Method for welding thin wall stainless steel tube and copper pipe piece

A technology of stainless steel pipe and welding method, which is applied in welding equipment, welding/welding/cutting articles, tubular articles, etc., can solve the problems of rubber gasket aging, non-discovery, water leakage, etc., and achieve firm and tight welding, convenient and fast construction, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail by the following examples.

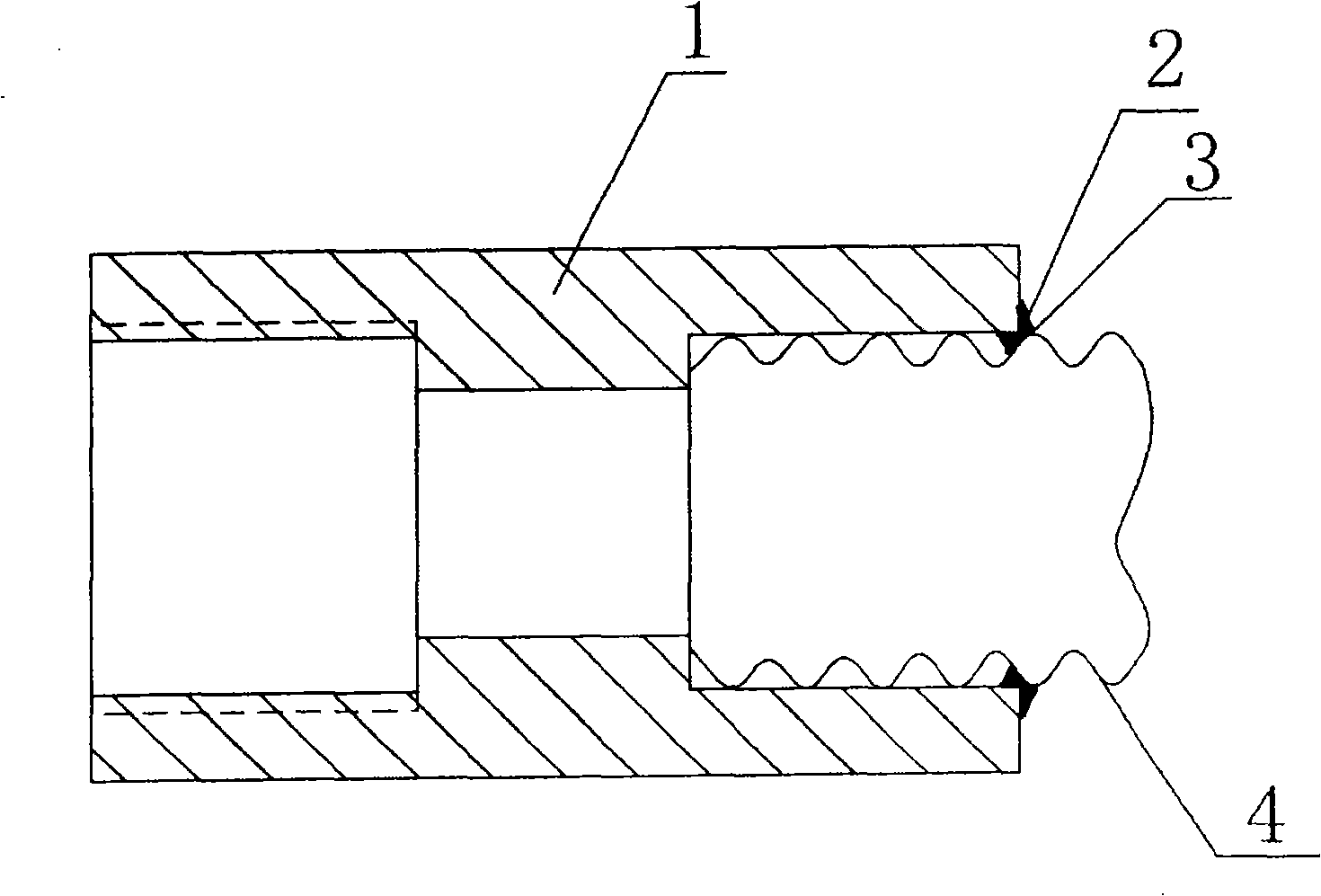

[0017] see figure 1 As shown, the welding method between the thin-walled stainless steel bellows 4 and the copper joint 1 is as follows: firstly clean the connecting portion of the thin-walled stainless steel bellows 4 and the connecting portion of the copper joint 1 and apply silver solder paste; The connecting part of the thin-walled stainless steel bellows 4 is inserted into the connecting part of the copper joint 1, and the outer wall of the copper joint 1 away from the connecting part is sprayed with a flame spray gun to heat the copper joint 1; when the connecting part of the copper joint 1 and the thin-walled stainless steel bellows 4 is indirectly heated to When the temperature is within the temperature range of 750°C-860°C (this temperature range is the melting temperature range of the silver electrode), the operator slowly puts the silver electrode along the exposed part 2 where ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com