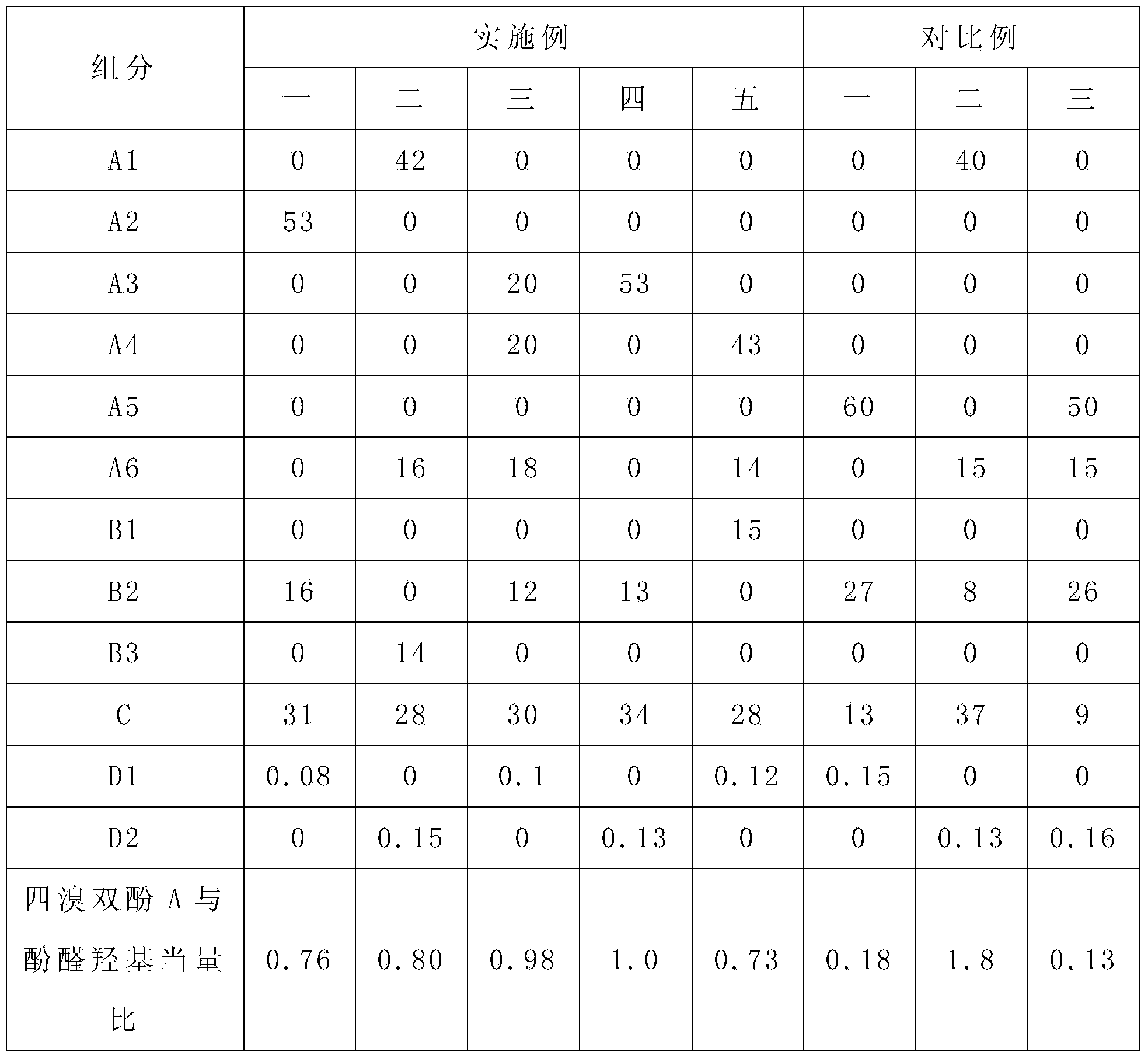

[0032] Embodiment and comparative example:

