A kind of preparation method of light-weight intermetallic compound-based matrix composite material

A technology of intermetallic compounds and composite materials, which is applied in the field of preparation of composite materials, can solve problems such as poor production safety, environmental impact, and large smog, and achieve the effects of high hardness, high interface bonding strength, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0039] Surface pretreatment of raw materials: select Ti foil and Al foil with a thickness of 520 μm and 620 μm respectively, and cut the metal foil into a square of 100mm×100mm for surface pretreatment. First, sand the surface of Ti foil and Al foil Grinding to remove the surface oxide skin until the fresh surface is exposed, then ultrasonically treat the polished Ti foil and Al foil for 15-20min, and finally clean the surface with alcohol to remove the remaining oxide particles and impurities, air dry and put into a desiccator for processing.

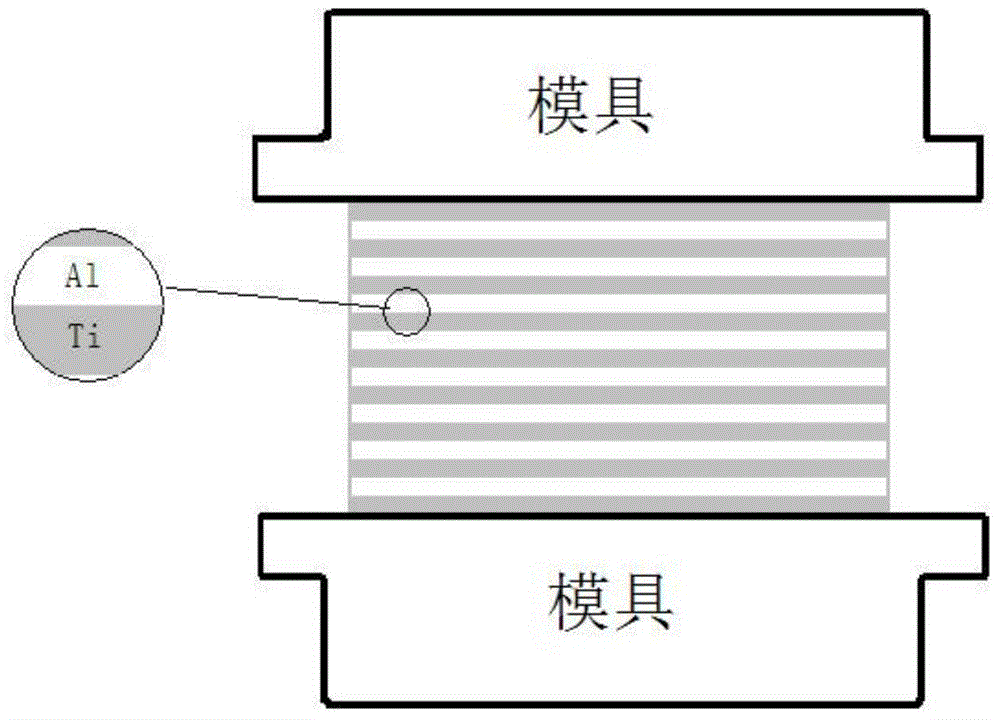

[0040] The two kinds of foils are overlapped, the layers of Ti foil and Al foil are 14 layers and 13 layers respectively, and the outermost layer is Ti foil, and the final number of layers is 27 layers. For the stacking method, please refer to the attached figure 1 .

[0041] Put the lamination of the above-mentioned metal foil into the graphite mold of the vacuum hot-press furnace, and carry out vacuum hot-press sintering, and its ba...

example 2

[0044] Compared with Example 1: the surface pretreatment process of the material is exactly the same as the composition of the material, the thickness of the ply, the number of layers and the way of stacking, but the process parameters of the vacuum hot pressing are different.

