Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71results about How to "Oxidation does not occur" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

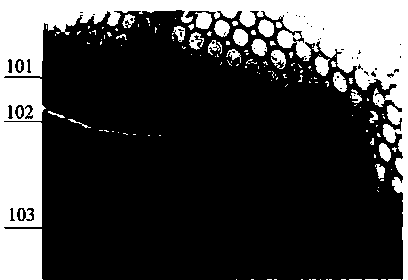

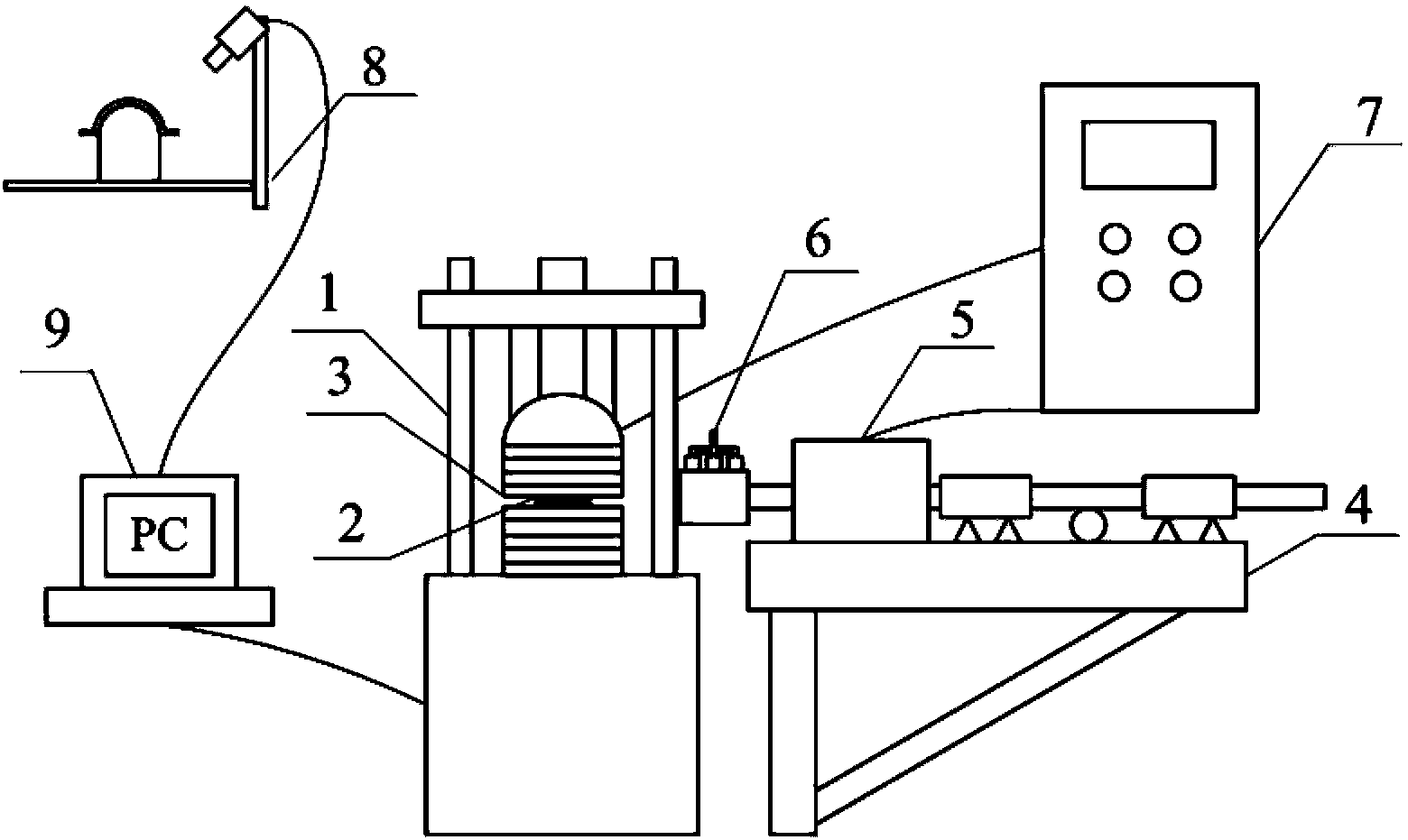

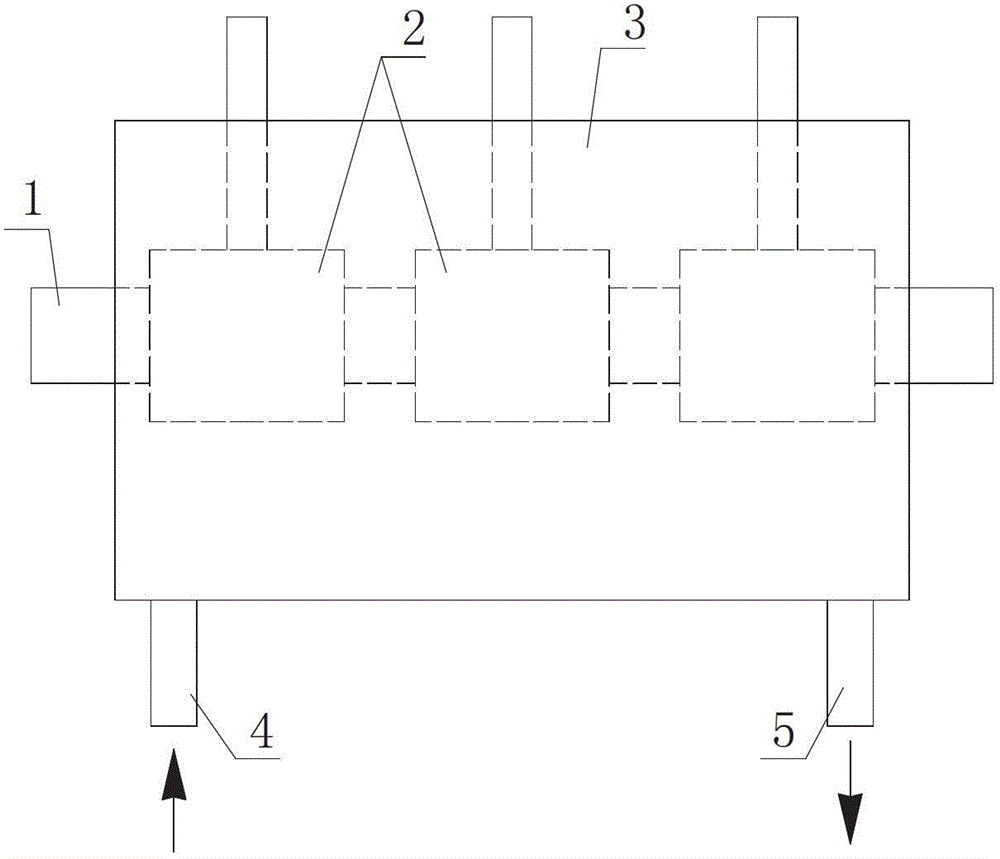

Method for acquiring metal temperature forming limit diagram (TFLD) and testing device therefor

InactiveCN103398909AThe test results are accurate and validEven heating speedInvestigating material ductilityForming limit diagramAlloy

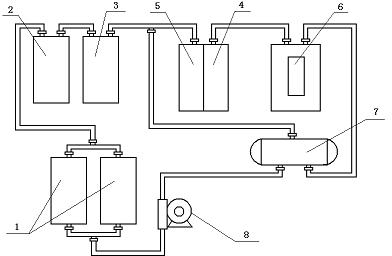

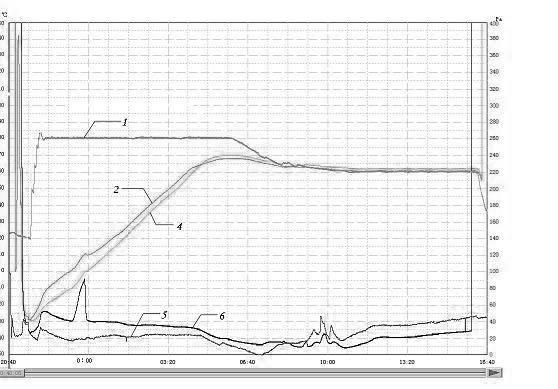

The invention discloses a method for acquiring a metal temperature forming limit diagram (TFLD). The method is characterized by comprising acquiring a TFLD of a high-strength steel plate thermal-forming process, and acquiring a TFLD of a lightweight alloy warm-forming process. The invention also discloses a test device of a TFLD. The test device is characterized by comprising a hydraulic tester, a mold, a mold heating furnace, an automatic feeding mechanism, a plate heating furnace, a plate fast-cooling device, a heating control system and a strain measurement analysis device. The method and the test device guarantee mold heating uniformity, do not change a plate forming temperature, satisfy temperature forming requirements, acquire the TFLD comprising the all-range isothermal or non-isothermal forming limit diagram in a test temperature range, have the advantages of simple operation, high automation degree and high work efficiency, and satisfy practical temperature forming process requirements.

Owner:DALIAN UNIV OF TECH

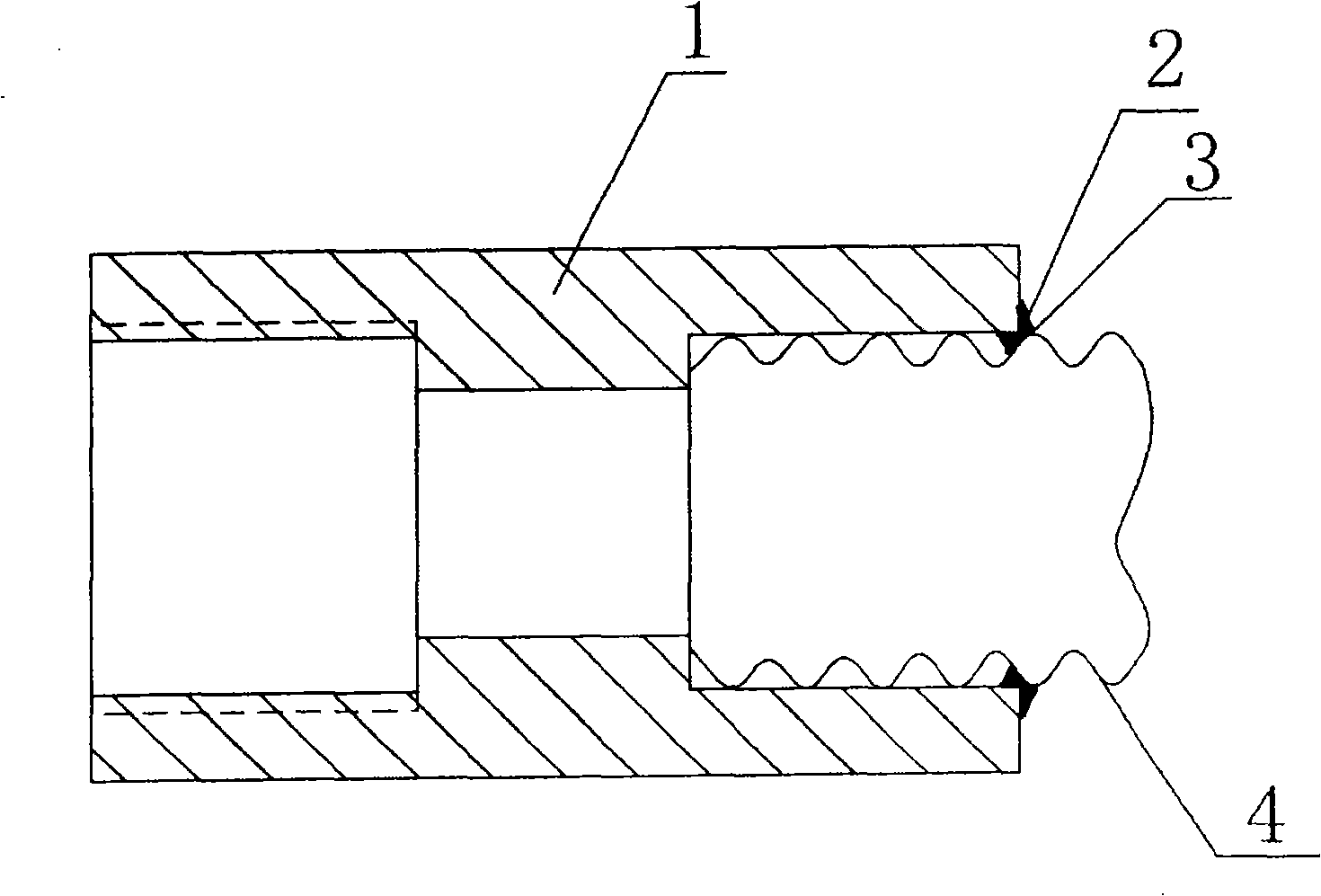

Method for welding thin wall stainless steel tube and copper pipe piece

InactiveCN101279394AMeet the use requirementsThe welding is firm and tightSoldering apparatusWelding/soldering/cutting articlesSolder pasteThermal water

The invention discloses a welding method of a thin-walled stainless steel tube and a copper tube part, which can lead the thin-walled stainless steel tube and the copper tube part to form a permanent fastening and sealing connecting structure at the connecting part. The welding method has simple process, the steps of the process thereof are that: (1) the connecting part of the thin-walled stainless steel tube and the copper tube part is cleaned, silver welding paste is coated at the connecting part of the thin-walled stainless steel tube and the copper tube part which is clean; (2) the connecting part of the thin-walled stainless steel tube is inserted in the connecting part of the copper tube part, the outer wall of the copper tube part is heated; (3) when the connecting part of the copper tube part and the thin-walled stainless steel tube is indirectly heated to the temperature range of 750 DEG C to 860 DEG C, a silver welding strip is arranged along the exposed position of the connecting part of the thin-walled stainless steel tube and the copper tube part, the silver welding strip is melted by utilizing the heat stored in the copper tube part, and the welding connection of the thin-walled stainless steel tube and the copper tube part can be completed after the cooling. The welding method can be widely applied in cold and hot water supply pipelines of various tap water supply pipelines and water heaters.

