Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76 results about "Aminoethyl-aminopropyl-trimethoxysilane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of aminosilane-functionalized graphene reinforced silica gel

InactiveCN102002161AHigh compressive strengthGood dispersionPigment treatment with organosilicon compoundsTriethoxysilaneSilica gel

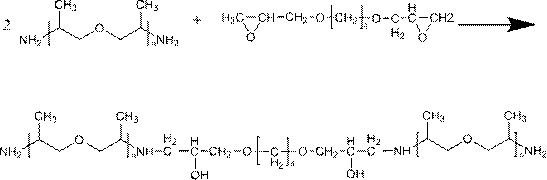

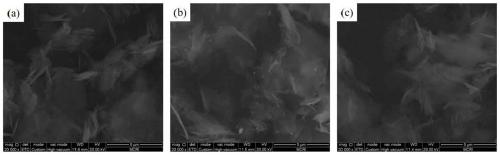

The invention provides a preparation method of aminosilane-functionalized graphene reinforced silica gel, which comprises the following steps: (1) preparation of aminosilane-functionalized graphene; and (2) preparation of aminosilane-functionalized graphene reinforced silica gel. The aminosilane-functionalized graphene has favorable dispersibility in water, ethanol, tetrahydrofuran, dimethyl sulfoxide, 3-aminopropyltriethoxysilane, 3-aminopropyltrimethoxysilane, N-aminoethyl-3-aminopropyltrimethoxysilane, N-aminoethyl-3-aminopropylmethyldiethoxysilane and N-aminoethyl-3-aminopropyltriethoxysilane. In addition, compared with common silica gel, the compression strength of the 3-aminopropyltriethoxysilane-functionalized graphene reinforced silica gel is increased by 20%, and the toughness thereof is increased by 92%.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Breathable polyurethane synthetic leather preparation method

InactiveCN106087451AImprove breathabilityComfortable to wearTextiles and paperPolymer scienceGluconacetobacter

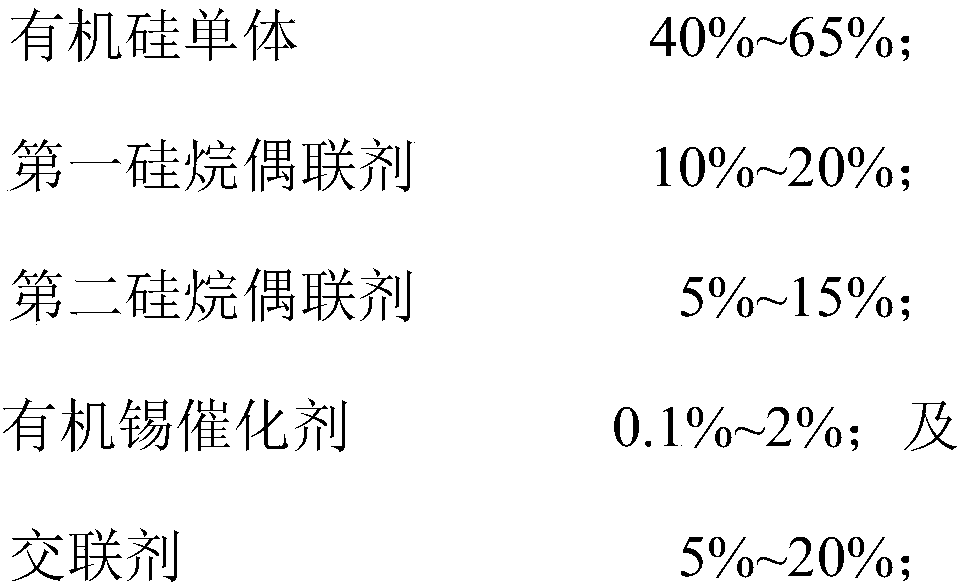

The invention belongs to the technical field of synthetic leather preparation and relates to a breathable polyurethane synthetic leather preparation method. The method includes: subjecting octamethyl cyclotetrasiloxane and gamma-aminoethyl aminopropyl trimethoxysilane to ring opening and polymerization to obtain amino modified silicon oil; reacting with polytetrahydrofuran glycol to obtain polyether modified amino silicon oil; reacting with isophorone diisocyanate to obtain a prepolymer; reacting with 2,2-dimethylolpropionic acid and the like, and carrying out operations such as neutralizing to obtain polyether amino silicon oil modified polyurethane; fermenting gluconacetobacter and polyether amino silicon oil modified polyurethane to obtain bacterial cellulose; mixing with part of polyether amino silicon oil modified polyurethane, adding additives, stirring, coating, and performing operations of solidifying, washing, drying and the like to obtain breathable polyurethane synthetic leather. The breathable polyurethane synthetic leather prepared according to the method is higher than 720mL / cm<2>.h in air permeability and light and comfortable to wear and is excellent in water permeability which is higher than 952g / m<2>.24h.

Owner:周荣

Preparation of 3D rapid prototyping alumina-zirconia-carbon ceramic powder material

InactiveCN104725046ASmall median diameterNarrow particle size distributionAdditive manufacturing apparatusAdhesiveSilanes

The invention discloses a method for preparing a 3D rapid prototyping alumina-zirconia-carbon ceramic powder material. The method is characterized by comprising the following steps: firstly, pre-treating alumina-zirconia-carbon ceramic powder with N-(beta-aminoethyl)-gamma-amino propyl trimethoxy silane and stearic acid to obtain pre-treated alumina-zirconia-carbon ceramic powder; then, adding the following components in percentage by mass: 60-70 percent of trichloroethane and 2-5 percent of bisphenol A polycarbonate into a reactor, stirring and dissolving, and adding 26-36 percent of the pre-treated alumina-zirconia-carbon ceramic powder, uniformly stirring and mixing, intensively stirring at constant temperature of 50+ / -5 DEG C, refluxing to react for 5-7 hours, and drying by spraying to obtain the rapid prototyping alumina-zirconia-carbon ceramic powder material. The material does not need to spray adhesive, can be directly molded in a molding temperature range of 220-230 DEG C, has the advantages of simple preparation process, easily controlled condition and low production cost, and is easy for industrial production.

Owner:UNIV OF JINAN

Anti-corrosion metal surface silane treatment agent and preparation method thereof

InactiveCN103087629AImprove corrosion resistancePolarization current density is smallAnti-corrosive paintsPolyurea/polyurethane coatingsBenzoic acidCellulose

The invention discloses an anti-corrosion metal surface silane treatment agent and a preparation method thereof. The anti-corrosion metal surface silane treatment agent is a mixed solution prepared from the following components: N-(beta-aminoethyl)-gamma-aminopropyltrimethoxy silane, film-forming resin, benzoic acid monoethanolamine, waterborne polyurethane, triethanolamine, propylene glycol, sodium tripolyphosphate, carboxymethyl cellulose, phytic acid, polydimethylsiloxane, sodium dodecyl benzene sulfonate, citric acid and isopropanol. The N-(beta-aminoethyl)-gamma-aminopropyltrimethoxy silane serves as a main material, the isopropanol serves as a solvent, and the cost is low; and meanwhile, the waterborne polyurethane resin and multiple different aids are added into the raw materials, the treatment time and treatment temperature are improved, the metal workpiece is treated by employing the silanization treatment agent, a multi-acid film layer is formed on the surface, the film layer has the characteristics of high adhesion force, no hole or crack, high denseness and uniformity and low polarization current density, and the production process is environment-friendly and pollution-free.

Owner:WUHU HENGKUN AUTO PARTS

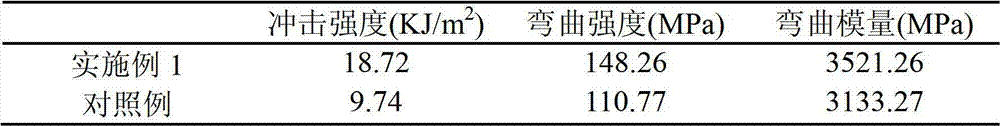

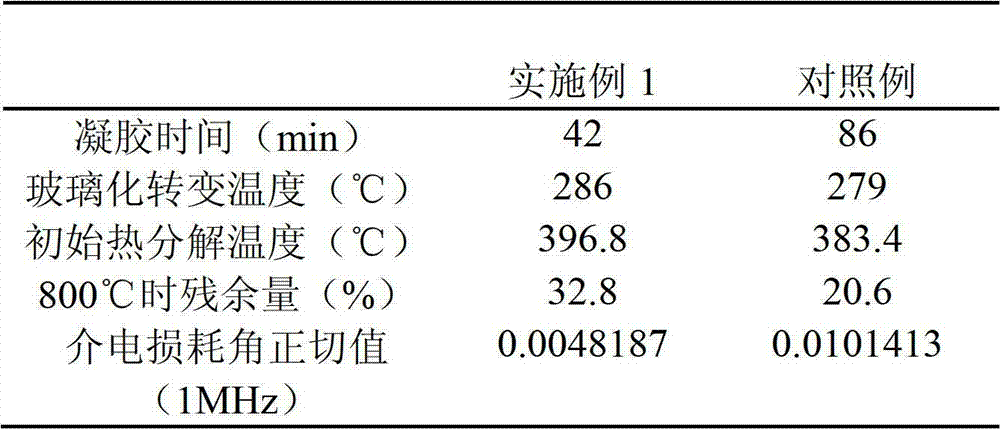

Modified bismaleimide resin and preparation method thereof

The invention relates to modified bismaleimide resin and a preparation method of the modified bismaleimide resin. The method comprises the following steps of: uniformly mixing N,N'-4,4'-diphenylmethane bismaleimide, diallyl bisphenol A and N-(beta-aminoethyl)-gamma-aminopropyl trimethoxy silane in proportion under a normal temperature and normal pressure condition, reacting at 40-60 DEG C for 40-100 minutes, rising the temperature to 130-150 DEG C, reacting for 40-100 minutes while keeping stirring, carrying out vacuum debubbling so as to obtain the modified bismaleimide resin, and carrying out the curing process and the curing treatment so as to obtain cured resin. According to the method, the activity of the siloxane upamido and the unique structure are utilized for comixing / copolymerization modification with the resin, so that the process is simple and easy to control. The prepared modified bismaleimide resin is small in melting viscosity and good in solvent dissolubility; and moreover, the prepared cured resin is increased in comprehensive properties such as toughness, heat resistance, dielectric property and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Easy glass cleaning liquid and preparation method thereof, as well as easily cleaned glass and preparation method and application thereof

ActiveCN108893054AStrong adhesionGood UV resistance and heat stabilityCoatingsSurface energyWeather resistance

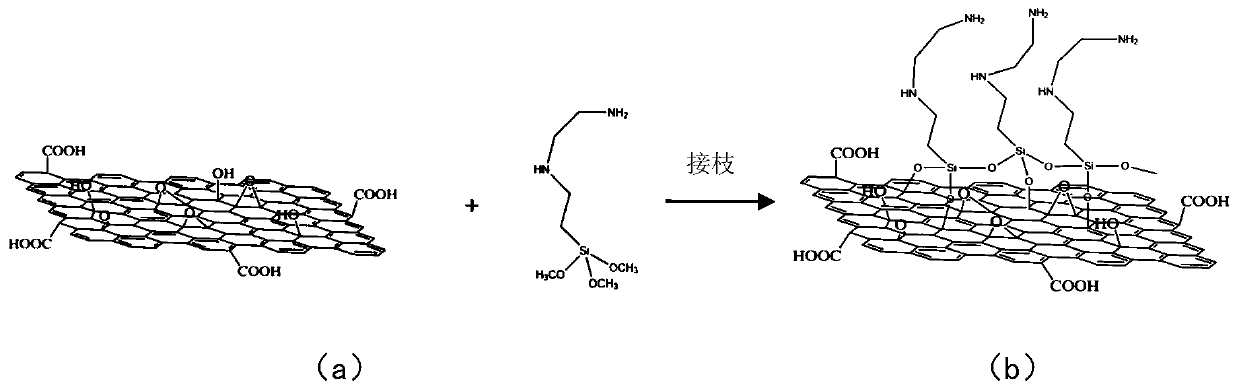

The invention relates to an easy glass cleaning liquid and a preparation method thereof, as well as easily cleaned glass and a preparation method and an application thereof. The easy glass cleaning liquid is prepared from the raw materials in percentage by mass: 40-65% of an organic silicon monomer, 10-20% of a first silane coupling agent, 5-15% of a second silane coupling agent, 0.1-2% of an organic tin catalyst and 5-20% of a crosslinking agent. The first silane coupling agent is selected from at least one of gamma-aminopropyltriethoxysilane and N-(beta-aminoethyl)-gamma-aminopropyltriethoxysilane; the second coupling agent is gamma-glycidyl ether aminopropyltriethoxysilane. The easy glass cleaning liquid can be reacted with active hydroxyl functional groups on the surface of glass to form chemical covalent bonds, so that a formed lyophobic coating is high in adhesion, relative good in ultraviolet resistance and heat-resistant stability on the surface of the glass, and has the effects of low surface energy, relatively good hydrophobic and self-cleaning effects of the organic silicon material, so that excellent weather resistance of the easily cleaned glass is endowed, the outdoorlong-term using demand is met, and the glass is also endowed with a remarkable hydrophobic easy-cleaning effect.

