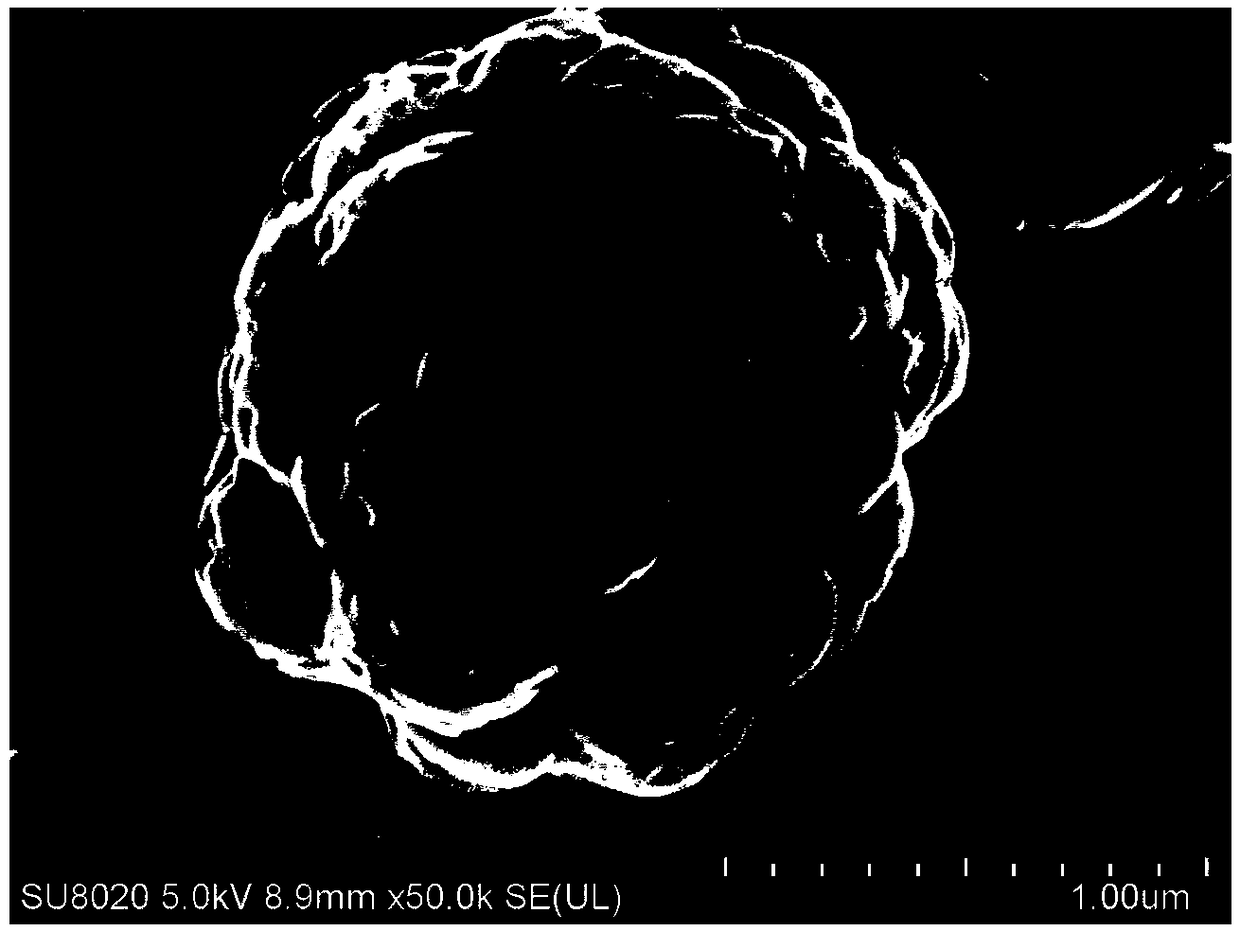

Porous flower-petal-shaped anatase TiO2 nano-crystal thin film and preparation method thereof

A nanocrystalline, petal-shaped technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of uneven composite degree, restriction of photocatalytic performance, secondary pollution, etc. The effect of controllable appearance, fast electron migration speed, and low photogenerated electron-hole recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of porous petal-shaped anatase TiO of the present embodiment 2 Preparation of nanocrystals, the preparation process is:

[0021] (1) Ultrasonic cleaning is performed on the titanium sheet. The specific cleaning process is as follows: ultrasonic cleaning in acetone for 30 minutes, ultrasonic cleaning in deionized water for 10 minutes, ultrasonic cleaning in alcohol for 20 minutes, and ultrasonic cleaning in deionized water for 10 minutes. After that, the cleaned The titanium sheets were dried and stored in an oven at 40°C.

[0022] (2) The concentration of HF acid solution used for hydrothermal synthesis is 10mmol / L, and its solvent is a mixed solvent of ethylene glycol and water, and the volume ratio of ethylene glycol and water is 1:7.

[0023] (3) Put the titanium sheet in step (1) in the polytetrafluoroethylene reactor containing the HF acid solution prepared in step (2) for hydrothermal reaction, wherein: the hydrothermal temperature is 160°C, and the hydrot...

Embodiment 2

[0027] The preparation method of this embodiment is the same as that of Example 1, except that the volume ratio of ethylene glycol and water in step (2) is 1:5, and the porous petal-shaped anatase TiO prepared in this embodiment 2 Nanocrystalline, after testing, its photocurrent density reaches 48.25μA / cm 2 .

Embodiment 3

[0029] The preparation method of this embodiment is the same as that of Example 1, except that the volume ratio of ethylene glycol and water in step (2) is 1:10, and the porous petal-shaped anatase TiO prepared in this embodiment 2 Nanocrystalline, after testing, its photocurrent density reaches 44.34μA / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com