Anti-freezing fluid for solar water heater and preparation method thereof

A solar water heater and antifreeze technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of decreased corrosion inhibition performance, easy to block pipes, etc., to prevent metal pitting, low price, and good corrosion inhibition effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the above-mentioned antifreeze solution for solar water heaters: first add deionized water to liquid ethylene glycol to prepare an ethylene glycol solution, then add benzotriazole and mercaptobenzothiazole to the ethylene glycol solution in sequence , sodium benzoate, sodium gluconate, cinnamic acid, borax, sodium phosphate, sodium nitrate, sodium hydroxide, defoamer and dye eleven kinds of materials, to obtain a transparent and clear antifreeze.

[0025] In the above preparation method, when adding materials to the ethylene glycol solution, after each material is added, the mixed solution is stirred evenly, and the next material is added after the mixed solution is clarified. This helps to increase the dissolution rate of the material.

[0026] The antifreeze of the above components is used in solar water heaters. The operating temperature range of solar water heaters varies greatly. The maximum operating temperature inside the device can rea...

Embodiment 1

[0032] Example 1: A kind of antifreeze suitable for areas with the lowest temperature of -10°C

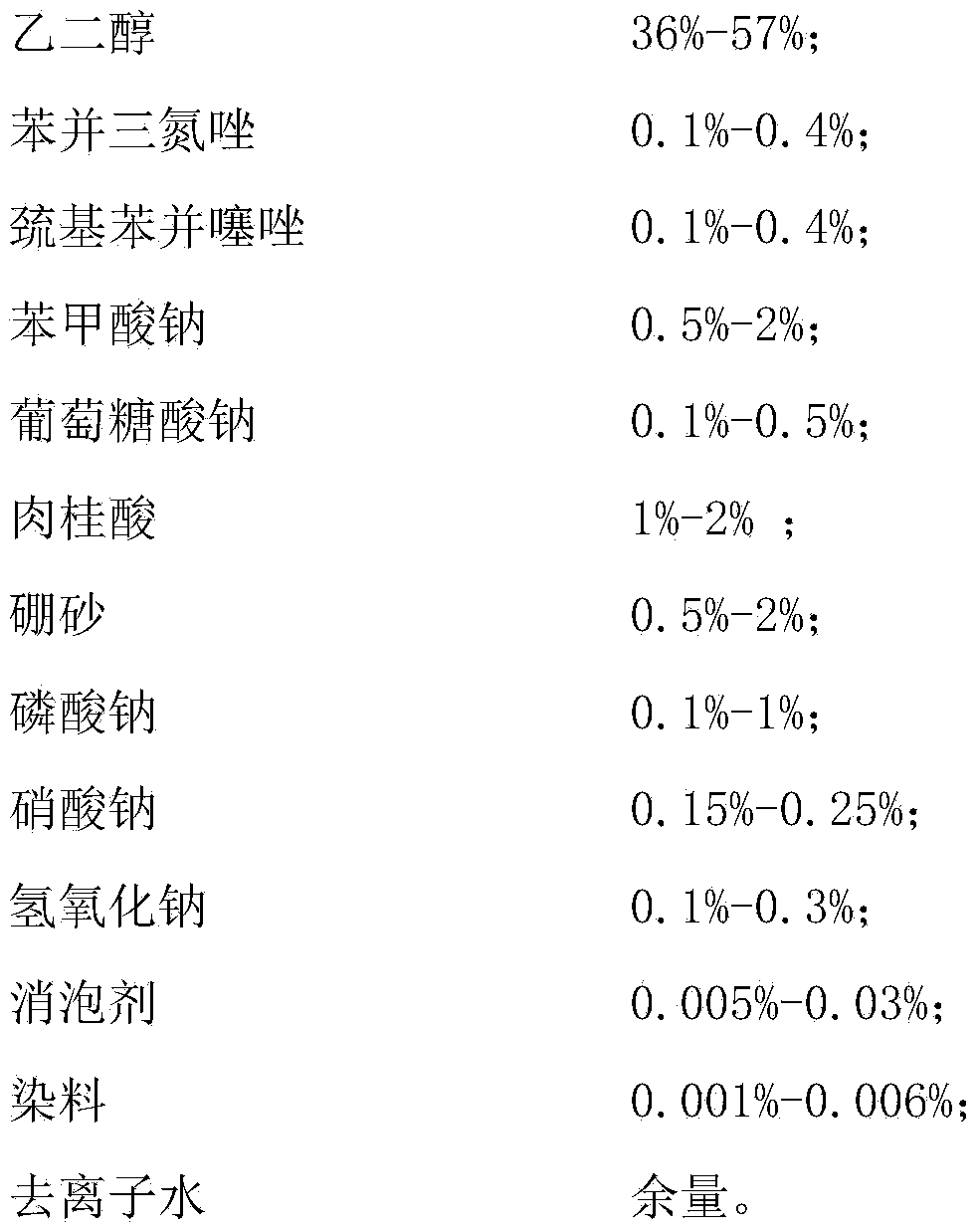

[0033] A kind of antifreeze used for solar water heaters, 100kg in total, is composed of the following components by mass percentage:

