Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100 results about "1h benzotriazole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

1H-Benzotriazole is an anticorrosive agent, which is useful in aircraft deicing and antifreeze fluids. It is also employed in dishwasher detergents. Further, it is used as a restrainer in photographic emulsions and also useful as a reagent for the determination of silver in analytical chemistry.

Non-aqueous coolant for engine

ActiveCN102002347AStable pHImprove antifreeze effectHeat-exchange elementsOctanoic AcidsPhosphoric acid

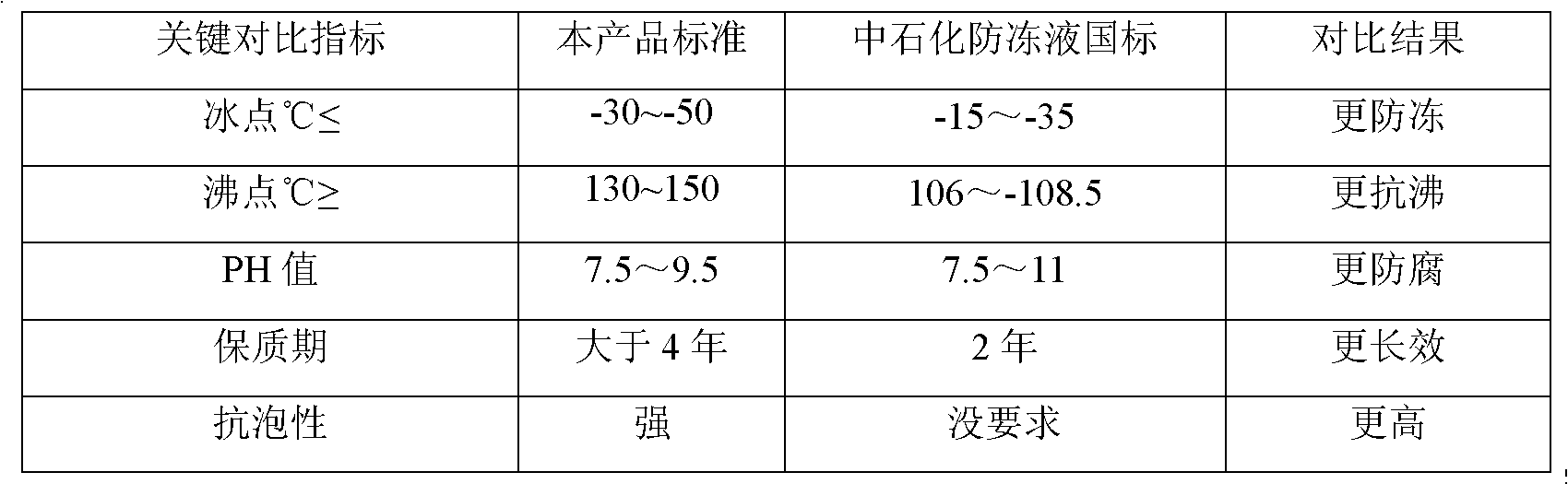

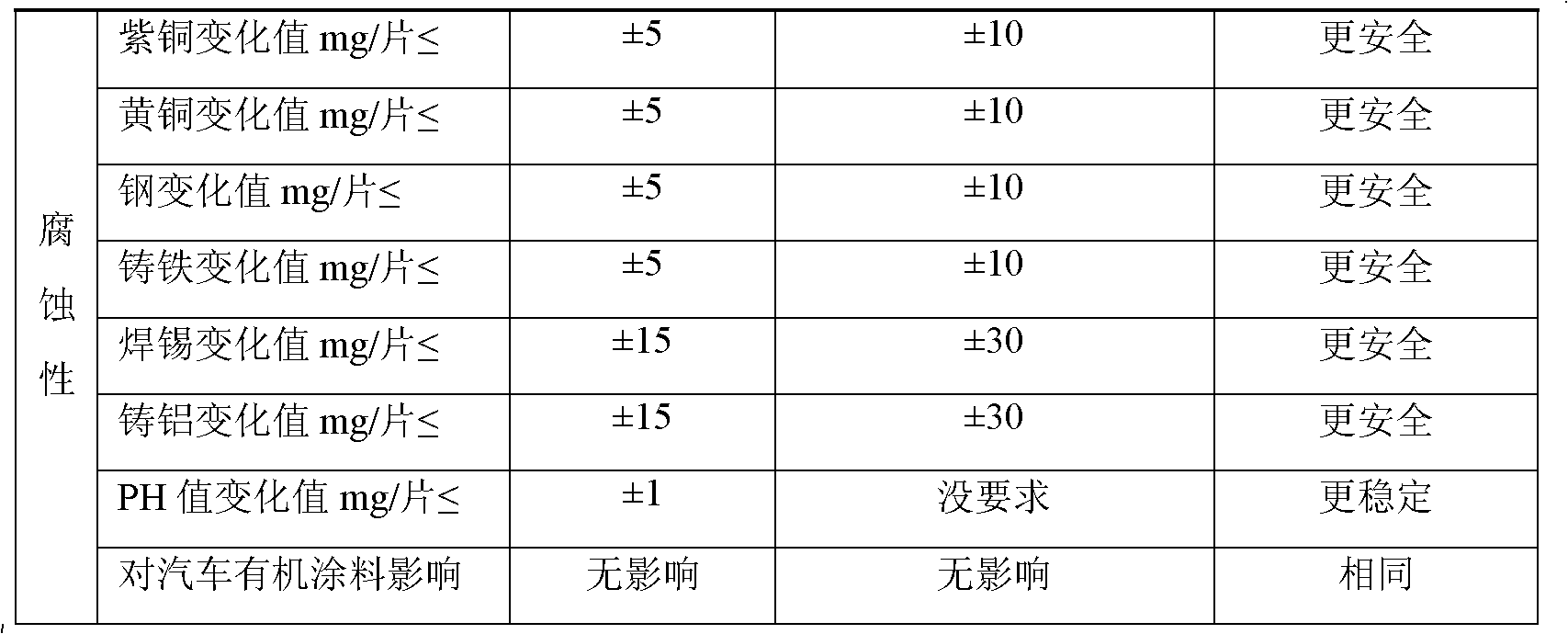

The invention relates to a non-aqueous coolant for an engine, which is characterized by comprising the following components in percent by weight: 10-80 percent of ethylene glycol, 10-80 percent of propylene glycol, 5-20 percent of polyol, 0.1-0.8 percent of phosphate-molybdate, 0.2-0.9 percent of silicate ester, 0.1-1 percent of 4-methyl 1H-benzotriazole, 0.2-0.8 percent of citric acid, 0.2-1 percent of sebacic acid, 0.1-1 percent of octanoic acid, 0.4-1.2 percent of citrate and 0.01-0.2 percent of cosolvent. The non-aqueous coolant has freezing point of -30--50 DEG C and boiling point of 130-150 DEG C, and ensures that the cold start of the engine is realized in cold weather; meanwhile, the working temperature of the engine is improved to 95-150 DEG C from the original 85-95 DEG C. The non-aqueous coolant belongs to a non-aqueous system, avoids electrochemical corrosion, and is a buffer system with pH of 7.5-9.5; and the added relevant auxiliaries have active corrosion resistance on aluminum and aluminum alloy and copper.

Owner:HEFEI UNIV OF TECH

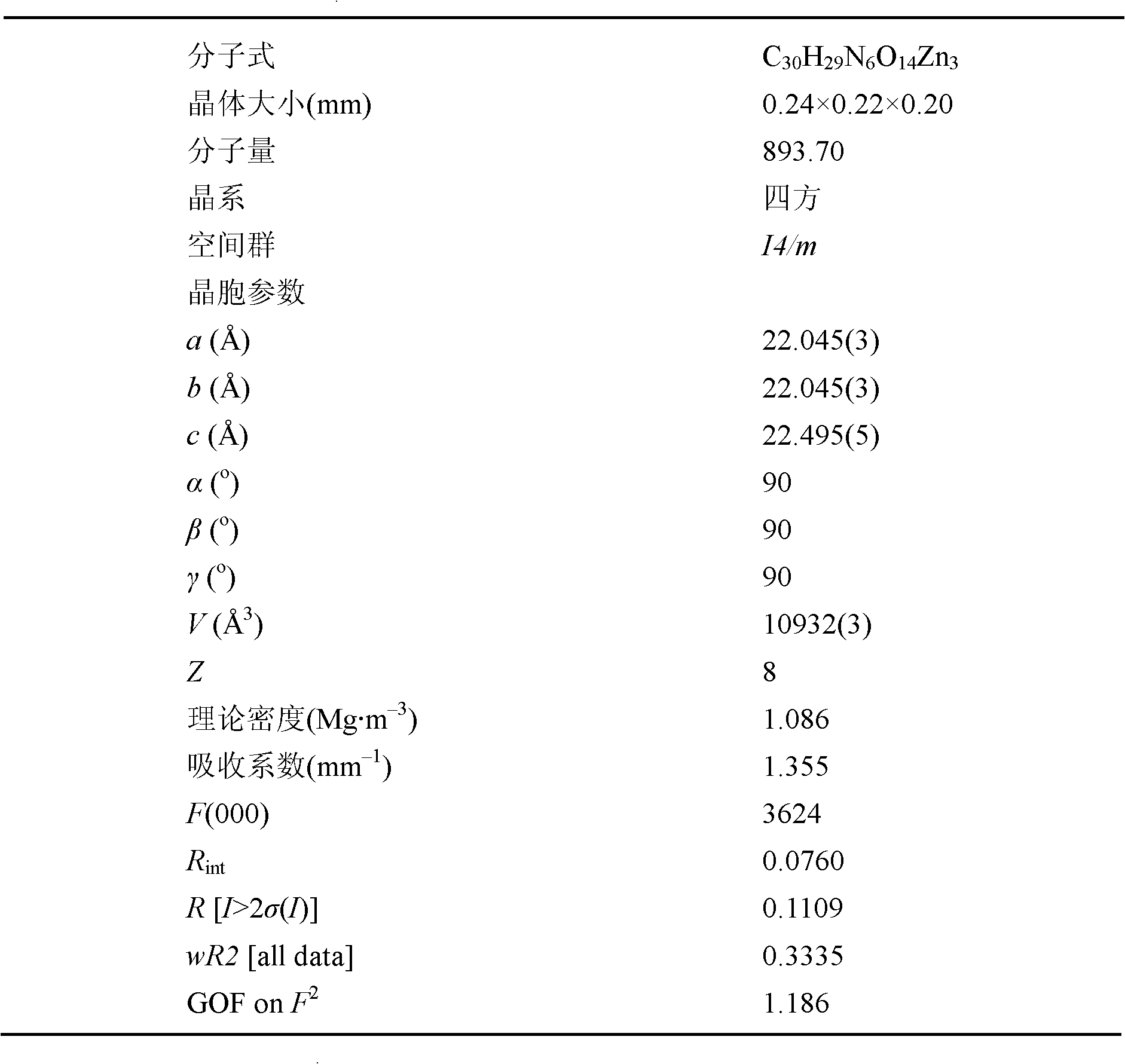

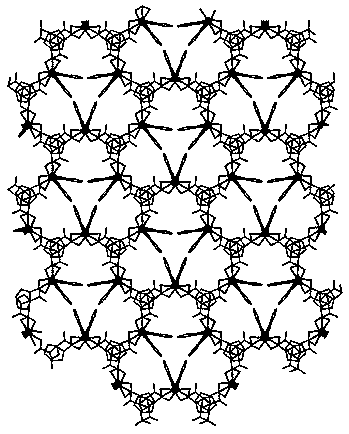

Zinc-cluster porous luminescent complex, and preparation method and application thereof

