Easy glass cleaning liquid and preparation method thereof, as well as easily cleaned glass and preparation method and application thereof

A glass and glass surface technology, applied in the direction of coating, can solve the problems of difficult long-term use, poor UV resistance, poor weather resistance, etc., and achieve the effect of strong adhesion, low surface energy, and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of above-mentioned glass easy-clean liquid comprises the following steps:

[0041] Step S110 , mixing the organosilicon monomer and the organotin catalyst and then heat-treating to a temperature of 55° C. to 80° C.

[0042] In one embodiment, the organosilicon monomer and the organotin catalyst are added into the reactor in batches, and the temperature is gradually raised to 55° C. to 80° C. under stirring. Further, the time for gradually increasing the temperature under stirring is 30 minutes to 60 minutes. Further, the organosilicon monomer and the organotin catalyst are simultaneously added into the reactor and stirred.

[0043] Step S120, at a temperature of 55° C. to 80° C., continue to add the remaining components and react for 2 h to 6 h.

[0044] In one embodiment, at a temperature of 55° C. to 80° C., the remaining components are continuously added and reacted for 2 hours to 6 hours, and then cooled to obtain a glass easy-cleaning liqui...

Embodiment 1

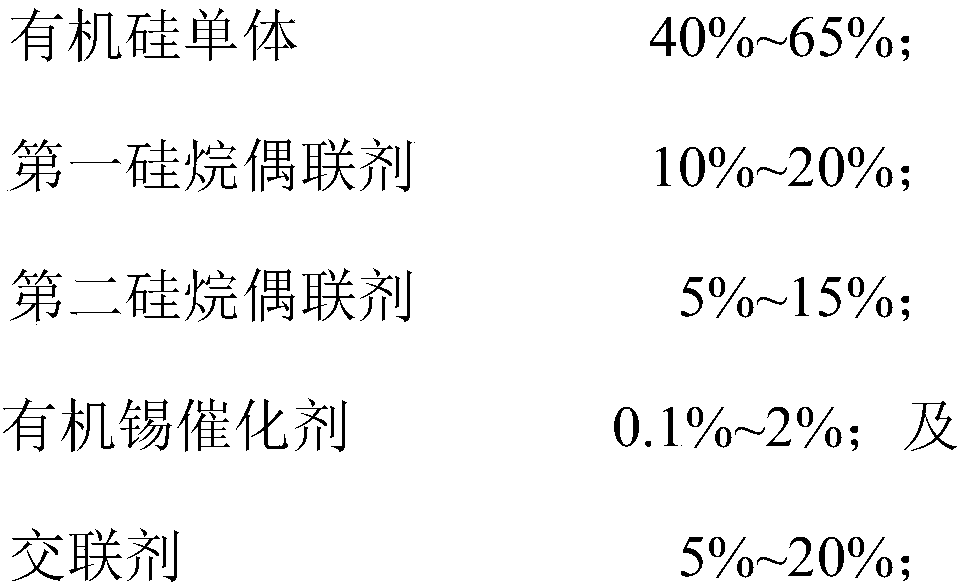

[0069] The raw materials for preparing the glass easy-to-clean solution of this embodiment include by mass percentage:

[0070]

[0071]

[0072] According to the proportions of the above-mentioned components, the glass easy-cleaning liquid is prepared. The preparation steps are as follows: measure and weigh isobutyltriethoxysilane and dibutyltin diacetate according to the proportions of the components, add them to the reaction kettle in 3 times, and stir Gradually raise the temperature to 55°C, stir for 0.5h, then add the remaining components into the reaction kettle, and keep the reaction temperature at 55°C, and the reaction time is 6h, and the glass easy-cleaning liquid is obtained after cooling.

[0073] The prepared glass easy-cleaning liquid is evenly coated on the surface of a clean and dry glass substrate by spraying equipment, wherein the glass substrate used is soda calcium fully tempered glass with a thickness of 3mm. The uniformity of the sprayed hydrophobic...

Embodiment 2

[0076] The raw materials for preparing the glass easy-to-clean solution of this embodiment include by mass percentage:

[0077]

[0078] According to the proportions of the above components, the glass easy-cleaning solution is prepared. The preparation steps are as follows: measure and weigh methyltriethoxysilane and stannous octoate according to the proportions of the components, add them to the reaction kettle in 3 times, and gradually heat up under stirring. to 80°C, stirred for 0.5h, then added the remaining components into the reaction kettle, and kept the reaction temperature at 80°C, the reaction time was 2h, and the glass easy-cleaning liquid was obtained after cooling.

[0079] The prepared glass easy-cleaning liquid is evenly coated on the surface of a clean and dry glass substrate by spraying equipment, wherein the glass substrate used is soda calcium fully tempered glass with a thickness of 6 mm. The uniformity of the sprayed hydrophobic and easy-to-clean coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com