Organosilicone dimeric surfactant and synthetic method thereof

A technology of surfactants and gemini surfaces, applied in the field of silicone gemini surfactants and their synthesis, can solve the problems of easy hydrolysis and poor oil solubility of trisiloxane gemini surfactants, etc., and achieve easy separation and simple post-treatment , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

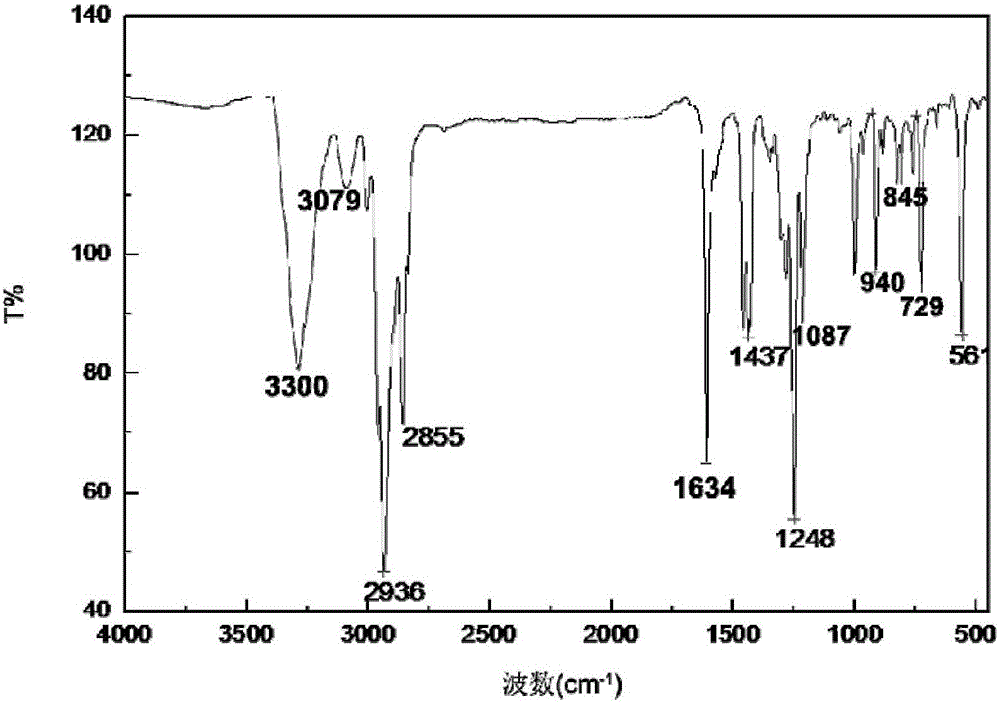

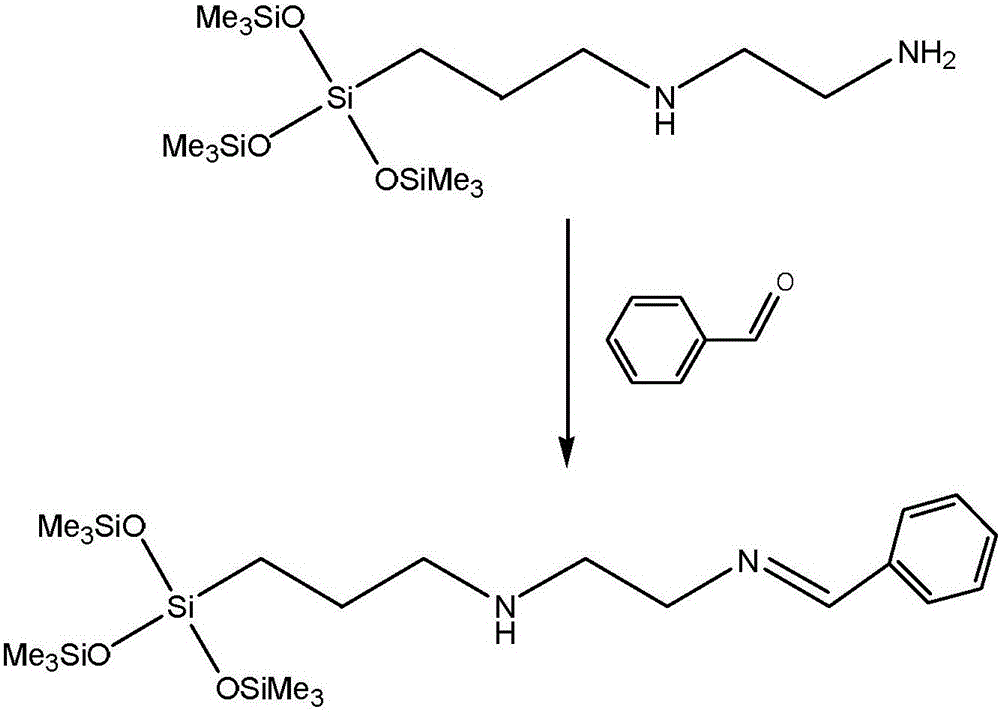

[0016] Specific embodiment one: the structural formula of the organosilicon gemini surfactant of the present embodiment is as follows:

[0017] where n=1, 2 or 3.

specific Embodiment approach 2

[0018] Specific embodiment two: the preparation method of the organosilicon gemini surfactant described in specific embodiment one is as follows:

[0019] 1. According to the molar ratio of aminoethylaminopropyltrimethoxysilane and hexamethyldisiloxane as 1:(10~20), mix aminoethylaminopropyltrimethoxysilane and hexamethyldisiloxane Add oxane into the reactor, then add tetramethylammonium hydroxide as a catalyst in the reactor, the amount of catalyst added is 0.1-0.5% of the amount of aminoethylaminopropyltrimethoxysilane, and nitrogen gas Protection, heating in an oil bath to 80-90°C, reflux reaction for 4-5 hours, recovering unreacted hexamethyldisiloxane, and then distilling under reduced pressure to obtain aminoethylaminopropyltetrasiloxane;

[0020] Two, take the aminoethylaminopropyltetrasiloxane obtained in step 1 and react with benzaldehyde, wherein the molar ratio of aminoethylaminopropyltetrasiloxane to benzaldehyde is 1:(1~1.3), and the ammonia Add ethylaminopropyl ...

specific Embodiment approach 3

[0023] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the specific steps for preparing diol diglycidyl ether in step three are as follows: take by weighing epichlorohydrin, sodium hydroxide, tetrabutylammonium bromide And containing α, ω-dihydric alcohols, wherein the mass ratio of epichlorohydrin to sodium hydroxide is 1: (1 ~ 1.1), and the amount of tetrabutylammonium bromide is that of epichlorohydrin 0.5-1.5%, containing α, ω-dihydric alcohols and the molar ratio of epichlorohydrin is 1: (2-4), first add epichlorohydrin, sodium hydroxide and tetrabutylammonium bromide into the reactor, then put the reactor in ice water at 0°C, dropwise add substances containing α, ω-dihydric alcohols under stirring conditions, after the dropwise addition, heat up to 40-45°C, and react 1-4 hours, then filter, wash the liquid phase with saturated ammonium chloride aqueous solution to neutrality, after layering, dry the organic layer liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com