Laser welding device and winding machine with same

A technology of laser welding and laser welding head, which is applied in the field of laser welding devices and winding machines, can solve problems such as poor welding, difficult control of cold welding time, uneven vibration amplitude and vibration frequency, etc., to prevent poor welding and good welding The effect of avoiding the increase of internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

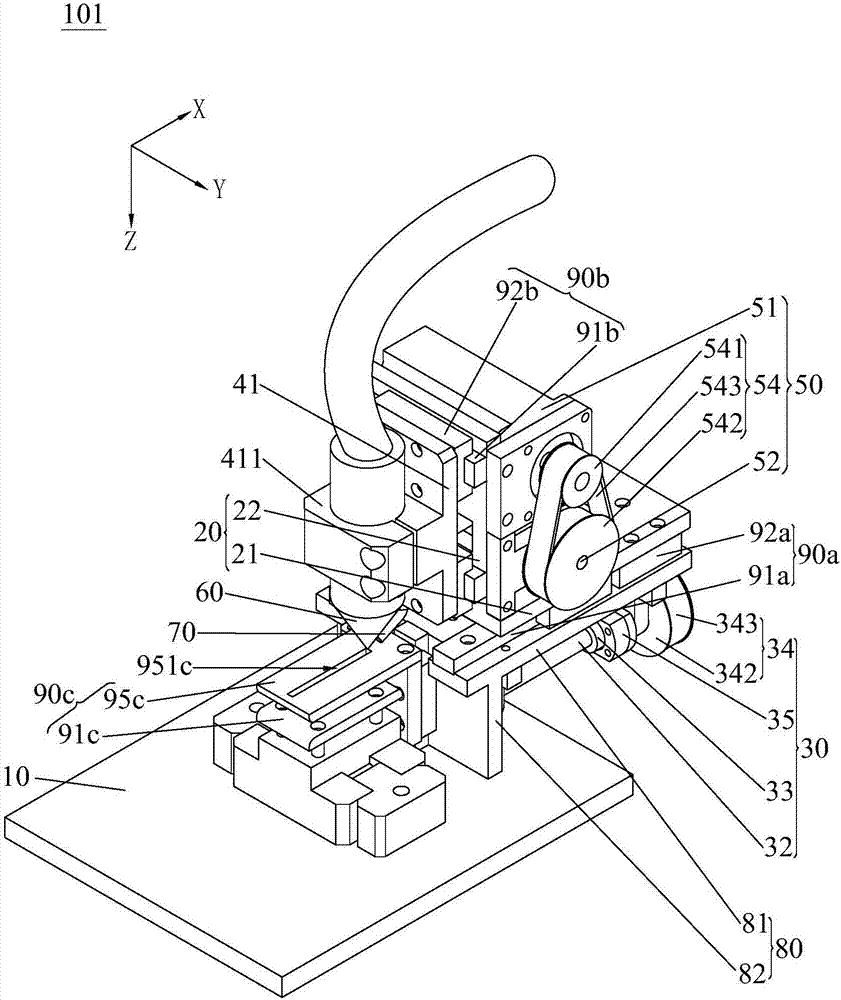

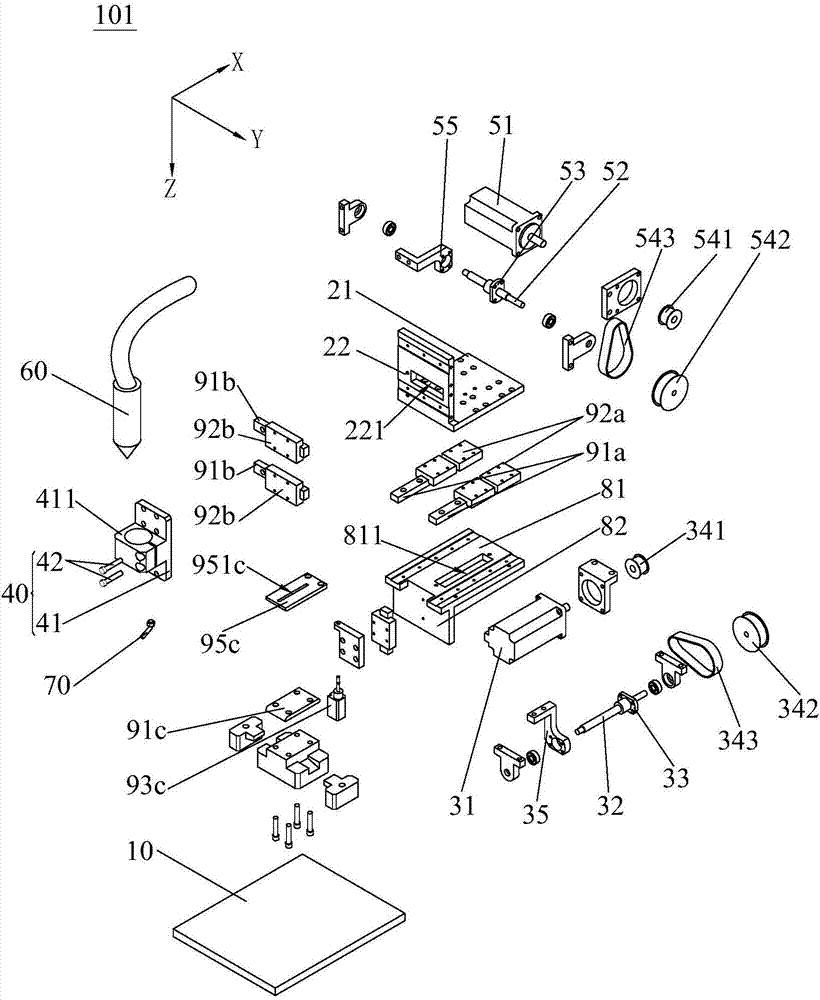

[0032] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

[0033] see Figure 1 to Figure 5, shows the laser welding device 101 of the first embodiment of the present invention, wherein, in the directions marked in the drawings, the X-axis represents the front-to-back direction, the Y-axis represents the left-right direction, and the Z-axis represents the vertical direction. The laser welding device 101 of this embodiment includes a base 10 , a sliding seat 20 , a first moving driving mechanism 30 , a locking mechanism 40 , a second moving driving mechanism 50 , a laser welding head 60 and an inert gas nozzle 70 . The sliding seat 20 is slidably arranged on the base 10 along the front-rear direction, the first mobile driving mechanism 30 is arranged on the base 10, and the first mobile driving mechanism 30 is transmission-connected to the sliding seat 20 to drive the sliding seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com