Preparation method of hexaaniline cyclotriphosphazene and non-halogen flame retardant epoxy resin composition

A technology based on cyclotriphosphazene and hexachlorocyclotriphosphazene, which is applied in the field of polymer composite material preparation, can solve the problems of increased viscosity of epoxy resin composite materials, corrosion of metal wires, reduced reliability and the like, and achieves flame retardant performance improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The embodiment of the present invention provides a preparation method of hexaanilinocyclotriphosphazene, the method comprising:

[0019] Add organic solvent, hexachlorocyclotriphosphazene, aniline, and acid-binding agent into the reaction device, stir, pass in nitrogen gas (nitrogen with a purity of not less than 99.9%) for protection, heat to 50-120°C, and then feed the reaction device Add tetrabutylammonium bromide catalyst, react for 5 to 16 hours, cool to room temperature, filter with suction, distill the filtrate under reduced pressure, evaporate and remove the solvent, and obtain a brown viscous product, which is placed in a drying box. After drying at 40-70° C. under vacuum for 8 hours, the powder product obtained by crushing is hexaanilinocyclotriphosphazene.

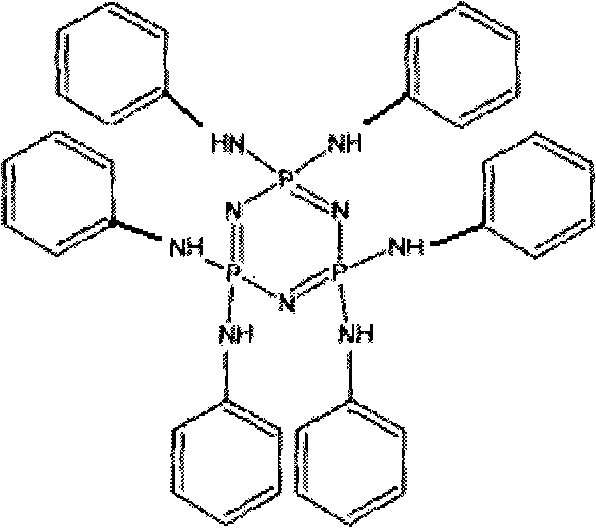

[0020] The structural formula of the hexaanilinocyclotriphosphazene made is:

[0021]

[0022] The solvent used in the above-mentioned method for preparing hexaanilinocyclotriphosphazene is any one or...

Embodiment 2

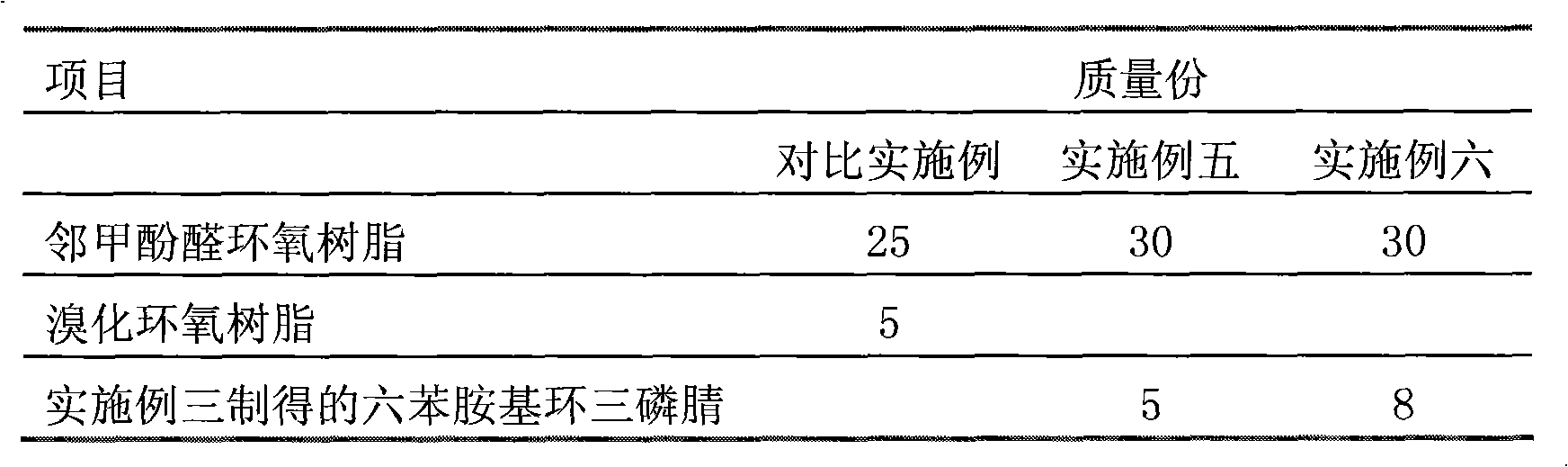

[0027] This example provides a method for preparing an epoxy resin composition using hexaanilinocyclotriphosphazene, mainly using the hexaanilinocyclotriphosphazene prepared in Example 1 to prepare a halogen-free flame-retardant epoxy resin Composition, the method specifically comprises:

[0028] The hexaanilinocyclotriphosphazene and o-cresol novolac epoxy resin, spherical silicon micropowder, imidazole curing accelerator, silane coupling agent, toughening agent and stearic acid prepared by the preparation method in the above-mentioned embodiment one The halogen-free flame-retardant epoxy resin composition is obtained after mixing the raw materials of the lubricant or wax lubricant, kneading, crushing, and degaussing treatment. Wherein, the mass proportion of hexaanilinocyclotriphosphazene and epoxy resin, curing agent, curing accelerator, silicon micropowder, lubricant, toughening agent and stearic acid is:

[0029] 10-30 parts by mass of o-cresol novolac epoxy resin

[00...

Embodiment 3

[0044] The present embodiment provides a kind of preparation method of hexaanilinocyclotriphosphazene, specifically comprises the following steps:

[0045]Take 5g of hexachlorocyclotriphosphazene and 80mL of tetrahydrofuran into a 250mL three-necked flask, add 12mL of triethylamine, fully stir and reflux, control the temperature of the water bath at 75°C, slowly add 8mL of aniline and 0.02g of tetrabutyl bromide Amine mixed solution, after reacting for 13h, was cooled to room temperature, obtained light yellow solution by suction filtration with vacuum pump, carried out normal pressure distillation to light yellow solution, removed solvent, obtained brown viscous thing, this material was placed in the vacuum oven (vacuum degree is less than -0.09MPa), dried at 60°C for 8 hours, and pulverized to obtain a brown powder product which is hexaanilinocyclotriphosphazene, with a yield of 80.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com