DHA (docosahexaenoic acid) oil low-temperature refining method

A low-temperature refining, oil technology, applied in the direction of oil/fat refining, fat production, etc., can solve the problems of affecting the appearance of oil, cost of use, high temperature, and long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

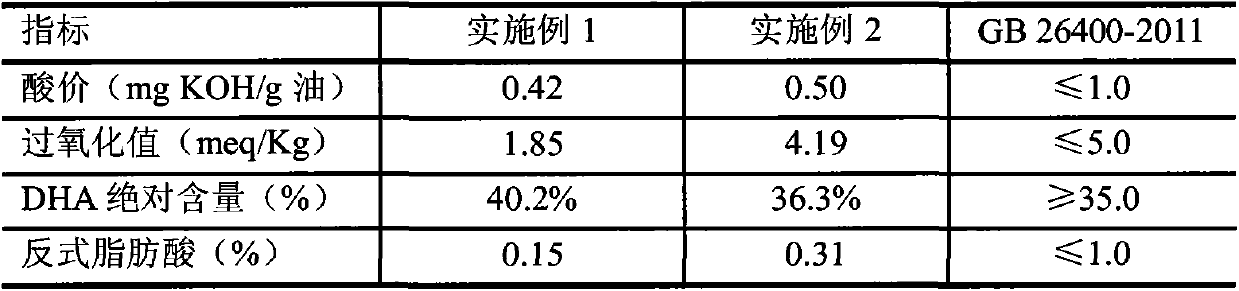

Examples

Embodiment 1

[0010] 1. Alkali refining and decolorization

[0011] 1. Take 1T of DHA crude oil, put it into a crude oil tank, heat the crude oil in a water bath at 25-55°C, add phosphoric acid solution and 2-3% oil-soluble soybean lecithin according to the oil weight 2-3‰, mix evenly, and stir for 20-50°C 30 minutes.

[0012] 2. Use ice water to cool the crude oil to 10°C. Add sodium hydroxide solution and stir rapidly for 30-40 minutes. When the oil-soap begins to separate, heat in a water bath and stir slowly. When the temperature of the oil rises to 55-75°C, stir for 20 minutes and stop, and let it settle.

[0013] 3. Wash with water according to 15% of the oil weight, let it settle for 2 hours to discharge waste water, and wash 5 times with water.

[0014] 4. Put the washed oil into the drying tank, dehydrate under vacuum condition, vacuum degree 0.09MPa, dehydrate at 70-85℃ for 30 minutes.

[0015] 5. Add an adsorbent with an oil weight of 10%, the decolorization temperature is 60-...

Embodiment 2

[0021] 1. Alkali refining and decolorization

[0022] 1. Take 1T of DHA crude oil, put it into the crude oil tank, heat the crude oil to 75-90°C in a water bath, add phosphoric acid solution and 2-3% oil-soluble soybean lecithin according to the oil weight 2-3‰, mix evenly, and stir for 20 ~30 minutes.

[0023] 2. Add sodium hydroxide solution and stir rapidly for 30-40 minutes. When the oil-soap begins to separate, heat in a water bath and stir slowly. When the oil temperature rises to 90°C, stir for 20 minutes and stop, and let it settle.

[0024] 3. Wash with water according to 15% of the oil weight, let it settle for 2 hours to release waste water, and wash 5 times with water.

[0025] 4. Put the washed oil into the drying tank, dehydrate under vacuum condition, vacuum degree 0.09MPa, dehydrate at 90°C for 30 minutes.

[0026] 5. Add an adsorbent with an oil weight of 10%, decolorize at 110°C, decolorize for 30 minutes, and filter with a plate and frame filter to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com