[0034]

[0035] The preparation method of the antifreeze of embodiment 1 is made into ethylene glycol solution with liquid ethylene glycol and deionized water, then in ethylene glycol solution, add benzotriazole, mercaptobenzothiazole, sodium benzoate, glucose successively Sodium nitrate, cinnamic acid, borax, sodium phosphate, sodium nitrate, sodium hydroxide, defoamer and dyes, each time after adding one raw material, stir, after the solution is clarified, add the next raw material to prepare antifreeze . The mass percent of each component in the antifreeze solution is shown above.

[0036] The main performance index of embodiment 1 is as shown in table 1.

[0037] Table 1

[0038] serial number

Test items

test value

...

Embodiment 2

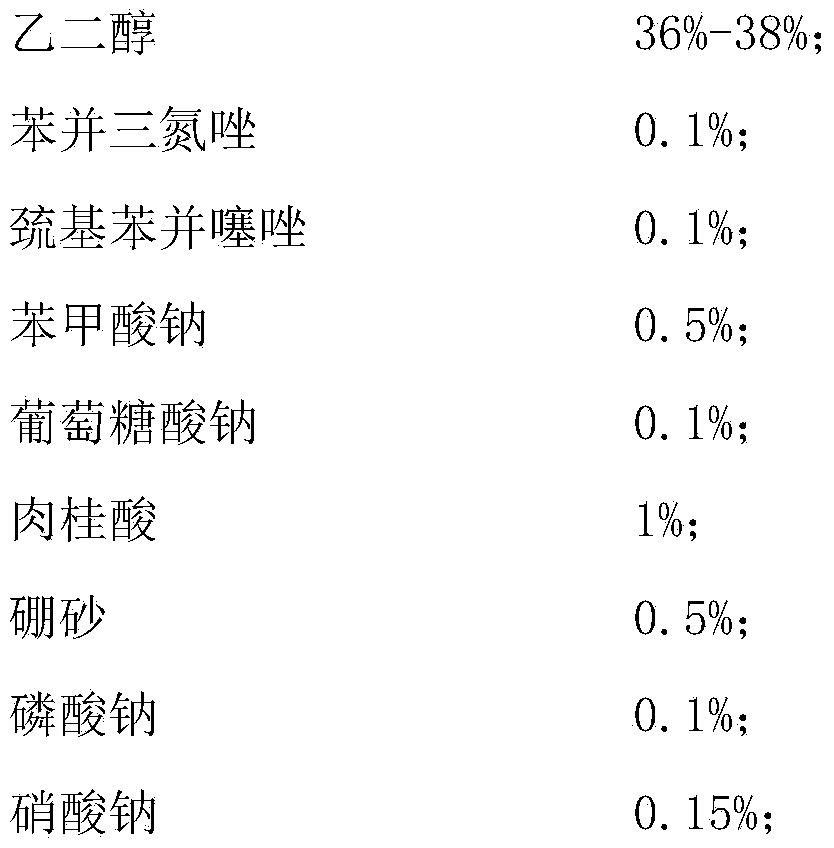

[0047] Example 2: An antifreeze solution suitable for regions with the lowest temperature of -20°C

[0048] A kind of antifreeze used for solar water heaters, 100kg in total, is composed of the following components by mass percentage:

[0049]

[0050] The preparation method of the antifreeze of embodiment 2 is made into ethylene glycol solution with liquid ethylene glycol and deionized water, then in ethylene glycol solution, add benzotriazole, mercaptobenzothiazole, sodium benzoate, glucose successively Sodium nitrate, cinnamic acid, borax, sodium phosphate, sodium nitrate, sodium hydroxide, defoamer and dyes, each time after adding one raw material, stir, after the solution is clarified, add the next raw material to prepare antifreeze . The mass percent of each component in the antifreeze solution is shown above.

[0051] The main indicators of this embodiment are shown in Table 3.

[0052] table 3

[0053] serial number

Test items

test value

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com