[0033] Unless otherwise specified below, "parts" represent "parts by weight", and "%" represent "% by weight":

[0034] A thermosetting resin composition, by solid weight, comprises the following components, as shown in the table below:

[0035] Table 1 Composition Formulation

[0036]

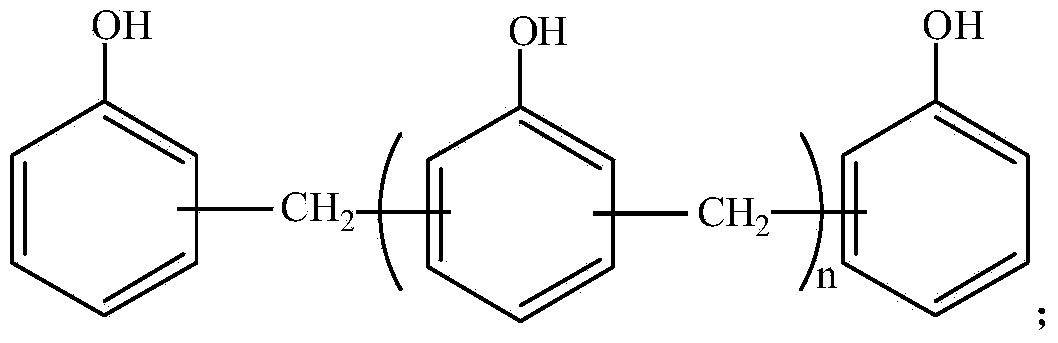

[0037] In the above table, component A means epoxy resin, component B means novolak resin, component C means tetrabromobisphenol A, and component D means accelerator.

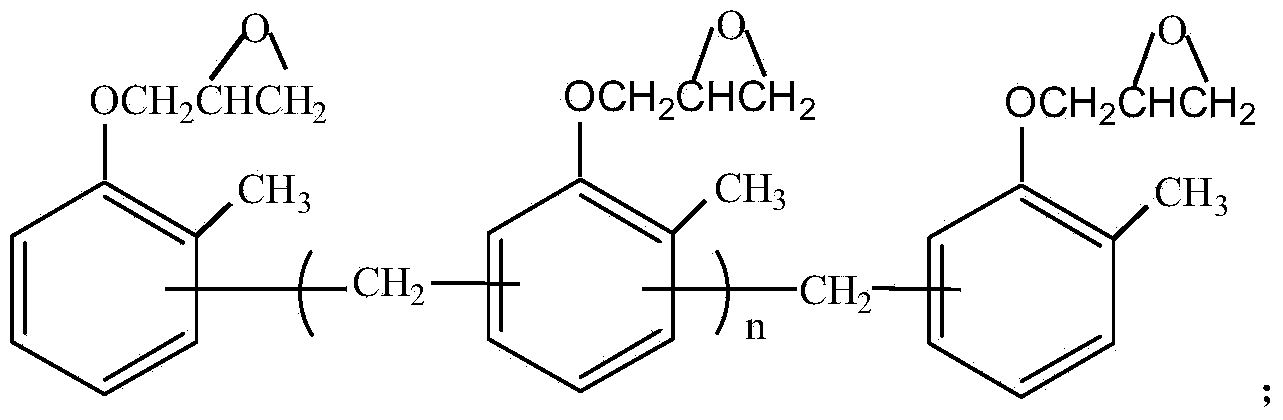

[0038] A: Epoxy resin;

[0039] A1: o-cresol novolak epoxy resin, the softening point is about 60°C;

[0040] A2: o-cresol novolak epoxy resin, the softening point is about 70°C;

[0041] A3: o-cresol novolac epoxy resin, the softening point is about 85°C;

[0042] A4: o-cresol novolac epoxy resin, the softening point is about 100°C;

[0043] A5: bisphenol A novolak epoxy resin, the softening point is about 70°C;

[0044] A6: Bisphenol A type brominated epoxy resin, the sof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com