Owner:陈雪辉 +1

Bamboo leaf flavonoid mint core-sheath compound fiber

ActiveCN104357952AHigh concentration of air ionsUnique polygonal structureConjugated cellulose/protein artificial filamentsFilament/thread formingPolyesterCalcium hydroxide

The invention relates to a fiber, and in particular relates to a bamboo leaf flavonoid mint core-sheath compound fiber. The bamboo leaf flavonoid mint core-sheath compound fiber is prepared by the following steps: treating tourmaline; treating a core layer material to form a non-woven needle-punched hemp palm fiber aerogel core layer material; treating a sheath layer material, namely, preparing first slurry from 0.1-0.3 part by weight of treated tourmaline, 0.6-0.8 part by weight ethylene glycol, 0.01-0.04 part by weight of bamboo leaf flavonoid and 0.02-0.05 part by weight of beta-cyclodextrin mint oil micro-powder, wherein the preparation method of the beta-cyclodextrin mint oil micro-powder comprises the step of mixing beta-cyclodextrin and mint oil according to the mass ratio of (8-15) to (40-65) at the temperature of 20-30 DEG C to form the beta-cyclodextrin mint oil micro-powder with morphology of a clathrate compound; carrying out an esterification reaction on phthalic acid and glycerol; after the reaction, feeding the first slurry, magnesium oxide and calcium hydroxide, and carrying out a polycondensation reaction; casting a belt and carrying out grain-sized dicing to obtain a polyester chip sheath layer material; carrying out composite melt spinning to prepare the bamboo leaf flavonoid mint core-sheath compound fiber. The bamboo leaf flavonoid mint core-sheath compound fiber has the functions of antibiosis and health protection, and is comfortable and environment-friendly.

Owner:HEYE HEALTH TECH CO LTD

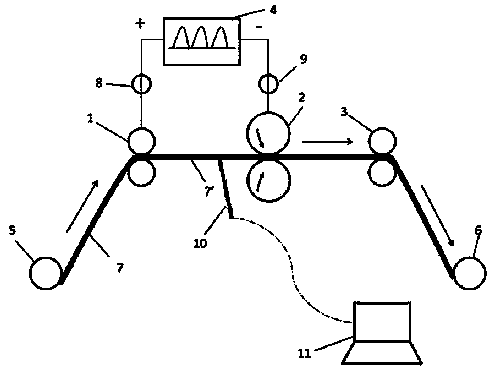

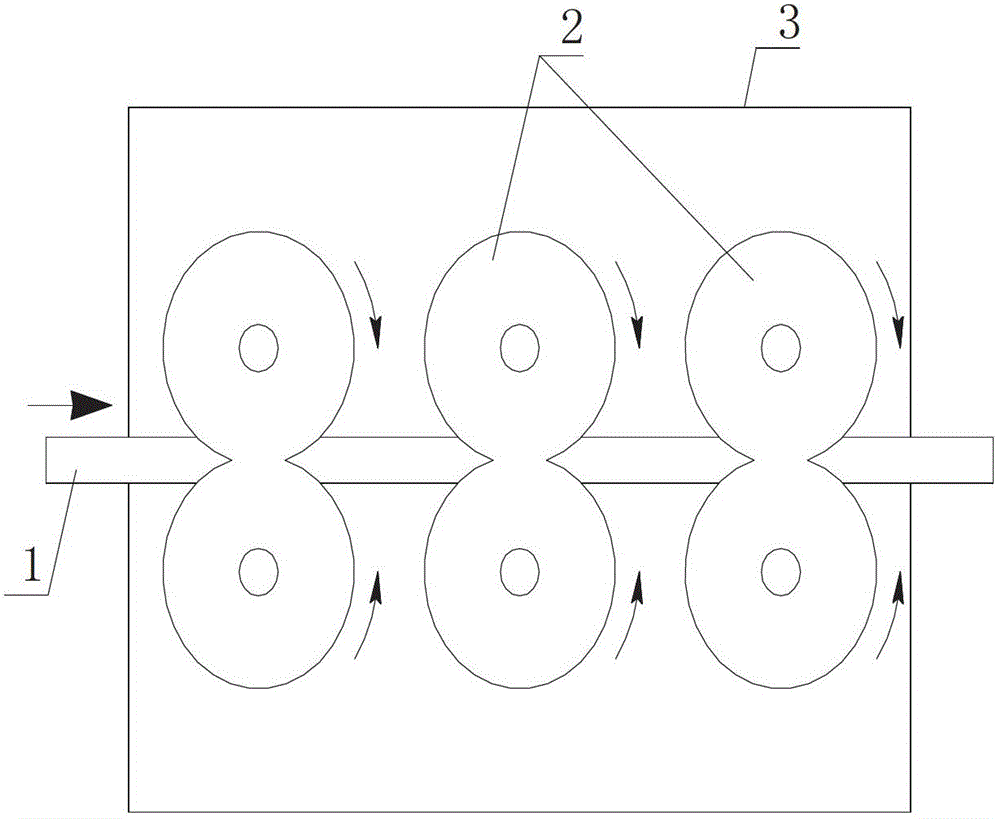

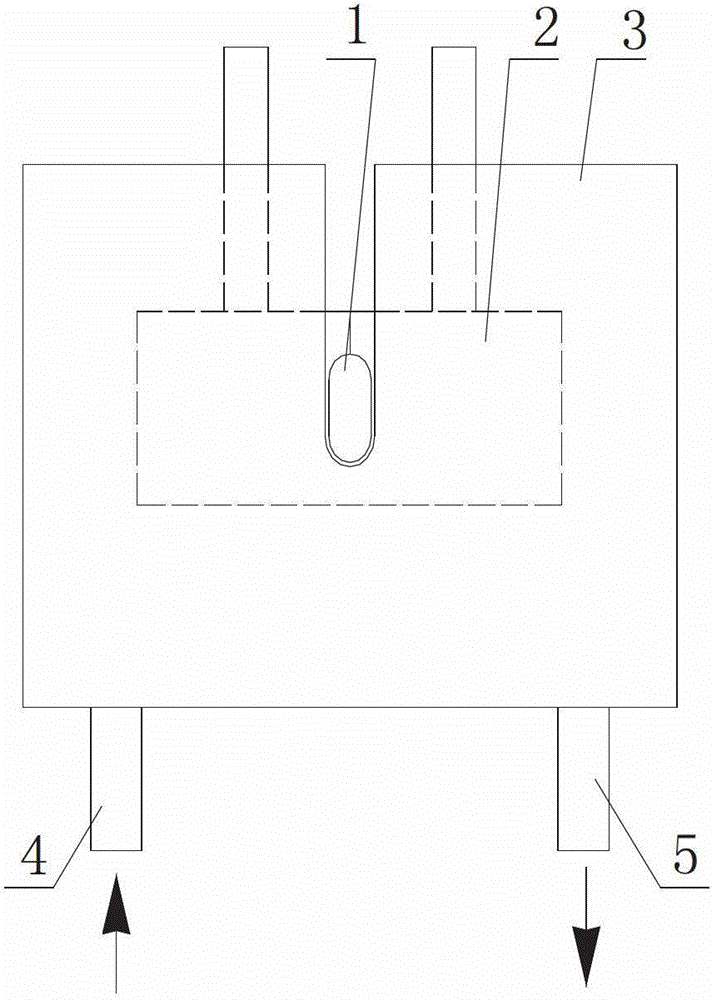

Method for promoting phase change strengthening and toughening of two-phase titanium alloy strip by using pulse current and strip

The invention discloses a method for promoting phase change strengthening and toughening of a two-phase titanium alloy strip by using pulse current. The method comprises the following steps: tensioning a TC4 titanium alloy strip through a decoiling device, a winding device, a roller and a support roller of a rolling mill, so that the strip is in tightly elastic contact with the roller; driving the strip to transmit at the speed of 150-800mm / min through friction force by virtue of the roller; inputting the pulse current into a power-up area section of the strip through the roller, the support roller and the like, wherein the pulse current generates a joule heating effect and a non-thermal effect in the power-up area section of the strip within 12-18 seconds, so that the internal microstructure of the strip turns into a two-phase long-axis structure or a two-phase dual-state structure from an original quasi-single phase thick equiaxed structure; and then cooling by natural air at room temperature. Through adjustment of parameters of the pulse current, the TC4 strip with the two-phase long-axis structure and the two-phase dual-state structure can be quickly obtained, thus the ductility is increased; the treatment temperature is far lower than 960 DEG C of a traditional thermal treatment process; the processing process of the titanium alloy strip can be finished without a short period of time at relatively low temperature without an oxidation phenomenon; and therefore, the method is energy-saving, environmentally friendly, safe and efficient.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Extraction technology of perilla frutescens essential oil

The invention relates to an extraction technology of a perilla frutescens essential oil. The technology comprises: cleaning, wall breaking, freezing drying, crushing and screening, as well as cycling extraction. The invention adopts ultrasonic wall breaking so as to make the subsequent extraction faster and reduces production cost. Employment of a freezing sublimation drying technology can reserve all the components in plants to the utmost, and the vacuum state avoids the influence of oxidation on drug effect. Meanwhile, essential oil yield is obviously improved. Carbon dioxide is an optimal extracting agent for pure natural substance extraction. As carbon dioxide has low viscosity and high diffusion coefficient, so that the extraction efficiency and the product yield can be high. Carbon dioxide is easily available and inexpensive, and is recyclable during extraction, thus reducing cost. As carbon dioxide is incombustible and non combustion-supporting, production sites have no danger. The invention makes use of the supercritical temperature of carbon dioxide for low temperature extraction so as to exempt biologically active substances from thermal degradation and other undesired auxiliary reactions.

Owner:JIANGSU NATURAL FOOD

Cactus juice and preparing method thereof

The present invention discloses a high-nutrient cactus juice and its extraction method capable of no breaking nutrient component of cactus, and it is characterized by that said cactus juice is extracted from Mexican mibangta edible cactus. Said extraction method includes the following steps: picking cactus leaf, cleaning, using presser to press juice, adding pectinase in juice, stirring, filtering, drying filtrate at 20-25 deg.C by airing, concentrating and packaging so as to obtain the invented product. Said cactus juice has rich nutrients, and has high medicinal and health-care value.

Owner:TAIFENG PLANTING & CULTIVATION SCI & TECH YANTAI CITY

Method for producing nodular cast iron in high aluminum through melting in three-stage furnace

This invention relates to a method for producing high aluminium-contd. spheroidal cast iron. The prodn. process is: (1). The process used for melting molten spheroidal iron is used for producing qualified molten spheroidal cast iron. (2). molten aluminium is proceeded degassing treatment by using tri-oxygen degassing agent, mixing said molten aluminium 25% and molten spheriodal iron 75%, keeping temp. of 1100 deg.C for 40 hrs, without oxidation being occurred. This invention three-section furnace for melting high-aluminium conte, theat-resisting spheroidal cast iron has advantages of: quick becoming effective, high economic benefit and the inventive product high-temp.-resisting spheroidal cast iron can be used for boiler, burner the like high temp. environment.

