Aminated titanium oxide modified polyimide fiber filter material and preparation method thereof

A technology of polyimide fiber and filter material, which is applied in the field of aminated titanium oxide modified polyimide fiber filter material and its preparation field, can solve the problems of reducing filtration efficiency, falling off and falling off of nano titanium oxide, and achieves the improvement of The effect of filtration efficiency, high specific surface area and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

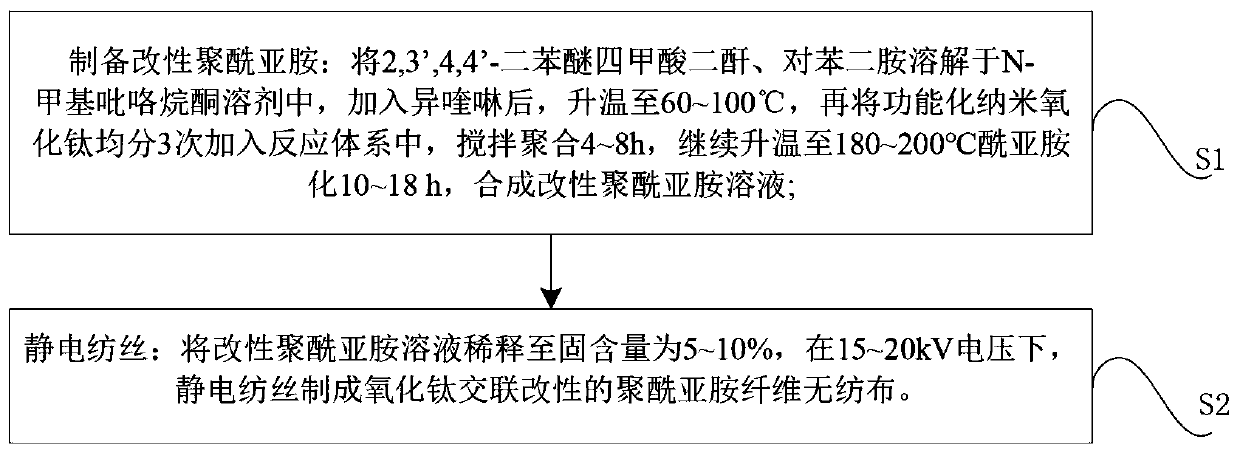

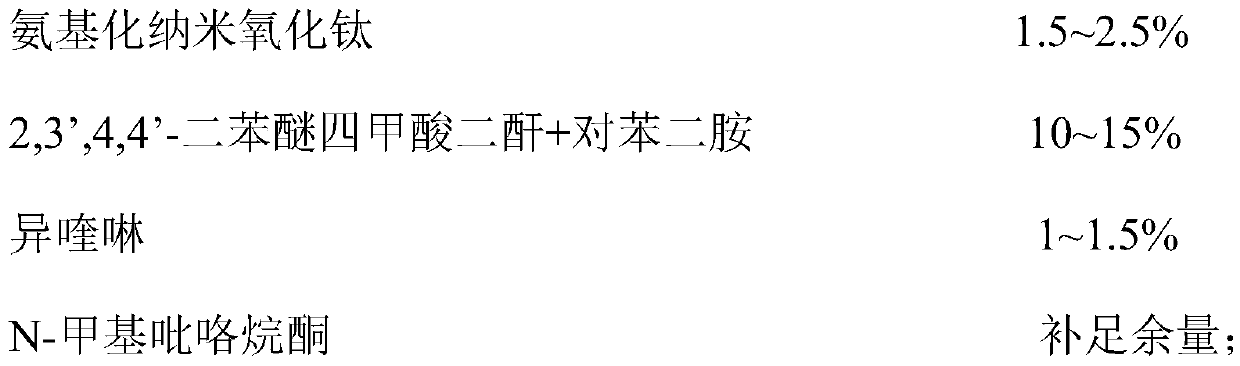

[0020] A preparation method of aminated titanium oxide modified polyimide fiber filter material: use aminated nano-titanium oxide to copolymerize with dianhydride monomers and diamine monomers, and then electrospin to form polyimide fibers without Spinning; Concretely comprises the following steps:

[0021] S1: Preparation of aminated nano-titanium oxide: Dissolve 25mmol of titanium tetrachloride and 10mmol of γ-aminoethylaminopropyltrimethoxysilane in 250mL of 50% ethanol solution, add dropwise 50mL of 2mol / L NaOH solution, and stir evenly. After hydrothermal reaction at 150°C for 6 hours, 2.5 mmol of N,N,N'-trimethylethylenediamine was added dropwise, left to age for 3 hours, filtered, washed and dried to obtain aminated nano-titanium oxide;

[0022] S2: Preparation of modified polyimide: Dissolve 7.715g of 2,3',4,4'-diphenyl ether tetracarboxylic dianhydride and 2.285g of p-phenylenediamine (the molar ratio of the two is 1:0.85) in 87.5 gN-Methylpyrrolidone solvent, add 1g...

Embodiment 2

[0025] A preparation method of aminated titanium oxide modified polyimide fiber filter material: use aminated nano-titanium oxide to copolymerize with dianhydride monomers and diamine monomers, and then electrospin to form polyimide fibers without Spinning; Concretely comprises the following steps:

[0026] S1: Preparation of aminated nano-titanium oxide: Dissolve 37.5mmol of titanium tetrachloride and 19.5mmol of γ-aminoethylaminopropyltrimethoxysilane in 250mL of 50% ethanol solution, add dropwise 75mL of 2mol / L NaOH solution, and stir well Afterwards, hydrothermal reaction at 150°C for 10 hours, then 4.4 mmol of N,N,N'-trimethylethylenediamine was added dropwise, left to age for 5 hours, filtered, washed and dried to obtain aminated nano-titanium oxide;

[0027] S2: Preparation of modified polyimide: Dissolve 9.644g of 2,3',4,4'-diphenyl ether tetracarboxylic dianhydride and 2.856g of p-phenylenediamine (the molar ratio of the two is 1:0.85) in 84.25 gN-methylpyrrolidone s...

Embodiment 3

[0030] A preparation method of aminated titanium oxide modified polyimide fiber filter material: it is formed by copolymerization of aminated nano-titanium oxide, dianhydride monomer and diamine monomer, and then electrospun into polyimide fiber without Spinning; Concretely comprises the following steps:

[0031] S1: Preparation of aminated nano-titanium oxide: Dissolve 50mmol of titanium tetrachloride and 18.75mmol of γ-aminoethylaminopropyltrimethoxysilane in 250mL of 50% ethanol solution, add dropwise 100mL of 2mol / L NaOH solution, and stir well , hydrothermal reaction at 150°C for 12 hours, then 3.75 mmol N,N,N'-trimethylethylenediamine was added dropwise, left to age for 6 hours, filtered, washed and dried to obtain aminated nano-titanium oxide;

[0032] S2: Preparation of modified polyimide: Dissolve 11.573g of 2,3',4,4'-diphenyl ether tetracarboxylic dianhydride and 3.427g of p-phenylenediamine (the molar ratio of the two is 1:0.85) in 81gN -In the methylpyrrolidone so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com