Method for acquiring metal temperature forming limit diagram (TFLD) and testing device therefor

A technology of warm forming and testing device, applied in the field of sheet metal forming, which can solve the problems of invisible grid, transformation of sheet metal structure, and difficulty in accurately obtaining high-strength steel sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

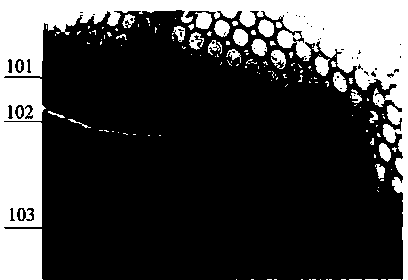

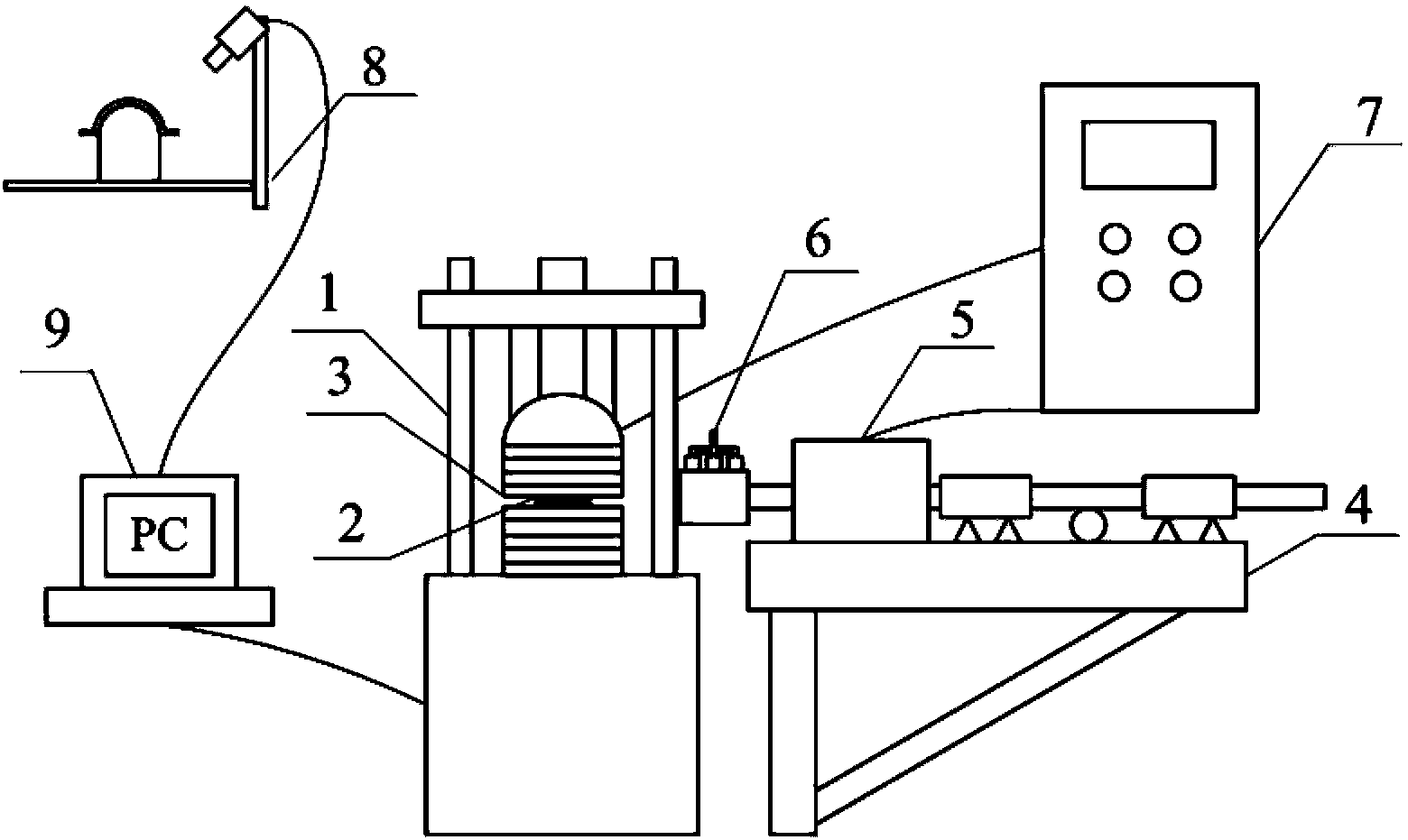

[0067] Such as figure 1 , figure 2 As shown, a TFLD test device for metal high-temperature warm forming limit, including a hydraulic testing machine 1, a mold 2, a mold heating furnace 3, an automatic feeding mechanism 4, a sheet metal heating furnace 5, a sheet metal rapid cooling device 6, and a heating control system 7 and strain measurement analysis device 8;

[0068] The hydraulic testing machine 1 is used to control the movement of the mold 2 mounted thereon, and the mold 2 is used to press and bulge the sample 10; the mold 2 includes a hemispherical punch 21, Die 22 and a blank holder 23 with drawbeads, the punch 21 is placed in the binder ring 23, the diameter of the ball head of the punch 21 is smaller than that of the die 22 and the binder The inner diameter of the ring 23; the punch 21, the die 22 and the blank holder ring 23 are coaxially installed on the hydraulic testing machine 1, and the die 22 is fixed on the hydraulic testing machine 1 On the central axi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com