Owner:王长亭

Method for preparing spherical amorphous boron powder by spray drying method

InactiveCN101734680AThe method is simpleShort preparation cycleBoron compoundsMetallurgyDistilled water

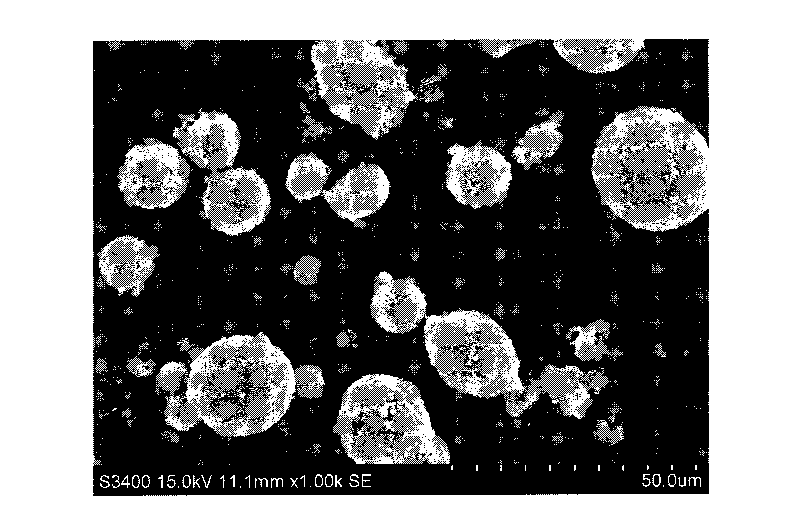

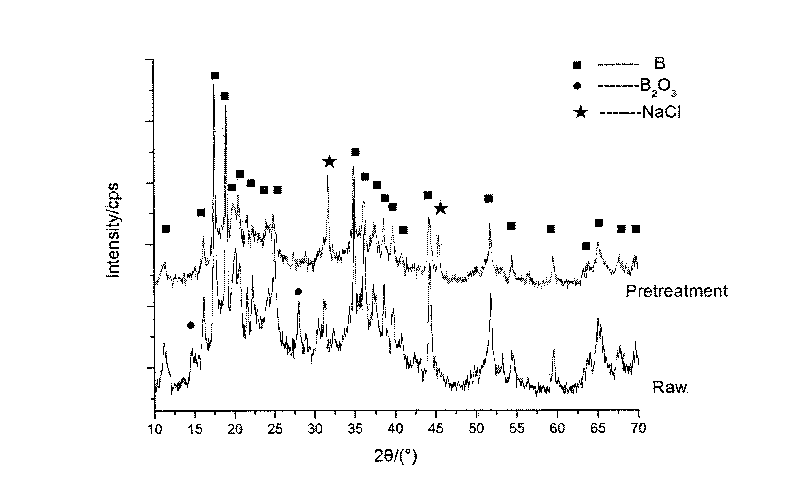

The invention relates to a method for preparing spherical amorphous boron powder by a spray drying method, which is characterized by comprising the following steps of: (1) pulping: evenly mixing boron powder and distilled water according to the mass ratio of 30:70 to 40:60, adding additive based on 2-6 percent of the boron powder, firstly, performing ultrasonic dispersion for 15-30 minutes and then stirring magnetically for 15-30 minutes to obtain the boron powder pulp, adding sodium hydroxide solution in the boron powder pulp and adjusting the pH value of the boron powder pulp to 9-12 to obtain the boron powder pulp after adjusting the pH value; (2) spray drying: performing spray drying on the boron powder pulp after adjusting the pH value in the step (1) with a spray dryer; and (3) vacuum drying: placing the spherical boron powder obtained in the step (2) in a vacuum drying box, and drying for 1-2 hours at 70-90 DEG C to obtain the spherical amorphous boron powder. The method is simple and easy to operate, and the spherical amorphous boron powder prepared by the method has excellent sphericity, high boron content and small grain size.

Owner:WUHAN UNIV OF TECH

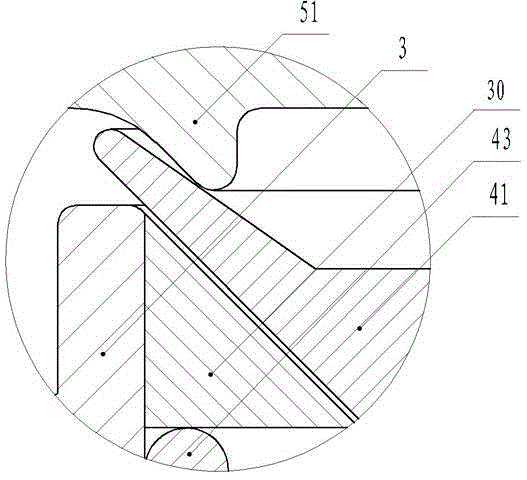

Composite melting pot for smelting magnesium and magnesium alloys

InactiveCN1670458AGuaranteed high temperature strengthAvoid secondary pollutionCrucible furnacesSpray coatingHigh-temperature corrosion

This invention provides a complex type crucible used in magnesium and magnesium alloy smelting. In order to conquer the problem of crucible easy corrosion and penetration, oxidizing desquamation, low quality and short life in high temperature, the crucible in this invention is compounded by ceramic material and double metal crucible made by heat-resisting steel or nickel base high-temperature alloy and carbon steel. The inner layer is the ceramic material that does not react with magnesium and magnesium alloy, central layer is carbon steel material, outer layer is heat-resisting steel or nickel base high-temperature alloy material. The connecting of double metal material is explosive bonding and the high temperature strength and creep resistant capability of crucible is increased, ceramic material form ceramic inner coating on carbon steel surface by spray coating or laser melting and coating technique. The outer layer make crucible not oxidation desquamation in high temperature, carbon steel avoids the high temperature oxidation, ceramic layer prevent crucible corroded by high temperature metal liquor and corrosion gas, the second pollution in smelting process is avoided. It can be used crude magnesium smelting purifying, and smelting preparing, melting and casting of magnesium alloy.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Solar cell, preparation method thereof, and solar cell module comprising solar cell

InactiveCN104752528AOxidation does not occurNo damageFinal product manufacturePhotovoltaic energy generationSilver pasteSilver electrode

The invention provides a solar cell, which comprises a silicon substrate sheet, a conductive layer covering the front surface of the silicon substrate sheet, a copper front electrode arranged on the surface of the conductive layer, a back surface field arranged on the back face of the silicon substrate sheet, and a back electrode conducted with the back surface field, wherein the conductive layer is an aluminum-doped zinc oxide layer, a tin-doped indium oxide layer, an antimony-doped tin oxide layer or a tin dioxide layer. The invention also provides a solar cell preparation method and a solar cell module comprising the solar cell. The copper back electrode and the copper front electrode obtained by using the technology of the invention have good appearances, strength of welding between the electrodes and a photovoltaic welding strip and electric performance of the cell remain almost the same as those of a battery with silver electrodes prepared by the traditional technology, and in addition, as copper paste is adopted to replace the traditional silver paste, the cost of the cell is greatly reduced.

Owner:BYD CO LTD

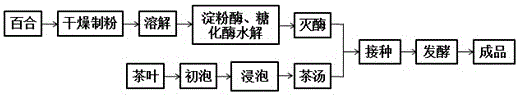

Lily tea wine and preparation method thereof

ActiveCN106398961ARetain nutrientsPromote absorptionDigestive systemAlcoholic beverage preparationMetaboliteAdditive ingredient

The invention discloses a lily tea wine and a preparation method thereof. The lily tea wine is prepared from 14 to 16 parts by weight of lily powder and 9 to 11 parts by weight of tea leaves; the lily tea wine is prepared through tea soup preparation, lily juice preparation, yeast activation, fermentation liquid preparation, inoculation and fermentation. The lily tea wine is prepared through fermentation, while the existing lily tea wine is mixed wine. Compared with the mixed wine and solid fermentation wine, the lily tea wine in the experiment uses lily starch as a raw material, and is prepared by a liquid state fermentation method after the hydrolysis on the starch, so that the nutrition is rich; the characteristics and the nutrition ingredients of the natural substances are remained; through microorganism metabolites, the absorption by a human body is easier; the lily tea wine has incomparable advantage over other wines; meanwhile, the color and luster are pleasing to the eyes; the sugar-acid ratio is proper; the alcohol content is low (10 percent, v / v); the health care function is realized.

Owner:TONGREN UNIV

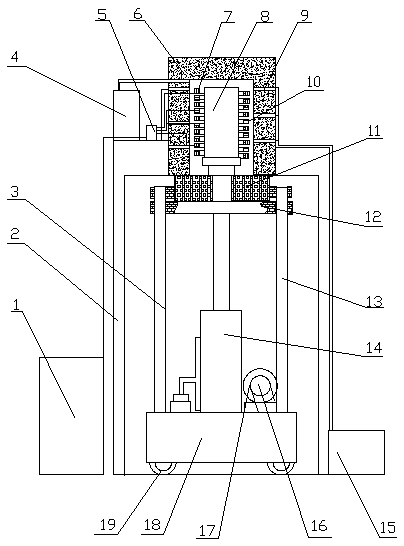

Vacuum insulation induction heating furnace for forging

The invention discloses a vacuum insulation induction heating furnace for forging. The vacuum insulation induction heating furnace for forging is characterized by comprising a heating part and a workpiece access part; the heating part includes an induction heating device and a vacuum pumping system; the induction heating device includes a bracket, a vacuum insulation cover, an induction oil and temperature measurers; the vacuum insulation cover is positioned at the upper end of the bracket; the lower end of the vacuum insulation cover is opened; an induction coil is positioned in the vacuum insulation cover; the temperature measurers are uniformly distributed on the vacuum insulation cover; the vacuum pumping system is communicated with the vacuum insulation cover; and the workpiece access part includes a lifting mechanism, an access driving mechanism and an operation car. The vacuum insulation induction heating furnace for forging adopts an induction heating mode to a workpiece under vacuum condition, is higher in heating speed, heat utilization rate and temperature uniformity, can save the resource, and facilitates to save the cost.

Owner:HUNAN LIFANG ROLLER +1

Seamless welding process of copper tube

InactiveCN109773296AOxidation does not occurEnsure brazing qualitySoldering apparatusCombustible gasWelding process

The invention discloses a seamless welding process of a copper tube, which aims at solving the problem of low brazing yield of the copper tube; the key points of the technical scheme are (1) pre-welding treatment; (2) inspection; (3) cutting; (4) installation of socket-and-spigot joint; (5) brazing clearance; (6) axial deviation of the copper tube; (7) selection of a welding torch and a welding nozzle; (8) selection of combustible gas; (9) flame regulation; (10) preheating and heating; (11) brazing connection; (12) heating and maintaining; (13) cooling operation; (14) post-welding treatment. The seamless welding process of the copper tube provided by the invention can improve the finished product rate of seamless welding, so that the copper tube has long service life and high stability after brazing.

Owner:TIANJIN ERJIAN WATER & ELECTRICAL INSTALLATION ENG

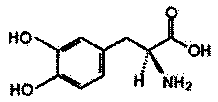

Levodopa refining method

ActiveCN109485581AReduce contentHigh purityOrganic compound preparationAmino-carboxyl compound preparationTyrosineDissolution

The invention discloses a levodopa refining method. The levodopa refining method comprises the following steps of (1) leaching liquor preparation, (2) dissolution, (3) impurity removal, (4) phenol removal and (5) recrystallization to obtain refined levodopa. According to the levodopa refining method, a prepared leaching liquor can fully dissolve levodopa and impurities; separating the levodopa through crystallization can help remove most of the impurities to ensure the quality of levodopa finished products and meanwhile to provide a good environment for subsequent tyrosine removal, thereby ensuring that tyrosine can be thoroughly removed. The prepared refined levodopa achieves a purity degree not lower than 99%, and when detected through a USP (United States Pharmacopeia) 38 method, has acontent of tyrosine not higher than 0.1%.