InactiveCN102491988AHigh purityHigh yieldFluorescence/phosphorescenceLuminescent compositionsN dimethylformamideBulk crystal

The invention provides a zinc-cluster porous luminescent complex. The chemical formula is [NH2(CH3)2][Zn3(BTC)2(BTA)].2DMF; the complex has a porous three-dimensional network structure; and one-dimensional channels are formed in c-axis directions of crystals, and dimethyl formamide molecules are filled in the channels. The preparation method comprises the following steps of: mixing trimesic acid, 1H-benzotriazole, zinc nitrate and N,N-dimethylformamide, performing crystallization reaction, naturally cooling to room temperature, and filtering a solution to obtain colorless transparent bulk crystals, namely single crystals of the complex. The invention has the advantages that: the preparation method is simple is process and easy to implement; the obtained crystals are high in purity, yield and reproducibility; the complex can produce fluorescence, has a fluorescence enhancement or quenching effect on copper and barium metal ions, can be used as a fluorescent material for preparing fluorescent probes, and is used for detecting metal ions in environments or foods; and the detection method is simple and higher in selectivity, and has a broad application prospect.

Owner:NANKAI UNIV

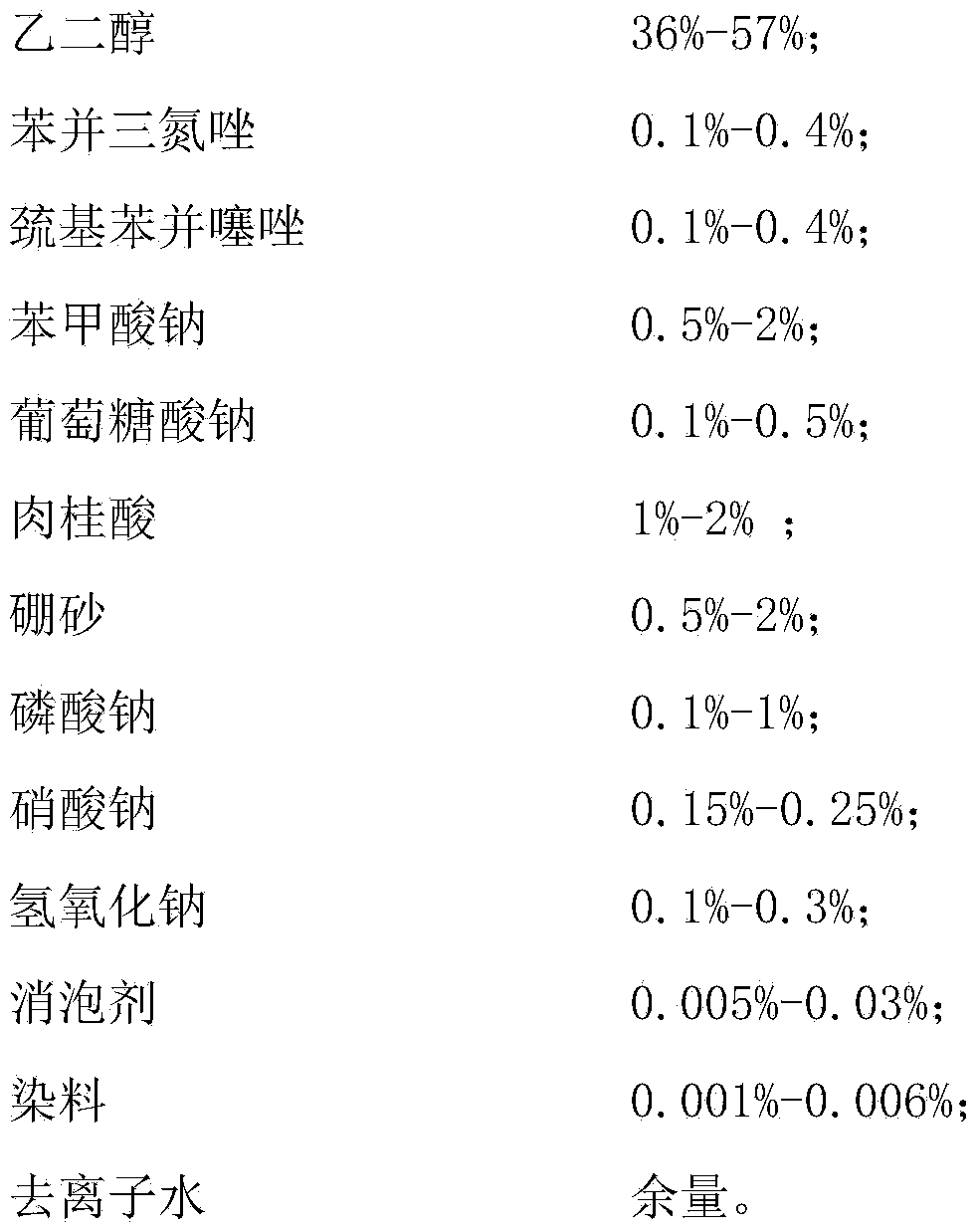

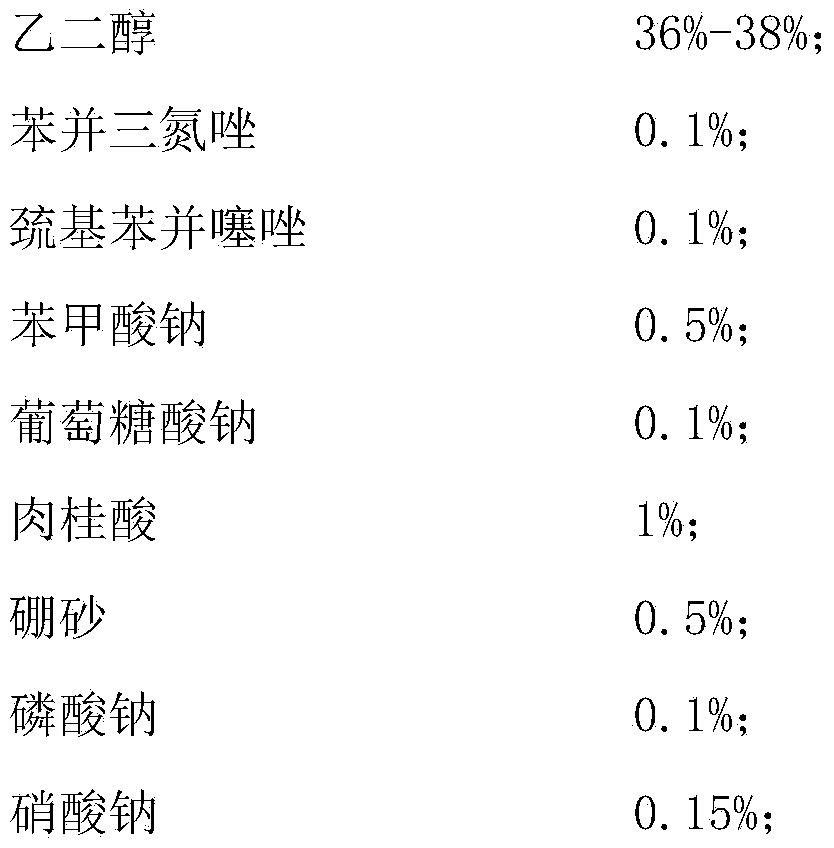

Anti-freezing fluid for solar water heater and preparation method thereof

The invention discloses an anti-freezing fluid for a solar water heater. The anti-freezing fluid is composed of the following components by weight percent: 36-57 percent of glycol, 0.1-0.4 percent of 1H-Benzotriazole, 01.-0.4 percent of mercaptobenzothiazole, 0.5-2 percent of sodium benzoate, 0.1-0.5 percent of sodium gluconate, 1-2 percent of cinnamic acid, 0.5-2 percent of borax, 0.1-1 percent of sodium phosphate, 0.15-0.25 percent of sodium nitrate, 0.1-0.3 percent of sodium hydroxide, 0.005-0.03 percent of an antifoamer, 0.001-0.006 percent of dye and deionized water in balancing amount. The anti-freezing fluid is good in stability, has the PH rangeability smaller than that of a common anti-freezing fluid at high temperature for a long time, does not separate out particles and flocculent precipitates to block a pipeline, and has good rust inhibition effect on metal material for manufacturing the solar heater. Moreover, the invention further provides a preparation method for the anti-freezing fluid, which is simple and easy to operate.

Owner:RICHU DONGFANG SOLAR ENERGY

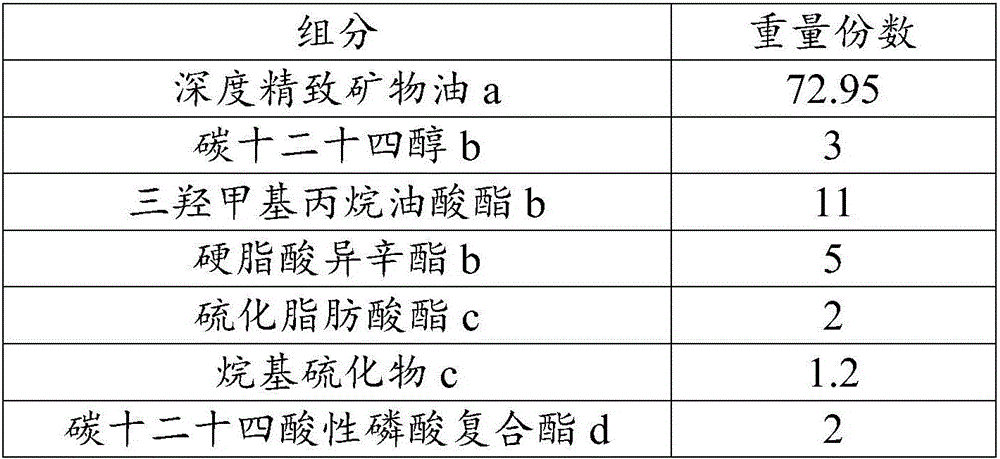

High-lubricating rolling oil composition and application thereof

ActiveCN106318568AImprove the lubrication effectMeet lubrication needsLubricant compositionPhosphateButylated hydroxytoluene

The invention relates to a high-lubricating rolling oil composition and application thereof. The composition is prepared from 40-90 parts of highly refined mineral oil, 10-30 parts of carbon dodecanol tetradecyl alcohol, isotridecyl alcohol, n-octanol, pentaerythritol oleate, trimethylolpropane trioleate, diisooctyl phthalate, 2-ethylhexyl palmitate, isooctyl stearate, methyl palmitate or butyl stearate, 1-5 parts of ZDTP, octadecyl zinc dithiophosphate, sulfurized olefin, sulfide aliphatic acid ester, sulfurized animal oil, alkyl sulfide or sulfur phosphorus molybdenum, 0.5-5 parts of amine thiophosphate, isooctyl acidic phosphate octadecylamine, tricresyl phosphate, tributyl phosphate, dibutyl phosphate and carbon-12 to carbon-14 acid phosphate compound ester, 0.1-5 parts of 2,6-butylated hydroxytoluene, N-phenyl naphthylamine, thioether phenol or alkyl diphenylamine and 0.01-2 parts of 1H-benzotriazole, thiadiazole derivative and benzotriazole.