Owner:CSG HOLDING +1

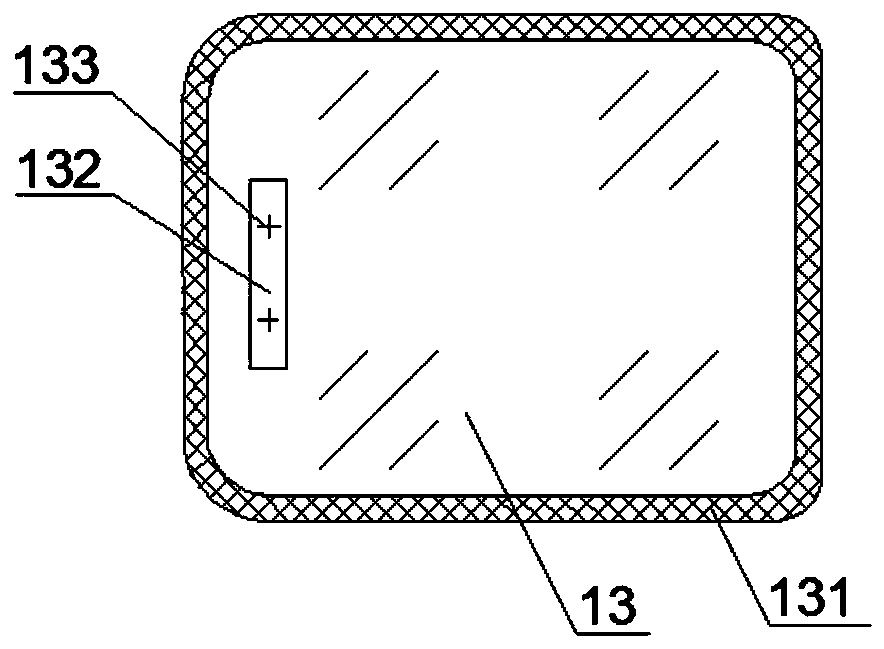

Plugging leather cup rubber for oil/gas transmission pipelines and preparation method thereof

The invention discloses plugging leather cup rubber for oil / gas transmission pipelines. The plugging leather cup rubber is prepared from the following raw materials in parts by weight: 30-40 parts of nitrile rubber, 20-30 parts of isoprene rubber, 20-40 parts of ethylene propylene terpolymer 5962 (LANXESS Deutschland), 10-15 parts of fluorosilicone rubber, 3-5 parts of natural rubber, 20-30 parts of fast extruding furnace black N550, 10-15 parts of modified white carbon black, 3-4 parts of aramid short fiber, 8-10 parts of modified wood ash, 4-6 parts of talcum powder, 4-6 parts of diatomite, 9-11 parts of modified iron tailing slag powder, 0.5-1 part of N,N'-m-phenylene bismaleimide, 0.5-1 part of accelerant TETD, 1-2 parts of zinc stearate, 2-4 parts of magnesia, 0.2-0.4 part of antiscorching agent CTP, 1-2 parts of microcrystalline wax, 1-2 parts of antioxidant DLTP, 1-2 parts of anti-aging agent ODA, 2-3 parts of N-2-(aminoethyl)-3-aminopropyl trimethoxysilane and 16-18 parts of epoxidized triglyceride. The rubber disclosed by the invention has excellent ozone resistance, excellent low temperature resistance and heat resistance and is large in operating temperature range and environment-friendly in process, so that the rubber material can be used for preparing various packing leather cups.

Owner:WUHU HENGKUN AUTO PARTS

Packing leather cup rubber for brake wheel cylinder of automobile and preparation method thereof

The invention discloses packing leather cup rubber for a brake wheel cylinder of an automobile. The packing leather cup rubber is prepared from the following raw materials in parts by weight: 30-40 parts of nitrile rubber, 20-30 parts of isoprene rubber, 20-40 parts of ethylene propylene terpolymer 5962 (LANXESS Deutschland), 10-15 parts of fluorosilicone rubber, 3-5 parts of natural rubber, 20-30 parts of fast extruding furnace black N550, 10-15 parts of modified white carbon black, 3-4 parts of graphite, 8-10 parts of modified wood ash, 4-6 parts of talcum powder, 4-6 parts of meerschaum, 9-11 parts of modified iron tailing slag powder, 0.5-1 part of N,N'-m-phenylene bismaleimide, 0.5-1 part of vulcanizing agent BP, 0.2-0.4 part of accelerant M, 0.3-0.6 part of accelerant TT, 1-2 parts of calcium stearate, 2-4 parts of zinc oxide, 0.2-0.4 part of ferrocene, 1-2 parts of rice bran wax, 1-2 parts of triphenyl phosphite, 1-2 parts of anti-aging agent RD, 2-3 parts of N-2-(aminoethyl)-3-aminopropyl trimethoxysilane and 16-18 parts of butyl epoxy oleate. The rubber disclosed by the invention has excellent ozone resistance, excellent low temperature resistance and heat resistance and is large in operating temperature range and environment-friendly in process, so that the rubber can be used for preparing various packing materials.

Owner:WUHU HENGKUN AUTO PARTS

Polylactic acid toughened flame-retardant automobile blister material and preparation method thereof

InactiveCN106543633AImprove thermal stabilityReduce solubilityResin matrixMelamine formaldehyde resin

The invention discloses a polylactic acid toughened flame-retardant automobile blister material and a preparation process thereof. The material is characterized by being prepared from the following raw materials: acrylonitrile-butadiene-styrene copolymer (ABS), linear phenolic resin, microencapsulated red phosphorus, basic magnesium sulfate whisker, nitrile rubber, mesoporous molecular sieve SBA-15, ammonium polyphosphate, melamine formaldehyde resin, kaolin, Sb2O3, simethicone, graphene, polylactic acid, thermoplastic polyurethane elastomer, maleic anhydride grafted POE, gamma-(3-(trimethoxysilyl)propyl)ethane-1,2-diamine, antioxidant 168 and the like. According to the polylactic acid toughened flame-retardant automobile blister material, the mesoporous molecular sieve and the linear phenolic resin have a bonding effect to improve the thermal stability of matrix resin; microencapsulated ammonium polyphosphate and antimony oxide / kaolin composite flame-retardant micropowder have synergistic effects to achieve a better flame retardant effect; and the graphene is added into the ABS resin matrix, so that the flame retardant property and thermal stability of the resin can be remarkably improved, and the mechanical performance is higher. Therefore, the polylactic acid toughened flame-retardant automobile blister material is prepared.

Owner:ANHUI BIGDIPPER SIGNAGE SYST

Preparation method of heat-resistant flame-retardant polyurethane

InactiveCN105860502AImprove mechanical propertiesImprove hydrolysis resistanceGlutaric acidTrimethylolpropane

The invention discloses a preparation method of heat-resistant flame-retardant waterborne polyurethane. The method comprises the following steps of stirring gamma-(Trimethoxysilyl)-3-aza-hexylamine, N, N-dimethylcyolohexlemine and tetrahydrofuran, and then adding phenyl dichlorophosphate; after the reaction, obtaining a P-N-Si flame retardant; performing a heat insulation reaction on dibromoneopentyl glycol, m-phthalic acid-5-stannous octoate, and then adding the terephthalic acid, glutaric acid and trimethylolpropane; performing heating and stannous octoate, and adding dimethyl benzene until the materials are fused; performing backflow reaction to obtain polyester polyol; adding the polyester polyol and toluene di-isocyanate into a reaction device; adding 1, 4-butylene glycol after the reaction; after the reaction, adding the P-N-Si flame retardant, expansible graphite, multiwalled carbon nanotube and triethylamine; after the reaction, adding acetone; obtaining a finished product after the treatment. The preparation method of heat-resistant flame-retardant polyurethane provided by the invention has the advantages that the steps are simple; the conditions are mild; the obtained composite material has high intensity, excellent flame-retardant performance and good heat resistance.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

High-strength high-hardness epoxy modified MS sealant and preparation method thereof

ActiveCN111732933AHigh strengthIncrease crosslink densityNon-macromolecular adhesive additivesOther chemical processesEpoxyPolymer science

The invention discloses a high-strength high-hardness epoxy modified MS sealant and a preparation method thereof. The epoxy modified MS sealant is prepared from a silane modified polyether polymer, polyoxypropylene ether glycol, calcium carbonate, silicon dioxide, an ultraviolet absorbent, a light stabilizer, vinyltrimethoxysilane, N-(beta-aminoethyl)-gamma-aminopropyltrimethoxysilane and dibutyltin dilaurate. The silane modified polyether polymer comprises the following components: difunctional polyetheramine, low molecular weight epoxy resin, epoxy silane and an epoxy accelerator. Accordingto the present invention, the polyether amine and the low molecular weight epoxy resin monomer are subjected to a reaction, and the epoxy silane is adopted to block the end, such that the performanceof the original MS polymer is retained, and the strength, the hardness and the water resistance of the body are improved.