Owner:GUANGXI INST OF CHINESE MEDICINE & PHARMA SCI

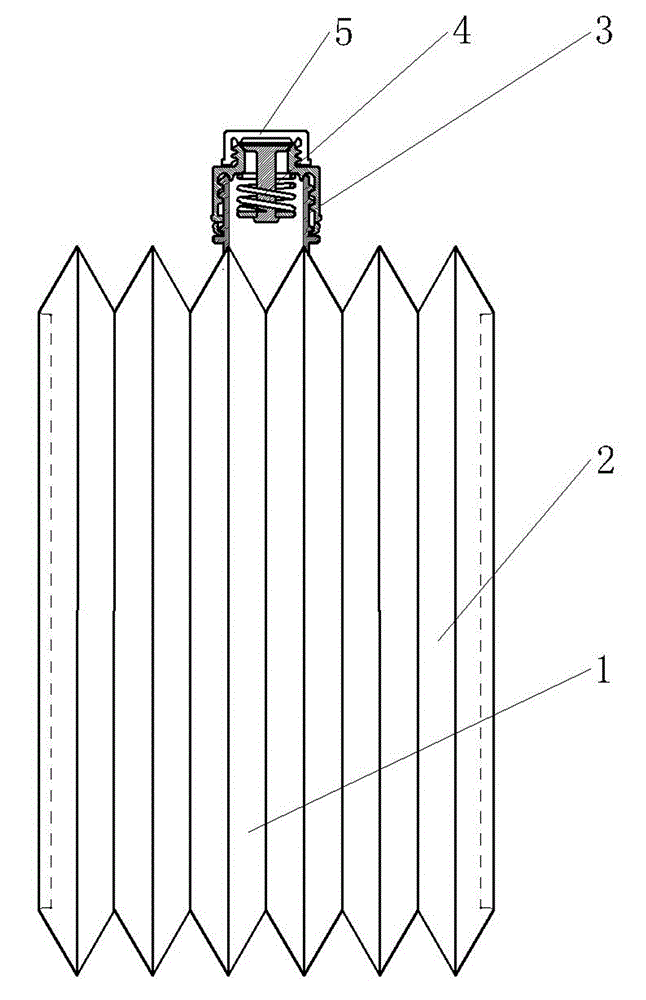

Anti-oxidation packaging bottle for edible oil

The invention discloses an anti-oxidation packaging bottle for edible oil. The anti-oxidation packaging bottle comprises a bottle body, a bottle mouth and a bottle cap, wherein the bottle mouth is integrally connected to the bottle body, and the bottle cap is in threaded connection to the bottle mouth. The bottle body is in a corrugated pipe shape and is formed by connecting a plurality of foldable units with sharp edges; and a one-way valve is arranged in the bottle mouth. According to the packaging bottle, only the oil in the bottle can flow out through the one-way valve, and air cannot enter the bottle through the bottle mouth; it is ensured that the edible oil in the bottle is isolated from the air, and oxidation of the edible oil is prevented; and the guarantee period is prolonged, and eating is safer.

Owner:神池县东远包装开发科技有限责任公司

Pore blocking method for surface modified layer of fuel cell polar plate

ActiveCN103614693AIncrease productivityNo need to consumeCell electrodesVacuum evaporation coatingFuel cellsInlet valve

The invention provides a pore blocking method for a surface modified layer of a fuel cell polar plate. According to the pore blocking method, a film is plated by using a physical vapor deposition method. The pore blocking method for the surface modified layer is characterized in that after a bipolar plate is plated with the film in a vacuum chamber of film plating equipment, the inner pressure of the vacuum chamber of the film plating equipment reaches 0.1*10<-3>Pa-10.0*10<-3>Pa and the temperature is 100-180 DEG C; an air inlet valve is switched on and air enters; the range of the pressure in the vacuum chamber of the film plating equipment is 1.1*10<-2>Pa-1.1*10<5>Pa; when air is naturally cooled to 20-50 DEG C along the equipment, the vacuum chamber is opened to finish oxidation pore blocking treatment. The pore blocking method has the beneficial effects that temperature and vacuum degree conditions of the equipment after the physical vapor deposition method is used for plating the film are utilized effectively; the modified layer is subjected to pore blocking in a natural cooling process of the equipment and the production efficiency is improved obviously; new equipment and materials do not need to be added, no energy source is consumed and the processing cost is low; the pore blocking method is only used for oxidizing a micro-pore; the corrosion resistance of the bipolar plate is improved under the precondition of guaranteeing that the electrical conductivity is not changed so that the service life is prolonged.

Owner:SUNRISE POWER CO LTD

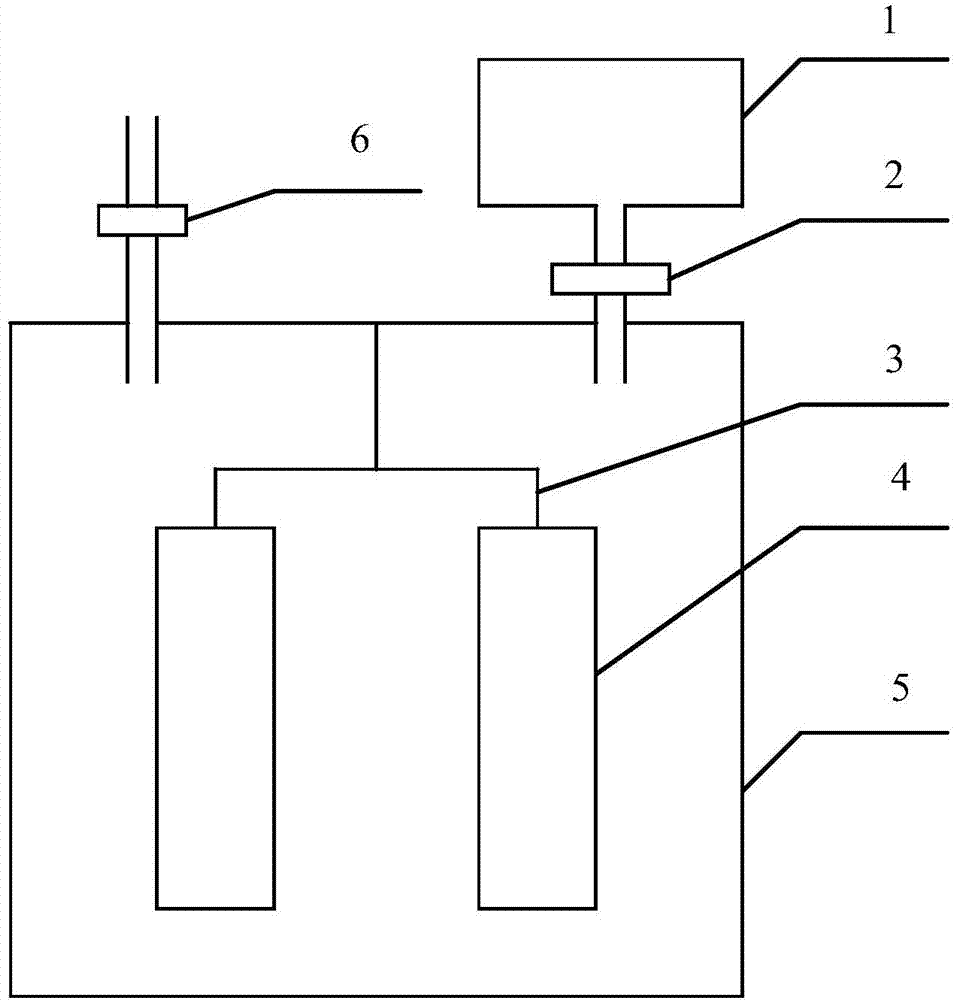

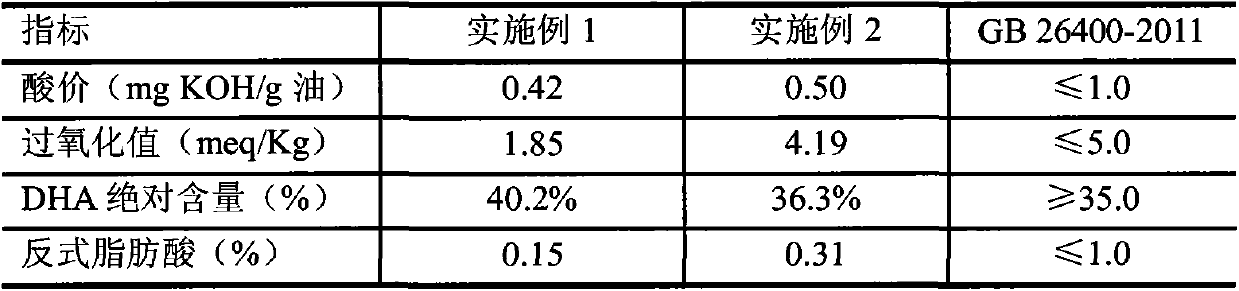

DHA (docosahexaenoic acid) oil low-temperature refining method

The invention relates to a DHA (docosahexaenoic acid) oil low-temperature refining method which comprises the following steps: slowly adding DHA oil into an alkali solution at low temperature, continuously stirring, standing, removing the lower-layer nigre, washing the oil layer with hot water, and collecting the oil layer; adding activated carbon and argil, decolorizing at low temperature, and filtering; and deodorizing at low temperature for a short time. The refined oil has the advantages of no condensation at low temperature, better flavor and small nutrient loss.

Owner:青岛海智源生命科技有限公司

Surface treatment process for enhancing electrolytic copper foil anti-oxidization performance

ActiveCN106544709AImprove high temperature oxidation resistanceOxidation does not occurElectrolysisIndium

The invention relates to a surface treatment process for enhancing electrolytic copper foil anti-oxidization performance. The surface treatment process comprises the steps of at first dissolving kalio-natrimn tartaricum as complexing agent, zinc sulfate, an additive A and an additive B into water, mixing and regulating the pH value, keeping the solution clarified to obtain an electroplate liquid, and placing an electrolytic copper foil in the electroplate liquid for electroplating. The additive A comprises one or more of ammonium molybdate, zirconium sulfate, aluminum sulfate, silver sulfate, indium sulfate, sodium vanadate and sodium tungstate. The additive B comprises one or more of sodium sulfite, sodium hyposulfite, potassium phosphite, sodium hypophosphite and monopotassium phosphate. The electrolytic copper foil prepared by the surface treatment process for enhancing electrolytic copper foil anti-oxidization performance, can achieve an enhancement of the high temperature anti-oxidization performance that under 260 DEG C, no oxidization occurs for 1 hour.

Owner:SHANDONG JINBAO ELECTRONICS

Online surface cleaning and protection liquid coating process of aluminum alloy high frequency welding pipes and for heat exchanger

InactiveCN102873065AReduce processing costsReduce processLiquid surface applicatorsHollow article cleaningPlate heat exchangerSurface cleaning

The invention discloses an online surface cleaning and protection liquid coating process of aluminum alloy high frequency welding pipes and for a heat exchanger and belongs to the field of aluminum alloy high frequency welding pipe processing. The new process is high in production efficiency, clean in welding pipe surface and stable in storage. The technical main point includes extruding and welding aluminum alloy belt materials into aluminum alloy round pipes, cooling the aluminum alloy round pipes, removing scars on the aluminum alloy round pipes, delivering the aluminum alloy round pipes into a flat pipe molding machine to form aluminum alloy flat pipes in molding mode, enabling the aluminum alloy flat pipes to pass through a box body provided with a rotating hair brush and protection liquid, utilizing the rotating hair brush to clean the outer surface of the aluminum alloy flat pipes, coating protection liquid on the pipes and conducting follow-up work procedures to obtain finished products. The online surface cleaning and protection liquid coating process is used for processing of the aluminum alloy high frequency welding pipes.

