Production automation test method and system for communication equipment

A technology of automated testing and communication equipment, applied in software testing/debugging, error detection/correction, instruments, etc., can solve the problems of lower test efficiency and quality, long manual test cycle, cumbersome manual test process, etc., to achieve convenient expansion and The effect of maintaining, improving test efficiency and improving test quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

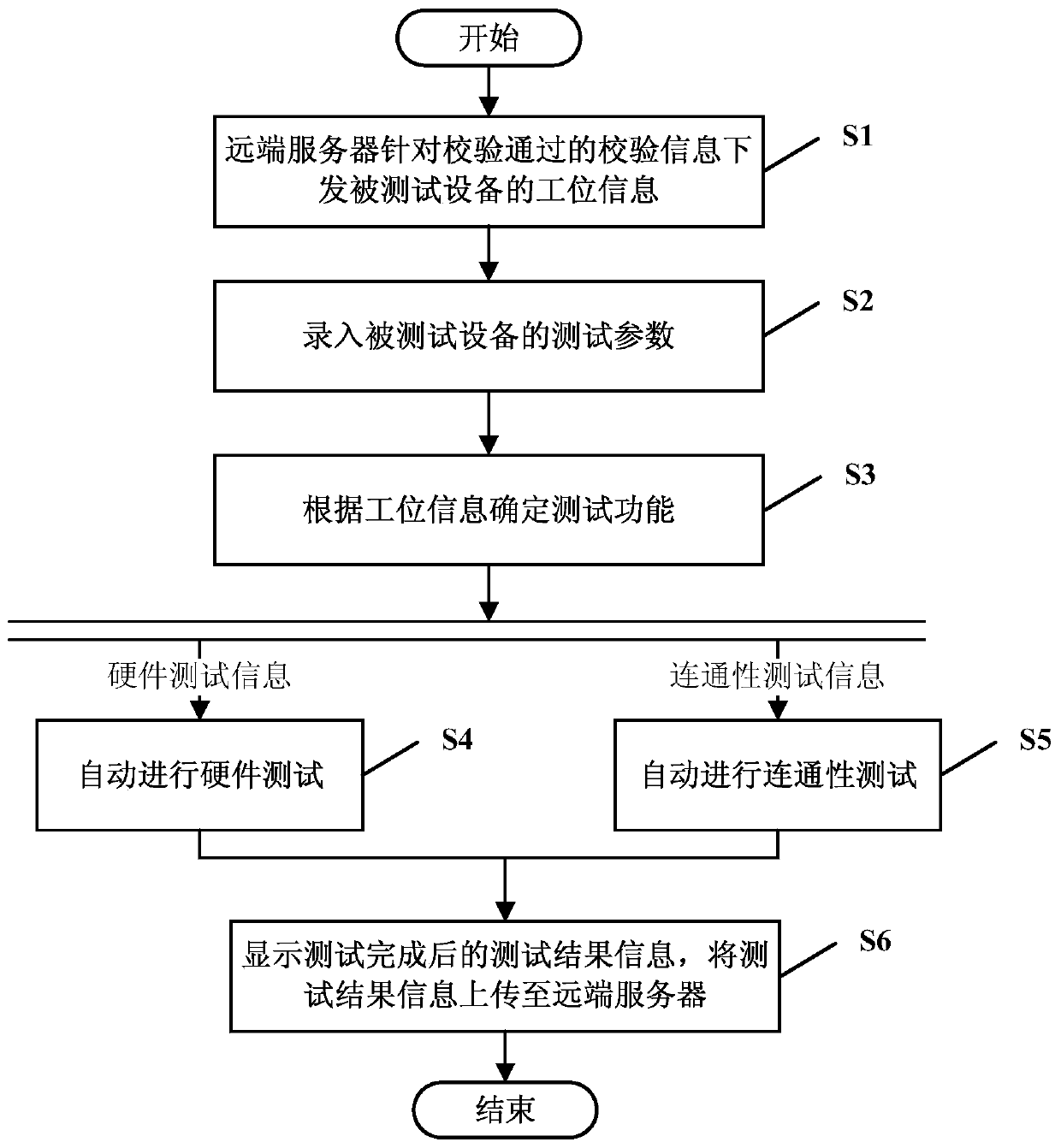

[0024] see figure 1 As shown, the production automation test method for communication equipment in the embodiment of the present invention includes the following steps:

[0025] S1: The production tester enters the verification information of the device under test (the order information and system identification information of the device under test, and the identity information of the production tester) on the graphical interface, and the remote server passes the verification of the verification information (calibration If the verification information exists in the remote server, the verification is passed), the station information of the device under test (that is, the specific function that the device under test needs to test) is issued according to the order information, and then go to S2.

[0026] S2: On the graphical interface, productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com