Owner:SUZHOU DIMA BIO TECH DEV

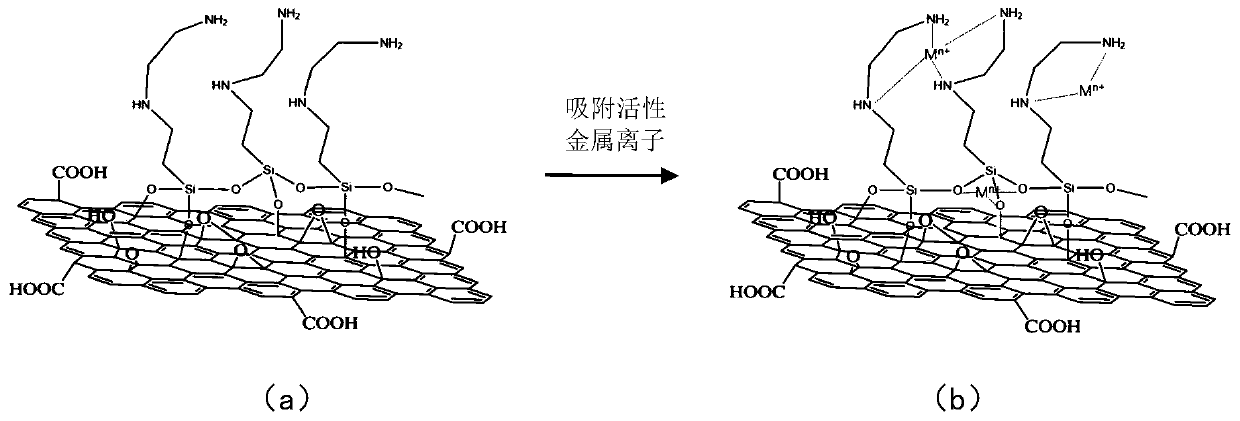

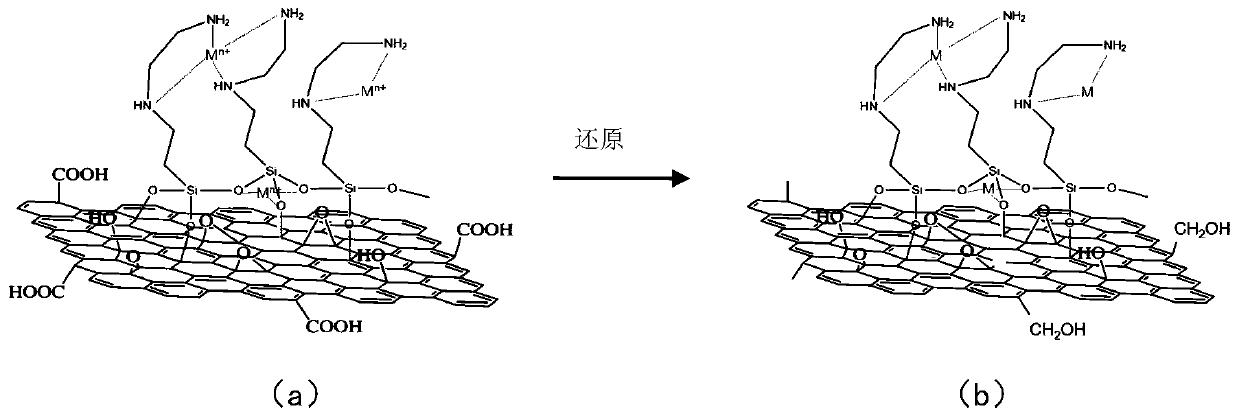

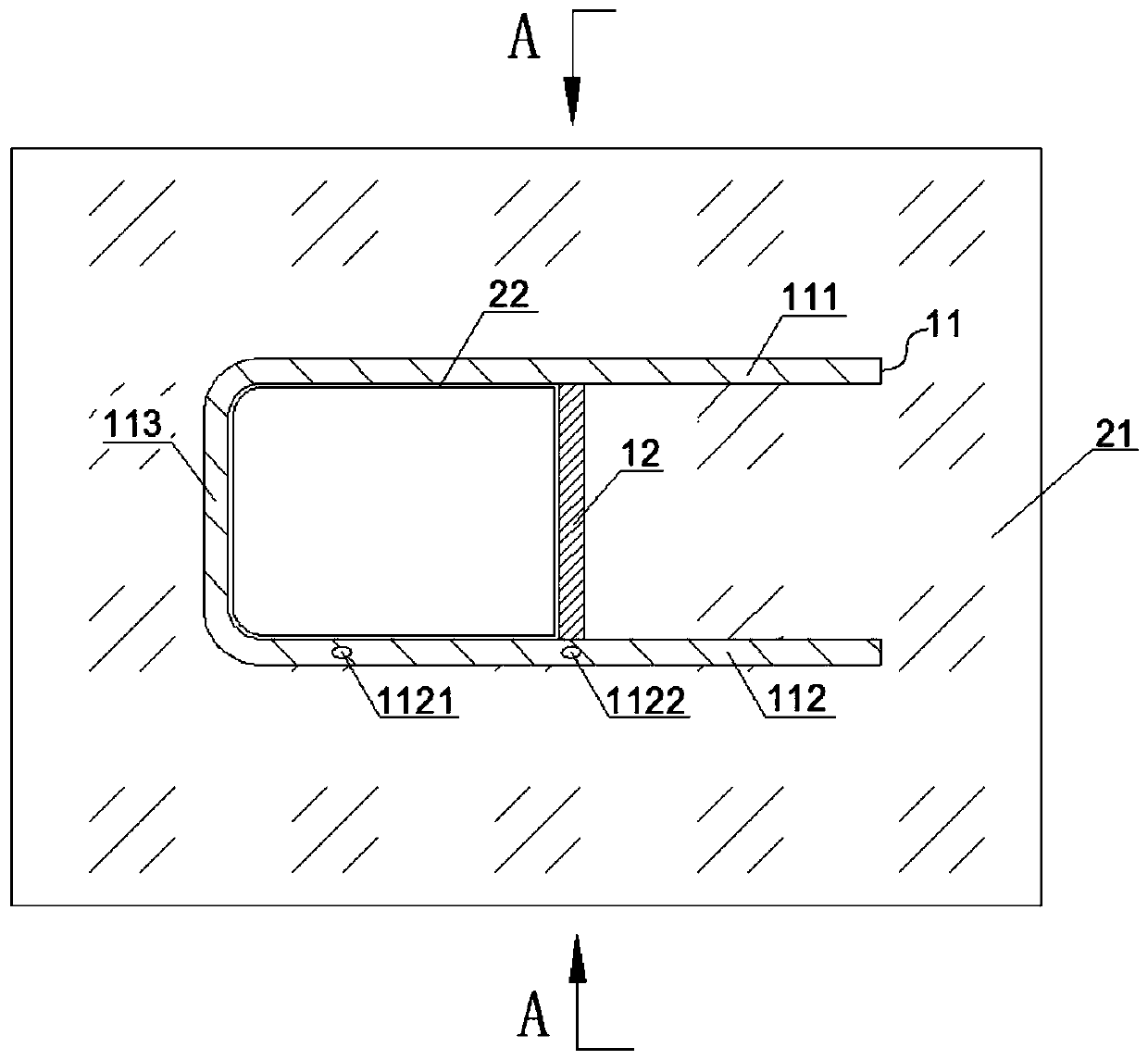

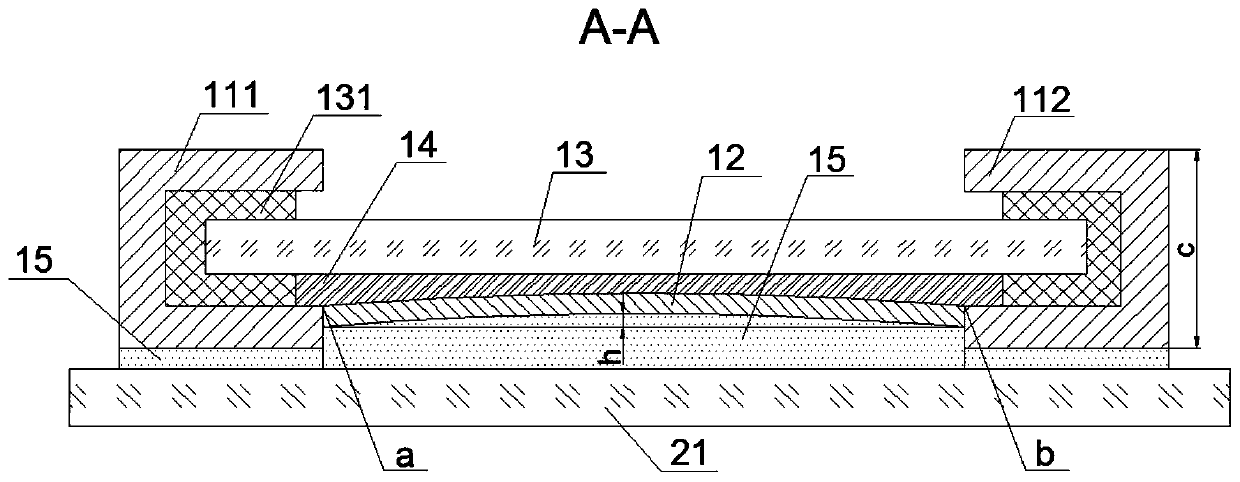

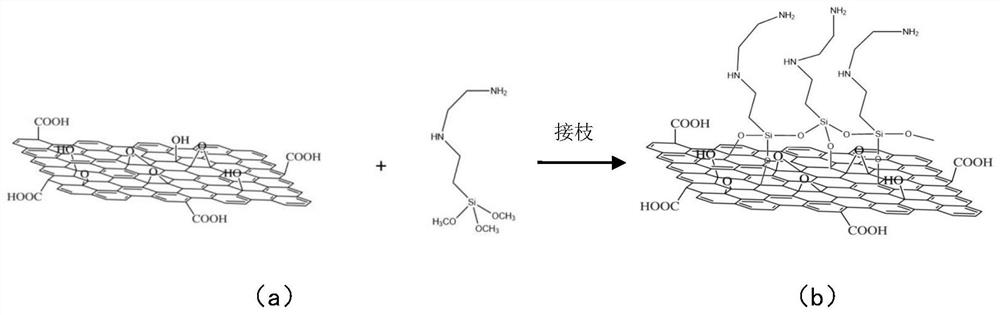

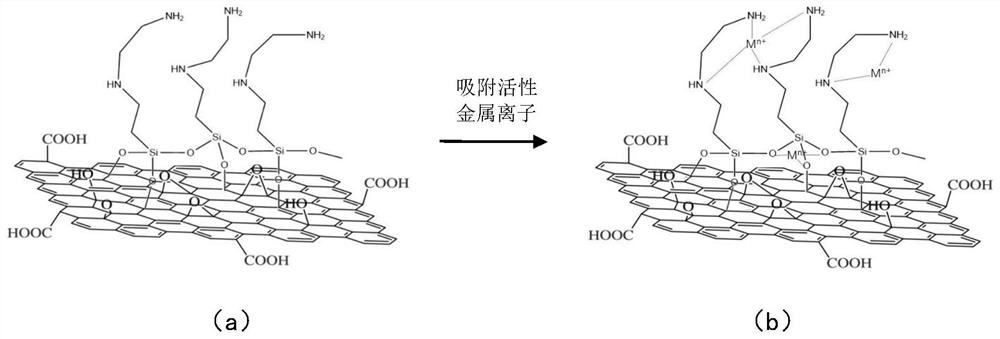

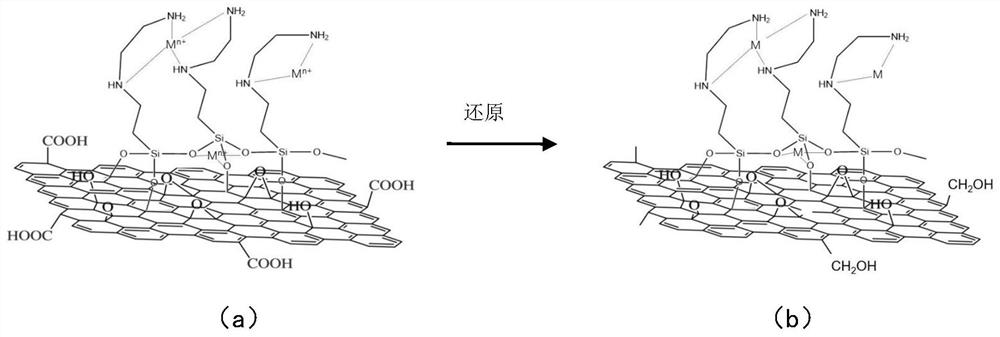

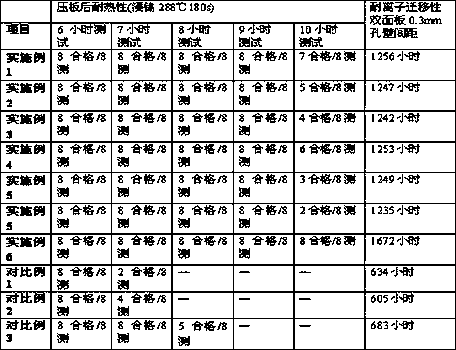

Through hole electroplating method of printed circuit board

The invention relates to a through hole electroplating method of a printed circuit board. The method comprises the following steps that graphene oxide is grafted to gamma-aminoethyl aminopropyl trimethoxy silane, and a product A is obtained; the product A adsorbs active metal ions to obtain a product B; the product B is physically adsorbed to the surface of an insulating substrate on the wall of athrough hole of the printed circuit board to form an adsorption layer; the adsorption layer is converted into an electric conduction layer through the chemical reduction process; and the wall of thethrough hole with the electric conduction layer is electroplated to form a metal layer. Graphene oxide is selected to be grafted to gamma-aminoethyl aminopropyl trimethoxy silane, due to the fact thathigh-density oxide bond functional sites are formed on the grating interface, and adsorption capacity to the active metal ions is effectively improved; and meanwhile, ethidene diamine perssads on thesurface of the electric conduction layer can effectively improve the capturing capacity to copper ions in a solution in the electroplating process, the mass transfer function of the copper ions is accelerated, accelerated deposition of a copper plated layer in the hole is facilitated, and therefore the uniform plating capacity of the plating solution is greatly enhanced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