Owner:广州大华仁盛铝合金管业有限公司

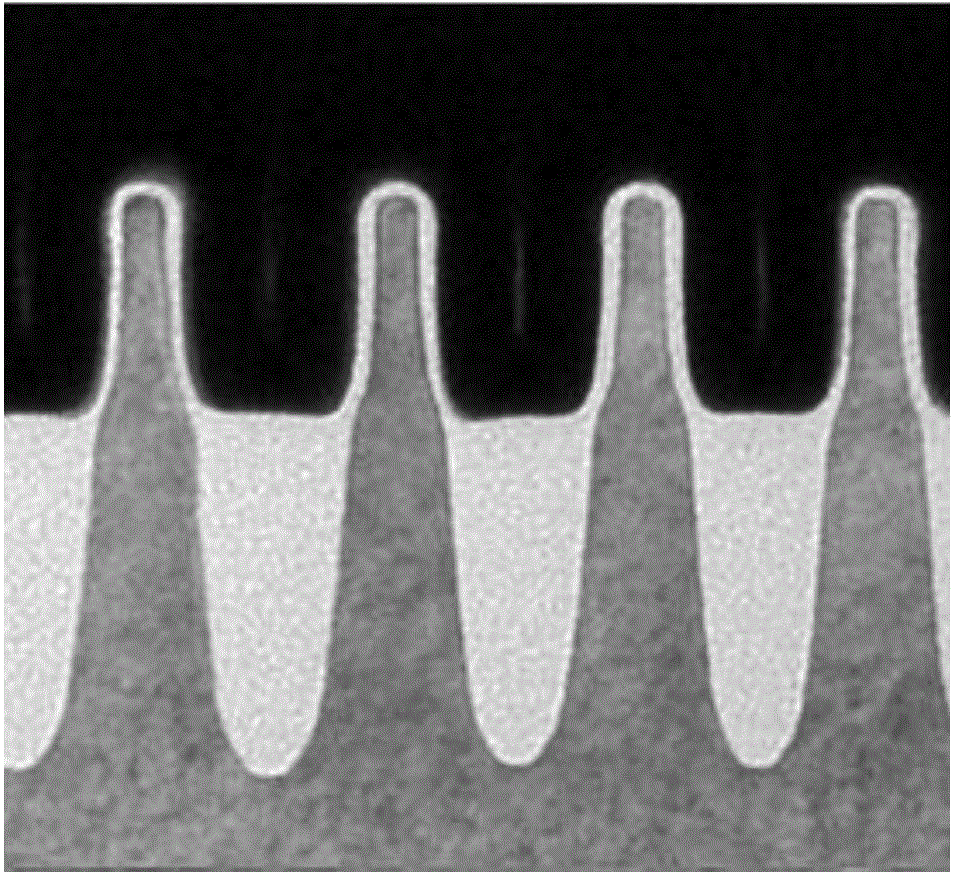

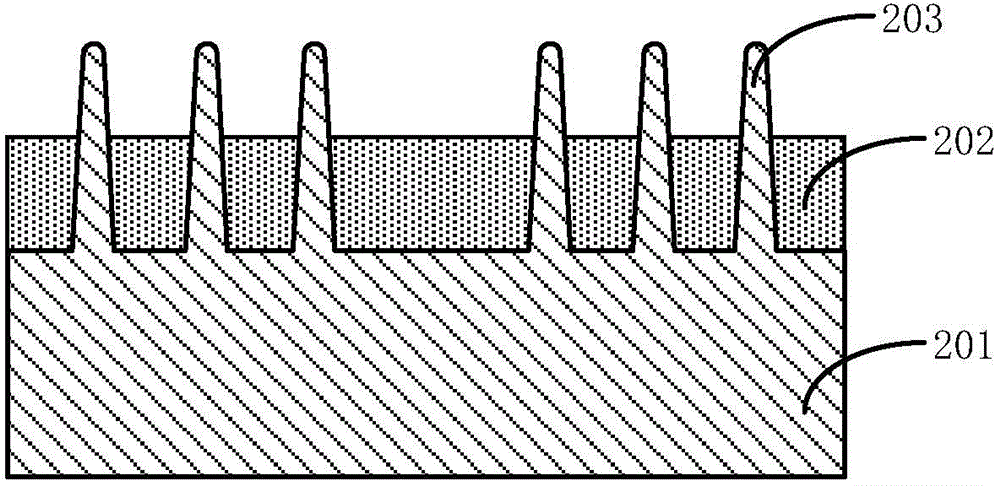

Semiconductor device and manufacturing method thereof, and electronic device

InactiveCN105826365AAvoid consumptionAvoid lostSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceDevice material

The invention relates to a semiconductor device and a manufacturing method thereof, and an electronic device. The method comprises steps: S1, a semiconductor substrate is provided, and a plurality of mutually-spaced fins are formed on the semiconductor substrate; S2, a sacrificial layer is formed on the surface of each fin to cover the fin; S3, a method generated by in-situ steam is selected to form an oxide layer on the surface of the sacrificial layer, an in-situ steam generation oxidation process is executed at the same time, the sacrificial layer is converted into an oxide, and a gate oxide is formed on the surface of the fin. The method of the invention has the advantages that an atomic layer deposition or molecular layer deposition method is selected to form the sacrificial layer, and consumption and loss of the fins are reduced; good conformal property is provided by selecting the atomic layer deposition or molecular layer deposition method; and ISSG oxidation happens on the thin sacrificial layer SiN, the SiN is finally converted into SiO2, and oxidation of the fins does not happen.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Ultrasonic vibration screen with inertia gas protection system

InactiveCN104741311AQuality assuranceEasy and quick passSievingScreeningUltrasonic vibrationEngineering

An ultrasonic vibration screen with an inertia gas protection system comprises a raw material tank which is communicated with a screen body. A gas tube is communicated with an Ar source tank through a gas valve A. A gas guide tube is connected with the screen body. The gas valve A, a gas valve B and an oxygen analysis instrument are connected with a central processing unit. The oxygen analysis instrument is arranged in the screen body. An ultrasonic generation unit is connected with the screen body, and two outlets in the screen body are connected with a power collection tank A and a powder collection tank B respectively. The remaining oxygen limit is set, and a ball valve B, a ball valve C and a ball valve E are closed. The Ar gas enters the screen body, air in the screen body is discharged, the oxygen analysis instrument transmits detection data to the central processing unit, and the gas valve A and the gas valve B are closed when the set numerical value is reached. When the data are higher than the set limit values, oxygen reaches the set limit value, the gas valve A and the gas valve B are closed, and the gas valve A is opened, the ultrasonic generation unit is started, and screening is started. By means of the system, clustering and oxidation during ultrafine powder screening are prevented.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

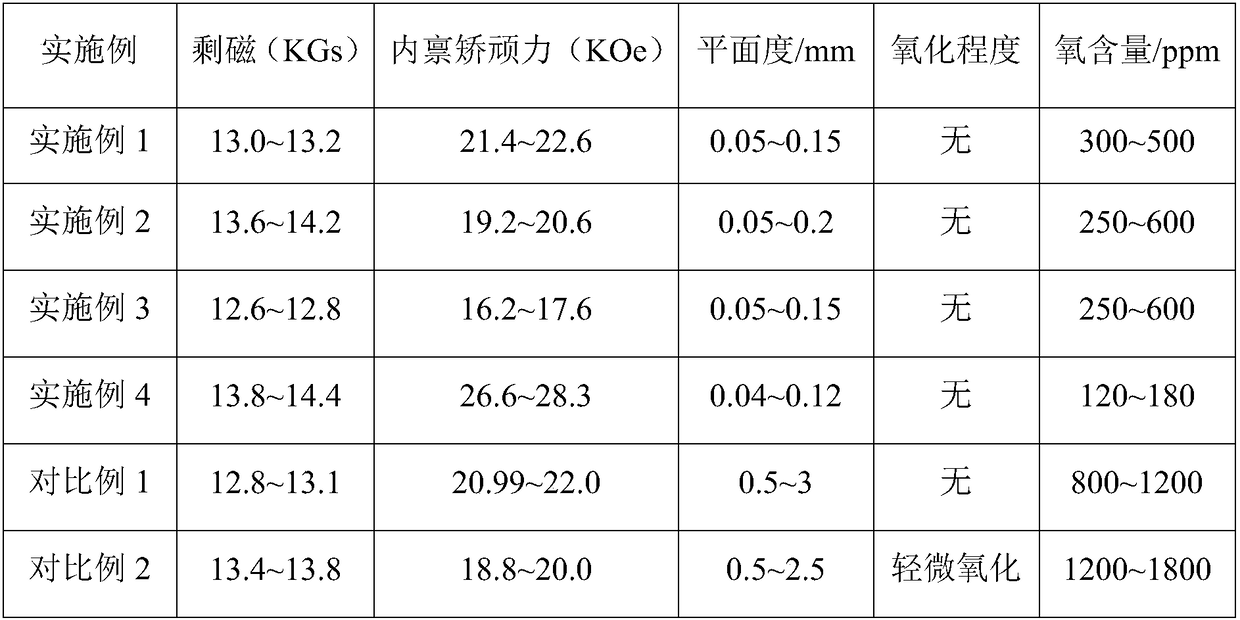

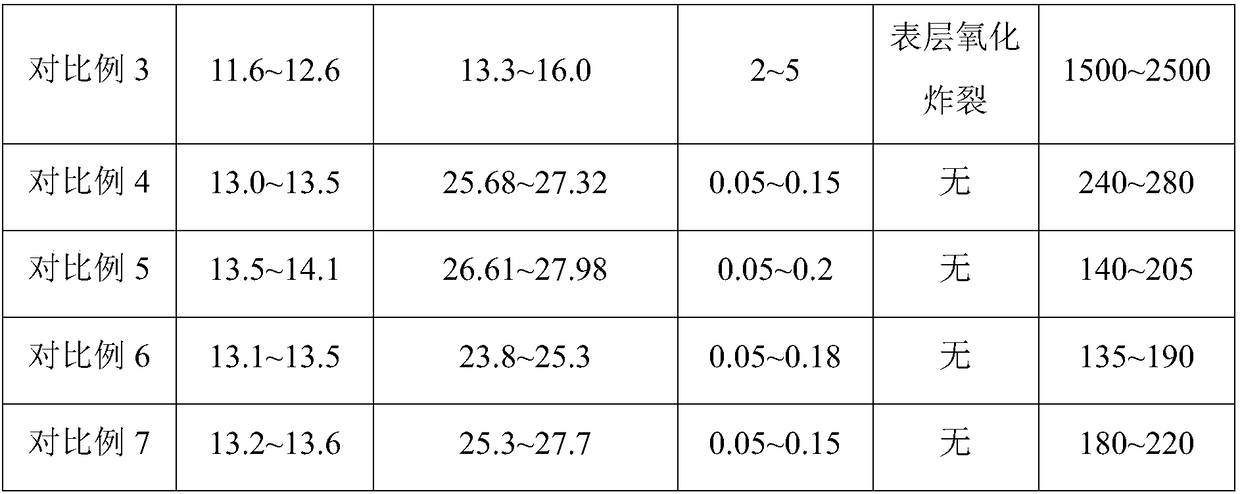

Preparation method of anti-oxidation neodymium-iron-boron magnet

ActiveCN108511180APrevent rare earthAvoid reactionInductances/transformers/magnets manufactureMagnetic materialsWater vaporMetallurgy

The invention discloses a preparation method of an anti-oxidation neodymium-iron-boron magnet. The method comprises the following steps of putting a green body of a neodymium-iron-boron magnet into asintering furnace, pumping the sintering furnace to vacuum and then introducing an argon gas until the pressure in the sintering furnace is 85-100Kpa; and opening a fan in the sintering furnace to rotate for 15-30min, carrying out vacuumizing again and carrying out sintering and tempering to obtain the neodymium-iron-boron magnet. According to the preparation method of the anti-oxidation neodymium-iron-boron magnet disclosed by the invention, the sintering furnace is vacuumized, the argon gas is introduced into the sintering furnace, and then the fan in the sintering furnace is opened to rotate to wash the furnace, so that oxygen and water vapor adsorbed in the sintering furnace are discharged, equivalently the problem of the oxygen is fundamentally solved, reaction of rare earth in the green body of the neodymium-iron-boron magnet and the oxygen is prevented and oxidation and deformation caused by a liquid shrinkage difference during sintering are avoided.

