Preparation method of Cr (III) ion imprinted material based on surface of MCM-41 molecular sieve

A technology of MCM-41 and ion imprinting, which is applied in the field of preparation of Cr ion imprinting materials, can solve the problems of slow mass transfer and difficult elution, and achieve good mechanical properties, good adsorption, and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

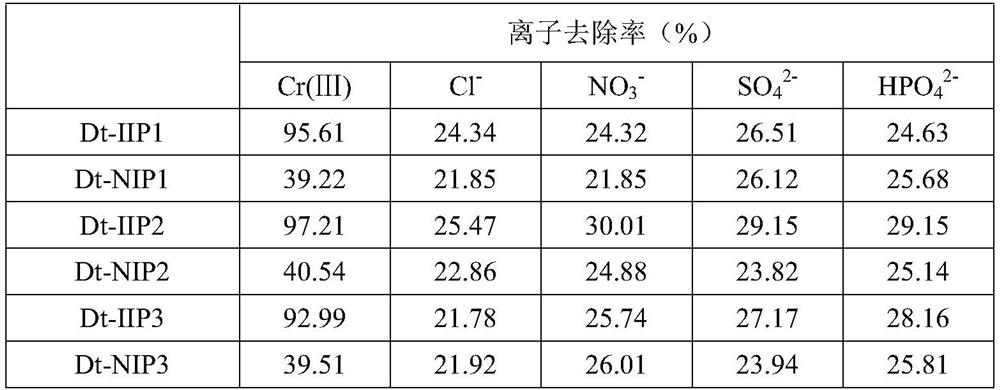

Embodiment 1

[0013] A preparation method based on the Cr(Ⅲ) ion imprinted material on the MCM-41 molecular sieve surface, comprising the steps:

[0014] (1) Preparation of MCM-41: Weigh 1.2 g of cetyltrimethylammonium bromide into a three-necked flask, and simultaneously measure 90 mL of ammonia water and 130 mL of distilled water into the three-necked flask. Stir at 60°C until cetyltrimethylammonium bromide is completely dissolved. Under vigorous stirring, 5 mL of ethyl orthosilicate was slowly added dropwise, and stirred at a constant speed, and reacted for 6 hours. Stop the reaction and pour it out while it is hot. At room temperature, it crystallizes for 3d. The solid particles were washed to neutral and dried. Burn in a muffle furnace at 550°C for 6 hours to remove hexadecyltrimethylammonium bromide to obtain MCM-41;

[0015] (2) Weigh 0.2mmol of chromium sulfate hexahydrate solid in a three-necked flask, then add 10mL of ultrapure water to fully dissolve it, then weigh 80-100mL of...

Embodiment 2

[0020] (1) Preparation of MCM-41: Weigh 1.2 g of cetyltrimethylammonium bromide into a three-necked flask, and simultaneously measure 90 mL of ammonia water and 130 mL of distilled water into the three-necked flask. Stir at 60°C until cetyltrimethylammonium bromide is completely dissolved. Under vigorous stirring, 5 mL of ethyl orthosilicate was slowly added dropwise, and stirred at a constant speed, and reacted for 6 hours. Stop the reaction and pour it out while it is hot. At room temperature, it crystallizes for 3d. The solid particles were washed to neutral and dried. Burn in a muffle furnace at 550°C for 6 hours to remove hexadecyltrimethylammonium bromide to obtain MCM-41;

[0021] (2) Weigh 0.25 mmol of chromium sulfate hexahydrate solid in a three-necked flask, then add 10 mL of ultrapure water to fully dissolve it, then weigh 80-100 mL of methanol and add it to the three-necked flask, mix well, and then add 2 mL of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, re...

Embodiment 3

[0026] (1) Preparation of MCM-41: Weigh 1.2 g of cetyltrimethylammonium bromide into a three-necked flask, and simultaneously measure 90 mL of ammonia water and 130 mL of distilled water into the three-necked flask. Stir at 60°C until cetyltrimethylammonium bromide is completely dissolved. Under vigorous stirring, 5 mL of ethyl orthosilicate was slowly added dropwise, and stirred at a constant speed, and reacted for 6 hours. Stop the reaction and pour it out while it is hot. At room temperature, it crystallizes for 3d. The solid particles were washed to neutral and dried. Burn in a muffle furnace at 550°C for 6 hours to remove hexadecyltrimethylammonium bromide to obtain MCM-41;

[0027] (2) Weigh 0.3 mmol of chromium sulfate hexahydrate solid in a three-necked flask, then add 10 mL of ultrapure water to fully dissolve it, then weigh 80-100 mL of methanol and add it to the three-necked flask, mix well, and then add 2 mL of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com