Owner:CHINA PETROLEUM & CHEM CORP

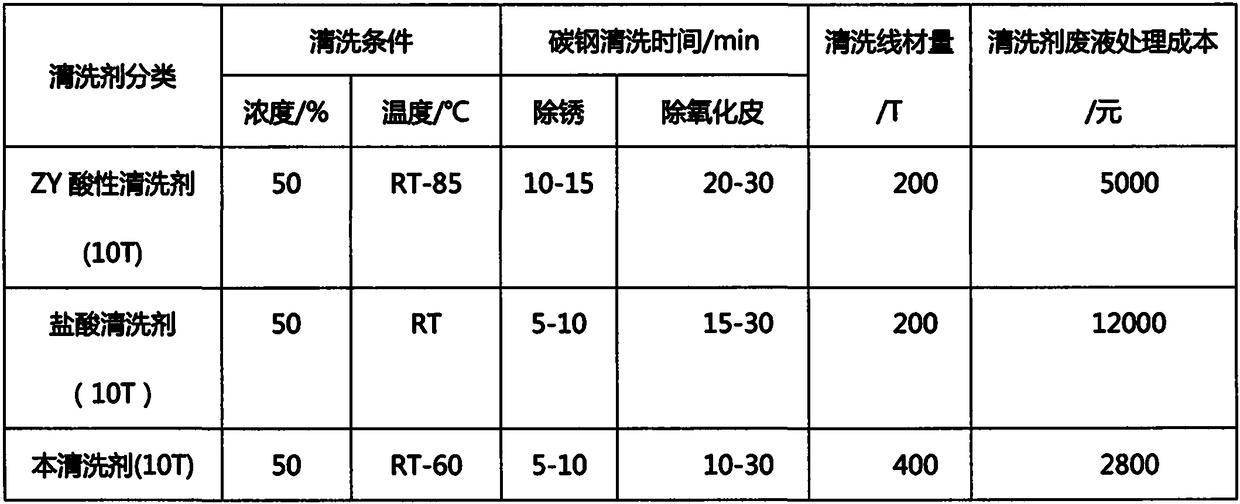

Acidic environment-friendly cleaning agent and preparation method thereof

The invention relates to an acidic environment-friendly cleaning agent and a preparation method thereof. The acidic environment-friendly cleaning agent comprises, counted by 100 parts, 10-40 parts ofphosphoric acid, 2-20 parts of 1-hydroxyethylidene 1,1-diphosphonic acid, 0.1-10 parts of phytic acid, 0.5-10 parts of other organic acids, 1-10 parts of an oxidizing agent, 0.2-5 parts of a polymericdispersing agent, 0.1-2 parts of an organic corrosion inhibiting agent, 0.5-2 parts of an organic penetrating agent and the balance of water. The other organic acids can be citric acid, oxalic acid,tartaric acid, formic acid, acetic acid and the like. The oxidizing agent can be sodium nitrate, zinc nitrate, calcium nitrate and the like. The polymeric dispersing agent can be polyvinyl alcohol 1688, polyethylene glycol 2000, polymaleic anhydride and the like. The organic corrosion inhibiting agent can be thiourea, imidazoline oleate, 1H-benzotriazole and the like. The organic penetrating agentcan be JFC, alkylphenol ethoxylates, nonylphenol ethoxylates and the like. The cleaning agent has the function of removing scale and removing rust, no waste gas is generated in the cleaning process,and the technical effects of environment friendliness and increasing of the cleaning quantity can be achieved.

Owner:东莞市颖兴金属表面处理材料有限公司

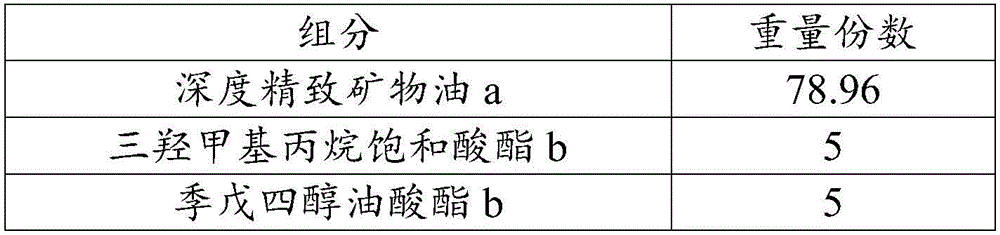

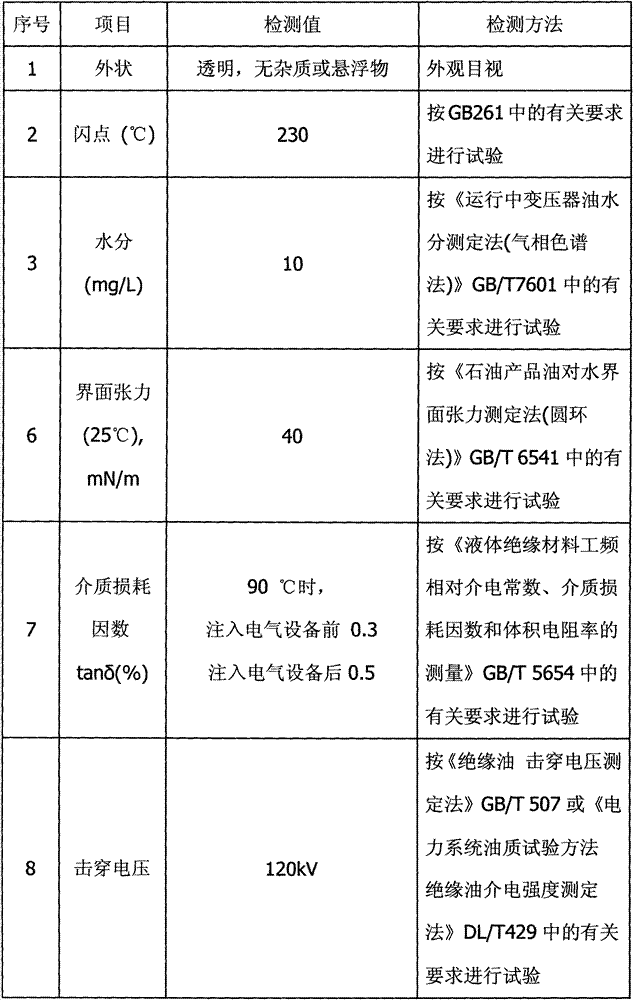

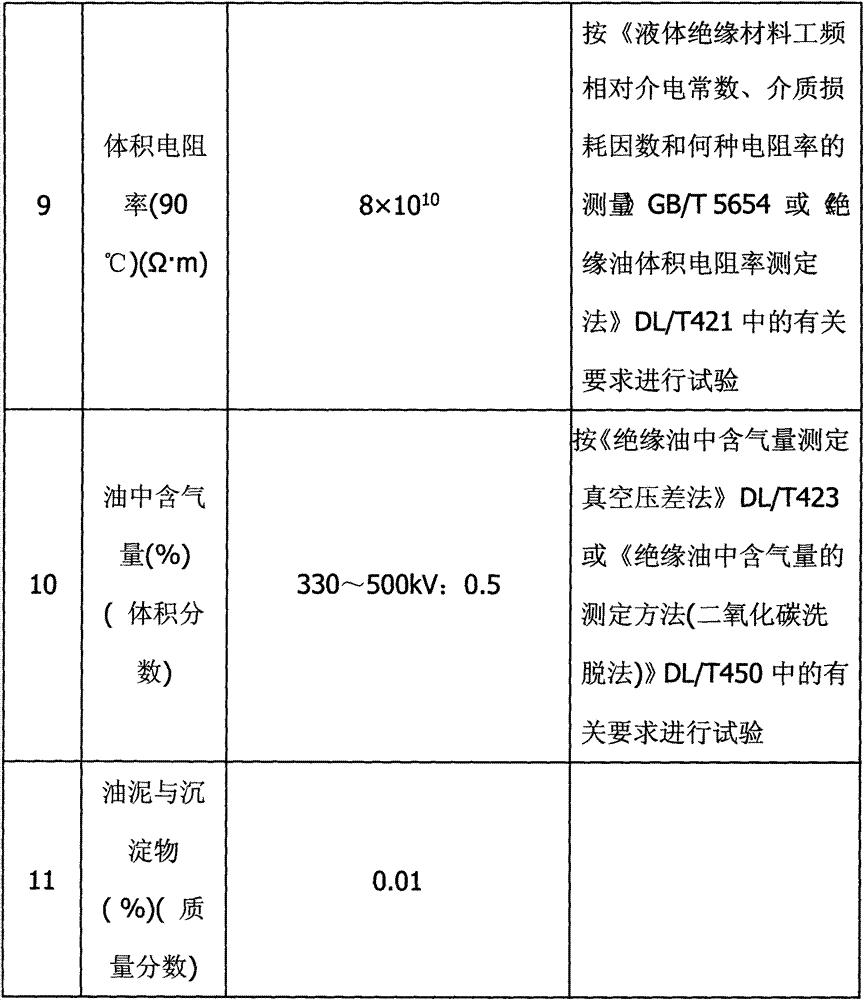

Insulating oil and preparation method thereof

ActiveCN103695099AHigh indexTo satisfy the market's needsLubricant compositionPhosphatePhosphoric acid

The invention discloses an insulating oil prepared from the following raw materials in parts by weight: 1000-1500 parts of a base oil, 150-200 parts of sodium hydroxide, 250-300 parts of EDTA, 150-200 parts of naphthenic acid, 50-100 parts of phosphate ester, 20-50 parts of sodium nitrite, 150-200 parts of triethanolamine, and 1-5 parts of 1H-benzotriazole. Further, the base oil is a refined mineral oil. Further, the base oil is a refined lubricating oil. Compared with the prior art, the insulating oil provided by the invention allows indexes to be all improved, and better meets market demand.