Primer glue for polyurethane structural adhesive, preparation method and applications thereof

ActiveCN110643324AHigh bonding strengthImprove adhesionNon-macromolecular adhesive additivesAircraft accessoriesEpoxyPolymer science

The invention relates to a primer glue for a polyurethane structural adhesive, a preparation method and applications thereof, wherein the raw materials comprise, by mass, 10-20% of N-(beta-aminoethyl-gamma-aminopropyl)trimethoxysilane, 10-30% of epoxy group 3-(2,3-epoxypropoxy)propyltrimethoxysilane, 10-30% of acryloyloxy gamma-(methacryloyloxy) propyltrimethoxysilane, 19.5-69.5% of isopropanol and 0.1-1% of nanometer carbon black. The invention further provides a sliding rail for bonding a window body by using the polyurethane structural adhesive and the primer glue. According to the invention, by matching the polyurethane structural adhesive and the primer glue, the problems of easy shedding, glue breaking and the like of the polyurethane structural adhesive during the use are solved soas to prolong the service life.

Owner:BEIJING HANGBO NEW MATERIAL TECH +1

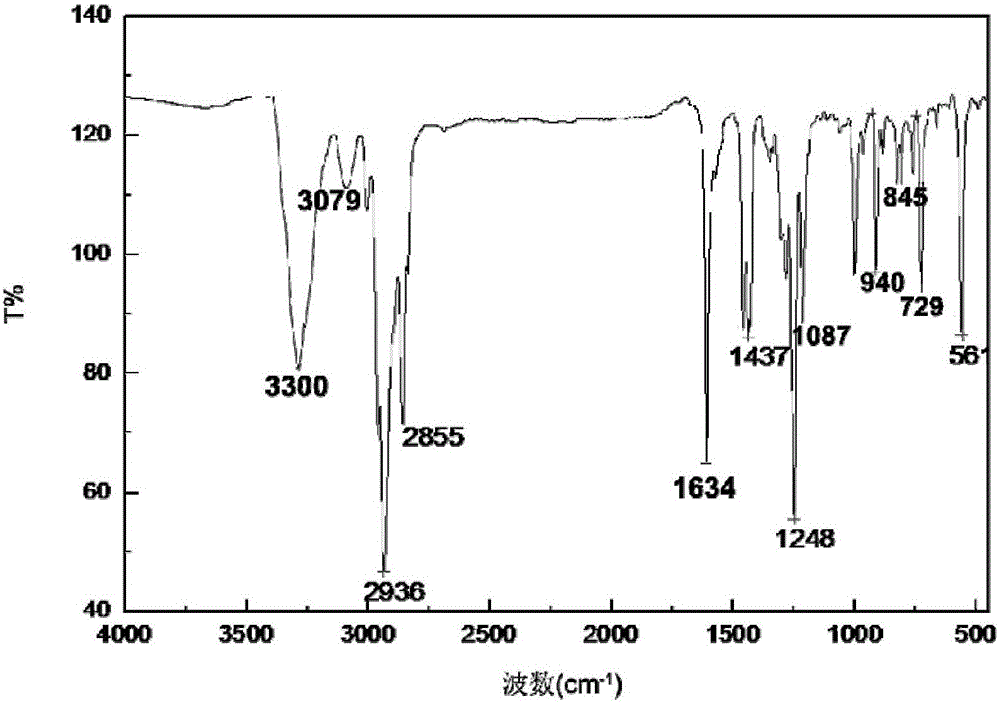

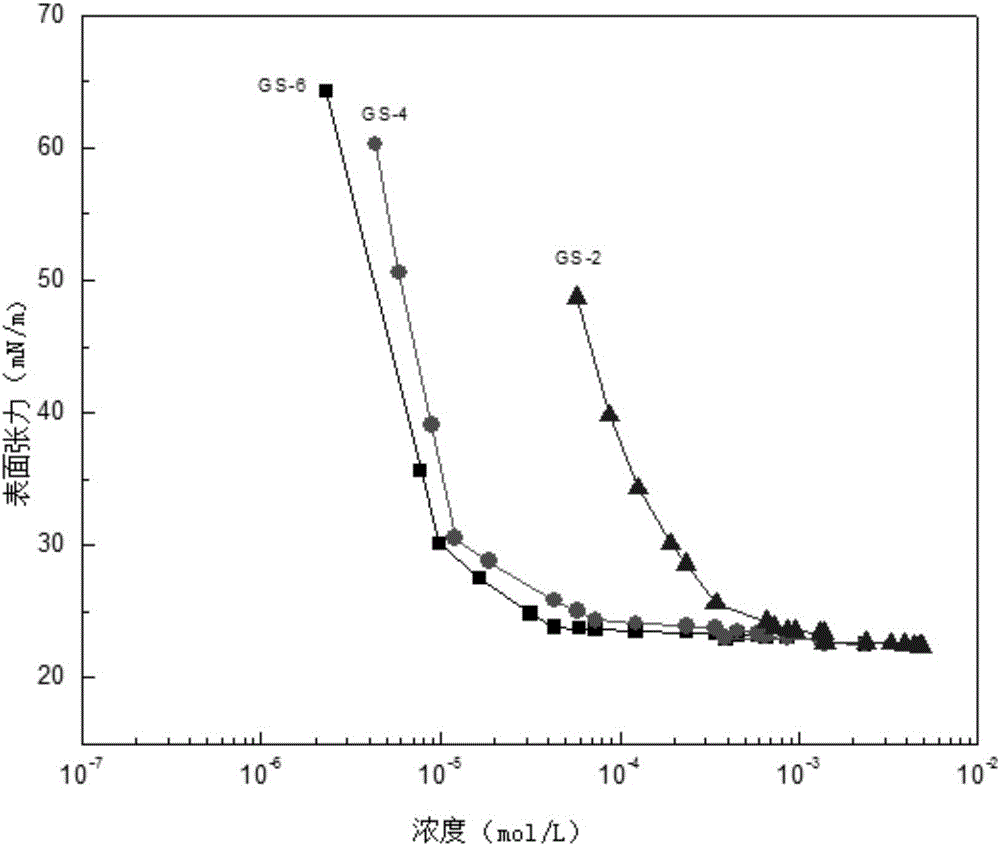

Organosilicone dimeric surfactant and synthetic method thereof

InactiveCN105879773AEasy to gatherImprove adsorption capacityGroup 4/14 element organic compoundsTransportation and packagingEpoxySolubility

The invention relates to organosilicone dimeric surfactant and a synthetic method thereof to solve the problems that trisiloxane dimeric surfactant is poor in oil solubility and is prone to hydrolysis. The structural formula of the organosilicone dimeric surfactant is shown in the description, wherein n is 1, 2 or 3. The synthetic method comprises the steps that hexamethyldisiloxane and [3-(2-Aminoethyl)aminopropyl]trimethoxysilane react to prepare aminoethyl aminopropyl tetrasiloxane, the aminoethyl aminopropyl tetrasiloxane reacts with benzaldehyde to obtain 2-benzyl ene ethyl-3-four silicon methoxyl propyl amine, diol diglycidyl ether is prepared from epoxy chloropropane and alpha,omega-dihydroxy alcohols, and 2-benzyl ene ethyl-3-four silicon methoxyl propyl amine and the corresponding glyceryl ether react so that the organosilicone dimeric surfactant can be obtained. The interfacial tension of the surfactant in a water phase is 22.9-23.5 Mn / m, the CAC value of the surfactant is 8.56*10 [5]-3.28*10 [4], and hydrolysis does not occur within 6 months. The surfactant can be used in the fields of industry and agriculture.

Owner:HEILONGJIANG HEIKE TECH CO LTD

Method for concentrating and detecting norovirus in water based on aminated silica gel

ActiveCN106190987AEnrichment efficiency is stableEasy to operateSsRNA viruses positive-senseMicrobiological testing/measurementWater basedCentrifugation