Owner:廊坊京磁精密材料有限公司

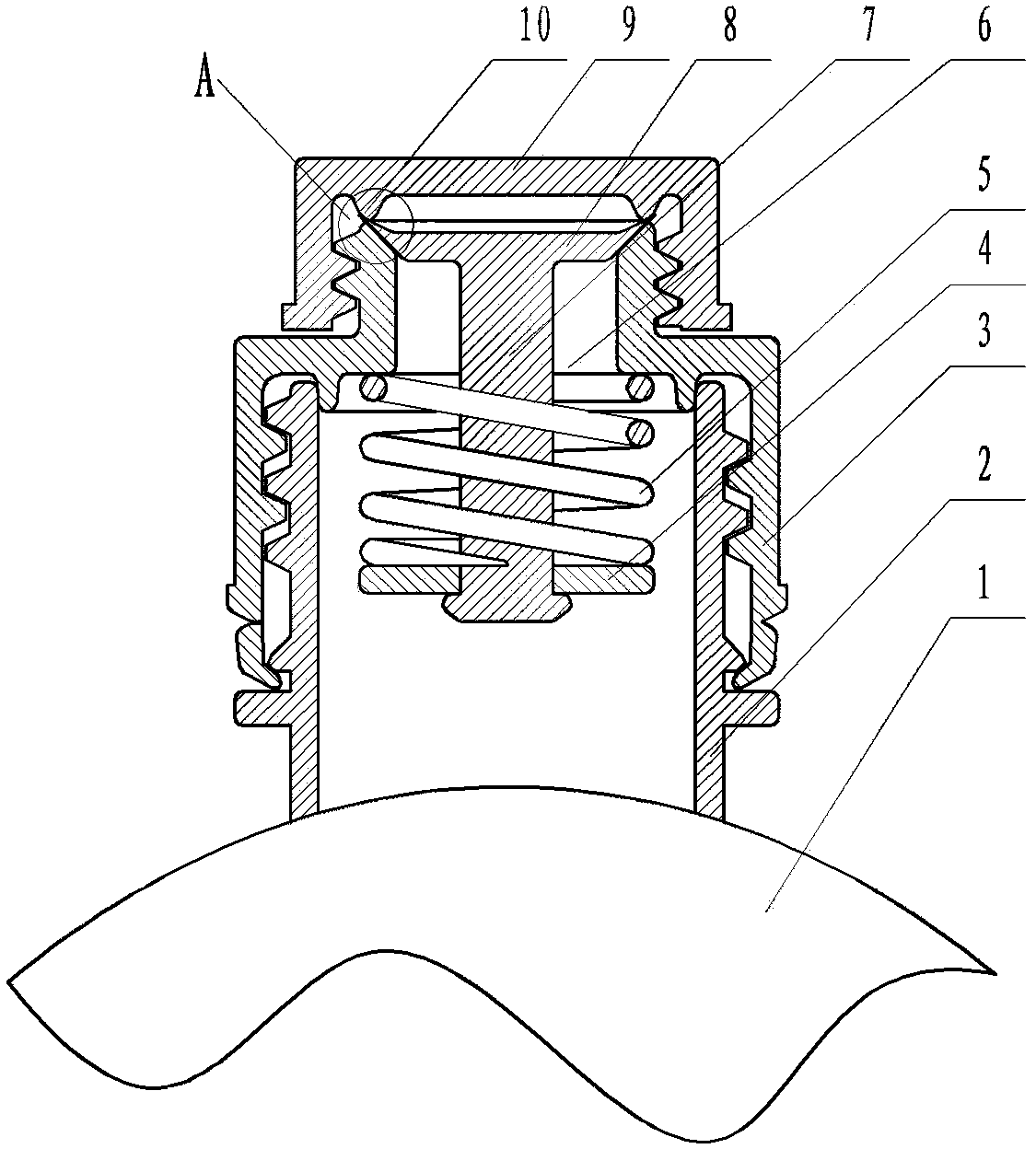

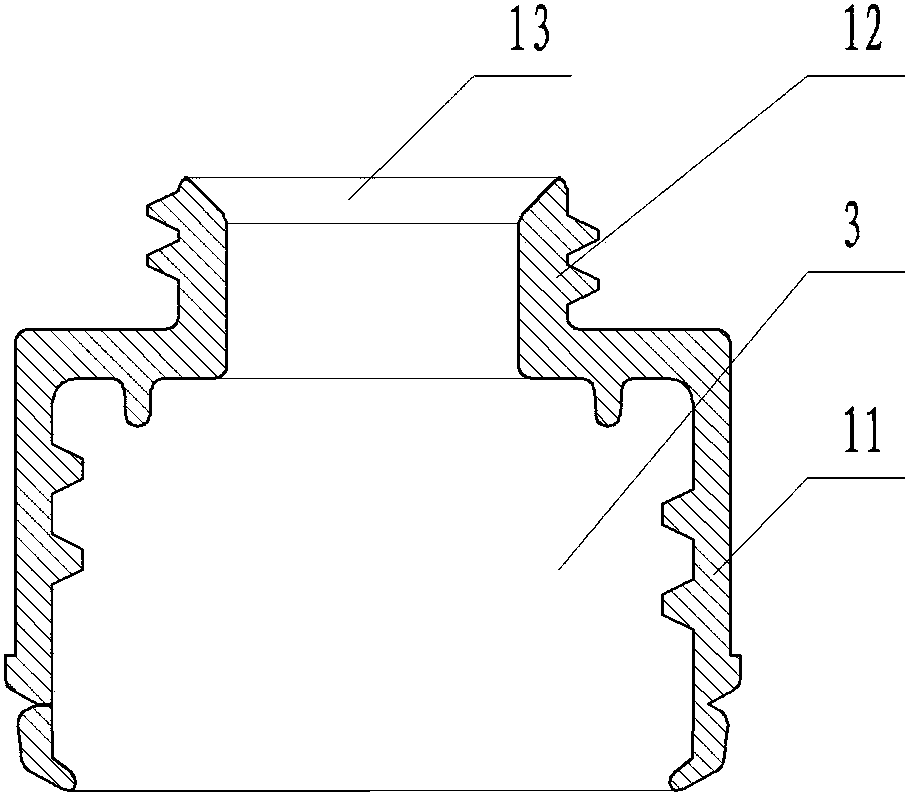

Self-sealing type bottle cap for oil bottle

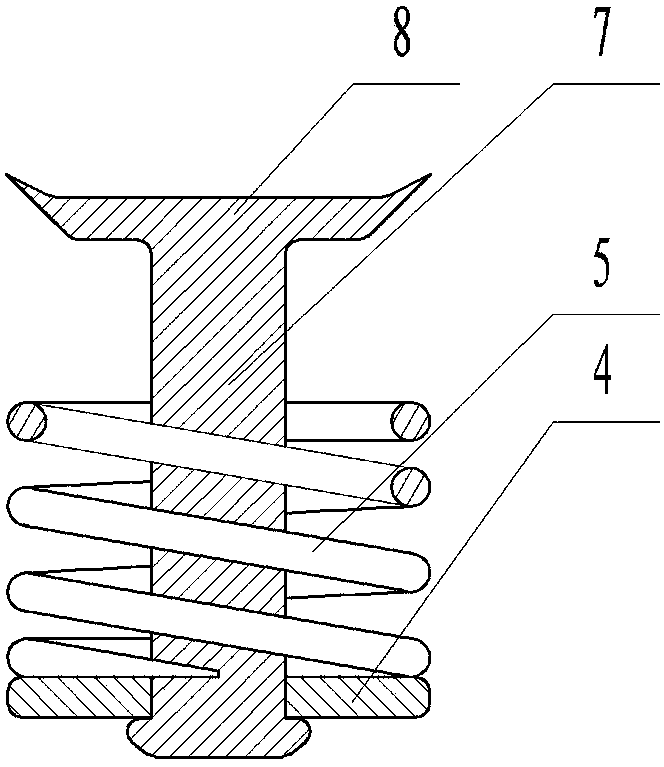

InactiveCN103482227ARelieve stressPrevent oxidationClosuresShock-sensitive articlesIn planeEngineering

The invention discloses a self-sealing type bottle cap for an oil bottle. The seal-sealing type bottle cap for the oil bottle consists of a sealing cap, a one-way valve and a bottle cap body, wherein the sealing cap consists of a cap opening and a cap body; the cap body is in threaded connection with the bottle opening of the oil bottle; a sealing surface is arranged on the inner side of the cap opening; the one-way valve is arranged on the sealing cap and consists of a valve seat, a valve rod, a spring blocking cushion and a spring; one end of the valve rod is integrally connected with the valve seat; the other end of the valve rod is provided with the spring blocking cushion; the spring is arranged on the valve rod and is positioned by the spring blocking cushion; the valve seat is positioned at the cap opening of the sealing cap and is in plane contact with the sealing surface of the cap opening; and the bottle cap body is in threaded connection to the cap opening of the sealing cap. The self-sealing type bottle cap for the oil bottle has the advantages that oil in the oil bottle can flow out through the one-way valve, but air cannot enter the oil bottle from the bottle opening, so that edible oil in the bottle is isolated from the air, oxidation of the edible oil is stopped, the expiration date of the edible oil is prolonged, and the edible oil is safe to eat.

Owner:神池县粮油机械研究所

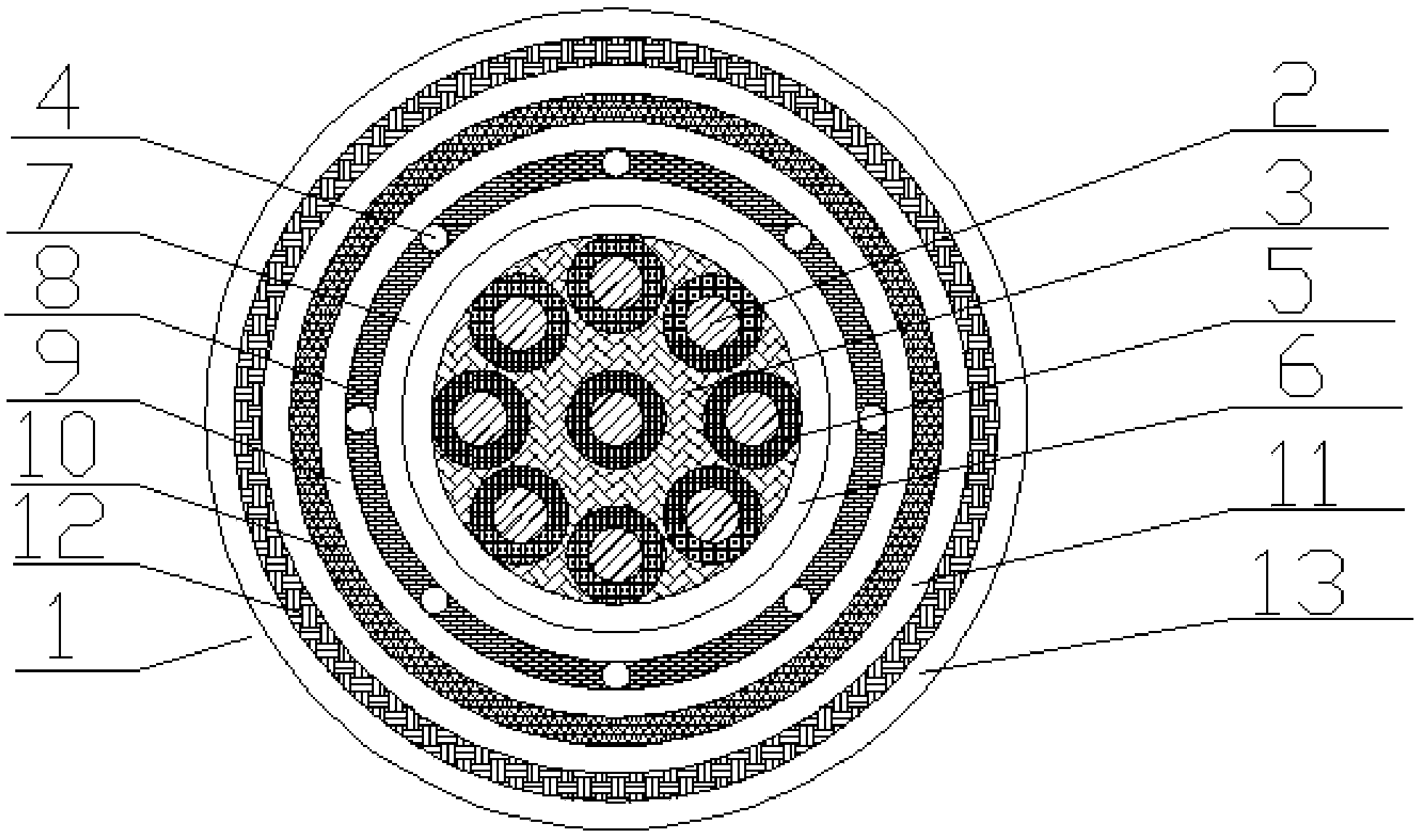

Environment-friendly, high-temperature-resistant and anti-shielding industrial control cable

InactiveCN104332227AReasonable structural designExtended service lifeInsulated cablesInsulated conductorsEnvironmental resistanceMetal coating

The invention discloses an environment-friendly, high-temperature-resistant and anti-shielding industrial control cable, comprising a cable body that includes conductors, an insulating layer, a shielding layer, an inner sheath and an outer sheath. The conductor is arranged inside the cable body; the section of the conductor is circular in shape; a copper foil layer is extruded outside the conductor; the insulating layer is tightly extruded outside the copper foil layers; the gap part between the insulating layer and the copper foil layers is filled with fillers; the shielding layer is tightly extruded outside the insulating layer; a plurality of uniformly arranged drainage cores are arranged inside the shielding layer; a resin bonding layer is arranged between the shielding layer and the insulating layer; a metal coating is arranged on the outer surface of the shielding layer; a reinforcing layer and a refractory layer are arranged outside the metal coating from inside to outside; the inner sheath is arranged on the outer surface of the refractory layer; the outer sheath is tightly extruded on the surface of the inner sheath. The environment-friendly, high-temperature-resistant and anti-shielding industrial control cable has the advantages of reasonable structural design, long service life and good shielding resistance.