Owner:JIYUAN POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

Preparation method for aminophenol modified daiamid type tree shaped numerator

The invention discloses a preparation method for dressing polyamidoamine dendrimer by amino acid. The reaction is performed in organic solvent, hydroxyl benztriazole HOBt, 2-(1H-benzotriazole)-N, N N`, N`-tetramethyluroniumhexafluorophosphate HBTU, N and N-diisopropylethylamine DIPEA are taken as catalyzer, to ensure that 2, 2, 4, 6 and 7-pentamethyldihydrobenzofuran-5-sulfonyl Pbf and 9-fluorenylmethyloxycarbonyl Fmoc dual-protection amino acid and terminal hydroxyl group PAMAM dendrimer can generate the condensation reaction. The refinement is performed through adopting dextran gel chromatography, to ensure that trifuoroacetic acid and piperidine can respectively divest of the Pbf protecting group and the Fmoc protecting group of the amino acid and the depurant amino acid can be obtained to dress the PAMAM dendrimer of the terminal hydroxyl group. The operation of the preparation method is simple, the condition is moderate, the price is low, the purer end product can be obtained, the preparation process can not damage the activation of the guanidino in the amino acid, and the preparation method is suitable for a great quantity of preparation and industrialized production.

Owner:SHANGHAI JIAO TONG UNIV

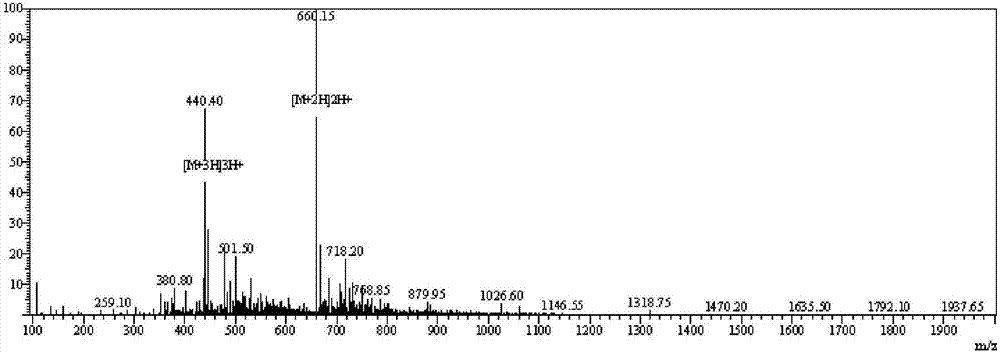

Chemical preparation method of cyclic decapeptide compound GG-110824

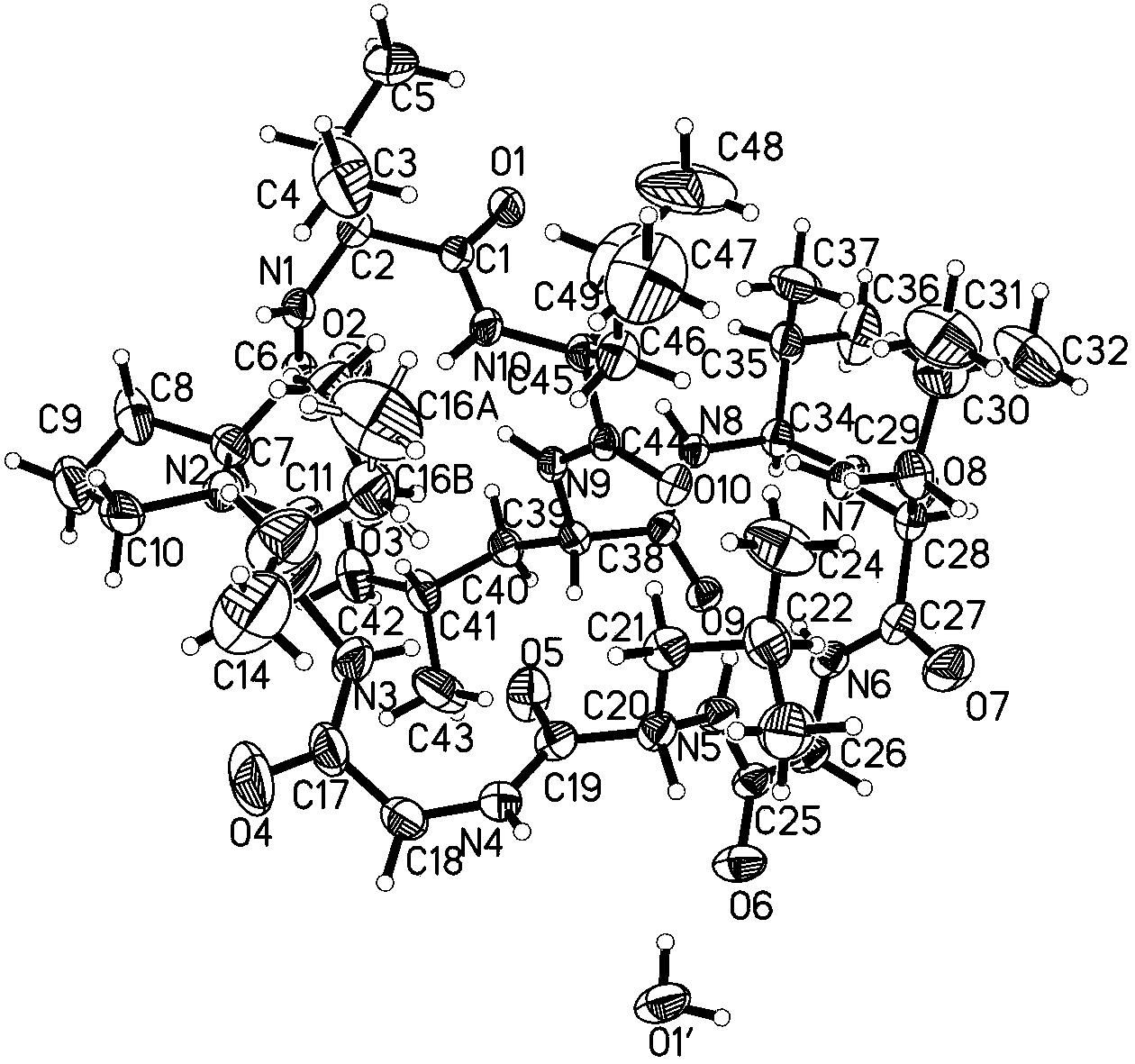

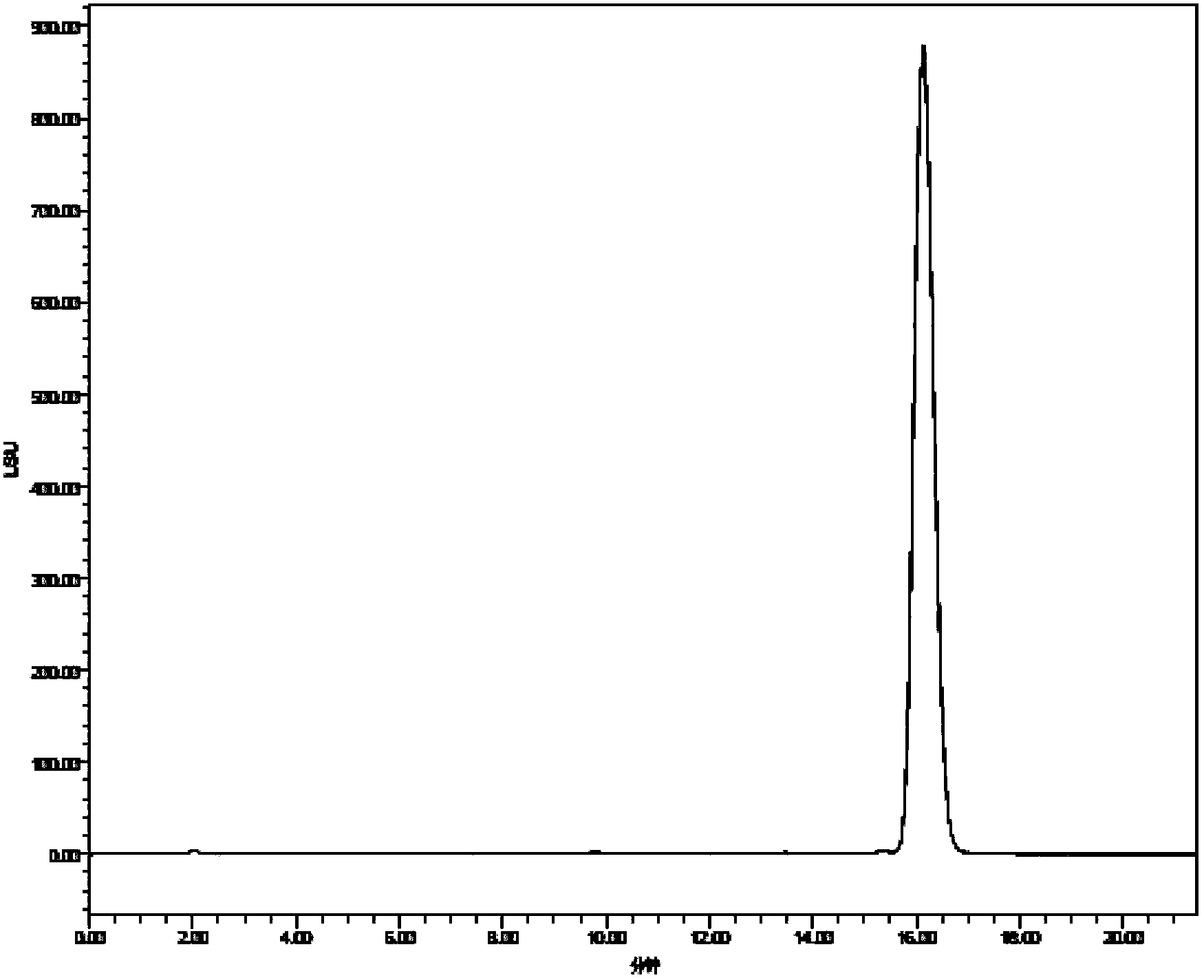

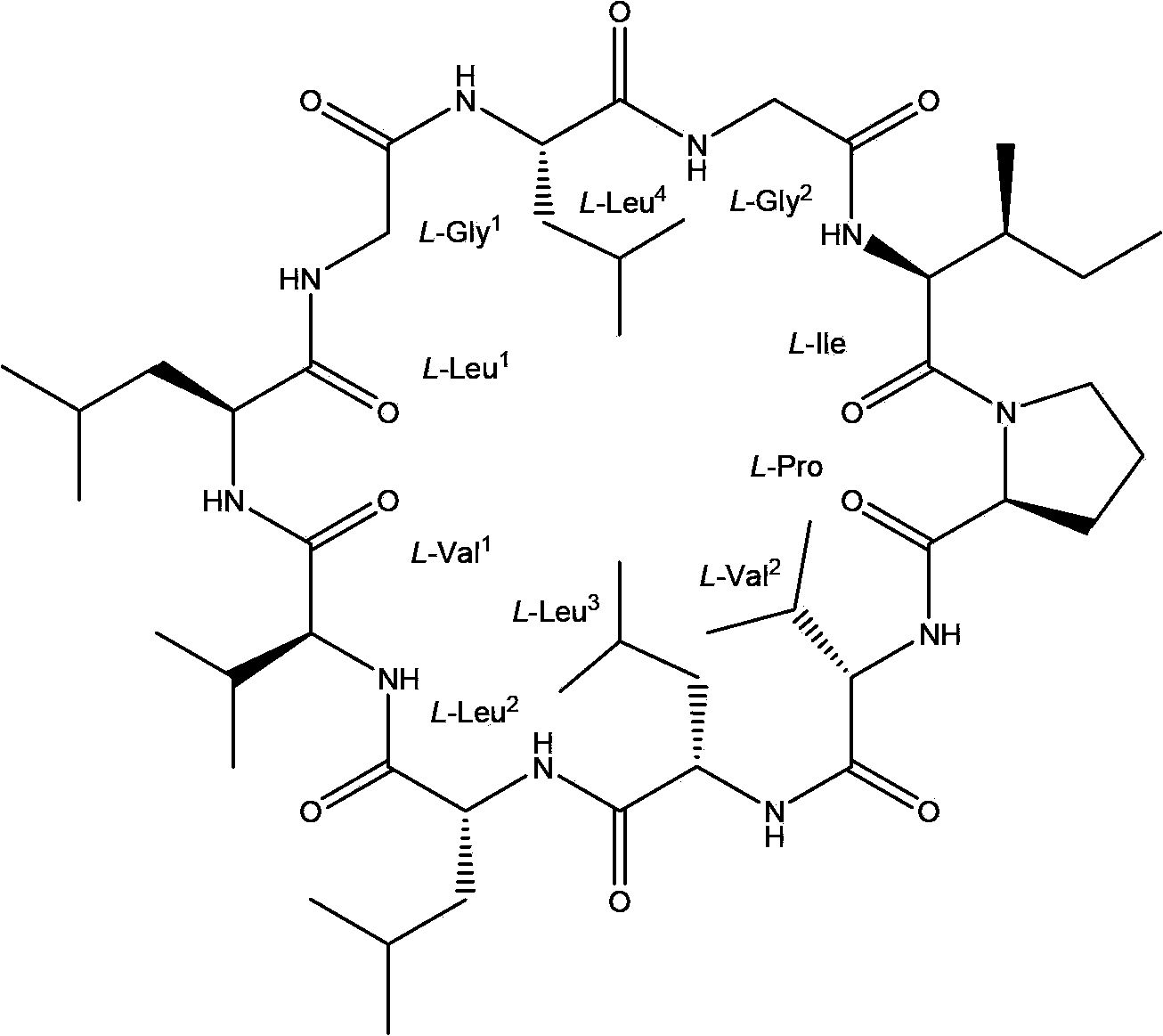

InactiveCN103665115AThree-dimensional structure guaranteeSimple preparation stepsPeptide preparation methodsChromatographic separationX-ray

The invention belongs to the field of pharmacy, and relates to a chemical preparation method of a cyclic decapeptide compound GG-110824. The cyclic decapeptide compound GG-110824 is formed by connecting ten alpha-L-amino acids end to end in sequence, has a structure shown by a formula (I) and is expressed as cyclo(Gly-Leu-Val-Leu-Leu-Val-Pro-Ile-Gly-Leu). The preparation method of the GG-110824 is a chemical preparation method of a solid phase synthesis straight chain peptide precursor and a liquid phase closed ring by taking Wang resin as a solid carrier, HATU / HOAt (2-(7-Aza-1H-benzotriazole-1-yl)-1,1,3,3-tetramethyluronium hexafluorophosphate / 1-Hydroxy-7-azabenzotriazole) as a condensating agent and N,N-dimethylfomamide as a solvent; the GG-110824 is obtained through chromatographic separation of reaction products, and the structure of a prepared product is conformed through monocrystal X-ray diffraction. The preparation method disclosed by the invention is simple in step and high in yield and has a very high practical value.

Owner:FUDAN UNIV

Fine chemical waste water treating agent for efficiently removing ammonia nitrogen

ActiveCN103896380AImprove removal efficiencyNo corrosionWater/sewage treatment by flocculation/precipitationHexamethylenetetramineSulfite salt

The invention discloses a fine chemical waste water treating agent for efficiently removing ammonia nitrogen, which is prepared from the following components in parts by weight: 20-25 parts of Nekal BX, 8-12 parts of sodium dodecylbenzenesulphonate, 0.5-1 part of 1H-benzotriazole, 0.5-1 part of hexamethylenetetramine, 5-7 parts of isothiazolone, 6-8 parts of sodium trimetaphosphate, 30-35 parts of polymerization ferric chloride, 6-10 parts of sodium silicate, 1-1.5 parts of citric acid, 2-3 parts of potassium ferrate, and 40-60 parts of deionized water. After being applied in fine chemical waste water treatment, the waste water treating agent can better achieve the combination effects of oxidization, adsorption, flocculation, precipitation, sterilization, disinfection, discoloring, deodorization and the like, is high in ammonia nitrogen removal rate, non-toxic, free from corroding equipment, and simple in a preparation method.

Owner:ANQING FENGYUAN CHEM

Anti-wear drawing fluid and preparation method thereof

InactiveCN103614223AExtended service lifeEasy to cleanLubricant compositionWorking temperatureCooling effect