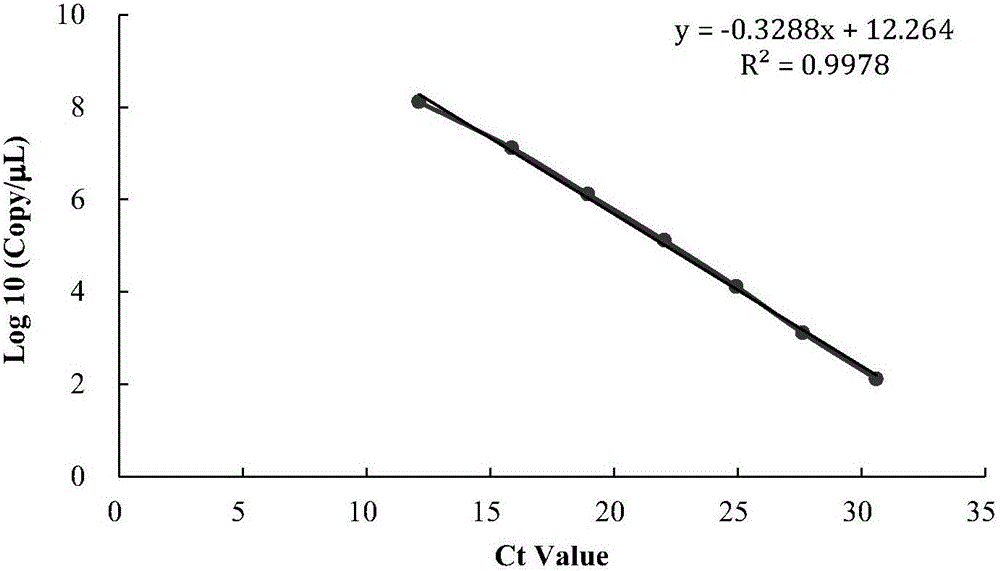

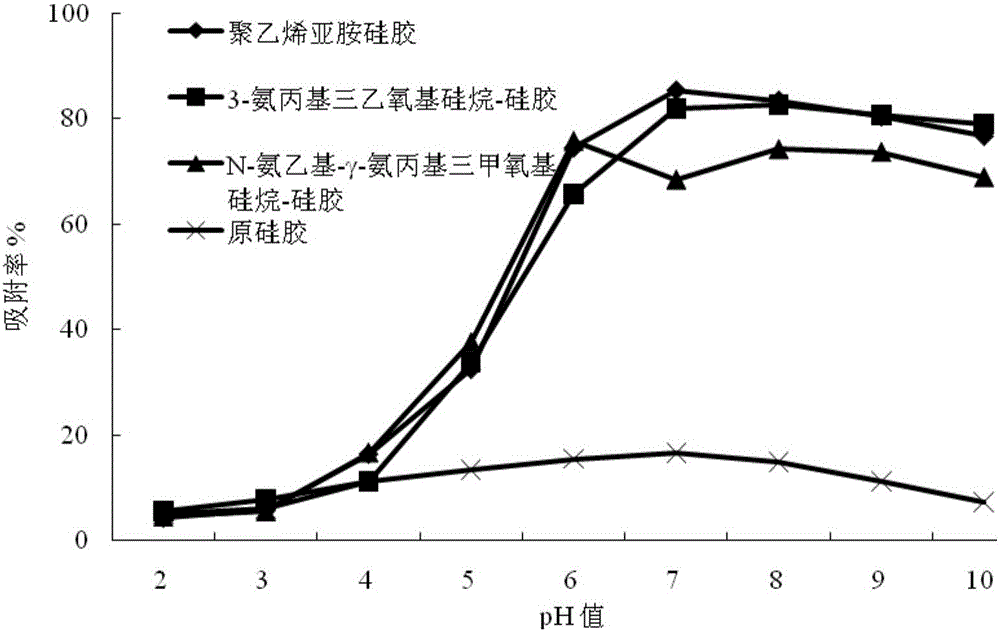

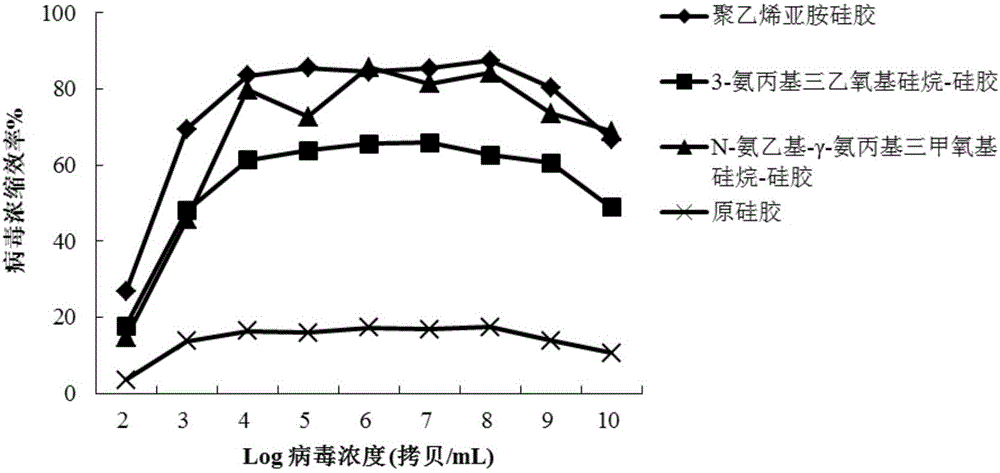

The invention discloses a method for concentrating and detecting norovirus in water based on aminated silica gel. The method comprises the following steps: mixing a norovirus containing polluted water sample to be detected with amination silica gel, carrying out oscillation incubation for 2 hours at a temperature of 20 to 30 DEG C under a pH value of 5 to 10, after incubation, performing centrifugation, soaking the precipitate in a BGT eluent for 15 to 30 minutes, wherein during the soaking period, an ultrasonic treatment (20-25 KHz) is performed for 5 minutes at a time interval of 45 seconds; carrying out centrifugation, and obtaining the supernate, namely the norovirus concentrate of the polluted water sample. The concentration efficiency is 7 to 8 times higher than that of non-aminated original silica gel and is also prominently higher than that of 3-aminopropyl triethoxysilane amino silica gel (60.65-65.91%) and N-aminoethyl-gamma-trimethoxysilane amino silica gel (72.65-85.76%).

Owner:ZHEJIANG CENT FOR DISEASE CONTROL & PREVENTION

Structural adhesive and preparation method thereof

InactiveCN106497500AImprove aging resistanceImproves UV resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesSilanesAdhesive

The invention discloses a structural adhesive and a preparation method thereof. The structural adhesive is prepared from the following ingredients by procedures: 350-400 parts of room-temperature-vulcanized methyl silicone rubber, 50-60 parts of silicone oil, 500-600 parts of nano activated calcium carbonate, 15-30 parts of heavy calcium carbonate, 30-40 parts of methyl tributylketoxime silane, 5-10 parts of vinyl tributylketoxime silane, 4-6 parts of aminopropyl triethoxysilane, 1-3 parts of glycidyl ether propyl trimethoxysilane, 1-2 parts of aminoethyl-aminopropyl trimethoxysilane / aminoethyl / aminopropyl triethoxysilane and 0.01-0.03 part of dibutyl tin dilaurate. The structural adhesive produced by the formula and process, provided by the invention, has good aging resistance, ultraviolet resistance and water resistance.

Owner:嘉兴天胶新材料股份有限公司

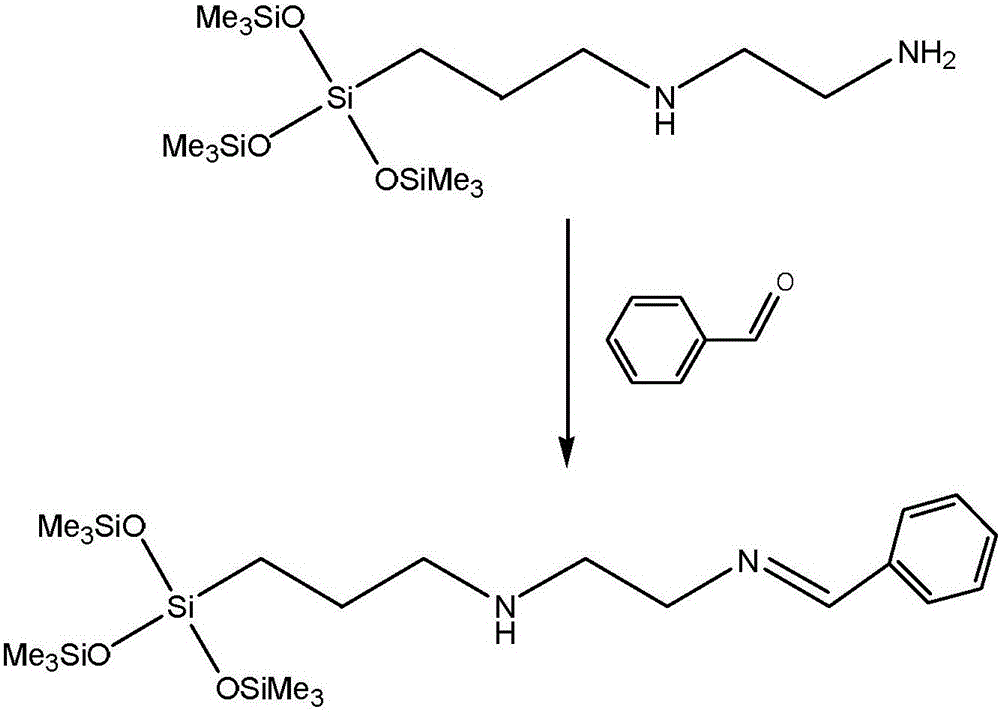

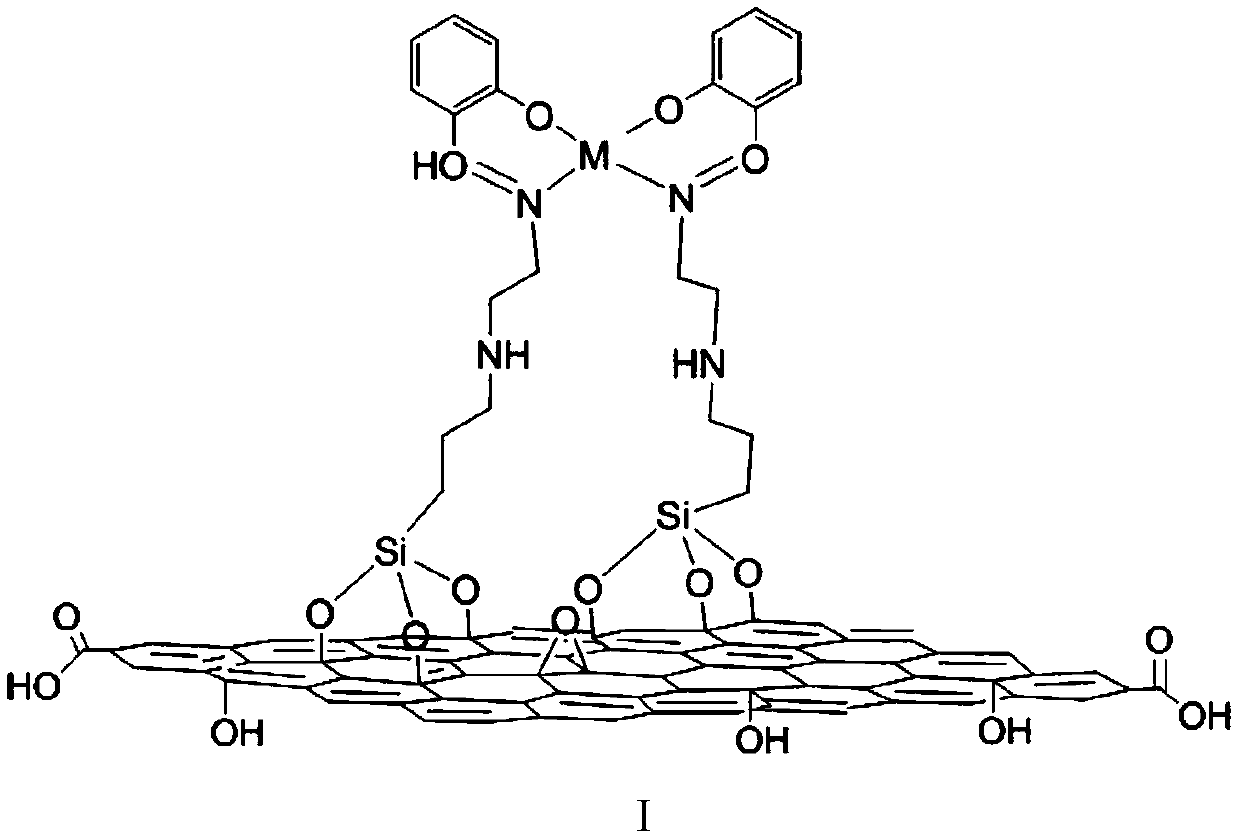

Graphene-Schiff base metal complex and preparation method thereof

ActiveCN111072708AAvoid easy reunionAvoid associativityGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsSalicylaldehydePtru catalyst