Owner:CHENGDU GUANYU TECH

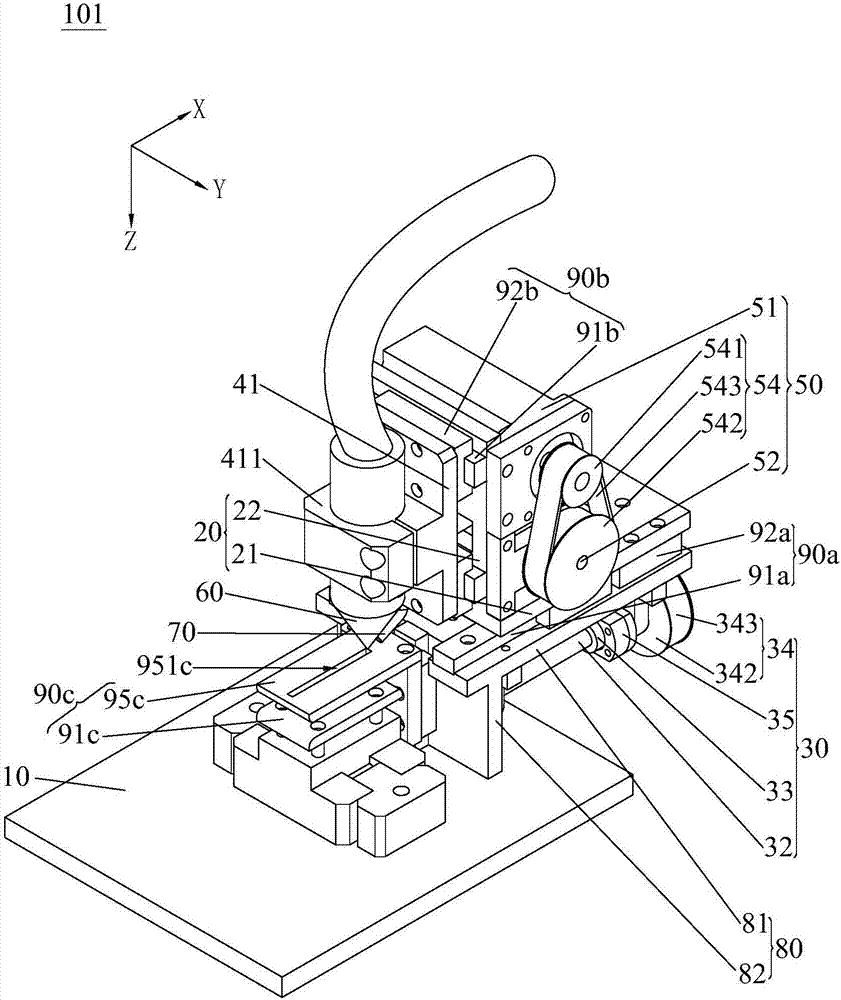

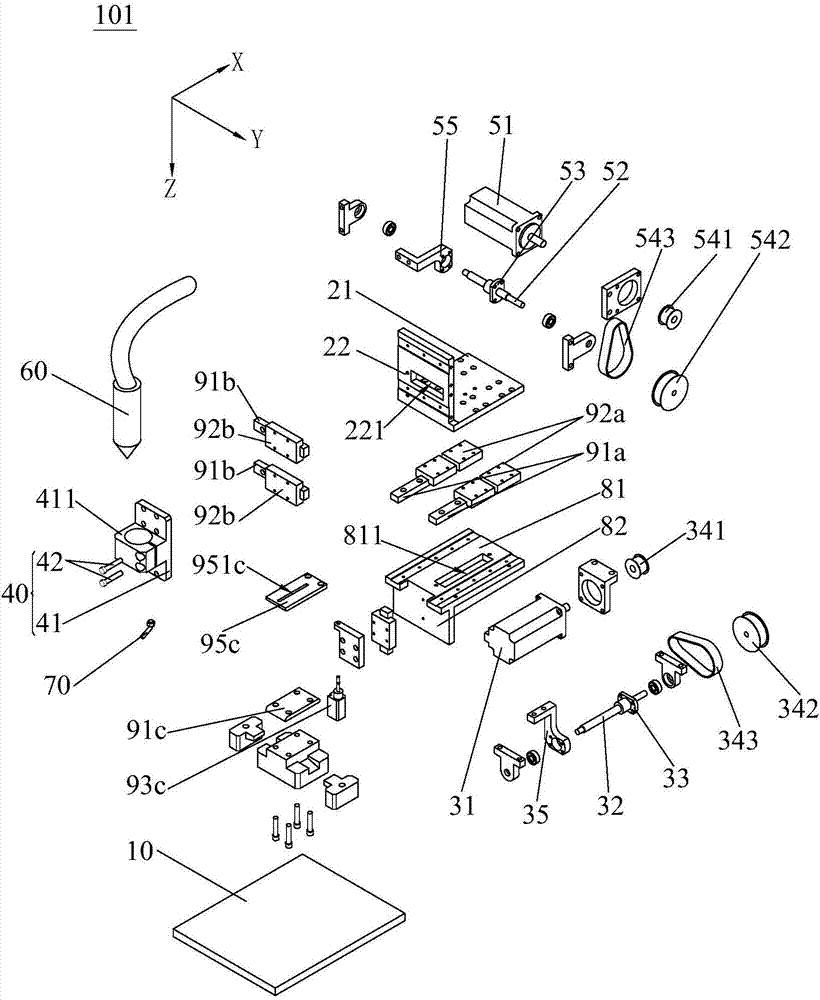

Laser welding device and winding machine with same

PendingCN107322160AOxidation does not occurAvoid direct contactLaser beam welding apparatusWinding machineUltrasonic welding

The invention discloses a laser welding device. The laser welding device comprises a pedestal, a sliding seat, a first moving driving mechanism, a second moving driving mechanism, a holding and locking mechanism, a laser welding head and an inert gas nozzle. The sliding seat is slidably arranged on the pedestal in the front-back direction, and the first moving driving mechanism is arranged on the pedestal and is connected to the sliding seat in a transmission mode so as to drive the sliding seat to slide in the front-back direction. The holding and locking mechanism is slidably arranged on the sliding seat in the left-right direction, and the second moving driving mechanism is arranged on the sliding seat and is connected to the holding and locking mechanism in a transmission mode so as to drive the holding and locking mechanism to slide in the left-right direction. The laser welding head is clamped and fixed to the holding and locking mechanism in a vertical-position-adjustable mode, and the inert gas nozzle is fixed to the holding and locking mechanism. An outlet of the inert gas nozzle is aligned at the welding position of the laser welding head. The laser welding device is small and exquisite in structure and is arranged on a winding machine to replace a traditional device for thorn and rivet welding, cooling welding and ultrasonic welding.

Owner:东莞士格电子集团有限公司

High temperature anti-oxidation coating for steel-copper solid-liquid bimetal composite casting

ActiveCN108192390BIncrease warm-up rateWarm up evenlyFireproof paintsPaints with free metalsHeat transfer efficiencyCopper

The invention discloses high-temperature anti-oxidation coating for steel-copper solid-liquid double-metal composite casting. The high-temperature anti-oxidation coating is prepared from 13 to 20 percent of copper powder, 40 to 43 percent of anhydrous sodium tetraborate and 37 to 47 percent of ethylene glycol. The high-temperature anti-oxidation coating disclosed by the invention has a better wetting property and the adhesive quality of the coating is improved; the coating thickness of the coating at high temperature can be remarkably improved and the heat transfer efficiency of the coating isremarkably enhanced; the combination of a double-metal composite material is facilitated. When the high-temperature anti-oxidation coating is pre-heated to high temperature of 1000 to 1200 DEG C, theanhydrous sodium tetraborate is melted and is separated from the copper powder; the copper powder is melted and permeates into a steel matrix to form a protection layer; the sodium tetraborate is crusted on the outer side of a copper layer. The interface bonding strength of the steel-copper double-metal composite material obtained by casting through the method can reach 192MPa at maximum.

Owner:ZHONGBEI UNIV

Heat supply control valve with accurate metering function

PendingCN112944025ACompact structureReasonable designPlug valvesOperating means/releasing devices for valvesClosed loop feedbackControl system

The invention discloses a heat supply control valve with an accurate metering function. The heat supply control valve with the accurate metering function comprises pipeline connectors, an electromagnetic flowmeter, an electric ball valve, a water inlet temperature sensor, a water return temperature sensor and a control device, wherein when the device is transversely placed as a whole, the first pipeline connector, the electric ball valve, the electromagnetic flowmeter and the second pipeline connector are sequentially connected from left to right; and the control device is fixedly connected to the upper side of the electric ball valve, and a through hole for the water inlet sensor to insert is formed in the lower side of the electric ball valve. According to the invention, the electric ball valve, the electromagnetic flowmeter, the water inlet temperature sensor, the water return temperature sensor and a measurement control circuit are integrated to form a closed-loop feedback control system, constant-flow heat supply or constant-power heat supply of the heat supply system can be realized, and the heat supply control valve with the accurate metering function is the optimal product for achieving balance of a heat supply pipe network and reasonable heat distribution, and has very positive significance on energy conservation and consumption reduction of the heat supply system.

Owner:山东齐芯智控科技有限公司

A high-aluminum bronze coating for volumetric damage repair and its preparation method

ActiveCN104962776BReduce the degree of oxidationSuppress generationMolten spray coatingHydrogenNitrogen