The invention discloses an anti-wear drawing fluid and a preparation method thereof. The anti-wear drawing fluid is characterized by being prepared from the following raw materials in parts by weight: 4-5 parts of chlorinated paraffin, 3-4 parts of sorbeth laurate, 1-2 parts of sodium dodecyl sulfate, 3-4 parts of polyacrylamide, 1-2 parts of 1H-benzotriazole, 1-2 parts of nanometer bentonite, 10-14 parts of an anti-grinding agent and 1000 parts of water. According to the drawing fluid, nanometer aluminium nitride powder added into the anti-grinding agent helps to promote heat radiation, reduce friction and prolong the service life of a drawing mold; the drawing fluid has extremely strong cleaning capability, is capable of rapidly cleaning dirt on metal surface and enables the finished product surface to be relatively bright and clean; the drawing fluid is excellent in cooling effect because of completely aqueous properties, and is capable of effectively controlling the work temperature of a drawing machine; and the drawing fluid is easily available in raw materials and simple in preparation technology, and helps to well solve the sewage discharging problem after the drawing fluid is used.

Owner:全威(铜陵)铜业科技有限公司

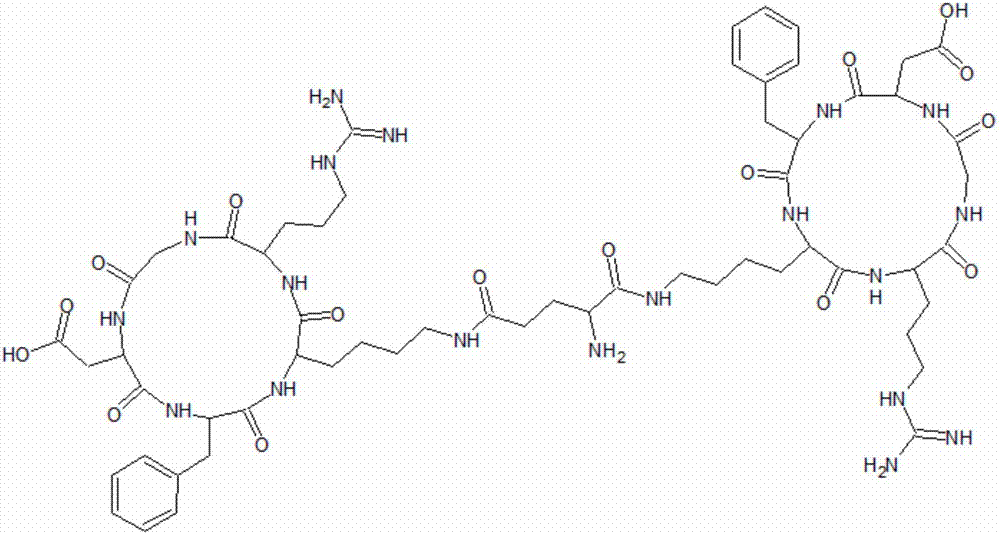

Biscyclopeptide E(c(RGDfK))2 and preparation method thereof

InactiveCN106916208AImprove stabilitySuitable for large-scale productionPeptide preparation methodsTetrafluoroborateArginine

The invention discloses a biscyclopeptide E(c(RGDfK))2 and a preparation method thereof. The method comprises the following steps: 1) immersing resin and Fmoc-Asp-oall (Fmoc-L-aspartic acid alpha-allyl ester )in DCM (dichloromethane), adding DIEA (N,N-diisopropylethylamine), carrying out a contact reaction, and washing the obtained reaction product; 2, adding DCM, methanol and DIEA to the above obtained system, carrying out end capping treatment, and adding piperidine to carry out deprotection; 3) adding G (glycine), HoBt (1-hydroxybenzotriazole) and TBTU (2-(1H-benzotriazole-1-yl)-1,1,3,3-tetramethyluronium tetrafluoroborate) to the reaction system, and carrying out a contact reaction; 4) sequentially adding R (arginine), K (lysine) and f (phenylalanine) into the reaction system, carrying out a contact reaction, adding Pd(PPh3)4, carrying out a propenyl group removal reaction, and adding piperidine to carry out deprotection; 5) adding DIEA, HoBt and HBTU into the system, carrying out a contact reaction, adding a hydrazine hydrate and DMF mixed solution, carrying out a secondary reaction, and washing the obtained reaction product to remove Dde; 6) dropwise adding Fmoc-Glu-OH, HoBt, DMF and TBTU to the reaction system, carrying out a contact reaction, and washing the obtained reaction product; and 7) adding piperidine to the reaction system to carry out deprotection, washing the obtained product with DMF, DCM and methanol, and carrying out post-treatment to obtain the biscyclopeptide E(c(RGDfK))2. The biscyclopeptide E(c(RGDfK))2 has excellent stability.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Online supermolecular cleaning agent for oil well, preparation method and online cleaning using method

ActiveCN106085396ARealize safe online cleaningAdvanced online cleaning methodCleaning apparatusDrilling compositionALLYL SUCROSECleansing Agents

The invention discloses an online supermolecular cleaning agent for an oil well, a preparation method and an online cleaning using method. The online supermolecular cleaning agent for the oil well is prepared from the following components in percentage by weight: 10%-15% of acrylic acid, 11%-15% of 1-hydroxyethane 1,1-diphosphonic acid, 4.5%-7% of fatty alcohol polyoxyethylene ether, 2%-3% of dodecyl dimethyl benzyl ammonium chloride, 2%-3% of 1H-benzotriazole, 2%-3% of trisodium phosphate, 1.5%-2.5% of ethylenediamine triacetic acid, 2%-3% of polyacrylic acid, 2%-2.5% of sodium silicate and the balance of water. With the adoption of the online supermolecular cleaning agent for the oil well, the oil well is cleaned rapidly and conveniently, and the cleaning efficiency is improved.

