A laboratory test method for reliability of uuv propulsion motor

A technology that promotes motors and testing methods, applied in the electromechanical field, can solve problems such as large investment, and achieve the effect of ensuring safe and reliable operation and accurate and effective test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

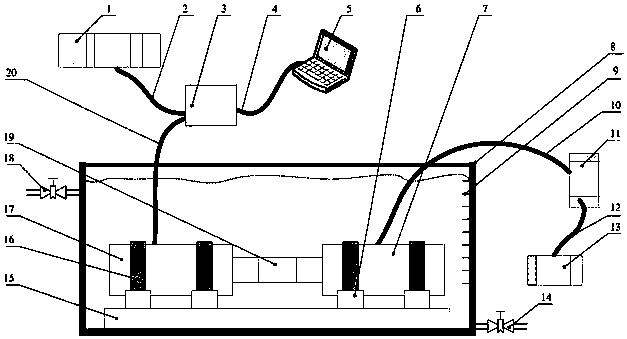

[0024] This embodiment provides a UUV propulsion motor reliability laboratory testing system, which is mainly used for the verification and assessment of the dynamic sealing performance of the underwater unmanned vehicle (UUV) watertight propulsion motor, and the reliability verification and assessment of the propulsion motor and its controller. It is used for reliability test and assessment of UUV watertight propulsion motor.

[0025] The reliability test of UUV propulsion motor refers to the full-load function test to detect whether it operates stably within the set time under full-load conditions and whether its mechanical and electrical parts can still meet the basic requirements of the propulsion motor after the stable operation. Performance index; if after the end of stable operation, its mechanical and electrical parts can still meet the basic performance index of the propulsion motor, its reliability is considered to meet the requirements.

[0026] Such as figure 1 As...

Embodiment 2

[0039]On the basis of the above-mentioned embodiment 1, in order to simulate the operating environment of the propulsion motor of the underwater unmanned vehicle (UUV) more realistically and to make the test results more accurate, the water tank 8 is replaced with a closed pressure vessel to simulate the underwater stressful environment. The propulsion motor 17 to be tested is installed in the autoclave, and the autoclave is provided with a pressure gauge for real-time display of the internal water pressure value. The pressure in the autoclave can be adjusted through the cooperation of the water outlet valve 14 and the water inlet valve 18 to realize the test of different water depths. For example, by keeping the pressure in the autoclave at 1MPa, the environment of 100m underwater can be simulated to test the propulsion under test. Reliability of motor 17 when used in water depth of 100m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com