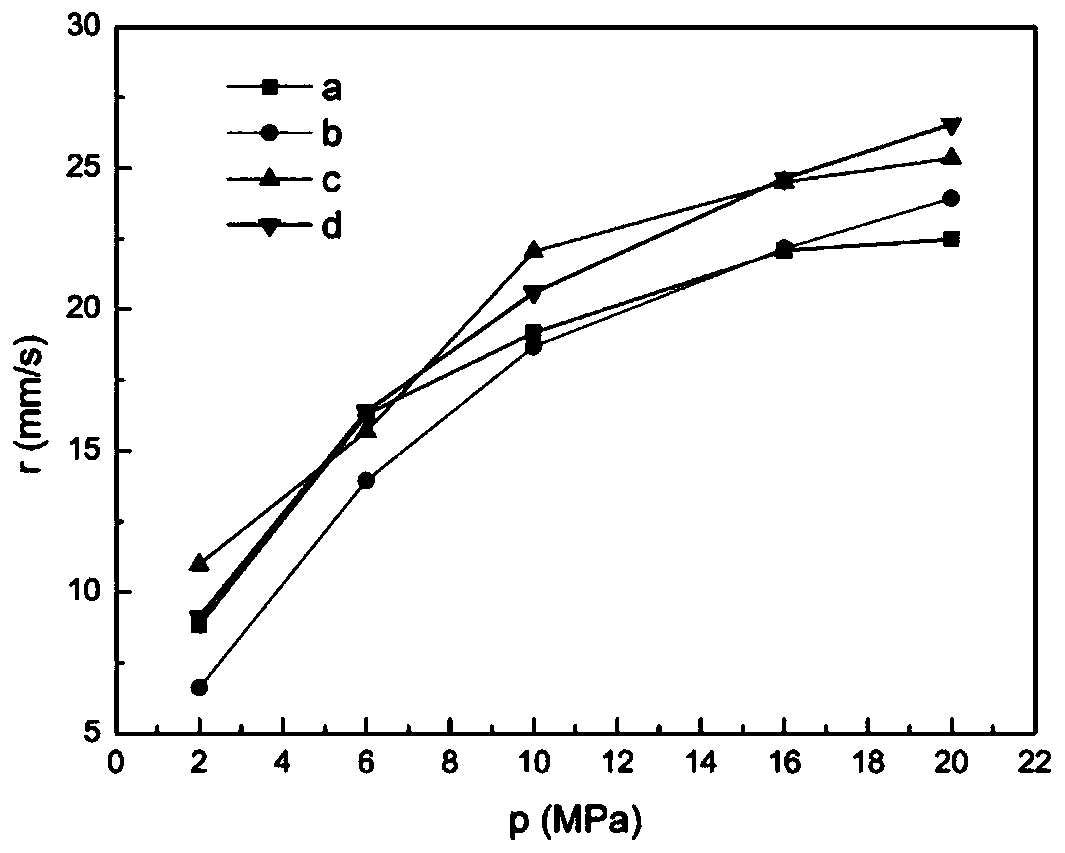

The invention discloses a graphene-Schiff base metal complex. The structural formula of the graphene-Schiff base metal complex is shown as I, and M represents catalytically active metal copper, cobaltor magnesium. The synthesis process comprises the following steps: (1) synthesizing aminated graphene from N-aminoethyl-gamma-aminopropyltrimethoxysilane modified graphene oxide; (2) reacting the aminated graphene with salicylaldehyde to synthesize a graphene-Schiff base complex; and (3) respectively reacting the graphene-Schiff base complex with copper nitrate, cobalt nitrate and a magnesium nitrate aqueous solution to synthesize the graphene-Schiff base metal complex. The graphene-Schiff base metal complex synthesized by the method can effectively improve the combustion rate of a modified double-base propellant containing octogen (HMX), and is an effective combustion catalyst of the modified double-base propellant.

Owner:XIAN MODERN CHEM RES INST

Preparation method of dibutyltin dilaurate and product thereof

The invention belongs to the field of synthesis and relates to a preparation method of dibutyltin dilaurate and a product thereof. The preparation method of dibutyltin dilaurate at least comprises the following steps that lauric acid, dibutyl stannous chloride and ethanol are sequentially added into a reactor, wherein the mole ratio of the lauric acid to the dibutyl stannous chloride to the ethanol is 2 to 1 to 10, a catalyst and trimethylolpropane-tri(thiohydracrylic acid) are sequentially added after even stirring, stirring reaction is performed at the temperature of 40 DEG C for 30-60 minutes, a sodium hydroxide solution is added, the pH value of the reaction is regulated to 7, then stirring reaction is performed at the temperature of 40 DEG C for 1-3 hours, and a reaction solution is obtained after reaction is completed; the solvent in the reaction solution is distilled off to obtain a product, the product is washed and then dried to obtain the dibutyltin dilaurate. The catalyst is N-(2-aminoethyl)-3-aminopropyl trimethoxy silane modified mesoporous silica.

Owner:启东市强强贸易有限公司

High-tensile strength cable protective casing and production method

InactiveCN105968688AHas excellent high tensile strengthExcellent high tensile strengthInsulated cablesInsulated conductorsPolyvinyl chlorideNano al2o3

The invention discloses a high tensile strength cable sheath tube, which is composed of raw materials: acrylonitrile-butadiene-styrene copolymer, polyvinyl chloride, chicken feather hydrolyzed powder, sodium pentanesulfonate, stearic acid decanoate Tetraalkyl ester, γ‑aminoethylaminopropyltrimethoxysilane, diethyl azodicarboxylate, polypropylene glycol dioxirane methyl ether, nano silicon carbide, nano magnesium nitride, nano aluminum oxide , Gum Arabic, Silica. The invention also discloses the production method of the above-mentioned sheath pipe, and the produced sheath pipe has the advantage of excellent high tensile strength, and at the same time, has good flame-retardant performance.

Owner:ANHUI HUAXING CABLE GROUP

High-insulativity polyamide resin inflaming retarding and insulating material

InactiveCN108467582AImprove insulation effectImprove insulation performancePlastic/resin/waxes insulatorsFiberAntioxidant

The invention provides a high-insulativity polyamide resin inflaming retarding and insulating material, and relates to the technical field of new materials. The flame retarding and insulating materialis prepared through the following raw materials: polyamide resin, phenolic resin, aluminum hydroxide, expanded graphite, magnesium hydrate, silicon dioxide, alumina, vermiculite, octadecyl benzyl dimethylammonium bromide, glass fibers, cotton fibers, Na-montmorillonite, urea, propylene carbonate, montmorillonoid, barium sulfate, a plasticizer, an antioxidant, a silane coupling agent, an accelerant and a compatilizer. According to the high-insulativity polyamide resin inflaming retarding and insulating material, the silane coupling agent is gamma-aminoethyl aminopropyl trimethoxysilane, so that the reinforcing effect of the glass fibers and the cotton fibers to the product can be effectively improved, and moreover, the volume resistivity of the product can be greatly improved while the mechanical performance, the heat resisting performance and the impact intensity of a composite material are improved; and the insulating effect is obvious.

Owner:CHANGSHU INTEREST SHARING INFORMATION TECH CO LTD

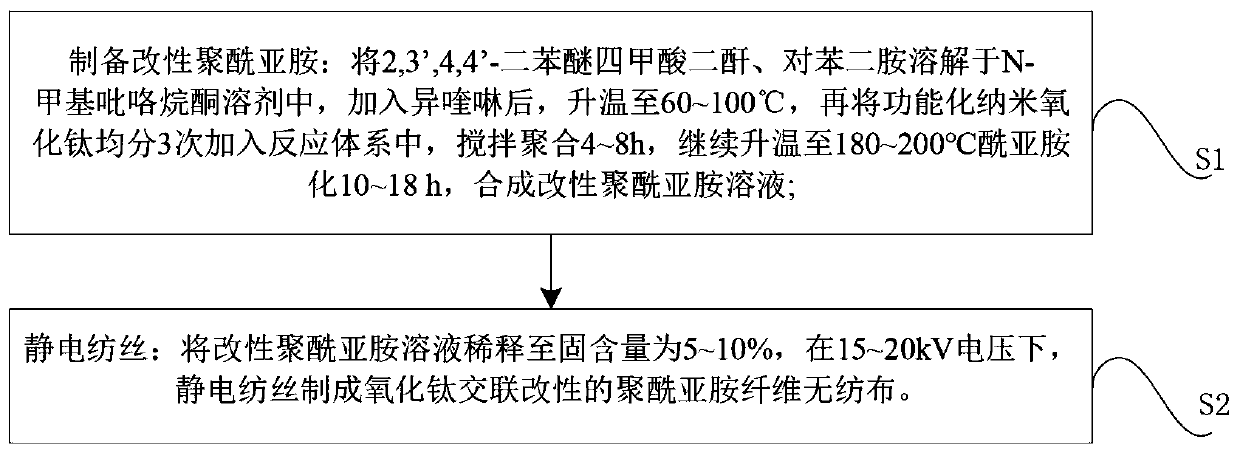

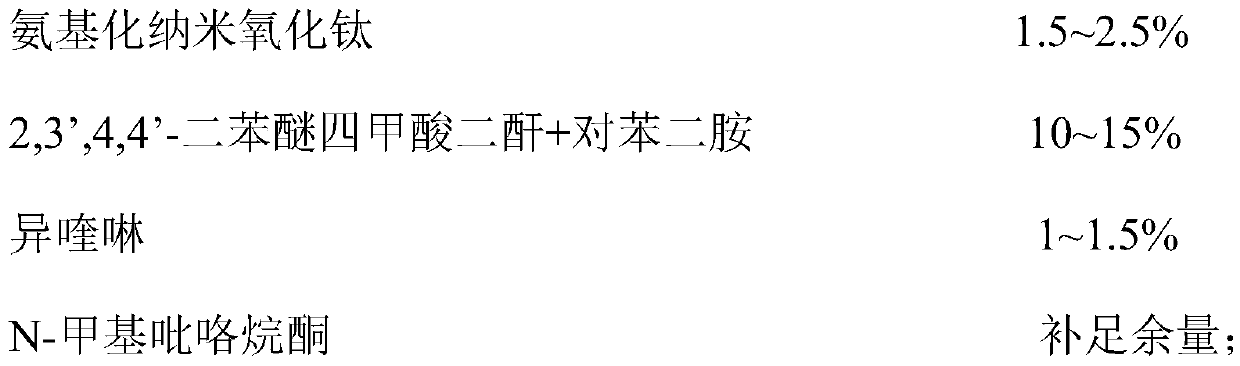

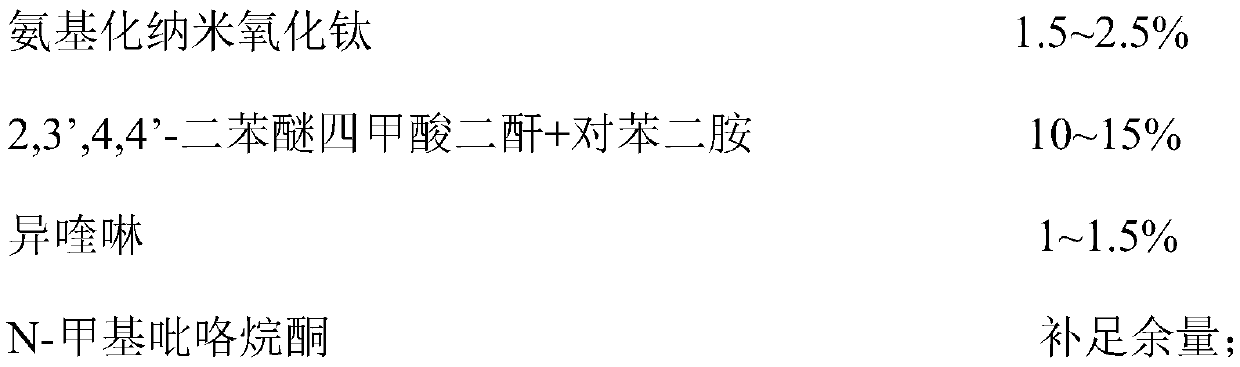

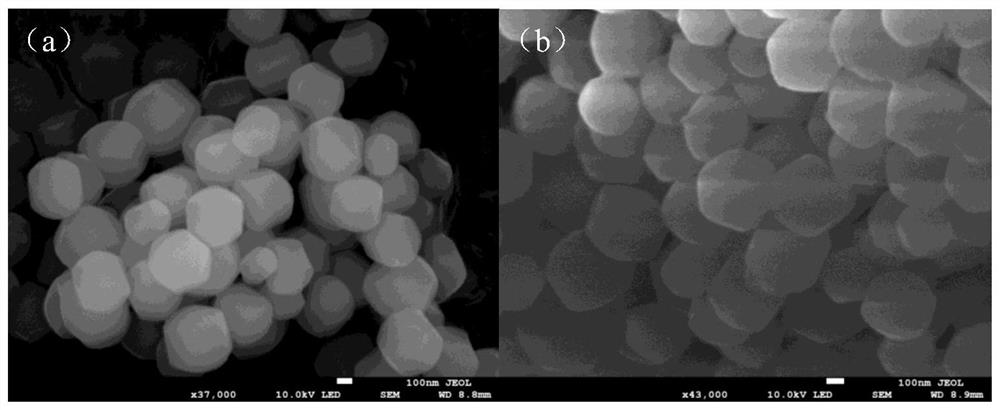

Aminated titanium oxide modified polyimide fiber filter material and preparation method thereof