Owner:QINGDAO JIENENG ENVIRONMENTAL PROTECTION CO LTD

Metal product polishing liquid and preparation method thereof

The invention discloses metal product polishing liquid. The polishing liquid is prepared from, by weight, 20-30 parts of citric acid, 50-100 parts of glacial acetic acid, 2-10 parts of 2-ethylimidazole, 5-12 parts of salicylic acid, 10-20 parts of glycolic acid, 8-15 parts of 1H-benzotriazole, 20-80 parts of polyethylene glycol 8000, 100-150 parts of tetrahydrofurfuryl alcohol, 50-150 parts of ethyl alcohol, 80-100 parts of butyl acetate, 5-12 parts of oleic alcohol polyoxyethylene ether, 5-12 parts of ethylenediamine, 4-6 parts of nano-silicon dioxide, 3-9 parts of nano-zinc oxide and 30-80 parts of auxiliaries. The metal product polishing liquid contains the auxiliaries, the auxiliaries contain rice bran and mango skin, an oxide layer on the surface of a metal product can be effectively removed by means of extraction, tea seed powder can remove blots on the surface of the metal product, effective substances in a polishing agent can easily make direct contact with the oxide layer on the surface of the metal product, the efficiency is improved when the polishing agent removes the oxide layer, and after being modified through iron powder, latex powder and natural resin can form a layer of compact protective film on the surface layer of the metal product after being polished.

Owner:广西钱隆投资管理有限公司

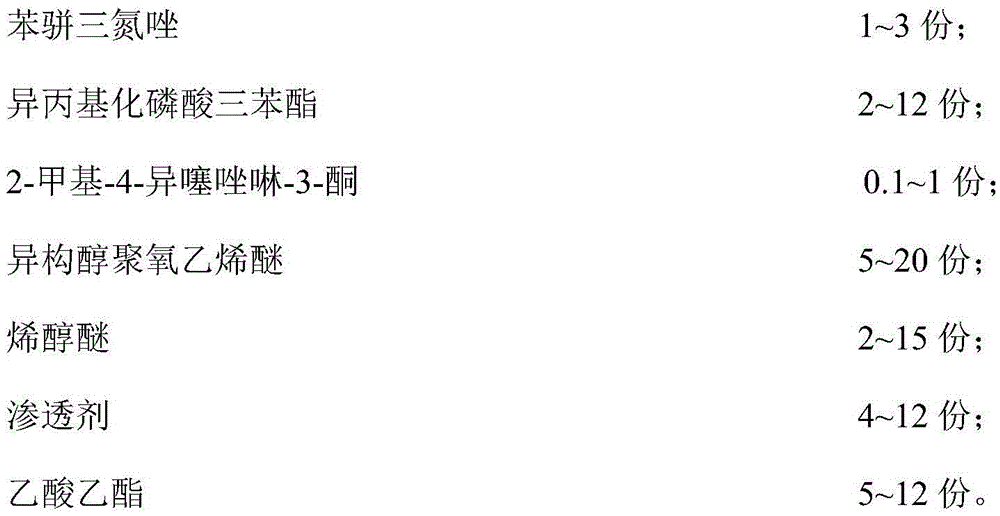

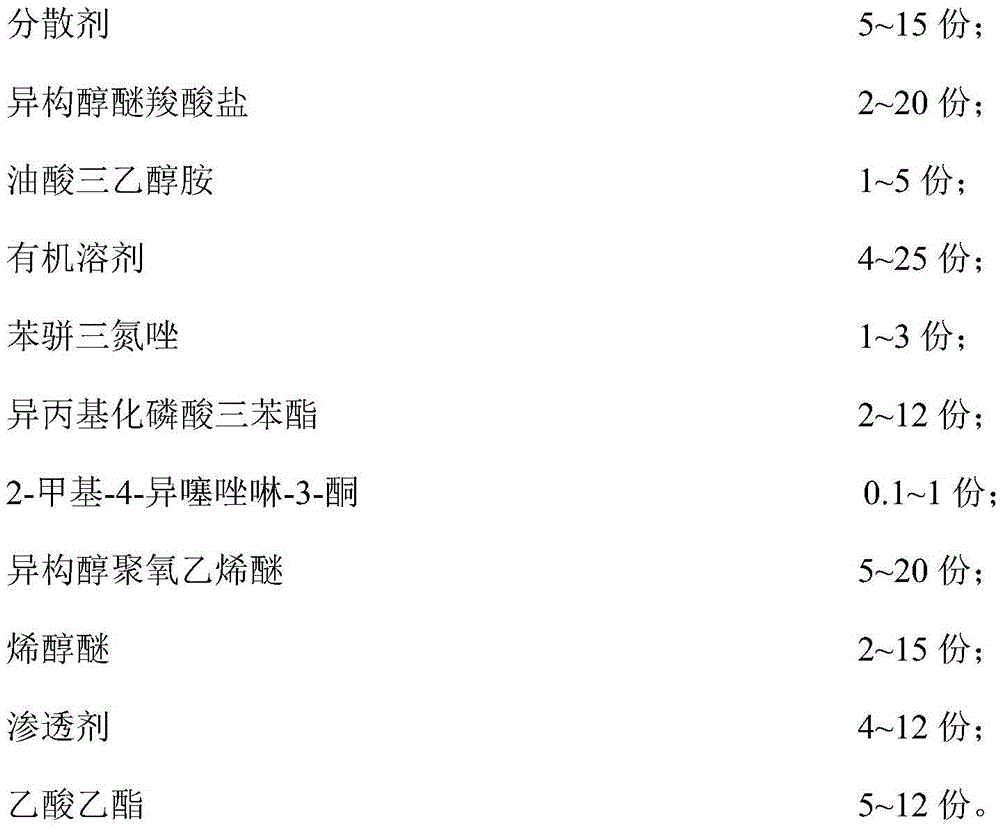

LED substrate dewaxing cleaning agent

ActiveCN105623895AImprove wax removal abilityProduce synergyNon-ionic surface-active compoundsOrganic detergent compounding agentsEnol etherCarboxylic salt

The invention discloses an LED substrate dewaxing cleaning agent. The LED substrate dewaxing cleaning agent comprises a dispersing agent, isomeric alcohol ether carboxylate, triethanolamine oleate, an organic solvent, 1H-benzotriazole, isopropylate triphenyl phosphate, 2-methyl-4-isothiazolin-3-one, isomeric alcohol ethoxylates, enol ether, a penetrant and ethyl acetate. The LED substrate dewaxing cleaning agent can be applied to various LED substrates, is high in cleaning efficiency, dewaxing capability and safety, free from environmental pollution, energy saving, low in washing cost and free from damage to the substrates during washing.

Owner:TAICANG HE S CIRCUIT BOARD CO LTD

Cooling liquid

The invention relates to the technical field of chemical materials, and specifically relates to a cooling liquid. The cooling liquid is composed of the following components in parts by weight: 3 to 12 parts of methyl n-silicate, 3 to 10 parts of co-solvent, 10 to 15 parts of sebacic acid, 7 to 15 parts of caprylic acid, 6 to 10 parts of critic acid, 55 to 70 parts of sorbitol, 2 to 7 parts of ammonium-phosphor molybdate, 1 to 5 parts of 4-methyl-1H-benzotriazole, 4 to 8 parts of sodium citrate, and 25 to 44 parts of water. The provided cooling liquid has the advantages of long lasting and instant effect.

Owner:荆春芳

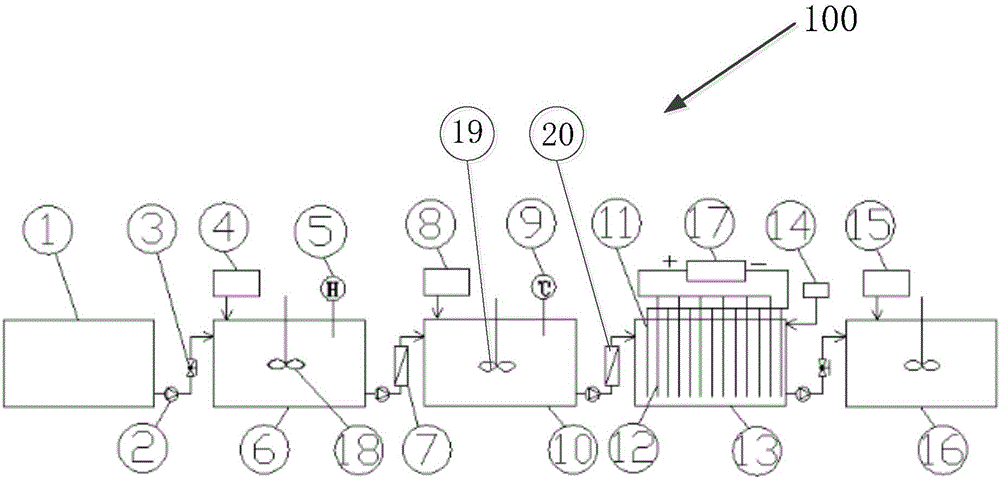

Brown waste liquid treatment device and brown waste liquid treatment method

InactiveCN106115991AHigh purityAvoid complexationTreatment involving filtrationMultistage water/sewage treatmentLiquid wasteElectrolysis

The invention is applicable to the field of waste water treatment, and provides a brown waste liquid treatment device. The brown waste liquid treatment device comprises a storage device for storing brown waste liquid, an electrolyzer used for electrolytic treatment of the brown waste liquid, and a COD (chemical oxygen demand) degradation device for oxidizing the brown waste liquid. The COD degradation device is connected between the storage device and the electrolyzer. The invention further provides a brown waste liquid treatment method. The brown waste liquid treatment device has the advantages that the COD degradation device is used for oxidizing the brown waste liquid before electrolytic treatment, and copper type slow-release agents such as 1H-benzotriazole in the brown waste liquid can be oxidized, so that bright blocky high-quality copper with high purity can be obtained.