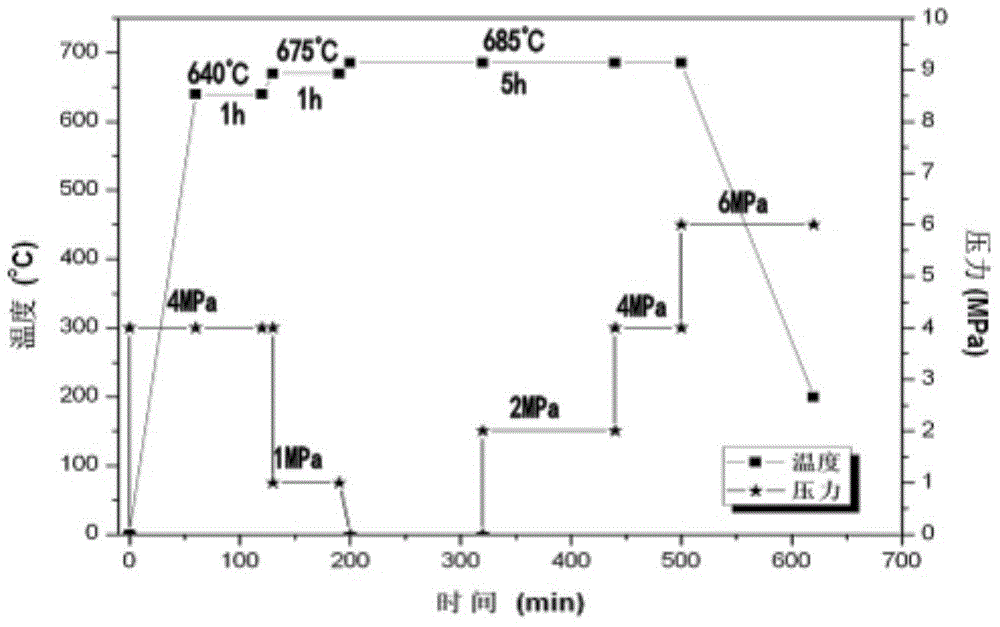

[0045] The vacuum hot pressing process of example 2 is referring to appendix Figure 5 : The background vacuum is 6.67×10 -3 Pa, heat up to 640°C at a heating rate of 10°C / min and hold for 1 hour, then raise the temperature to 675°C at a heating rate of 3.5°C / min, hold for 1 hour, and then heat to 685°C / min at a heating rate of 1°C / min. Keep warm for 7h. A pressure of 4MPa was applied during the heating process and the 640°C holding stage, no pressure was applied during the first 2h of the 675°C holding stage and the 685°C holding stage, a pressure of 2MPa was applied during the last 5h of the 685°C holding stage, and a pressure of 4MPa was applied during the cooling stage.

[0046] This sintering an...

example 3

[0049] Compared with Example 1: the surface pretreatment process of its metal foil material is exactly the same, and the composition of the original material remains unchanged. The thickness of the Ti foil remains unchanged, and the thickness of the Al foil used is 840 μm. The layers of the Ti foil and the Al foil are adjusted to 13 layers and 12 layers, respectively, and the surface-treated metal foils are overlapped so that the outermost end is Ti layer.

[0050] The heat treatment process that example 3 adopts is identical with example 2, and process parameter is referring to appendix Figure 5 .

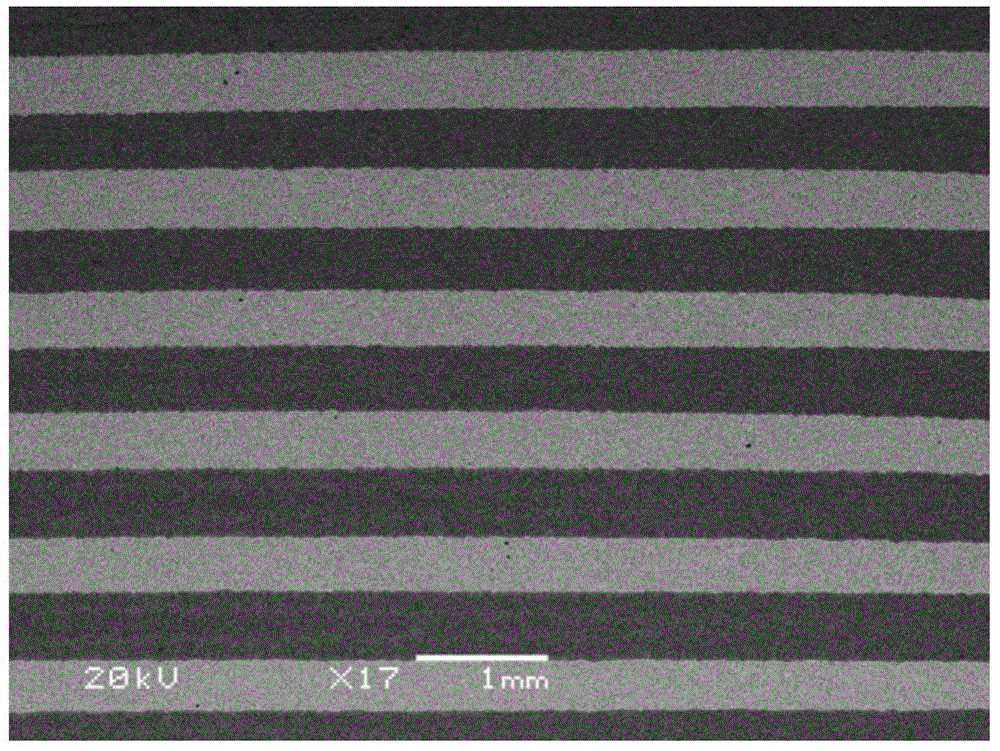

[0051] The microstructure of the composite material that makes among the example 3 is referring to appendix Figure 7 . After measurement, Ti layer and Al 3 The thickness of the Ti layer is 240 μm and 960 μm respectively, and the volume percentage of the reinforcement Ti in the composite material is 20%, and this sample is named 20%Ti / Al 3 Ti. The mechanical properties of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com