InactiveCN111514660ANo sheddingNo peelingDispersed particle filtrationMonocomponent synthetic polymer artificial filamentPolymer sciencePyrrolidinones

The invention discloses an aminated titanium oxide modified polyimide fiber filtering material. The aminated titanium oxide modified polyimide fiber filtering material is formed by copolymerizing aminated nano titanium oxide, a dianhydride monomer and a diamine monomer, and then electrospinning to form a polyimide fiber non-woven fabric; wherein the copolymerization reaction system comprises the following raw materials in percentage by mass: 1.5 to 2.5 percent of aminated nano titanium oxide, 10 to 15 percent of 2, 3 ', 4, 4'-diphenyl ether tetracarboxylic dianhydride and p-phenylenediamine, 1to 1.5 percent of isoquinoline and the balance of N-methyl pyrrolidone; the preparation method of the aminated nano titanium oxide comprises the following steps: dissolving titanium tetrachloride and gamma-aminoethyl aminopropyl trimethoxysilane in a 50% ethanol solution, dropwise adding a 2mol / L NaOH solution, uniformly stirring, carrying out hydrothermal reaction at 150 DEG C for 6-12 hours, dropwise adding N, N, N '-trimethylethylenediamine, performing standing for aging for 3-6 hours, filtering, washing and drying. According to the preparation method, the modification effect of nano titanium oxide on polyimide from the molecular level is realized for the first time, the prepared filtering material is high in stability and good in mechanical property, durability and weather resistance, and the phenomena of falling and stripping of the nano titanium oxide are avoided.

Owner:蚌埠泰鑫材料技术有限公司

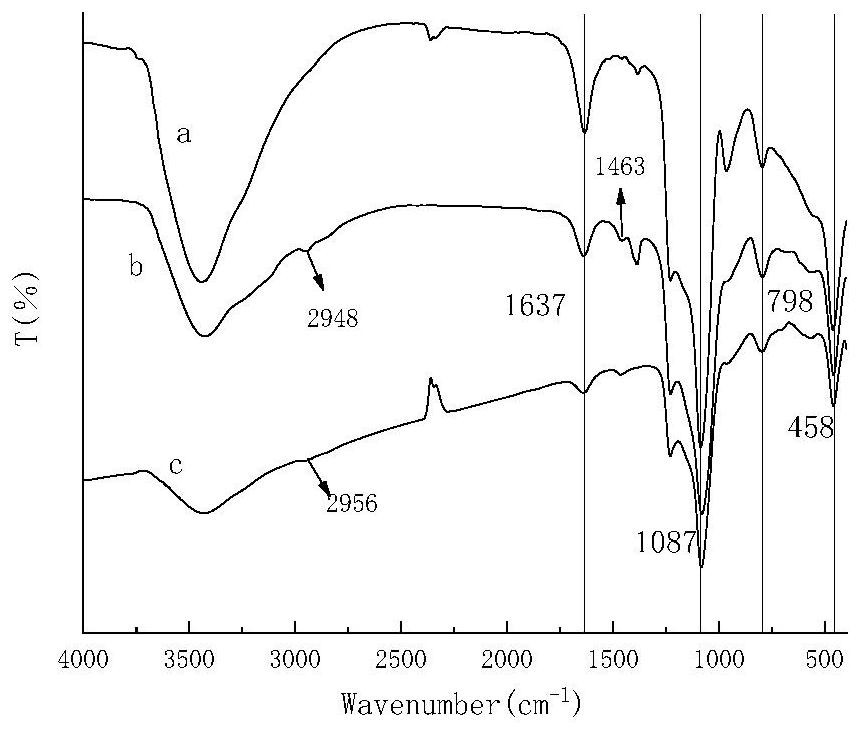

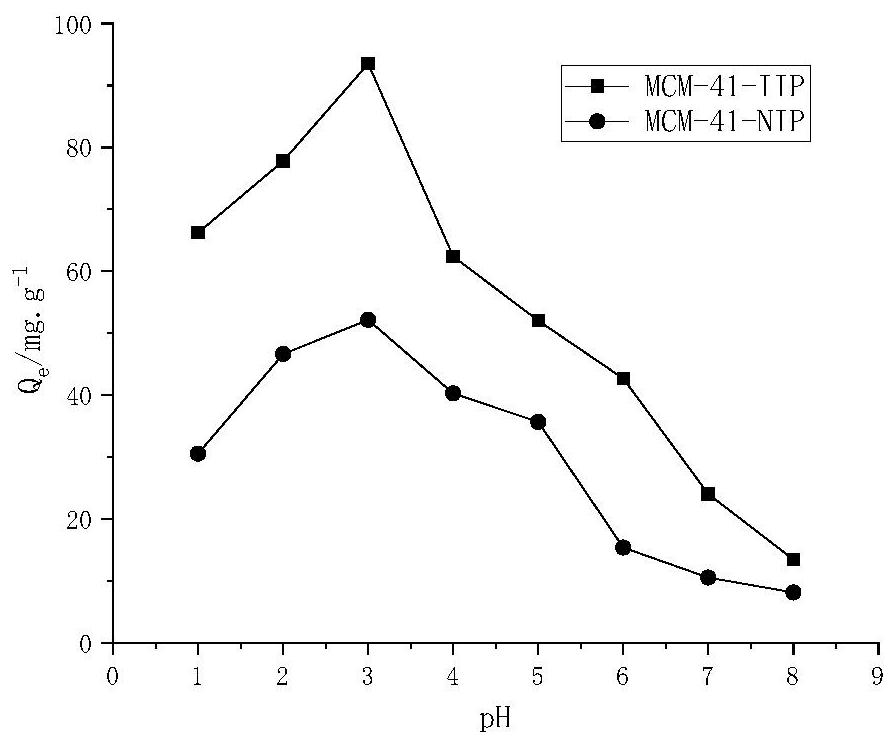

Preparation method of Cr (VI) ion imprinted material based on surface of MCM-41 molecular sieve

InactiveCN111729659ALarge specific surface areaImprove mechanical propertiesOther chemical processesWater contaminantsMolecular sieveEpoxy

The invention discloses a preparation method of a Cr (VI) ion imprinted material based on the surface of an MCM-41 molecular sieve. According to the method, mesoporous MCM-41 is used as a carrier, Cr(VI) ions are used as a template, N-(beta-aminoethyl)-gamma-aminopropyltrimethoxysilane is used as a functional monomer, epoxy chloropropane is used as a cross-linking agent, hydrochloric acid is usedas an eluent, and the Cr (VI) ion imprinted material based on the surface of an MCM-41 molecular sieve is prepared through a surface ionic imprinting technology. The Cr (VI) ion imprinted material based on the surface of an MCM-41 molecular sieve has the advantages of simple steps, convenience in operation, high production efficiency and the like, and has good adsorbability and selectivity for Cr(VI) ions in water.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

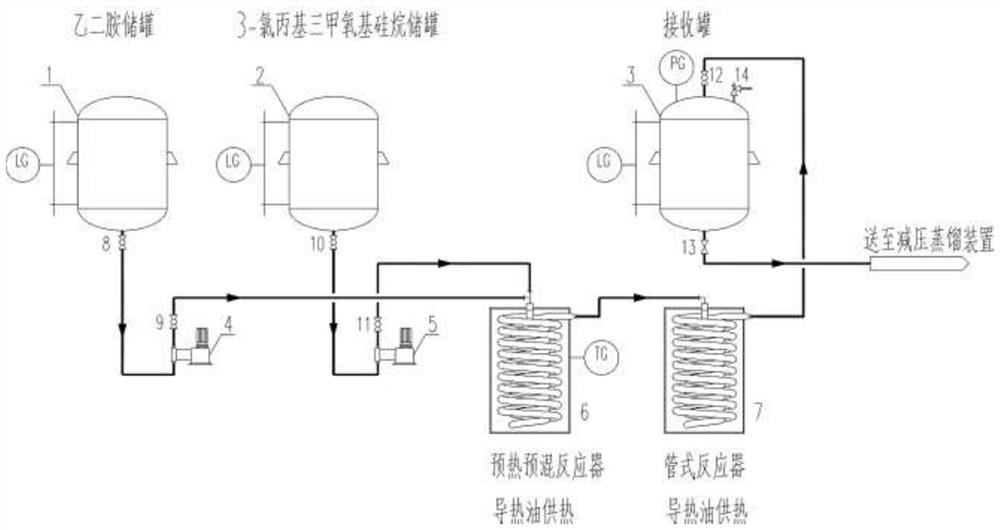

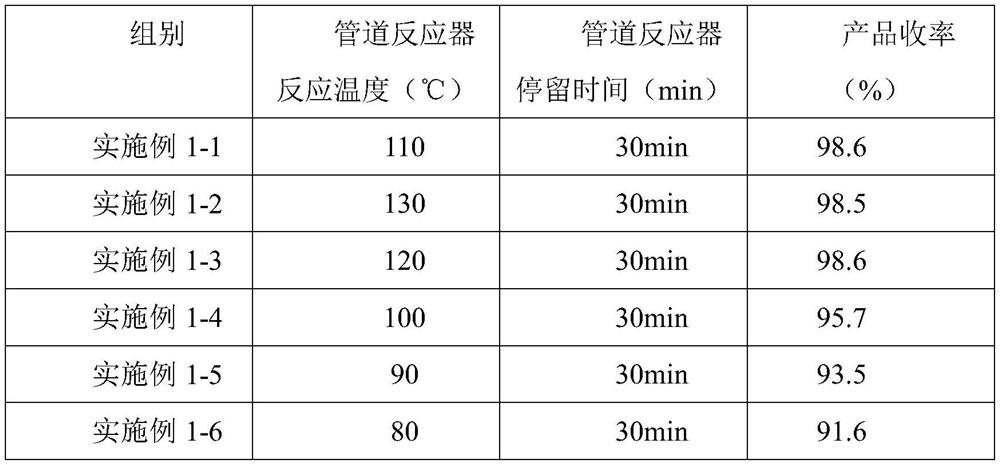

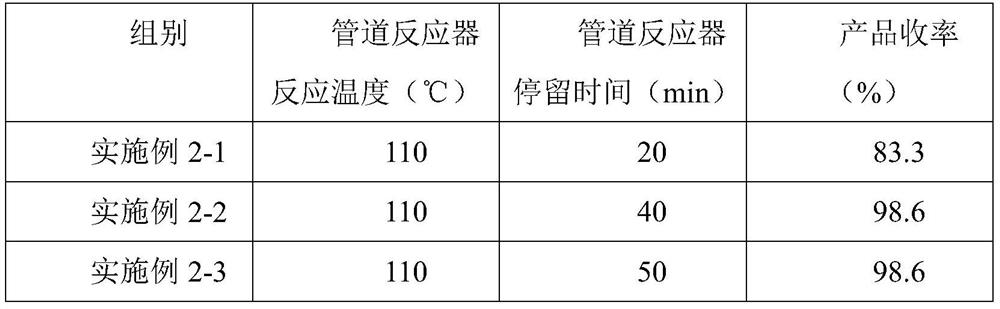

Method for preparing N-(2-aminoethyl)-3-aminopropyltrimethoxysilane by adopting pipeline reactor

PendingCN113501840AReduce dosageReduce manufacturing costGroup 4/14 element organic compoundsEthylene diamineReaction temperature

The invention discloses a method for preparing N-(2-aminoethyl)-3-aminopropyltrimethoxysilane by adopting a pipeline reactor, which comprises the steps of by taking 3-chloropropyltrimethoxysilane and ethidene diamine as raw materials, and reacting the raw materials consisting of ethidene diamine and 3-chloropropyltrimethoxysilane in the pipeline reactor, wherein the retention time of the raw materials in the pipeline reactor is 20-50 minutes, and the reaction temperature of the pipeline reactor is controlled to be 80-130 DEG C; and enabling a reaction product discharged from an outlet of the pipeline reactor to be subjected to separation treatment, and obtaining N-(2-aminoethyl)-3-aminopropyltrimethoxysilane serving as a product. The tubular reactor is adopted, so that the reaction time is greatly shortened, and the production efficiency is remarkably improved.