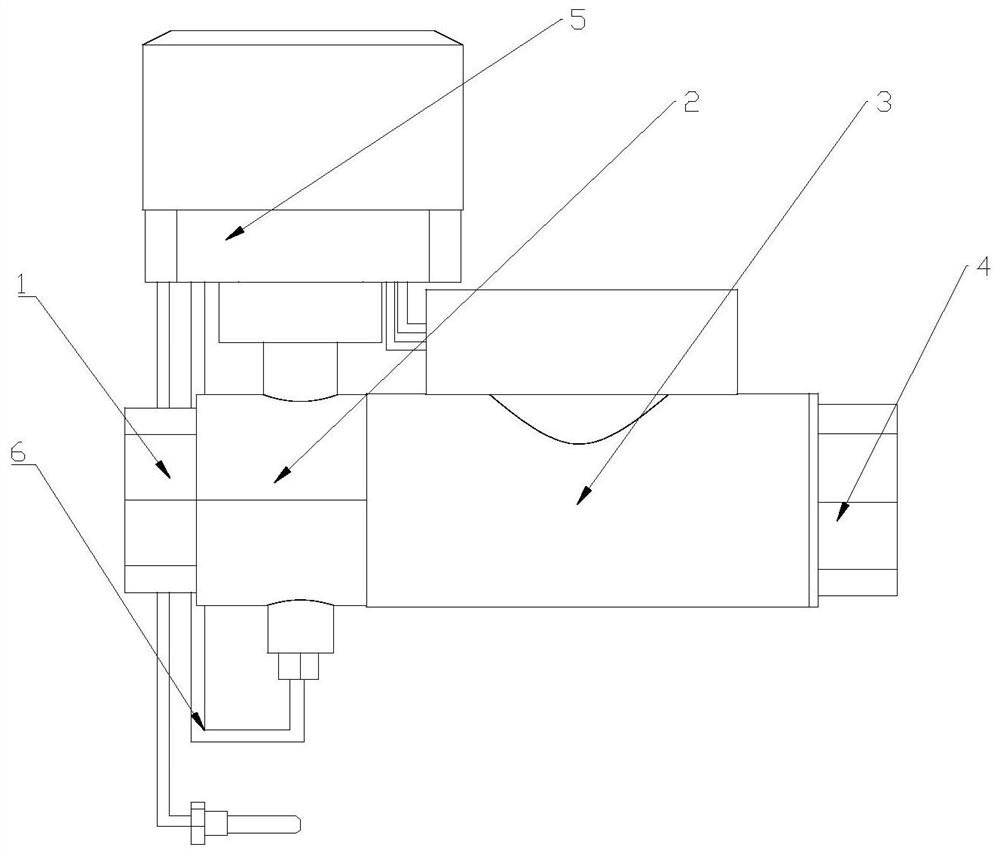

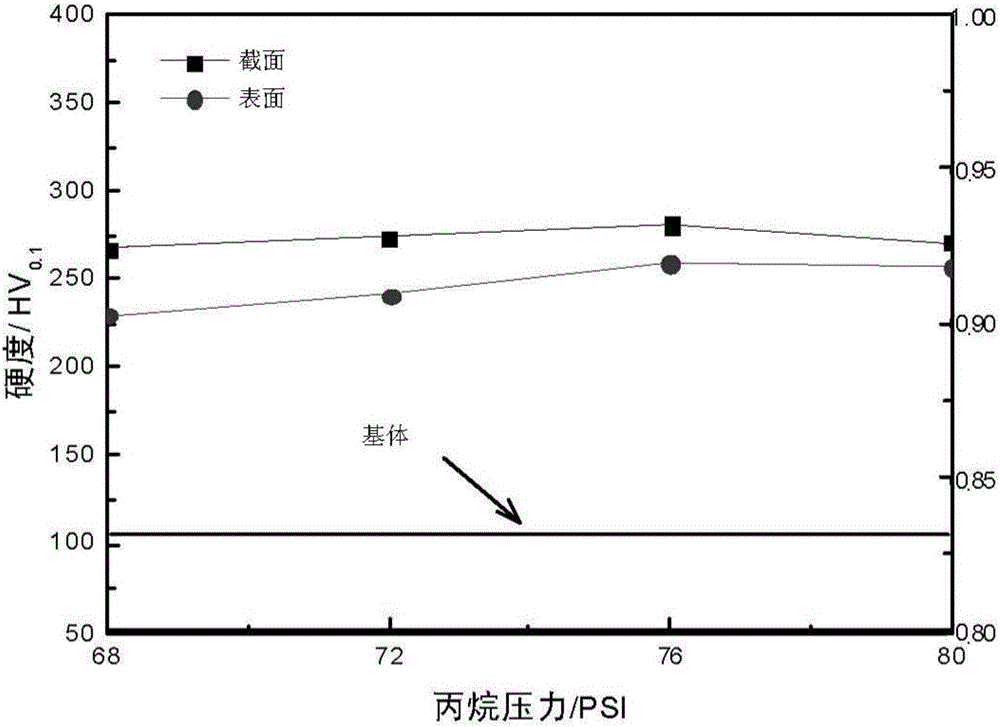

The invention discloses a high-alumina bronze coating for repairing volume damage and a preparation method of the high-alumina bronze coating. The thickness of the high-alumina bronze coating can reach 2.5-4mm, the high-alumina bronze coating is prepared by means of coating the surface of a copper alloy matrix by using gas-atomization high-alumina bronze powder through a low-temperature supersonic spraying technology, the temperature of flame flow in the low-temperature supersonic spraying technology is only 600-900 DEG C, dimethylmethane serves as main gas, compressed air serves as oxidant gas, hydrogen serves as reducing gas, and nitrogen serves as power conveying carrier gas; and technological parameters of coating include that air pressure is 90 PSI, the pressure of the dimethylmethane is 68-80PSI, the flow of the hydrogen is 40L / min, the flow of the nitrogen is 40L / min, and the spraying distance is 140mm. The prepared high-alumina bronze coating is low in oxidation degree, low in thermal stress and large in thickness; and large-sized volume damage caused by severe wear of aluminum alloy parts of equipment can be repaired.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

A kind of preparation method of light-weight intermetallic compound-based matrix composite material

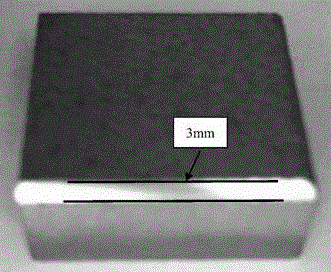

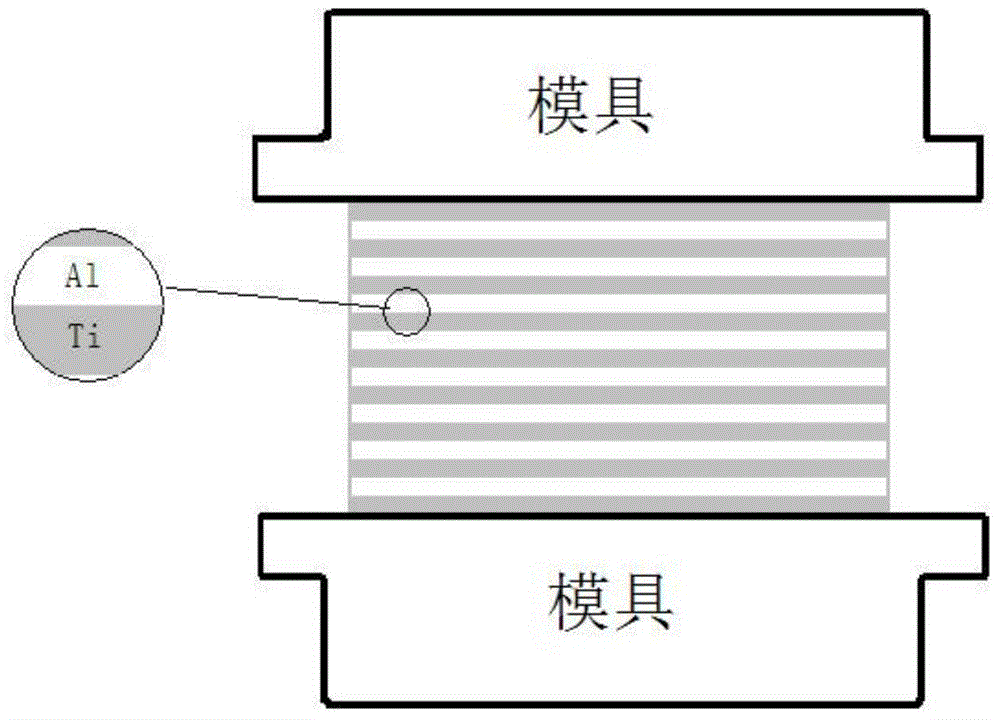

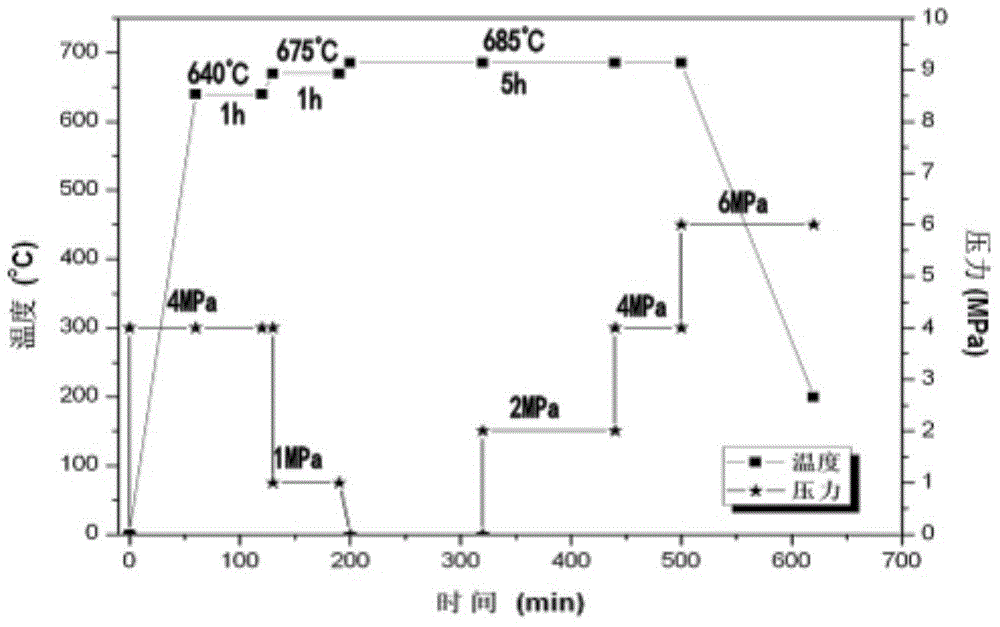

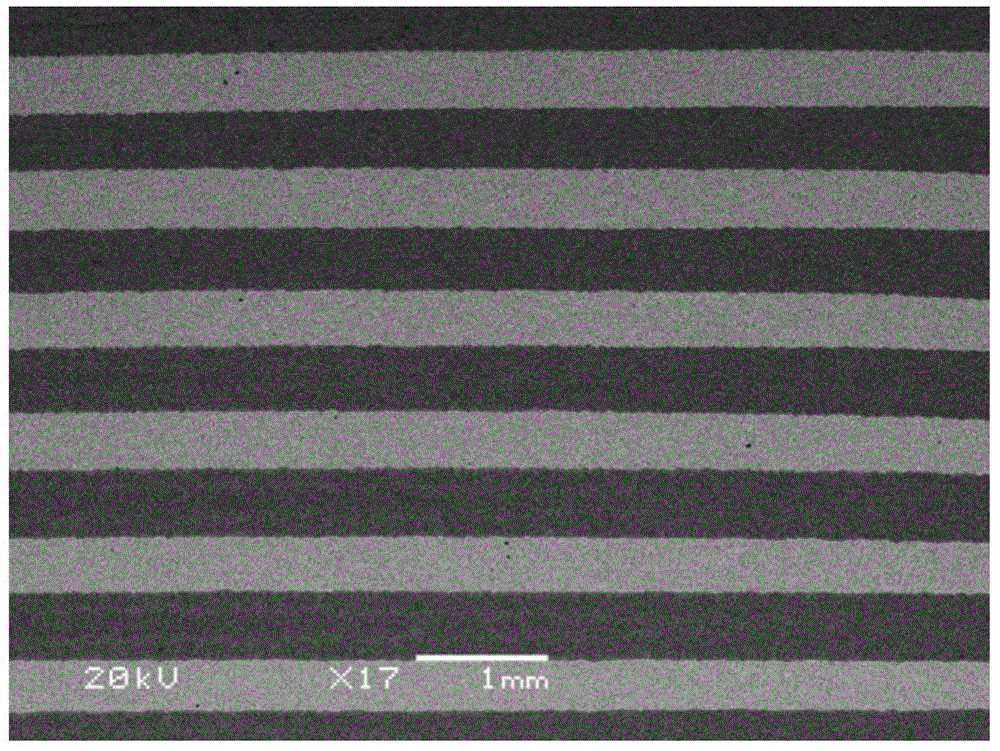

InactiveCN103572187BHigh strengthHigh hardnessLaminationLamination apparatusManufactured materialLow density

The invention provides a preparation method of a light-weight intermetallic compound based layered composite material. The preparation method comprises the following steps: with Ti foil and Al foil as raw materials, alternately stacking the pretreated Ti foil and Al foil, keeping the Ti foil at the outmost layer, and carrying out vacuum hot pressing treatment under the conditions that the base pressure is 6.67*10<-3>Pa, the reaction temperature is 640-685 DEG C, the heating rate is 1-10 DEG C / min, the applied pressure is 0-4MPa, and the temperature preservation time is 1-10h. According to the preparation method, the mutually stacked Ti foil and Al foil are subjected to diffusion reaction by using a vacuum hot pressing method to generate an intermetallic compound Al3Ti, and the intermetallic compound Al3Ti and the residual Ti layer are formed into a layered composite material with a Ti layer as a reinforcement body. The intermetallic compound Al3Ti has high strength and hardness, low density and higher fragility, while the Ti layer is the reinforcement body with better toughness, so that the obtained intermetallic compound based layered composite material has high toughness on the basis of high strength.

Owner:HARBIN ENG UNIV

Lotus root noodles and drying method thereof

The present invention relates to fruit and vegetable noodles and particularly lotus root noodles. The lotus root noodles consist of the following components in parts by mass: 6-9 parts of coix seed flour, 6-9 parts of soybean powder, 5-8 parts of glutinous rice flour, 0.1-0.4 part of salt, 50-65 parts of flour, 1.6-2.5 parts of baking soda and 1.0-2.5 parts of white sugar. Pressed wet noodles are sent into a steam room, the wet noodles passed the steam room are soaked into a juice storage pool loaded with lotus root juice, the soaked noodles are hung up, the wet noodles after the step 2 are sent into a cold air room to be hung up, and the cold air flows from the upper side of the wet noodles to the lower side of the wet noodles; step 4: the dry flour is sprayed on the surfaces of the wet noodles in the step 3; and step 5: the dry flour sprayed wet noodles are put into a low-temperature and low-humidity room to conduct a hot air drying. The method solves the problem that during the drying process, the lotus root noodles are easily oxidized and discolored, and the present invention aims to provide the lotus root noodles which can avoid discoloration.

Owner:GUIZHOU PROVINCE FENGGANG COUNTY HETANGQIUYUN ORGANIC PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com