Insulating oil and preparation method thereof

An insulating oil and base oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problem of insufficient power insulating oil indicators, and achieve the effect of meeting market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Add base oil 1000 to the reaction kettle, then add sodium hydroxide 150 and EDTA250, stir well to completely dissolve sodium hydroxide and EDTA, then add naphthenic acid 150, phosphate ester 50, sodium nitrite 20, triethanolamine 150, benzene Paratriazole 1 was stirred and heated to 70°C for homogenization, and finally cooled to normal temperature to obtain insulating oil.

Embodiment 2

[0013] Add base oil 1500 to the reaction kettle, then add sodium hydroxide 200 and EDTA250~300, stir well to completely dissolve sodium hydroxide and EDTA, then add naphthenic acid 200, phosphate ester 100, sodium nitrite 50, triethanolamine 200 , Benzotriazole 5 Stir and heat up to 70°C for homogenization, and finally cool to normal temperature to obtain insulating oil.

Embodiment 3

[0015] Add base oil 1200 to the reaction kettle, then add sodium hydroxide 180 and EDTA280, stir well to completely dissolve sodium hydroxide and EDTA, then add naphthenic acid 180, phosphate ester 80, sodium nitrite 30, triethanolamine 180, benzene Paratriazole 3 was stirred and heated up to 70°C for homogenization, and finally cooled to normal temperature to obtain insulating oil.

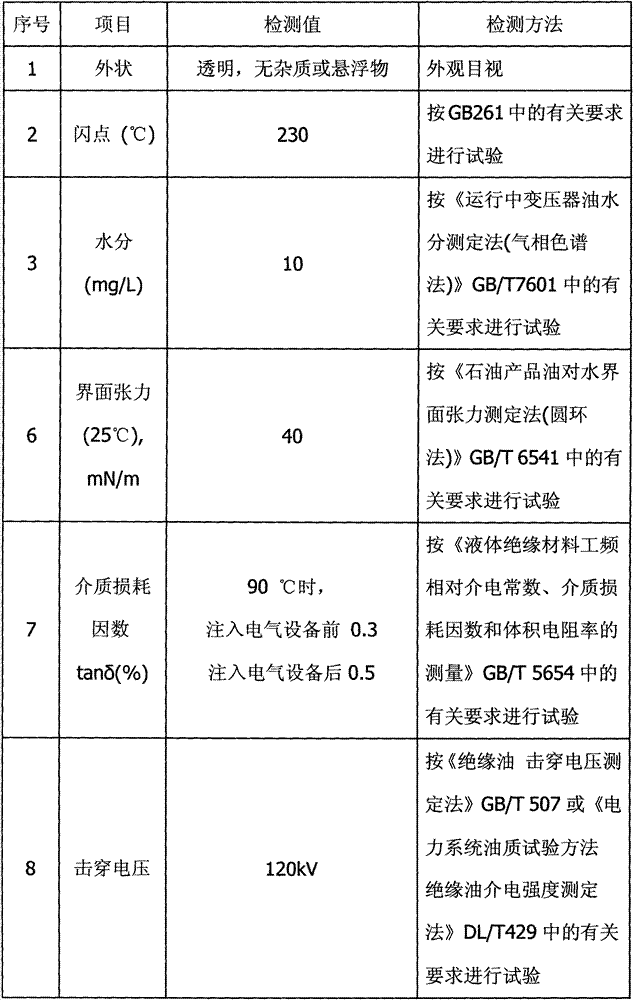

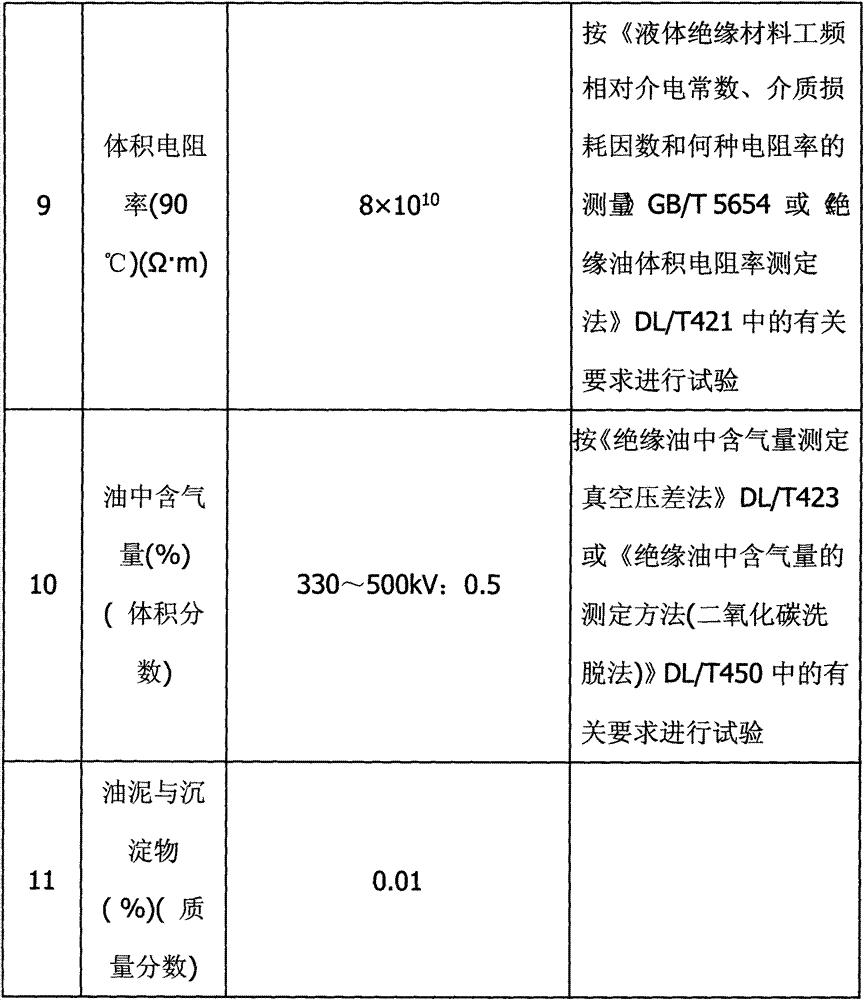

[0016] The indicators of the insulating oil of the tested embodiment 3 are shown in the table below:

[0017]

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com