Owner:SHENZHEN JECH TECH

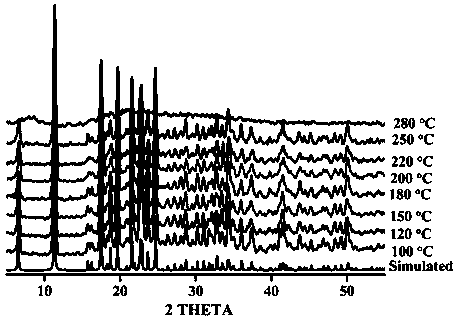

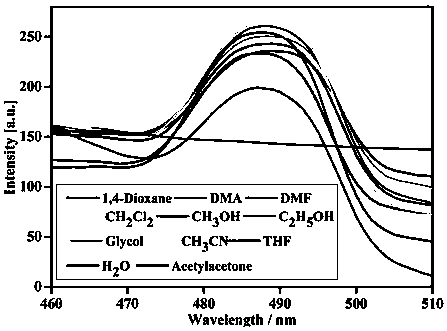

Zinc-organic frame with acetylacetone fluorescence response and preparation method thereof

ActiveCN108384027AImprove thermal stabilityEasy to synthesizeFluorescence/phosphorescenceLuminescent compositionsSpace groupX-ray

A zinc-organic frame material with acetylacetone fluorescence response has a chemical formula of {[(CH3)2NH2][Zn(FDA)(BTZ)2]}n, wherein n is a natural number from 1 to positive infinity, FDA is acquired by deprotonation of 2,5-furandicarboxylic acid (H2FDA), and BTZ is acquired by deprotonation of 1H-benzotriazole (HBTZ). The zinc-organic frame material belongs to a trigonal system, has a space group of R3c and has cell parameters of a=27.0865(3) , b=27.0865(3) , c=11.2171(2) , alpha=90 degrees, beta=90 degrees and gamma=120 degrees. The zinc-organic frame material has good thermal stability;variable temperature XRD (X-ray diffraction) shows that crystal form of the zinc-organic frame material remains stable at 280 DEG C; the zinc-organic frame material has good fluorescence response to acetylacetone and may act as an acetylacetone fluorescence probe. The zinc-organic frame material has the advantages of good synthetic simplicity, good implementing convenience, high yield and the like; therefore, the zinc-organic frame material has great potential application value in the preparation of fluorescence probe solid-state devices.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI

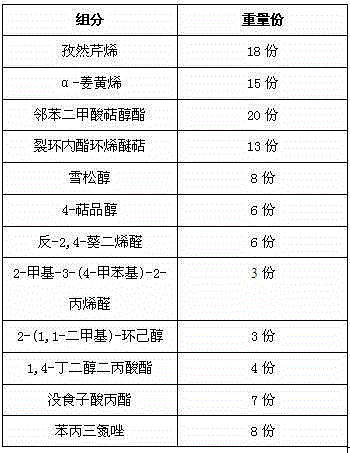

Armyworm and spica parallelangula alpheraky attractant and application thereof to planting of buckwheat in saline-alkali soil

InactiveCN105028424AIncrease trappingReduce incidenceBiocidePest attractantsPolygonum fagopyrumAlkali soil

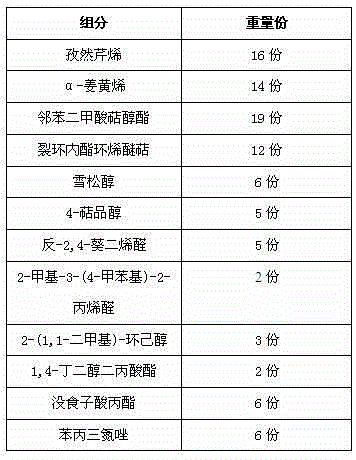

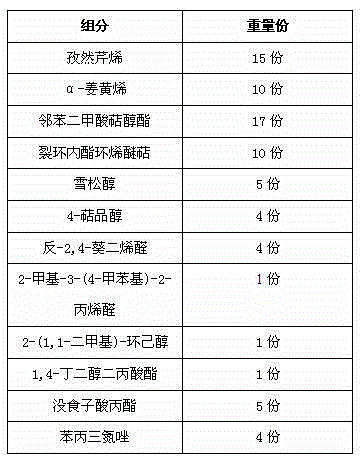

The invention provides an armyworm and spica parallelangula alpheraky attractant and application thereof to planting of buckwheat in saline-alkali soil. The armyworm and spica parallelangula alpheraky attractant comprises the following components: p-cymene, alpha-curcumene, propylgallate, 1H-Benzotriazole, terpenol phthalate, split-ring lactone iridoid, himachalol, 4-terpineol, trans-2,4-decadienal, 2-methyl-3-(4-tolyl)-2-acrolein, 2-(1,1-dimethyl)-cyclohexanol and 1,4-butanediol dipropanoate. When the armyworm and spica parallelangula alpheraky attractant is applied to planting of buckwheat in saline-alkali soil, the average daily trap quantity of armyworms is 21-28 per trap, and the average daily trap quantity of spica parallelangula alpheraky is 28-36 per trap; the pest incidence of armyworms is only 6-9%, and the pest incidence of spica parallelangula alpheraky is only 5-8%; the pest occurrence area of armyworms is only 12-18% and the pest occurrence area of spica parallelangula alpheraky is only 9-16%.

Owner:WEIFANG YOURONG IND

High-adhesion alumina sol automobile clutch friction material and preparation method thereof

InactiveCN105038704ALower surface energyReduce surface activityOther chemical processesFriction liningHexagonal boron nitrideSilanes

The invention discloses a high-adhesion alumina sol automobile clutch friction material which comprises, by weight parts, 2-3 parts of sodium alkyl benzene sulfonate, 0.4-0.8 part of 1H-Benzotriazole, 3-4 parts of hexagonal boron nitride, 4-6 parts of alumina sol, 1-2 parts of ethylparaben, 3-7 parts of barium sulfate, 3-5 parts of vinyl trimethoxy silane, 50-60 parts of acetone, 20-30 parts of dimethyl sulfoxide, 25-30 parts of absolute ethyl alcohol, 50-60 parts of methyl methacrylate, 20-26 parts of butyl acrylate, 0.3-1 part of dodecylthiol, 20-34 parts of titanic sulfate, 16-20 parts of glucose, 60-70 parts of nanometer carbon powder, 200-300 parts of isopropanol, 80-100 parts of nylon 66 and 0.04-0.06 part of azodiisobutyronitrile. The alumina sol is adopted to perform modified treatment of a nylon material, the compatibility between the nylon material and polymethyl methacrylate (PMMA) and nano particles can be effectively improved, and the stability of finished products is improved.

Owner:来安县隆华摩擦材料有限公司

Energy-saving nursing agent of central air conditioning

InactiveCN105621636AWon't clogImprove safety and reliabilitySpecific water treatment objectivesScale removal and water softeningGraphiteChilled water

The invention belongs to the field of fine chemical engineering and in particular relates to an energy-saving nursing agent for cleaning, film-forming protection and corrosion prevention and scale inhibition of a chilled water system of a central air conditioning. The energy-saving nursing agent of the central air conditioning is prepared from the following components in percentage by weight: 15 percent to 21 percent of 1-hydroxyethylidene-1,1-diphosphonic acid, 0.1 percent to 0.2 percent of a penetrating agent, 3 percent to 5 percent of an amide type cosolvent, 1 percent to 3 percent of a cationic surfactant, 2 percent to 3 percent of 1H-benzotriazole, 0.4 percent to 1 percent of high-finesse graphite powder and the balance of water. The nursing liquid of the central air conditioning, provided by the invention, has the following advantages of stable properties, no toxin and odor, safety and reliability and simplicity and convenience for utilization.

Owner:QINGDAO JIENENG ENVIRONMENTAL PROTECTION CO LTD

Energy-saving heating superconductive liquid

InactiveCN102191019AFast heat conductionLarge latent heat of vaporizationHeat-exchange elementsSodium metasilicateHigh energy

The invention discloses energy-saving heating superconductive liquid, which comprises potassium dichromate, sodium nitrite, sodium tetraborate, silicone oil, methyl-1H-benzotriazole, sodium metasilicate, triethanolamine and water, wherein the ratio of potassium dichromate to sodium nitrite to sodium tetraborate to silicone oil to methyl-1H-benzotriazole to sodium metasilicate to triethanolamine in the superconductive liquid is 3:1:10:1:1:1:2. The energy-saving heating superconductive liquid has the advantages that: noises are eliminated in a flowing process, heat can be transferred within 30 minutes which is improved by 50 percent than that required by water, and energy is saved by 30 percent; heat can be transferred by a single pipe or double pipe, and the energy-saving heating superconductive liquid can be used permanently when added once; when heating is suspended, the heating radiators and terrestrial heat heating equipment are protected from being damaged by freezing below 30 DEG C; latent heat of vaporization is high, and when the superconductive liquid undergoes high-energy physical change under heat, radiation is performed to raise temperature quickly and the starting temperature is very low; while a water heating system using water for heat transfer has the drawbacks of slow temperature rise and slow transfer; therefore, temperature rises immediately when the energy-saving heating superconductive liquid is heated, a great convenience is brought to users, and preheating time is saved.

Owner:孟令启

Water-soluble antioxidant derusting antirust liquid and preparation method thereof

The invention discloses a water-soluble antioxidant derusting antirust liquid which is prepared from the following raw materials in parts by weight: 1-2 parts of 1H-benzotriazole, 1-2 parts of dodecenylsuccinic acid, 3-4 parts of sodium malate, 6-8 parts of flax oil, 2-3 parts of hydrochloric acid, 4-5 parts of polypropylene glycol acrylate, 1-2 parts of peregal O, 6-9 parts of sodium silicate, 1-2 parts of triglycidyl cyanurate, 1-2 parts of EDTA disodium, 4-5 parts of an auxiliary agent, and 300 parts of water. Through combined action of the high-molecular polymer monomers and the chelating agent, a thin film can be formed on a metal surface, thereby playing roles in isolating air, adhering an antirust agent and preventing oxidation; through use of sodium malate and the flax oil, the antirust liquid not only isolates the air, but also resists oxidation; through use of hydrochloric acid, the antirust liquid can rapidly remove rust; the antirust liquid is easy to clean up, and can immediately be removed by water washing; and the antirust liquid has few harmful substances, can prevent metals from discoloring, and is applicable to long and short term rust prevention of metal products and machinery parts.

Owner:MINGGUANG CITY LIUXIANG PUMP IND

Synthesis process of 1-n-butyl-1H-benzotriazole

The invention discloses a synthesis process of 1-n-butyl-1H-benzotriazole. The synthesis process comprises the following steps: dissolving benzotriazole in an ethanol solution containing sodium ethoxide, stirring, adding a phase transfer catalyst, keeping room temperature, dropping the ethanol solution containing 1-bromo-n-butane, completing the dropping, heating to 45-55 DEG C, reacting for 1.5-2.5h, recovering ethanol for applying mechanically after the end of reaction, dissolving residues with water, extracting by using an extracting agent, merging organic layers, recovering the extracting agent, performing decompression rectification on the residues, and collecting fractions to obtain a product. The synthesis process of the 1-n-butyl-1H-benzotriazole, disclosed by the invention, has the advantages of high quality, high purity and low energy consumption of the product, simple production equipment, easy control of process parameters and low investment.

Owner:NANTONG BOTAO CHEM

Compound organic solderability preservatives (OSP) treating agent for lead-free printed circuit board (PCB)

InactiveCN105671538AEasy maintenanceWill not cause bending deformationMetallic material coating processesNon-metallic protective coating applicationCompound organicFormate

The invention discloses a compound organic solderability preservatives (OSP) treating agent for a lead-free printed circuit board (PCB). The compound OSP treating agent comprises, by weight, 0.5%-5% of 1H-Benzotriazole, 0.5%-2.5% of 2-Ethylbenzimidazole, 1%-5% of 2-heptyl-5nitrobenzimidazole, 0.2%-1.4% of 1-phenyl-5-sulfenyl tetrazole, 1%-4% of sulfanilamide thioglycoic acid, 0.1%-0.5% of copper acetate, 0.1%-0.5% of copper formate, 1%-5% of potassium iodide, 0.1%-1% of ammonia water, 4%-12% of organic acid, 1%-8% of a solubilizer, 0.1%-1% of a buffering agent, and the balance water. By means of the compound OSP treating agent, OSP which are high in adhesive force, resistant to oxidation, resistant to high temperatures, compact and transparent can be smoothly formed on the surface of a copper circuit on the PCB, a formed film is uniform and flat, heat shock resistance is good, and the treating agent is suitable for machining of single-faced and double-faced boards; a solution is stable, maintenance is easy, the operation temperature of the aqueous solution can be controlled to be 80 DEG C or lower, bending deformation of a substrate is avoided, operation cost is low, and the rate of finished products is high.

Owner:滁州嘉泰科技有限公司

Anti-corrosion motor vehicle antifreeze fluid

InactiveCN104774596AImprove corrosion resistanceEffective protectionHeat-exchange elementsRaw materialChemistry

The invention discloses anti-corrosion motor vehicle antifreeze fluid. The raw materials include, by mass, 80-90 percent of ethanediol, 0.05-0.15 percent of pigment, 0.5-1.5 percent of zinc chloride, 0.05-0.15 percent of methyl-1H-benzotriazole, 0.5-1.5 percent of sodium tetraborate, 0.5-1.5 percent of polyamino acid and the balance deionized water. The anti-corrosion motor vehicle antifreeze fluid is high in anti-corrosion performance, can effectively prevent water scales from forming, has good protection performance for any materials of a cooling part of an engine, has the excellent performance of preventing freezing in winter, preventing boiler in summer, preventing water scales and corrosion all the year round and the like, effectively protects a water cooling system of a motor vehicle, prolongs the service life of the water cooling system, reduces the cost and further has the advantage of being environmentally friendly.

Owner:NINGBO JOYSONQUIN AUTOMOTIVE SYST HLDG CO LTD

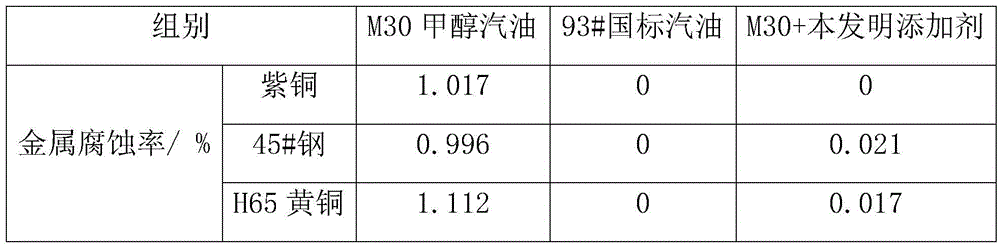

Methanol gasoline additive

InactiveCN105670717AImprove combustion efficiencyReduce corrosionLiquid carbonaceous fuelsFuel additivesHexaethylene glycolPhosphate

The invention provides a methanol gasoline additive. The additive comprises the following components in parts by weight: 22-28 parts of 3-methyl-1-butanol, 12-15 parts of 1-methoxy-2-propanol, 8-10 parts of propylene glycol methyl ether acetate, 4-6 parts of tert-butyl methyl ether, 3-5 parts of isooctyl phosphate, 3-5 parts of polyethylene glycol tert-octylphenyl ether, 6-8 parts of hexaethylene glycol monodecyl ether, 4-6 parts of 1H-benzotriazole, and 6-8 parts of triethylene glycol monobutyl ether. The methanol gasoline additive is prepared by composite stirring of each component with obvious synergistic effects; the additive realizes the effect that corrosion of automobile metal due to methanol gasoline in usage process is reduced, and at the same time compared with 93# gasoline and common M30 gasoline, the additive improves combustion efficiency of methanol gasoline and enhances power.

Owner:谭建国

Selectivity light-transmitting and heat-insulating coating and preparing method thereof

InactiveCN104693946AControl Infrared BandSuitable room temperatureReflecting/signal paintsAcrylic resinCis-Butenedioic Acid

The invention discloses a selectivity light-transmitting and heat-insulating coating and a preparing method thereof. The coating comprises, by mass, 10 parts to 20 parts of methyl methacrylate, 10 parts to 20 parts of vinyl benzene, 1 part to 4 parts of acrylic resin, 3 parts to 8 parts of cellulose acetate butyrate, 1 part to 6 parts of trimethylolpropane tris-acrylate, 3 parts to 8 parts of nitrous acid diisopropylamine, 2 parts to 6 parts of sodium benzoate, 8 parts to 15 parts of polyhydric alcohol, 2 parts to 5 parts of polyvinyl pyrrolidone, 2 parts to 5 parts of ethoxyquin, 3 parts to 8 parts of amino silicon oil, 2 parts to 6 parts of chlorinated paraffin, 1 part to 5 parts of dibutyltin dilaurate, 1 part to 3 parts of maleic anhydride, 2 parts to 5 parts of 1h-benzotriazole, 2 parts to 5 parts of curing agents, 3 parts to 6 parts of light stabilizers, 4 parts to 8 parts of surface active agents and 1 part to 5 parts of dispersing agents. The good effect can be achieved on preventing solar radiation, so that the proper room temperature is kept indoors.

Owner:SUZHOU VIVOTIDE BIOTECH

High-water-resistance high-lubricating rolling oil composition and application thereof

ActiveCN106318570AGood water separation effectReduce generationLubricant compositionEthylhexyl palmitateButylated hydroxytoluene

The invention relates to a high-water-resistance high-lubricating rolling oil composition and application thereof. The composition is prepared from, by weight, 70-92 parts of component a which is highly refined mineral oil, 5-20 parts of component b selected from at least one of pentaerythritol oleate, trimethylolpropane trioleate, ethylhexyl palmitate, isooctyl stearate, dibutyl phthalate and branched chain type polyhydroxy alcohol fatty acid ester, 1-5 parts of component c selected from at least one of inactive sulfurized olefin, inactive sulfide aliphatic acid ester, sulfurized animal oil and alkyl sulfide, 1-10 parts of component d selected from at least one of tributyl phosphate, tricresyl phosphate and dibutyl phosphate, 0.1-5 parts of component e selected from at least one of 2,6-butylated hydroxytoluene, N-phenyl naphthylamine, 1H-benzotriazole and alkyl diphenylamine, and 0.01-1 part of component f selected from at least one of polyether, methyl silicone oil and polydimethylsiloxane.

Owner:CHINA PETROLEUM & CHEM CORP

Environment-friendly plastic toughened through fibers and preparation method thereof

The invention discloses environment-friendly plastic toughened through fibers. The environment-friendly plastic is prepared from, by weight, 0.1-0.2 part of polyglyceryl-10 oleate, 10-14 parts of epoxidized soybean oil, 3-4 parts of ammonium dihydrogen phosphate, 2-3 parts of hydroxyethyl cellulose, 4-6 parts of sisal fibers, 160-200 parts of high-density polypropylene, 0.7-1 part of calcium acetylacetonate, 3-5 parts of maleic anhydride, 0.1-0.2 part of 1H-benzotriazole, 2-3 parts of environment-friendly auxiliaries, 0.1-0.2 part of diisopropylethanolamine, 4-5 parts of heavy calcium carbonate, 10-12 parts of attapulgite, 0.1-0.2 part of divinyl benzene and 0.4-1 part of sodium carbonate. According to the environment-friendly plastic toughened through the fibers, the auxiliaries are added, the dispersity of all the materials in the plastic is effectively improved, agglomeration is effectively prevented, and the stability of finished plastic is improved; hydroxyethyl cellulose, the sisal fibers and the like are further added, the strength and flexibility of the finished plastic are effectively improved; the plastic material is free of volatilization of poisonous and harmful ingredients and good in environmental protection property.

Owner:宁波辉门科技有限公司

Rolling oil composition soluble in degreasing agent and application of composition

The invention relates to a rolling oil composition soluble in a degreasing agent and application of the composition mainly in order to solve the problems that existing rolling oil and the degreasing agent are poor in separation performance and the service life of the degreasing agent is affected. The composition is prepared from, by weight, 75-95 parts of component a which is highly refined mineral oil, 2-15 parts of component b selected from at least one of pentaerythritol oleate, isooctyl palmitate, isooctyl stearate, dibutyl phthalate or methyl palmitate, 1-8 parts of component c selected from at least one of inactive sulfurized olefin, tributyl phosphate, tricresyl phosphate, dibutyl phosphate and amine neutralized phosphate ester, 0.01-3 parts of component d selected from at least one of alkenyl succinic acid, butanedioic acid and alkyl succinic acid half-ester, 0.01-1.0 part of component e selected from at least one of propylene epoxide diamine polycondensate, ethylene oxide / propylene epoxide block polyether and polyether silicone oil comb-type copolymer and 0.1-5 parts of component f selected from at least one of N-phenylnaphthylamine, 1H-benzotriazole and alkyl diphenylamine.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com