Owner:ZHEJIANG KAIHUA SYNTHETIC MATERIAL +1

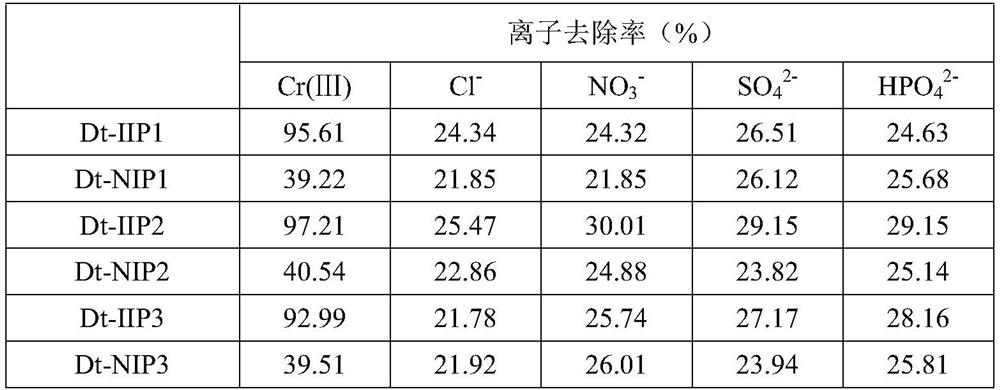

Preparation method of Cr (III) ion imprinted material based on surface of MCM-41 molecular sieve

InactiveCN111729658ALarge specific surface areaImprove mechanical propertiesOther chemical processesWater contaminantsMolecular sieveEpoxy

The invention discloses a preparation method of a Cr (III) ion imprinted material based on the surface of an MCM-41 molecular sieve. According to the method, N-(beta-aminoethyl)-gamma-aminopropyltrimethoxysilane is used as a functional monomer, epoxy chloropropane is used as a cross-linking agent, mesoporous MCM-41 is used as a carrier, and the Cr (III) ion imprinted material based on the surfaceof an MCM-41 molecular sieve is prepared by adopting a surface imprinting method. The mesoporous MCM-41 Cr (III) ion imprinted adsorption material disclosed by the invention has a specific three-dimensional hole structure, is good in mechanical property and easy to elute, can be used for specific recognition and selective removal of Cr (III) ions in an aqueous solution, and has the advantages of low cost, environment-friendliness and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Environment-friendly and energy-saving UV (Ultraviolet) printing ink

InactiveCN106833110AImprove light curing efficiencyHigh hiding powerInksDiphenylphosphine oxideEngineering

The invention discloses environment-friendly and energy-saving UV (Ultraviolet) printing ink. The environment-friendly and energy-saving UV printing ink is prepared by mixing resin, 2,4,6 (trimethylbenzoyl)diphenylphosphine oxide, an aminoethylaminopropyl trimethoxysilane coupling agent, organic pigment, filling, a de-foaming agent and a flatting agent. The environment-friendly and energy-saving UV printing ink disclosed by the invention is high in UV light curing efficiency; the light curing time is about 5s and a post-heating process is not needed; environmental friendliness and energy saving are realized: the UV printing ink is applied to a colored crystal industry and the energy consumption is greatly reduced; and the utilization time is short, so that the energy consumption is greatly reduced. A cured film has high covering power, the rigidity of 3H and excellent wearing resistance and adhesive force; and after an adhesion test, the environment-friendly and energy-saving UV printing ink is 100% not released. The environment-friendly and energy-saving UV printing ink has excellent water resistance; a formula contains no volatile organic solvents and no irritating odor, and a screen is not plugged in a screen-printing process; and the reproducibility of screen points is good and convenience is provided for manufacturing a high-precision pattern. The environment-friendly and energy-saving UV printing ink is especially suitable for printing a glass substrate.

Owner:江世妹

A kind of through-hole electroplating method of printed circuit board

The invention relates to a through-hole electroplating method of a printed circuit board, comprising the following steps: grafting graphene oxide with γ-aminoethylaminopropyltrimethoxysilane to obtain a product A; making the product A adsorb active metal ions, The product B is obtained; the product B is physically adsorbed to the surface of the insulating substrate of the through-hole wall of the printed circuit board to form an adsorption layer; the adsorption layer is converted into a conductive layer through a chemical reduction process; the through-hole wall with a conductive layer is electroplated A metal layer is formed. In the present invention, graphene oxide is selected and grafted with γ-aminoethylaminopropyltrimethoxysilane. Due to the formation of high-density oxygen bond functional sites at the grafting interface, the adsorption capacity for active metal ions is effectively improved, and the conductive layer The ethylenediamine groups on the surface can effectively improve the ability to capture copper ions in the solution during the electroplating process, accelerate the mass transfer of copper ions, and facilitate the accelerated deposition of copper plating in the holes, thereby greatly enhancing the uniformity of the plating solution. Plating ability.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

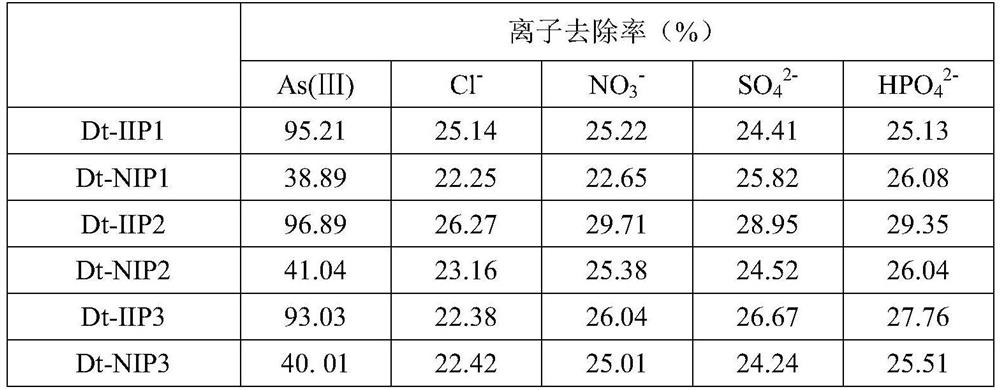

Ultra-thin electronic glass fiber cloth surface treatment fluid and preparation method thereof

ActiveCN111576040AImprove heat resistanceImprove ion migration resistanceGrip property fibresLiquid/gas/vapor textile treatmentGlass fiberPolymer science

The invention provides ultra-thin electronic glass fiber cloth surface treatment fluid and a preparation method thereof, and belongs to the technical field of electronic grade glass fiber surface treatment. The ultra-thin electronic glass fiber cloth surface treatment fluid comprises the following raw materials in parts by weight: 98 parts of water, 1.1 to 1.5 parts of surface treating agent, 0.1to 1 part of weak acid, and 0.002 to 0.01 part of antifoaming agent; the surface treating agent comprises Y-aminopropyltrimethoxysilane and N-(2-aminoethyl)-3-aminopropyltrimethoxysilane; and the Y-aminopropyltrimethoxysilane and the N-(2-aminoethyl)-3-aminopropyltrimethoxysilane are mixed according to a weight ratio of 1.1 to 1.3:1. The ultra-thin electronic glass fiber cloth surface treatment fluid provided by the invention increases the bonding force between resins and glass fiber cloths, improves the heat resistance and ion migration resistance of electronic glass fiber cloths, and makes the electronic glass fiber cloths more suitable for manufacturing high-end printed circuit copper clad laminates.

Owner:山东兴国大成电子材料有限公司

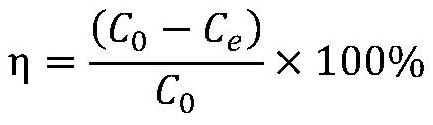

Preparation method of As (III) ion imprinted material based on surface of MCM-41 molecular sieve

InactiveCN111760561ALarge specific surface areaImprove mechanical propertiesOther chemical processesWater contaminantsMolecular sieveEpoxy

The invention discloses a preparation method of an As (III) ion imprinted material based on the surface of an MCM-41 molecular sieve. According to the method, N-(beta-aminoethyl)-gamma-aminopropyltrimethoxysilane is used as a functional monomer, epoxy chloropropane is used as a cross-linking agent, an MCM-41 molecular sieve is used as a carrier, and the As (III) ion imprinted material based on thesurface of the MCM-41 molecular sieve is prepared by adopting a surface imprinting method. The As (III) ion imprinted material based on the surface of the MCM-41 molecular sieve has a specific three-dimensional cavity structure, is good in mechanical property and easy to elute, can be used for specific recognition and selective removal of As (III) ions in an aqueous solution, and has the advantages of low cost, environment frendliness and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Coating of inner wall of metal container for containing white wine, and preparation method thereof

ActiveCN103173096AStrong adhesionIncrease the degree of cross-linkingAnti-corrosive paintsEpoxy resin coatingsSodium phosphatesPolyethylene glycol

The invention discloses a coating of the inner wall of a metal container for containing a white wine. The coating is composed of a component A and a component B according to a component A / component B weight ratio of 3-5:1, wherein the component A is composed of the following raw materials, by weight, 60-70 parts of an E-20 epoxy resin, 20-25 parts of dimethylbenzene, 5-8 parts of ethyl acetate, 8-10 parts of aluminum triphosphate, 4-6 parts of a modified composite filler, 4-5 parts of ammonia water, 3-5 parts of aluminum hydroxide, 3-5 parts of nanometer zinc oxide, 1-2 parts of polydimethylsiloxane, 1-2 parts of plant ash, 2-4 parts of polybutylacrylate, 1-2 parts of diethylamine, 1-2 parts of 2,6-di-tert-butyl-p-cresol, 1-2 parts of sodium tripolyphosphate, 0.8-1 part of an antioxidant DLTP, 0.8-1 part of N-2-(aminoethyl)-3-aminopropyltrimethoxysilane, and 0.6-1 part of polyethylene glycol. The film of the coating has excellent adhesion, high cross-linking degree, good hardness and good alcohol resistance; and the addition of the modified composite filler further enhances the mechanical and physical performances and the stability of the coating film.

Owner:ANHUI XINMEIGE PACKAGING DEV CO LTD

Anti-cracking plastic pipe and preparation method thereof

The invention provides an anti-cracking plastic pipe and a preparation method thereof and relates to the technical field of plastic pipe processing. The anti-cracking plastic pipe is prepared from thefollowing raw materials: polycarbonate, phenolic resin, low density polyethylene, dodecanedioic acid diester, bisphenol A cyanate ester, o-chlorophenyl isocyanatecarbon, carbon fiber, nano silicon dioxide, ethyl cellulose, a compatilizer, diphenyl methane diisocyanate, hexamethyl phosphoryl triamine, a composite antioxidant, epoxy ethane, castor oil, a plasticizer and gamma-aminoethyl aminopropyltrimethoxysilane. The preparation method mainly comprises steps of base material mixing, raw material pretreatment, auxiliary material treatment, booster mixing, mixing and forming, and the like. Byadopting the anti-cracking plastic pipe, defects of the prior art can be overcome, the anti-oxidation performance of the plastic pipe can be improved, the plastic pipe can be prevented from cold and heat cracking, the mechanical properties of the plastic pipe can be improved, and the service life of the plastic pipe can be prolonged.

Owner:天长市诚信塑业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com