Through hole electroplating method of printed circuit board

A technology for printed circuit board and through-hole electroplating, applied in the field of printed circuit boards, can solve problems such as unfavorable human health, and achieve the effects of fast electron migration, improved electroplating efficiency, and good specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

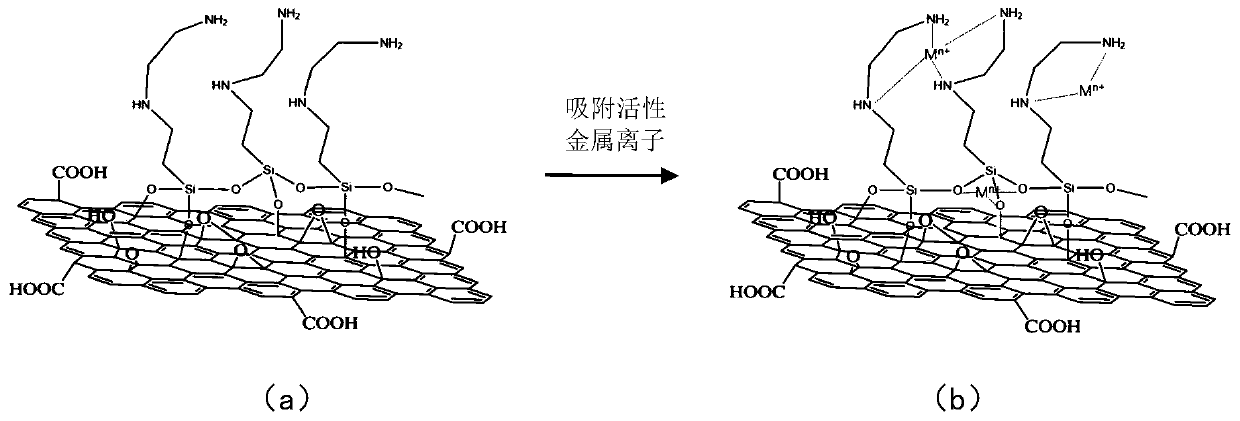

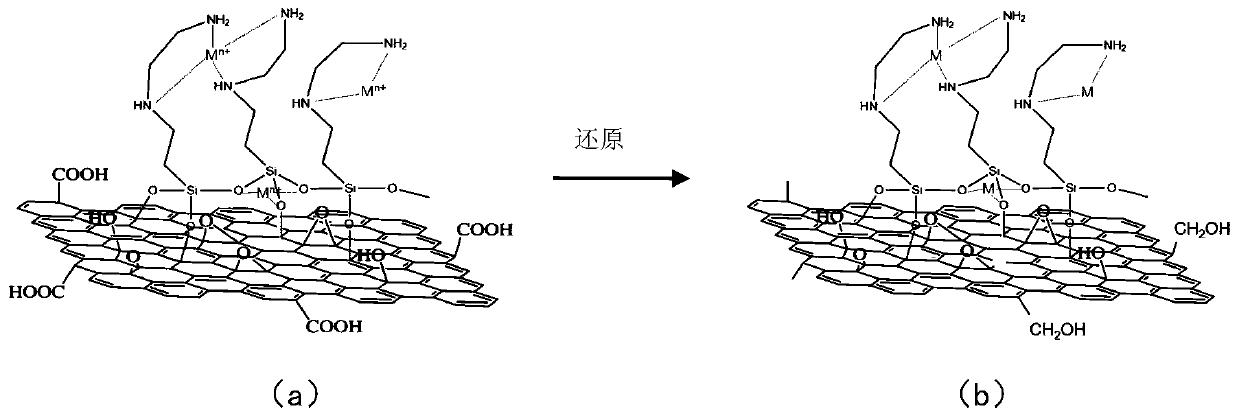

[0050] Such as Figure 1-6 As shown, a method for through-hole plating of a printed circuit board provided in an embodiment of the present invention includes the following steps:

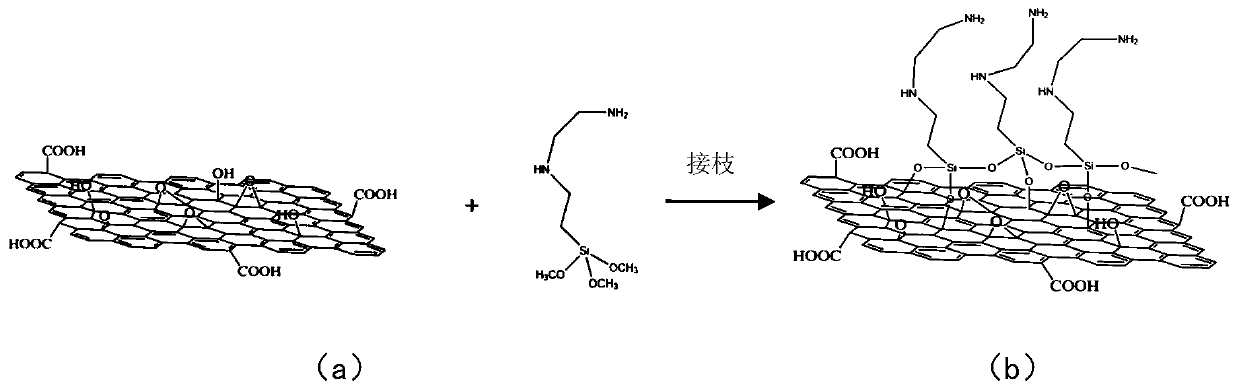

[0051] Step 1: Make graphene oxide graft γ-aminoethylaminopropyltrimethoxysilane to obtain product A, such as figure 1 shown, where figure 1 In (a), the left side is the structural formula of graphene oxide, and the right side is the structural formula of γ-aminoethylaminopropyltrimethoxysilane, figure 1 (b) is the structural formula of the product A after grafting;

[0052] Dissolve 50mg of γ-aminoethylaminopropyltrimethoxysilane and 100mg of graphene oxide in 100mL of ethanol solution, then stir and react at 65°C at 100rpm for 10h, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap