Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Meet the requirements of green and sustainable development" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

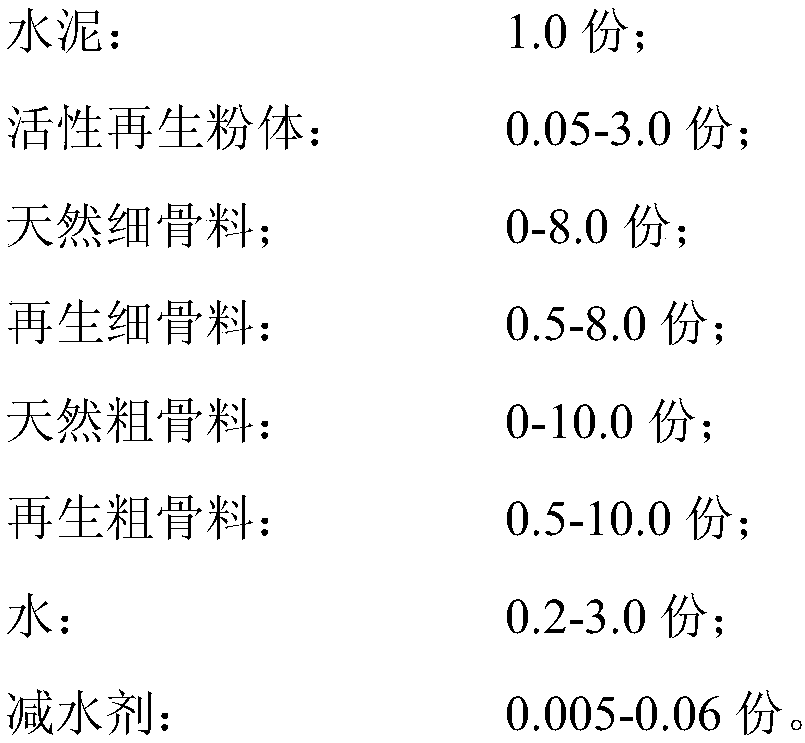

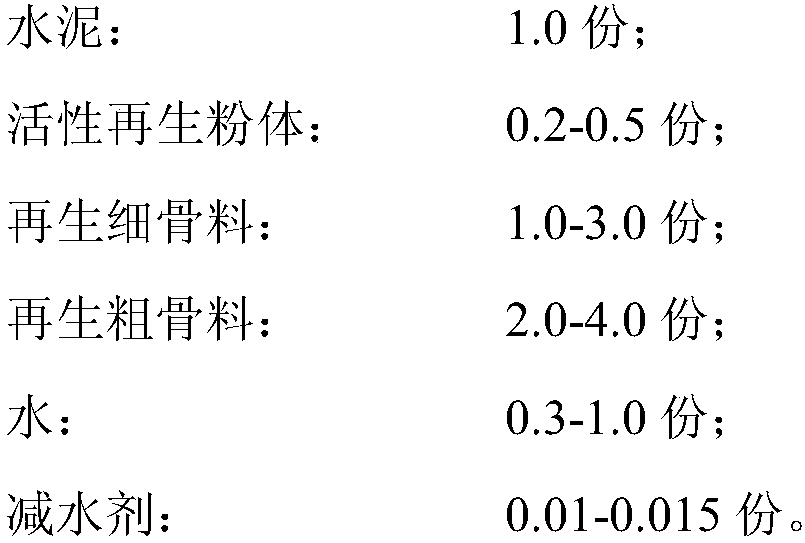

Regenerated concrete block material and production method thereof

InactiveCN108558303AImprove resource utilizationReduce manufacturing costSolid waste managementCement productionSocial benefitsHydration reaction

The invention provides a formula for preparing a regenerated concrete block material by using high activity regenerated powder and a regenerated aggregate. The invention further provides a productionmethod of the regenerated concrete block material based on a system of 'regenerated powder-regenerated coarse aggregate-regenerated fine aggregate'. The regenerated concrete block material prepared byusing the system of 'regenerated powder-regenerated coarse aggregate-regenerated fine aggregate' has excellent mechanical strength, the strength level range is 5-50 MPa, and the requirements of the concrete block material strength under different working conditions are met. The invention provides a novel developing route for the resource recycling of construction wastes. The performance of the regenerated powder is similar to the performance of mineral admixture such as fly ash and the like, the activity is higher, secondary hydration reaction of a cement-based material can be promoted to relieve the current situation of insufficient supplying of mineral admixture such as fly ash and the like, and the regenerated concrete block material has higher economic benefit and social benefit.

Owner:TONGJI UNIV

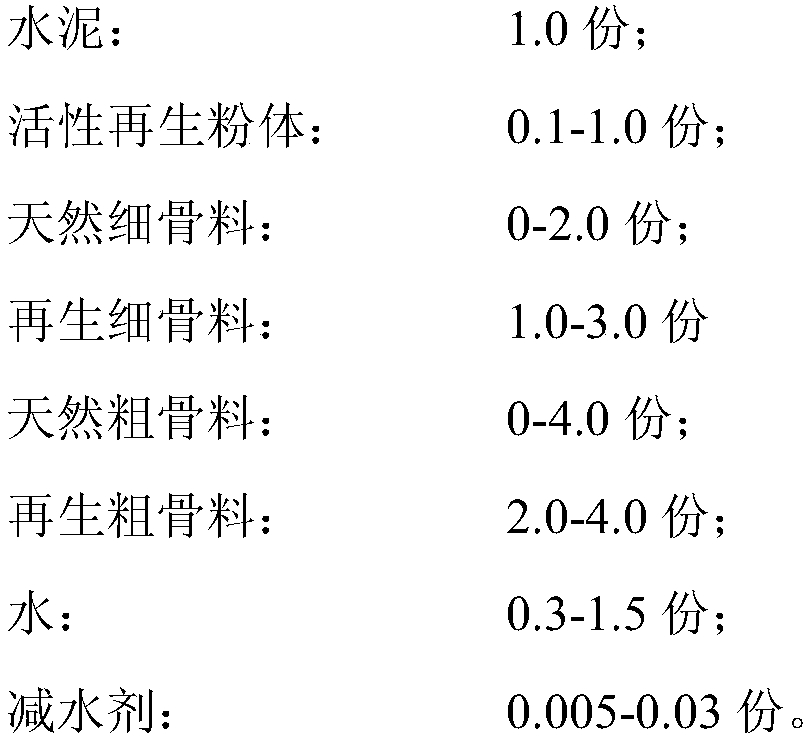

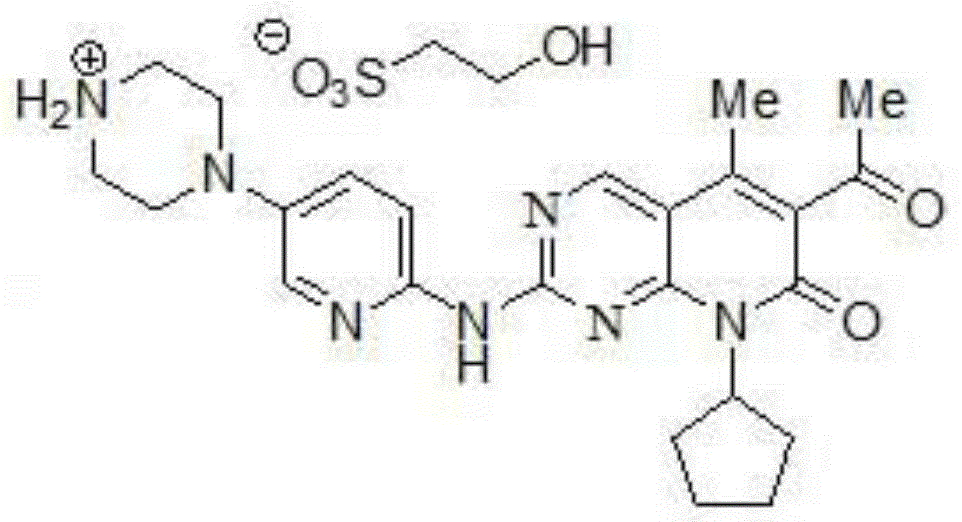

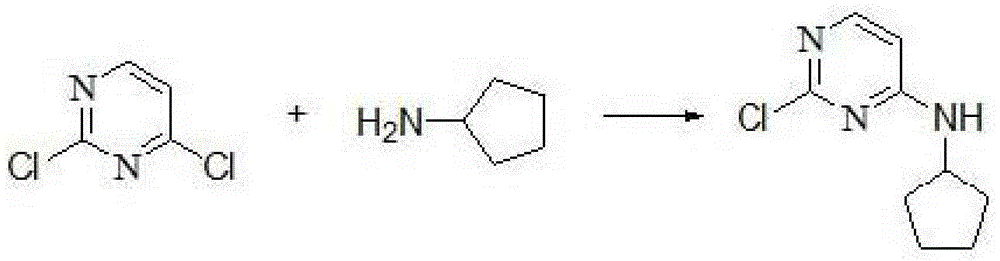

Palbociclib preparation method

InactiveCN104910149ASave raw materialsReduce manufacturing costOrganic chemistryCarboxylic acidTert butyl

The present invention is a palbociclib preparation method, a solid A is obtained by substitution reaction of 2, 4-dichloro pyrimidine and cyclopentyl amine, a solid B is obtained by dehydration reaction of 2,2-diacetyl-acetic acid and the solid A, a solid C is obtained by cyclization reaction of the solid B, a solid D is obtained by reaction of the solid C and 4-(6-amino-pyridin-3-yl)-piperazine-1-carboxylic acid tert-butyl ester, and palbociclib is obtained by salt-forming reaction of the solid D and ethylenehydrinsulfonic acid, the palbociclib preparation method comprises five steps, compared with the prior art, the steps are less, and comprise no step restricting enlargement of the process, the raw material is cheap, the use of expensive palladium reagents is avoided, manufacturing cost is lower; at the same time, use of bromine causing greater environmental pollution impact is avoided, and the preparation method meets the requirements of green and sustainable development.

Owner:上海百奇医药科技有限公司

Cellulose nanofibril aerogel loaded with photocatalyst and preparation method thereof

ActiveCN106492847AEasy to recycleInhibit growthGas treatmentDispersed particle separationCelluloseChloride salt

The invention discloses a cellulose nanofibril aerogel loaded with a photocatalyst and a preparation method thereof. The preparation method comprises the steps of: (1) dissolving bismuth nitrate in a cellulose nanofibril suspension liquid, and mixing the substances evenly to obtain a mixed solution; (2) drying the mixed solution obtained in step (1) to obtain cellulose nanofibril aerogel loaded with bismuth ions; (3) dissolving a soluble bromide salt and a soluble chloride salt in deionized water, stirring the substances fully to obtain a halide salt solution; and (4) impregnating the cellulose nanofibril aerogel loaded with bismuth ions obtained in step (2) in the halide salt solution obtained in step (3), then taking the cellulose nanofibril aerogel out for drying, and conducting calcinations, thus obtaining the cellulose nanofibril aerogel loaded with the photocatalyst. The aerogel can achieve catalytic degradation of organic matters under visible light, also has high light utilization rate and good photocatalytic effect, and the nano-photocatalytic material is easy for recycling.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Preparation method for functional wood capable of degrading organic pollutants through photocatalysis

ActiveCN106493810AGood degradation effectStrong catalytic degradation abilityGas treatmentDispersed particle separationPhotocatalytic degradationIon

The invention discloses a preparation method for functional wood capable of degrading organic pollutants through photocatalysis. The preparation method comprises the following steps that wood is subjected to pretreatment, internal pores of the wood are gotten through, and hydroxyl on the surface of the wood is exposed; bismuth nitrate is taken to be dissolved in an acid solution, then, coupling agents are added, stirring is conducted, and a mixed solution is obtained; soluble iodized salts and soluble chlorate are taken to be dissolved in water, stirring is conducted for dissolving, and a halide salt solution is obtained; the pretreated wood is soaked into the mixture solution, subjected to pressurized soaking, taken out and dewatered, and the wood adsorbed with bismuth ions is obtained; the wood adsorbed with the bismuth ions is soaked into the halide salt solution, subjected to pressurized soaking, taken out and subjected to vacuum drying, and then the functional wood capable of degrading the organic pollutants through photocatalysis can be obtained. The functional wood prepared through the method is high in light use ratio, can effectively degrade the organic pollutants under visible light radiation and is good in degradation effect.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

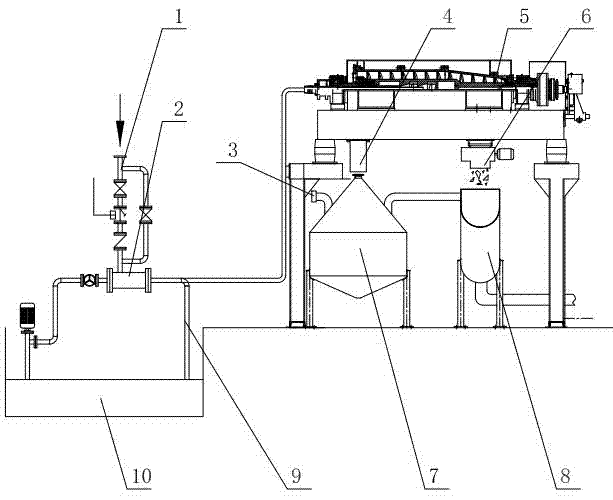

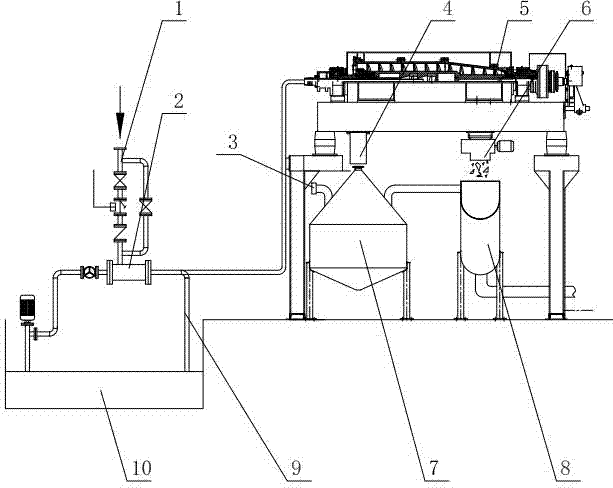

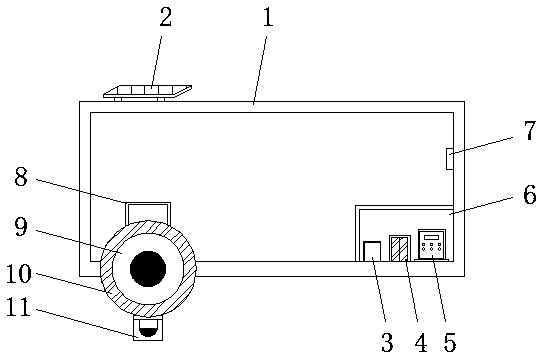

Kitchen waste oil-water-solid separation device of kitchen waste

InactiveCN103086557AIncrease pressureGuaranteed to workFatty/oily/floating substances removal devicesMultistage water/sewage treatmentProduction lineInjection port

The invention discloses a kitchen waste oil-water-solid separation device consisting of a steam mixing section, a solid-liquid separation section and an oil-water separation section, wherein the steam mixing section is provided with a steam-water mixer; high-temperature steam is input from the steam inlet of the steam-water mixer; the absorption inlet of the steam-water mixer is communicated with a slag-liquid mixing groove; the injection port of the steam-water mixer is communicated with the input end of a solid-liquid separation machine; and the liquid exhaust port of the solid-liquid separation machine exhausts to an oil-water separator. According to the invention, the steam-water mixer for heating directly on a pipeline mixes high-temperature steam in crushing slag liquids, not only can the operation continuity be ensured, but also the whole treatment can be operated in a production line, continuity and scale mode, and moreover, mixed liquids output from the injection port has high temperature and high pressure, and enter the solid-liquid separator directly for solid-liquid separation, and additional delivery equipment is not required; and the efficiency is high, and the separation quality is good.

Owner:WUXI SAIYA ENVIRONMENTAL PROTECTION TECH

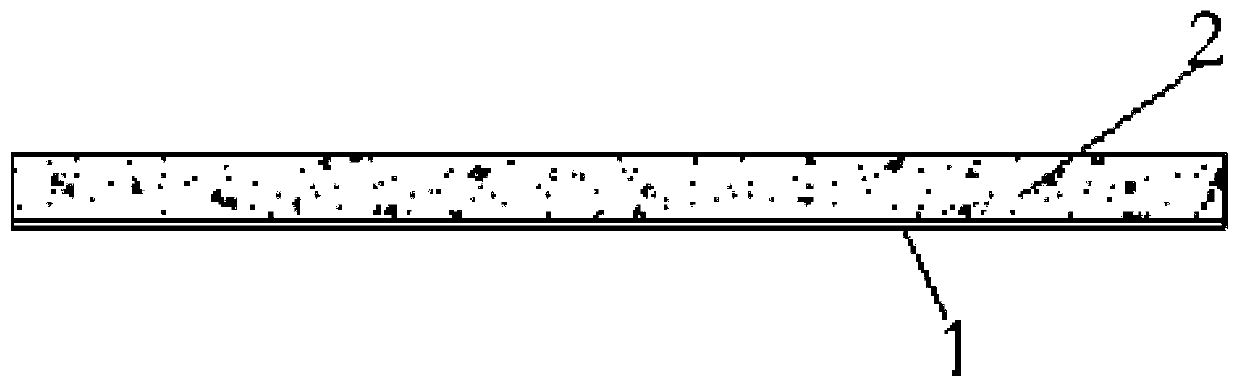

Hybrid fiber concrete prefabricated laminated slab and preparation method thereof

InactiveCN111268969AIncreased durabilityGood compatibilityFloorsSurface layering apparatusPolyvinyl alcoholRebar

The invention discloses a hybrid fiber concrete prefabricated laminated slab and a preparation method thereof. The hybrid fiber concrete prefabricated laminated slab comprises a bottom plate fiber concrete layer, and a post-pouring layer is arranged on the bottom plate fiber concrete layer; the bottom fiber concrete layer comprises cement, fly ash, silica fume, sand, a water reducing agent, steelfibers, polyvinyl alcohol fibers and water; the post-pouring layer is formed by pouring common reinforced concrete; the hybrid concrete slab is arranged in the lower tension area, the advantages of high tensile strength and good ductility of the hybrid concrete are effectively played, the upper part is pressed by adopting the common reinforced concrete, and the characteristics of the two types ofconcrete are fully played; the steel fibers are doped into the hybrid fiber concrete so that the later strength and toughness of the concrete are effectively enhanced; the thickness of the laminated slab is reduced, the self-weight is reduced and the cost is saved, the manufacturing process is simple, and application and popularization are facilitated.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

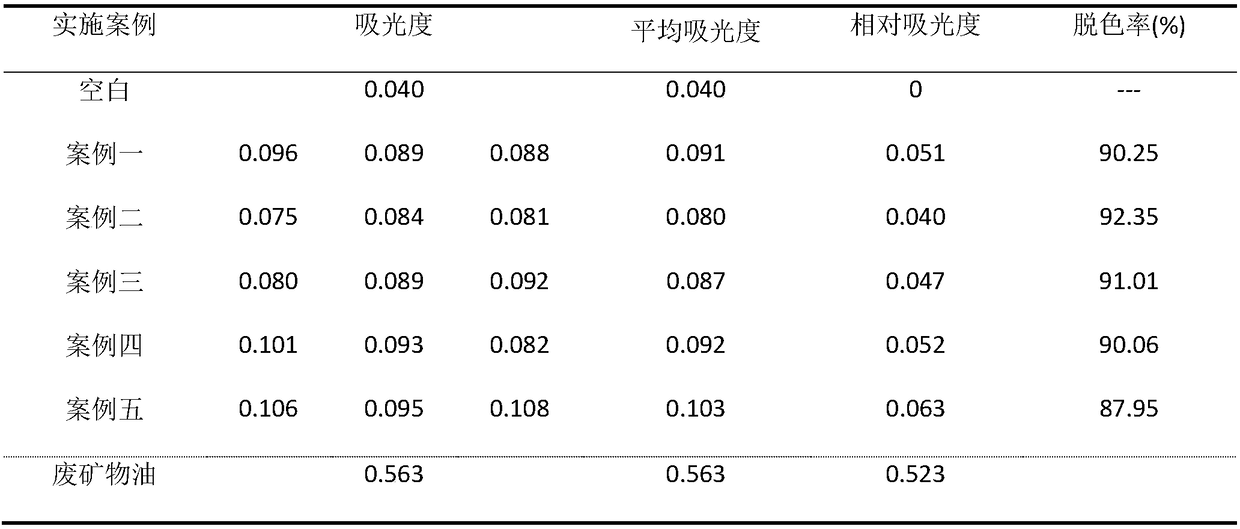

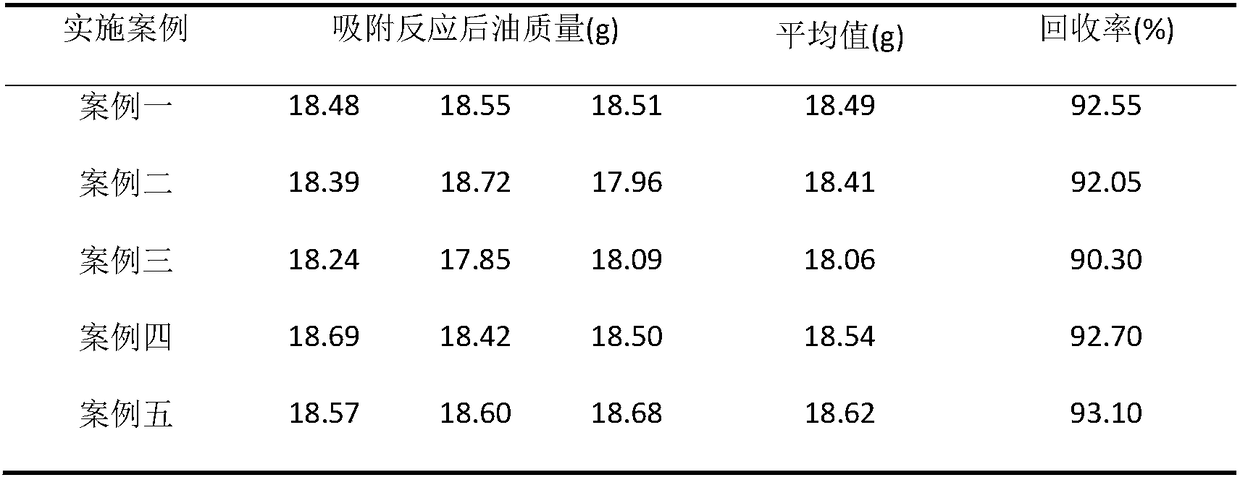

Method for regenerating waste lubricating oil by combining solvent extraction with composite metal oxide adsorbent

The invention discloses a method for regenerating waste lubricating oil by combining solvent extraction with a composite metal oxide adsorbent. The method comprises the steps: loading waste lubricating oil to be regenerated into a container, placing in a constant temperature drying box, depositing for at least 12 h, and removing primary upper clear oil; then adding an organic solvent to the primary upper clear oil, carrying out extraction and refining treatment, cooling the obtained oil-containing mixture to room temperature, then depositing the oil-containing mixture for at least 2 h, then removing secondary upper clear oil, next taking the secondary upper clear oil, mixing with the composite metal oxide adsorbent to form a reactant system, controlling the temperature of the reactant system to 60-90 DEG C, and decolorizing the secondary upper clear oil for 20-40 min; and finally, separating to remove a compound metal oxide decolorizer, and thus obtaining regenerated base oil. Qualityindexes of the waste oil treated by the method meet the requirement standards of the base oil, an acid-free and alkali-free process is adopted throughout the process, the yield of the regenerated oilis high, the repeated utilization rate of the adsorbent is high, and the requirements of green sustainable development are met.

Owner:SHANGHAI UNIV

Close-fit sportswear fabric and method for manufacturing same

InactiveCN105755642ARaise quality standardsMeet the standardsBiochemical fibre treatmentLiquid repellent fibresMoisture absorptionEngineering

The invention discloses a close-fit sportswear fabric and a method for manufacturing the same. The close-fit sportswear fabric and the method have the advantages that three types of fibers are blended and woven, ramie fibers are modified and treated, accordingly, the close-fit sportswear fabric is excellent in moisture absorption performance and breathability, is antibacterial and has functions of inhibiting bacteria and adsorbing toxic and harmful substances, and necessary waterproof, non-ironing requirements and the like on outdoor sports jackets further can be met; the blended fabric is made of natural fibers and renewable fibers, is made of sufficient raw materials and has broad markets, and green and sustainable development requirements vigorously advocated by China can be met.

Owner:德清县新鑫达丝绸炼染有限公司

Outdoor work garment fabric and preparation method thereof

InactiveCN105755643AHarm reductionRestore drapeWeft knittingWarp knittingEngineeringSustainable development

The invention discloses an outdoor work garment fabric and a preparation method thereof. By modification of ramie fibers, the fabric not only is light, abrasion resistant and excellent in breathability and moisture absorption performance but also has antibacterial and bacteriostatic functions and a toxic and harmful substance adsorption function and further meets requirements on water proofing, ultraviolet proofing and the like of outdoor work garment fabrics. The outdoor work garment fabric which is made from the ramie fibers is sufficient in raw material and extensive in market prospect and meets the requirement of green sustainable development which is advocated strongly nationally.

Owner:德清县新鑫达丝绸炼染有限公司

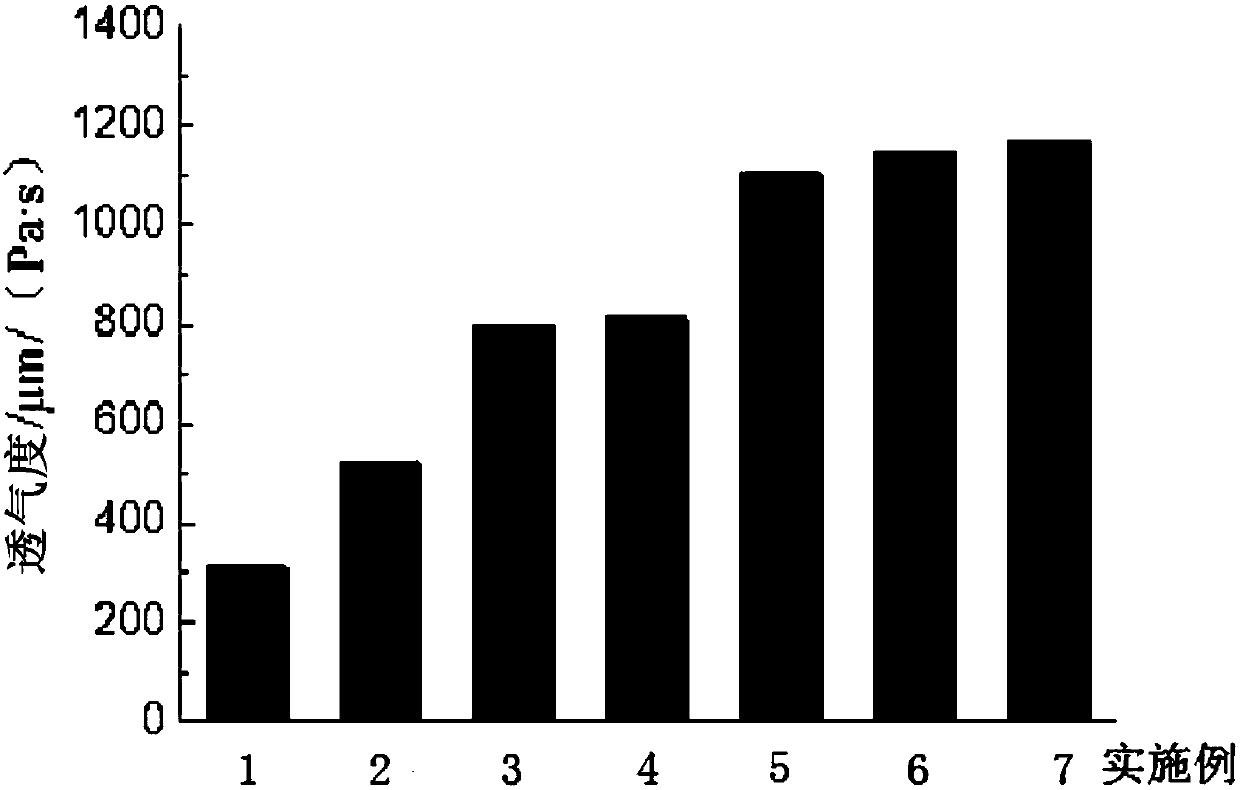

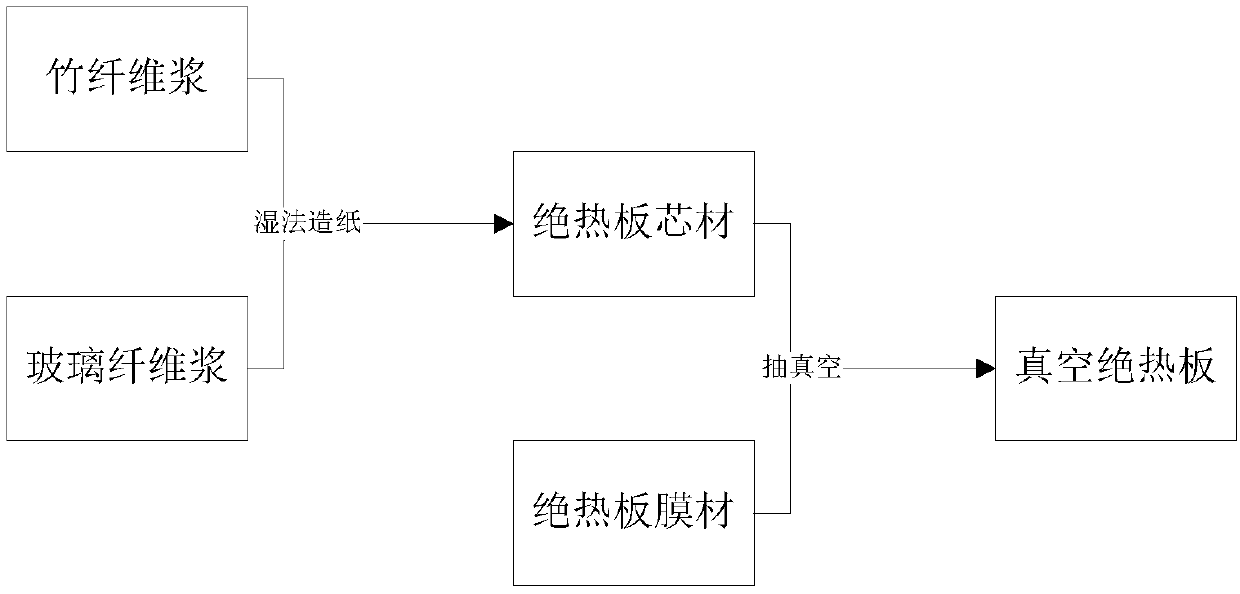

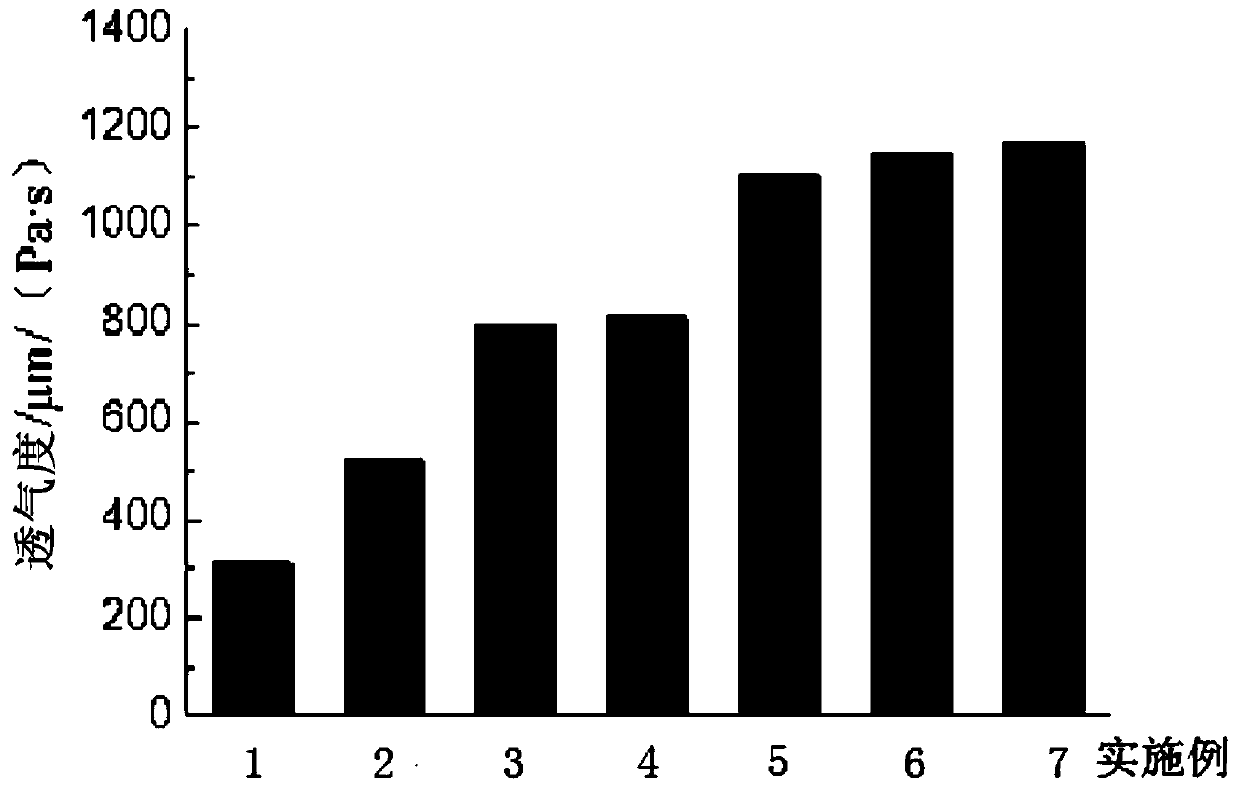

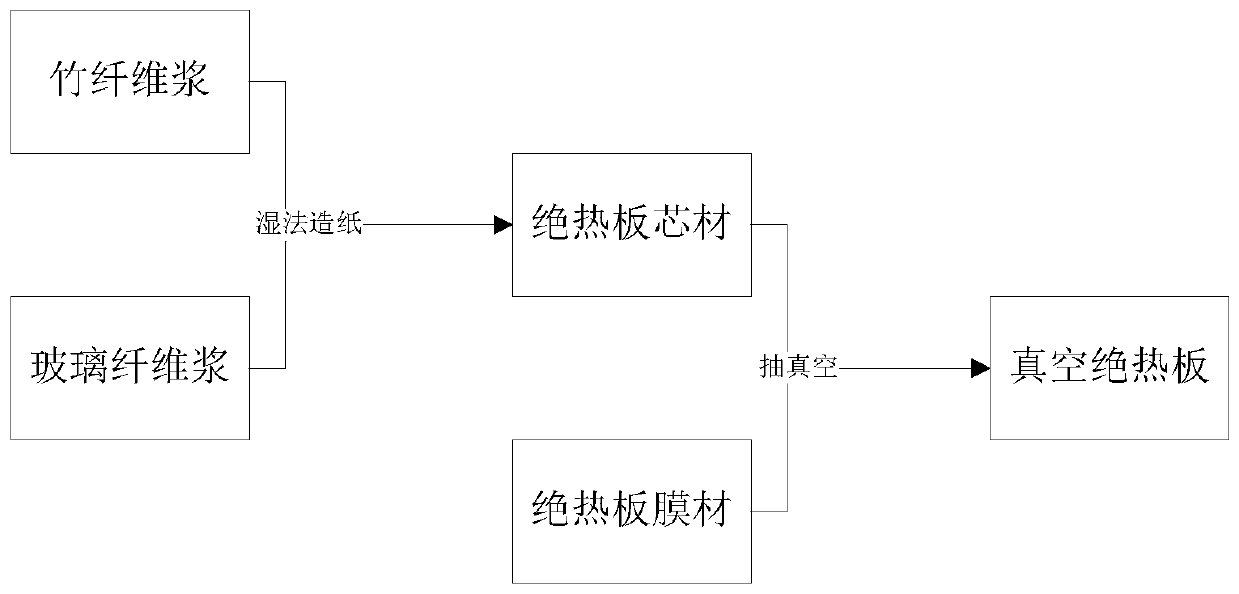

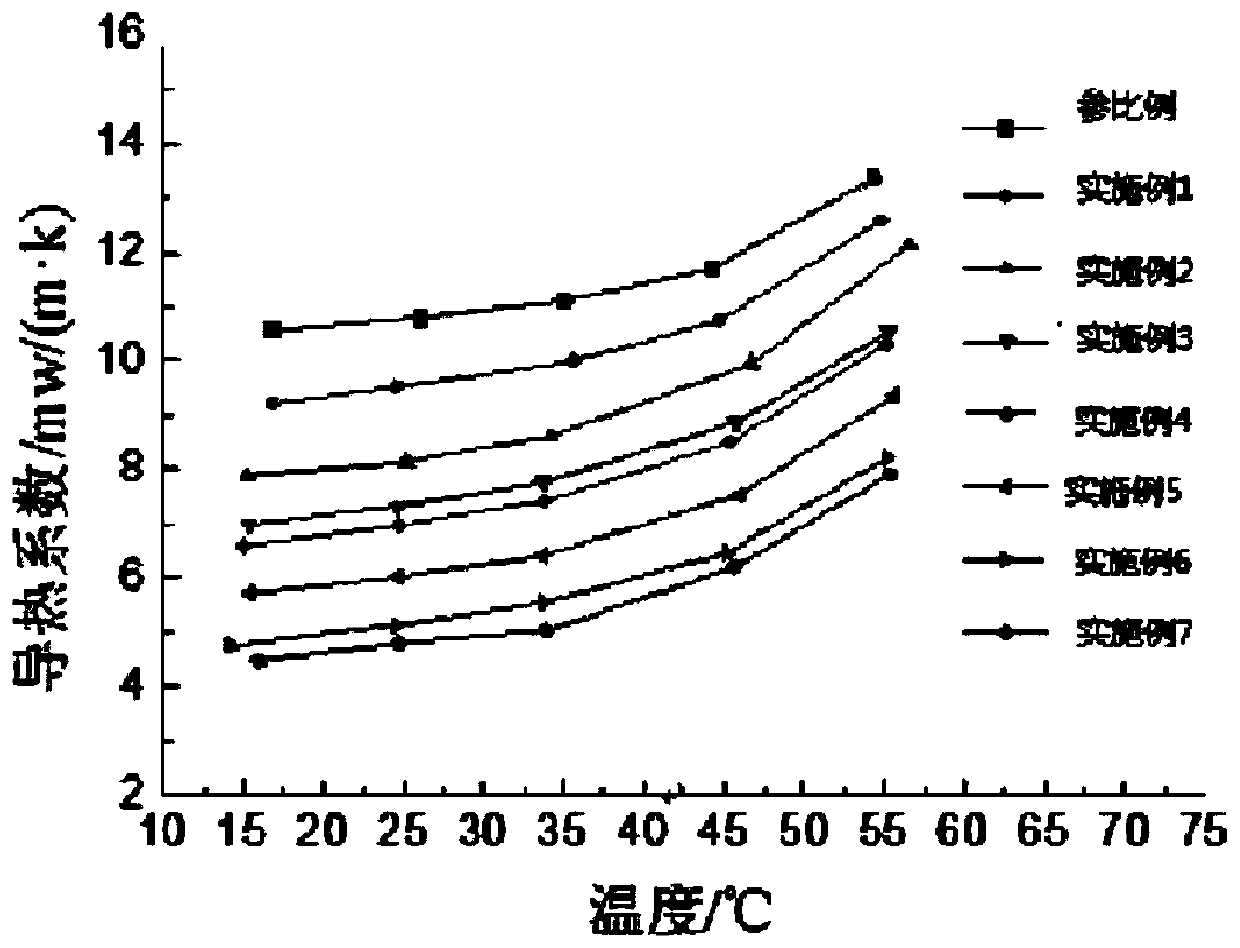

Vacuum thermal insulation plate core material, vacuum thermal insulation plate and preparation method of vacuum thermal insulation plate

ActiveCN107606396AReduce usageReduce pollutionThermal insulationPipe protection by thermal insulationGlass fiberFiber

A vacuum thermal insulation plate core material comprises bamboo fibers and glass fibers. A vacuum thermal insulation plate comprises the core material. By adoption of the technical scheme, the novelvacuum thermal insulation plate core material is prepared by mixing the bamboo fibers with the glass fibers, the use quantity of the glass fibers in the core material is reduced, the cost of the vacuum thermal insulation plate is reduced, energy saving and environment friendliness are achieved, the severe issues of environmental pollution and energy shortage brought by the development of the economy are relieved, and the national requirement of environment-friendly and sustainable development is better met.

Owner:FUJIAN AGRI & FORESTRY UNIV

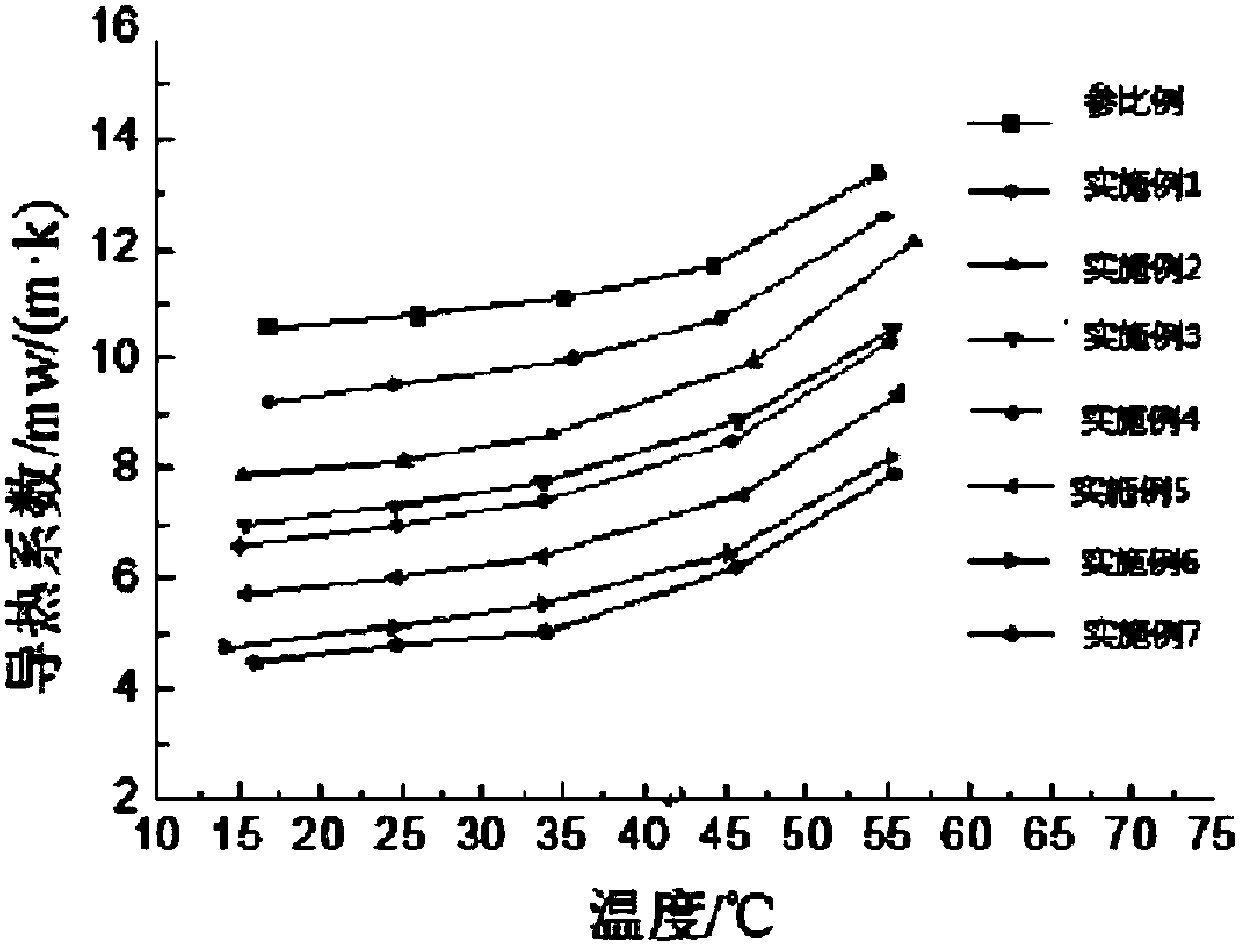

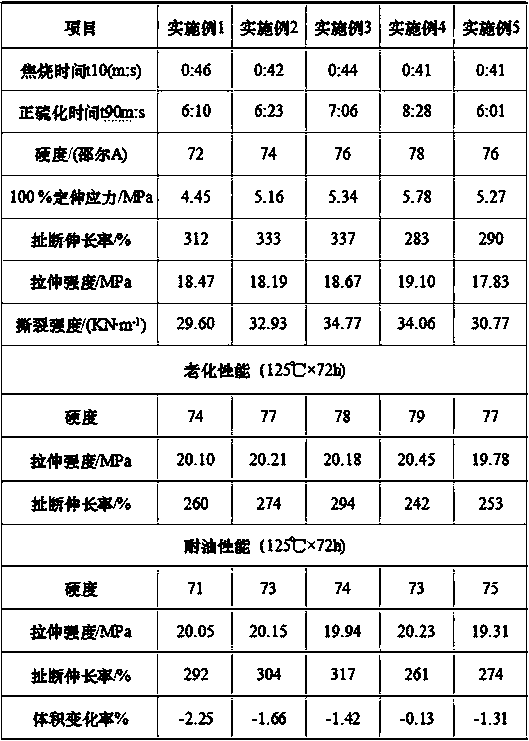

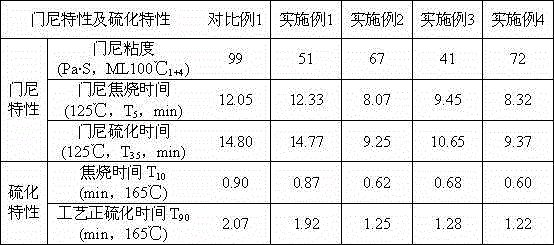

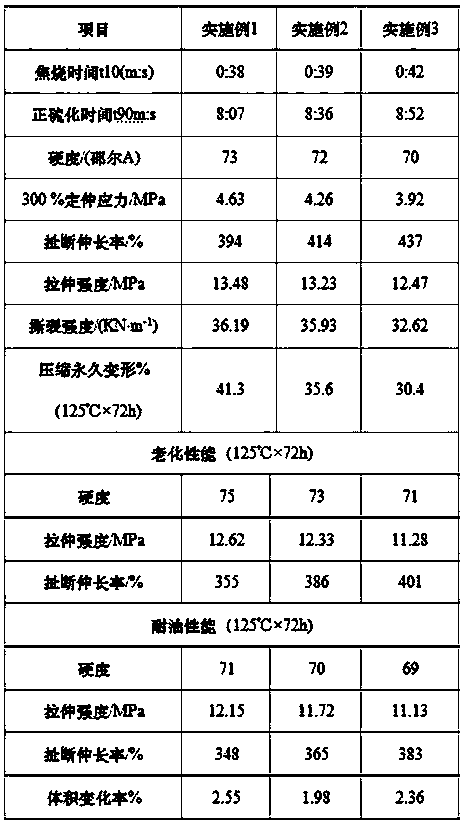

Highly-oil-resistant rubber-hose inner-layer rubber material filled with low-molecular-weight PPC premix and preparation method thereof

ActiveCN108467522AImprove mechanical propertiesImprove aging resistanceRubber materialPolymer science

The invention discloses a highly-oil-resistant rubber-hose inner-layer rubber material filled with a low-molecular-weight PPC premix. The highly-oil-resistant rubber-hose inner-layer rubber material comprises the following components in parts by mass: 80 parts of nitrile rubber, 20 parts of hydrogenated nitrile rubber, 50 to 63 parts of carbon black, 0 to 10 parts of alkaline white carbon black, 2.5 to 3.5 parts of a vulcanizing agent, 1.8 to 2.2 parts of a vulcanization auxiliary agent, 3 to 5 parts of zinc oxide, 1 to 2 parts of stearic acid, 2 to 3 parts of an anti-aging agent system, 4.4 to 22 parts of the low-molecular-weight PPC premix and 0 to 8 parts of a plasticizer. According to the invention, low-molecular-weight PPC is prepared into a premix, so use is convenient; meanwhile, the alkaline white carbon black is adopted to partially replace a traditional reinforcing agent namely carbon black, so mechanical properties, aging resistance and oil resistance of oil-resistant rubberhose inner-layer rubber are improved; the service life of a rubber hose is prolonged; cost and energy consumption of mixing are reduced; application of the low-molecular-weight PPC alleviates environmental pollution; greenhouse effect is reduced; and important significance of comprehensive utilization of carbon dioxide resources is realized.

Owner:常州苏橡橡塑制品有限公司

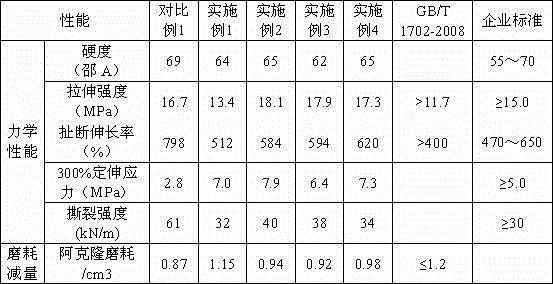

Colored hand cart tire rubber material filled with semi-wet modified attapulgite and preparation method of colored hand cart tire rubber material

ActiveCN105111521AImprove vulcanization efficiencyHigh mechanical strengthSpecial tyresRubber materialStearic acid

The invention provides a colored hand cart tire rubber material filled with semi-wet modified attapulgite. The colored hand cart tire rubber material comprises the following components in parts by mass: 70 parts of natural rubber, 30 parts of butadiene styrene rubber, 20-60 parts of semi-wet modified attapulgite, 0-25 parts of precipitated silica, 1.4-1.6 parts of a vulcanizing agent, 1.4-1.9 parts of an accelerant system, 5-8 parts of zinc oxide, 2-4 parts of stearic acid, 0-0.75 part of a white carbon black modifier, 3.5 parts of an anti-aging agent system, 4-6 parts of solid coumarone and 0.4-0.6 part of a colorant. The traditional rubber processing material and process are adopted, and the industrial-grade semi-wet modified attapulgite is applied to a colored hand cart tire, which is a development of a novel application field of attapulgite and is beneficial to the popularization and application of the semi-wet modified attapulgite to hand cart tire enterprises.

Owner:江苏欧廷高分子材料有限公司

A core material of a vacuum insulation panel, a vacuum insulation panel and a preparation method thereof

ActiveCN107606396BReduce usageReduce pollutionThermal insulationPipe protection by thermal insulationFiberGlass fiber

A vacuum thermal insulation plate core material comprises bamboo fibers and glass fibers. A vacuum thermal insulation plate comprises the core material. By adoption of the technical scheme, the novelvacuum thermal insulation plate core material is prepared by mixing the bamboo fibers with the glass fibers, the use quantity of the glass fibers in the core material is reduced, the cost of the vacuum thermal insulation plate is reduced, energy saving and environment friendliness are achieved, the severe issues of environmental pollution and energy shortage brought by the development of the economy are relieved, and the national requirement of environment-friendly and sustainable development is better met.

Owner:FUJIAN AGRI & FORESTRY UNIV

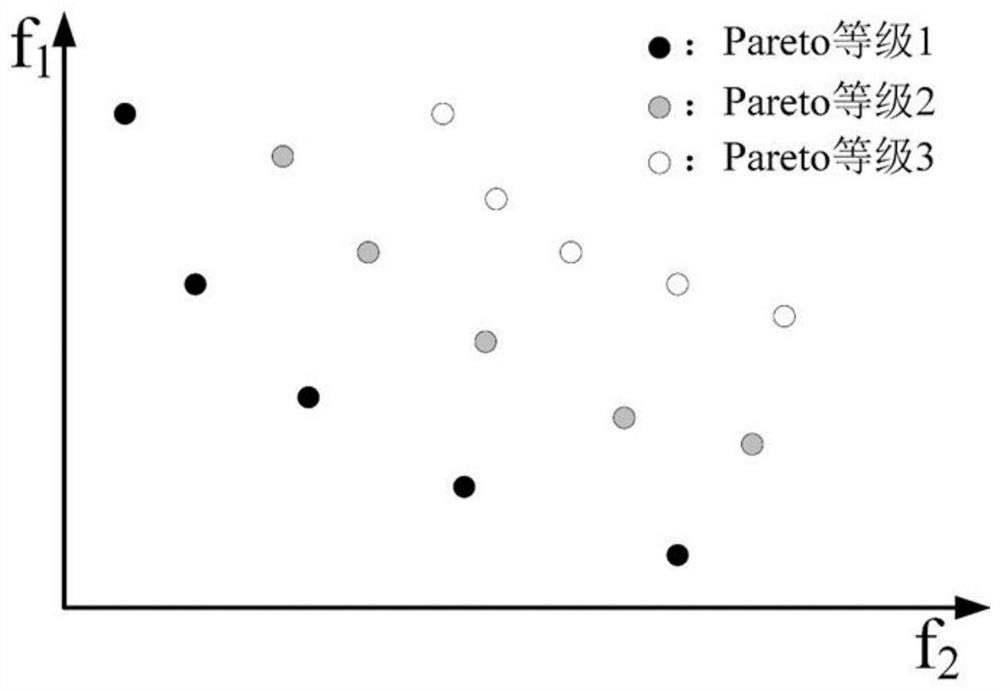

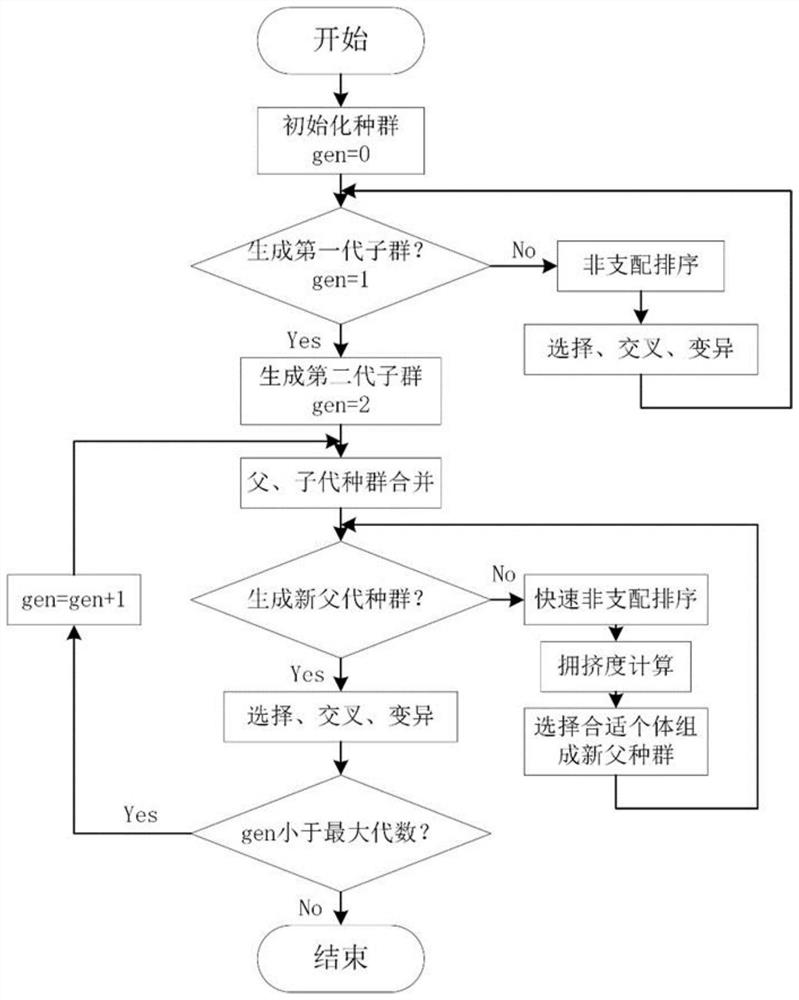

Gate dam group joint scheduling method and system based on improved elitism strategy genetic algorithm

ActiveCN113379117AImprove solution efficiencyImprove efficiencyGeneral water supply conservationForecastingTheoretical computer scienceGenetics algorithms

The invention provides a gate dam group joint scheduling method and system based on an improved elitism strategy genetic algorithm. The optimization efficiency and convergence speed in gate dam group multi-target joint scheduling model solving can be effectively improved. The gate dam group joint scheduling method is characterized by comprising the following steps: 1, establishing a model, a, determining an objective function, b, setting constraint conditions, and setting related variables to be non-negative; step 2, acquiring data of each parameter related to the model from historical data and actually measured data of the gate dam group; 3, substituting the data obtained in the step 2, and solving the model by adopting an improved elitism strategy genetic algorithm; and step 4, performing gate dam group joint scheduling according to a solving result of the model in the step 1 in the step 3.

Owner:WUHAN UNIV

Method for preparing oil absorbing and degrading material by waste keratins

InactiveCN103937772AHigh oil absorptionThe specific gravity of the sponge is smallMicroorganism based processesOn/in organic carrierSlagRoom temperature

The invention relates to a method for preparing oil absorbing and degrading material by waste keratins. The method comprises the following steps: (1) cleaning and drying the waste keratins to obtain clean objects, then, cutting the clean objects and then adding the cut objects into a solution to be dissolved, and filtering to remove residual slags to obtain a keratin solution; and (2) placing the keratin solution at room temperature to crosslink, filtering and drying to obtain a sponge sample, and adding a bacterial culture medium to immobilize bacteria to obtain the oil absorbing and degrading material. The method provided by the invention is low in cost,environmental friendly and free from secondary pollution in the technical process, has very significant scientific meaning and application value to the present world short of resources and energy resources, and further meets the concept of circular economy and the strategic demand of a conservation-minded society.

Owner:DONGHUA UNIV +1

High-flash-point safe alkyd anticorrosive coating and preparation process thereof

InactiveCN113755082ANo pollution in the processMeet the requirements of green and sustainable developmentSiccativesAnti-corrosive paintsBenzoic acidPolymer science

The invention provides a high-flash-point safe alkyd anticorrosive coating and a preparation process thereof. The anticorrosive coating prepared by the invention is compounded by taking renewable high-iodine-value oleic acid alkyd resin as an adhesive and taking a high-flash-point solvent, emulsified water, a high-efficiency drier, titanium dioxide, nano barium sulfate and the like as pigments and fillers; linseed oil with a high iodine value and basic alkyd resin are used for preparing the oleic acid alkyd resin with a high iodine value, so that the compactness, dryness and water resistance of the coating are synchronously improved; the linseed oil with a high iodine value is prepared by limiting the content ratio of maleic anhydride, linseed oil and azodiisobutyronitrile, so that the hydrolytic stability of the resin is improved; the basic alkyd resin with stable gloss, gloss retention, water resistance and outdoor durability is prepared by limiting the contents of maleic anhydride, linoleic acid, benzoic acid, tung linoleic acid, pentaerythritol and isophthalic acid; and the high-iodine-value oleic acid alkyd resin is modified by hollow titanium dioxide microspheres with the particle size of 250-300nm, so that the compactness of the coating is improved, and the corrosion resistance is greatly enhanced.

Owner:无锡市造漆厂有限公司

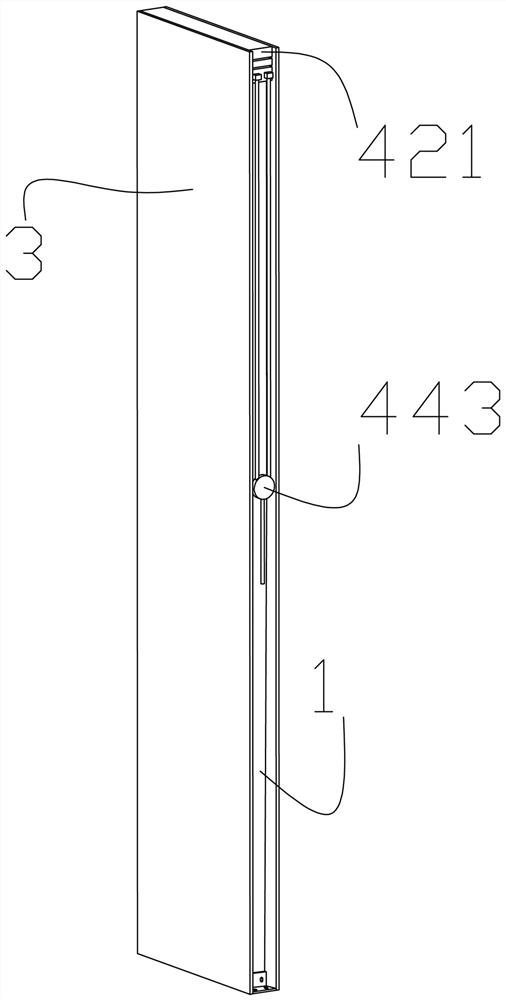

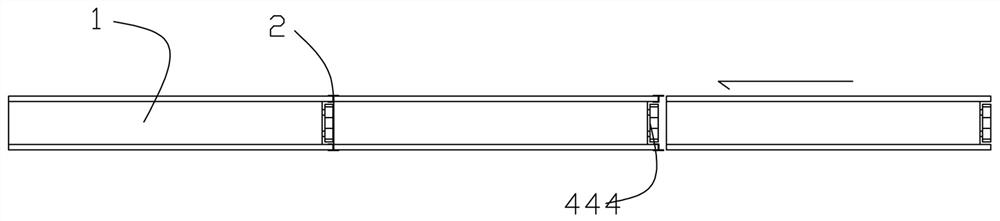

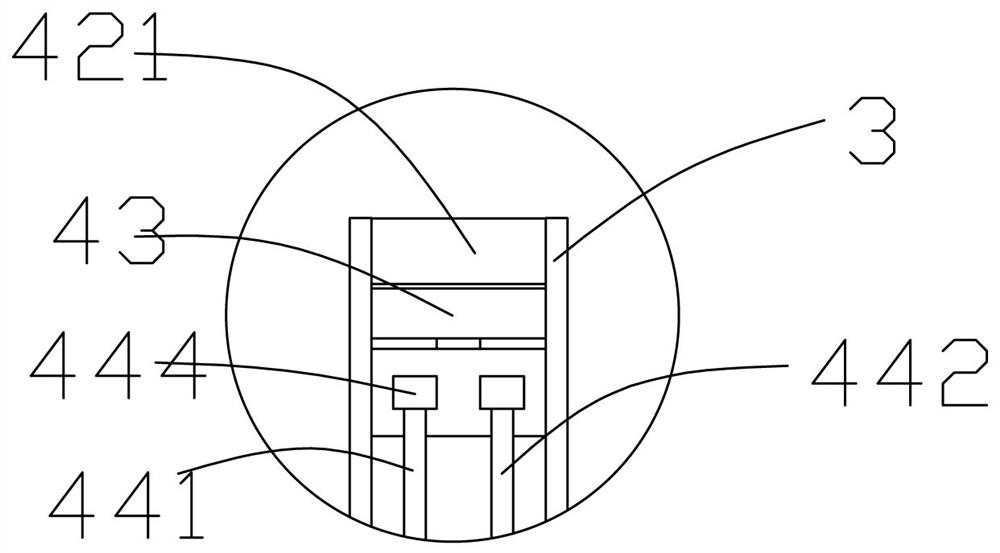

Pneumatic detachable movable partition wall and mounting method

PendingCN111926951ADoes not take up central main spaceImprove protectionWallsEngineeringStructural engineering

The invention discloses a pneumatic detachable movable partition wall and a mounting method. The pneumatic detachable movable partition wall is formed by splicing a plurality of partition sash modules. Each partition sash module comprises a partition sash frame, veneers arranged on the two sides of the partition sash frame, and a jacking assembly arranged at the top of the partition sash frame andused for erecting, locking and fixing the partition sash frame by adjusting the air pressure. According to the pneumatic detachable movable partition wall and the mounting method, air cylinder poweris adopted to replace traditional mechanical power, and a pneumatic device does not occupy the main central space of the partition sash modules; and replacement, disassembly and assembly are convenient, the definition requirements of the movable partition wall are better met, and meanwhile, damage to a product and the environment is avoided, the repeated utilization rate is higher, and the green sustainable development requirements are met.

Owner:ZHEJIANG YASHA DECORATION

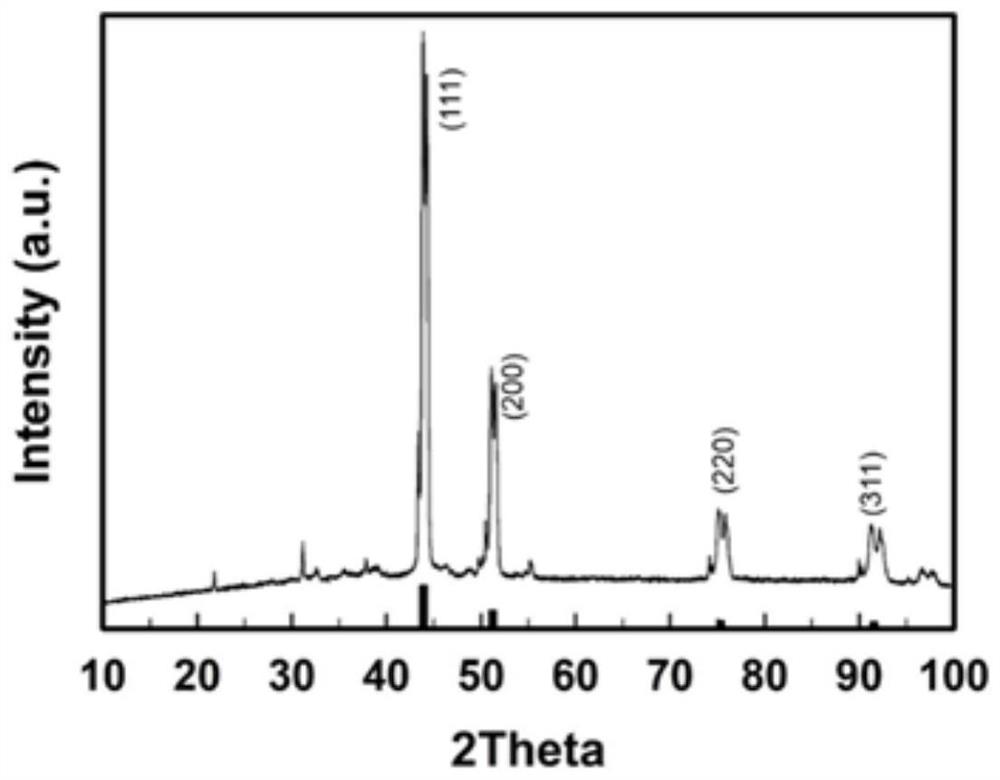

Electrolyzed water catalyst applicable to full pH range and preparation method thereof

PendingCN113913859AReduce corrosionHigh HER activityNon-noble metal oxide coatingsPtru catalystElectrolysed water

The invention discloses an electrolyzed water catalyst applicable to a full pH range and a preparation method thereof, and the preparation method comprises the following steps: firstly, preparing a copper-nickel organic complex through solvothermal, and then calcining the complex in an inert atmosphere to obtain a carbon-oxygen functional group modified non-noble metal CuNiCo-coated C=O alloy electrocatalyst. The catalyst has high HER activity in a neutral environment and a whole pH range, greatly reduces the cost, and is more suitable for industrial mass production.

Owner:四川启睿克科技有限公司

Light-color oil-resistant sealing ring rubber material and preparation method thereof

The invention discloses a light-color oil-resistant sealing ring rubber material, which is prepared from the following ingredients in parts by mass: 80 parts of nitrile rubber, 20 parts of acrylate rubber, 0 to 25 parts of precipitated white carbon black, 10 parts of basic white carbon black, 1.0 to 1.2 parts of vulcanizing agents TCY, 3 parts of acid acceptors, 5 parts of calcium carbonate, 2 parts of accelerants DTDM, 1.5 parts of accelerants CZ, 1.5 parts of accelerants TMTD, 1 part of KH-560, 0.8 part of PEG-4000, 3 to 5 parts of zinc oxide, 1.5 to 2 parts of stearic acid, 2 to 3 parts ofanti-aging agent system, 14 to 42 parts of low molecular weight PPC pre-mixed compounds and 0 to 6.7 parts of DOS. Boehmite and low molecular weight PPC are made into pre-mixed compounds; the medium resistance and pressure change performance of the light-color oil-resistant sealing ring rubber material are improved; the service life of the sealing ring is prolonged; meanwhile, the cost is reduced;the mixing process is improved; the application field of the low molecular weight PPC is expanded; the comprehensive utilization of resources is realized.

Owner:XUZHOU COLLEGE OF INDAL TECH

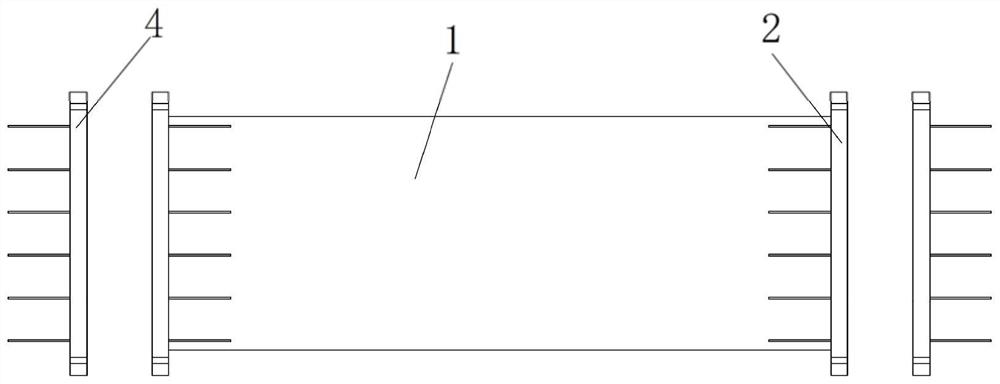

Prefabricated hybrid fiber concrete replaceable coupling beam and preparation method thereof

The invention provides a prefabricated hybrid fiber concrete replaceable coupling beam and a preparation method thereof. The prefabricated hybrid fiber concrete replaceable coupling beam comprises a coupling beam body, coupling beam anchoring parts are arranged at the two ends of the coupling beam body, and the coupling beam anchoring parts are connected with wall columns through connecting bolts;and the connecting beam body comprises hybrid fiber concrete and beam body reinforcing steel bars, and the hybrid fiber concrete wraps the outer sides of the beam body reinforcing steel bars. The hybrid fiber concrete is obtained by mixing cement, fly ash, silica fume, sand, a water reducing agent, steel fibers, polyvinyl alcohol fibers and water. The coupling beam body is formed by pouring the hybrid fiber concrete and the beam body reinforcing steel bars, and the toughness, bending resistance and impact resistance of the coupling beam concrete are effectively improved by doping steel fibers; by doping the polyvinyl alcohol fibers, the toughness, ductility and fracture resistance of the coupling beam concrete are effectively improved, and then the coupling beam body has good anti-seismicproperty; and the coupling beam anchoring parts are connected with the wall columns through the bolts, the coupling beam can be replaced, the manufacturing process is simple, and the cost is low.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

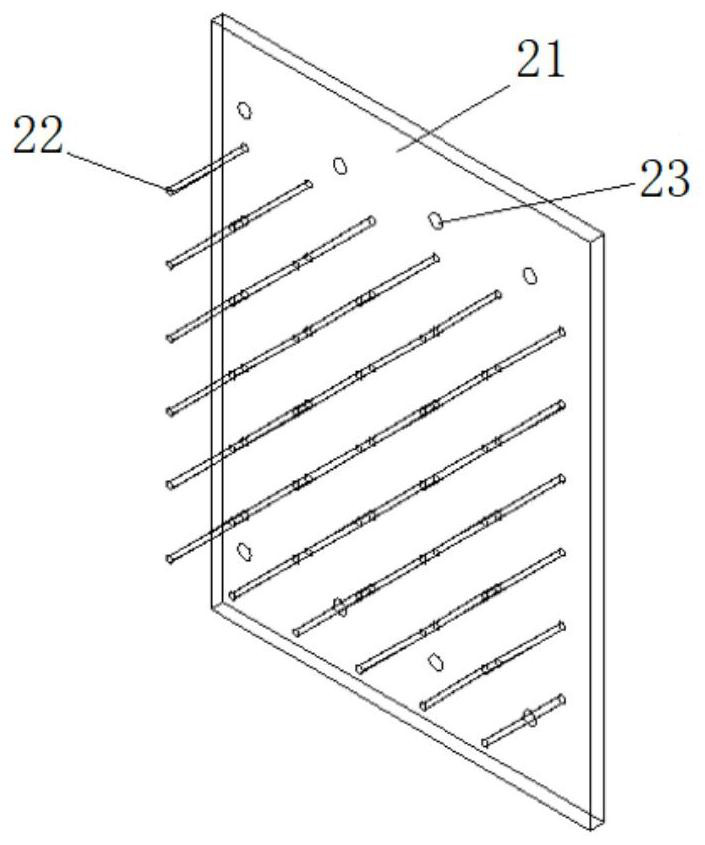

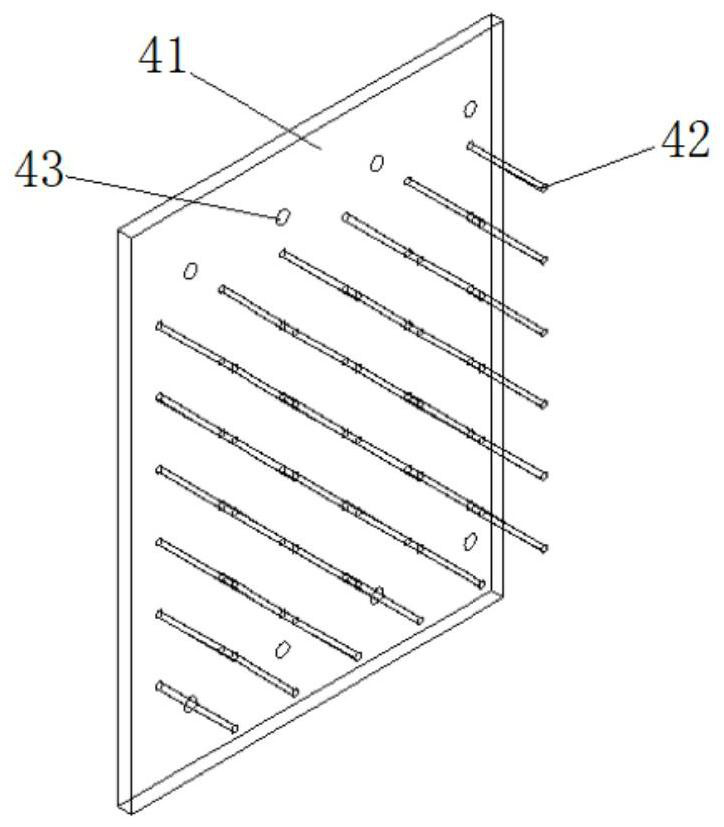

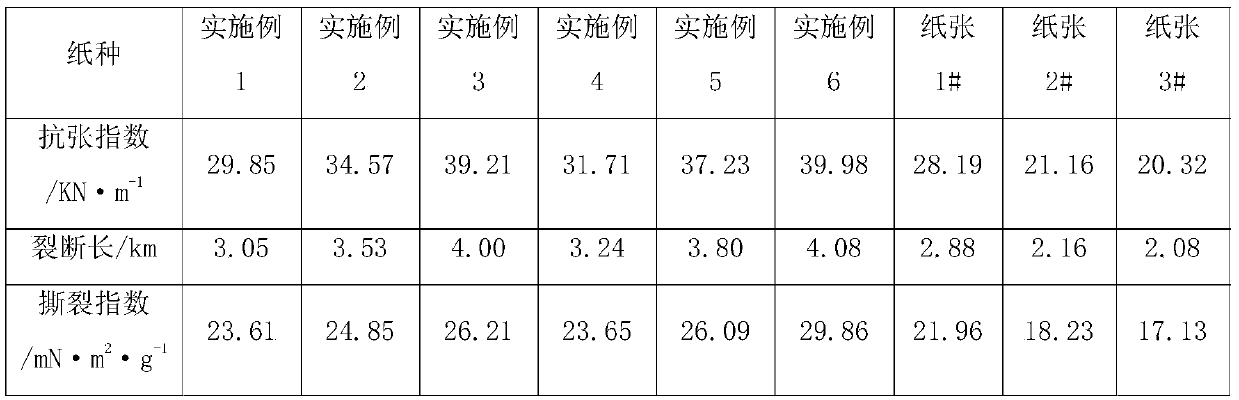

A kind of high-strength green environmental protection paper and its preparation method and application

ActiveCN107687111BImprove securityImprove stabilityNon-fibrous pulp additionFlexible coversFood packagingGuar gum

The invention discloses high-strength environment-friendly paper and a preparation method and application thereof. The preparation method of the high-strength environment-friendly paper comprises thefollowing steps: beating a bamboo pulp raw material to obtain SR bamboo pulp with the beating degree of 30-50 degrees; then pretreating the bamboo pulp or PLA fiber in a cationic guar gum solution; making paper from the pretreated bamboo pulp and the untreated PLA fiber, or the untreated bamboo pulp and the pretreated PLA fiber according to an absolute dry mass ratio of 7:3 to obtain the high-strength environment-friendly paper. According to the preparation method, through pretreatment in the cationic guar gum solution, the fiber strength of the bamboo fiber, the chemical polarity on the surface of the PLA fiber and the interfacial compatibility between fibers are improved, and ultimately, the physical properties of the paper are significantly improved. All used materials are environmentally friendly, and the obtained paper has relatively high strength and can be well applied to various fields of daily paper, food packaging paper and the like.

Owner:SOUTH CHINA UNIV OF TECH

Kitchen waste oil-water-solid separation device of kitchen waste

InactiveCN103086557BIncrease pressureGuaranteed to workFatty/oily/floating substances removal devicesMultistage water/sewage treatmentProduction lineInjection port

The invention discloses a kitchen waste oil-water-solid separation device consisting of a steam mixing section, a solid-liquid separation section and an oil-water separation section, wherein the steam mixing section is provided with a steam-water mixer; high-temperature steam is input from the steam inlet of the steam-water mixer; the absorption inlet of the steam-water mixer is communicated with a slag-liquid mixing groove; the injection port of the steam-water mixer is communicated with the input end of a solid-liquid separation machine; and the liquid exhaust port of the solid-liquid separation machine exhausts to an oil-water separator. According to the invention, the steam-water mixer for heating directly on a pipeline mixes high-temperature steam in crushing slag liquids, not only can the operation continuity be ensured, but also the whole treatment can be operated in a production line, continuity and scale mode, and moreover, mixed liquids output from the injection port has high temperature and high pressure, and enter the solid-liquid separator directly for solid-liquid separation, and additional delivery equipment is not required; and the efficiency is high, and the separation quality is good.

Owner:WUXI SAIYA ENVIRONMENTAL PROTECTION TECH

Soothing essential oil capable of activating collaterals, relaxing tendons, relieving pain and preparation method

InactiveCN113855780AImprove stabilityLess irritatingHydroxy compound active ingredientsAntipyreticCitrus volkamerianaCitrus Pectin

The invention provides soothing essential oil capable of activating collaterals, relaxing tendons, relieving pain and a preparation method. By limiting the components of the raw materials and adjusting a process, the stability of the essential oil is improved, and the irritation of the essential oil is reduced; cinnamon or ginger essential oil is extracted under the synergistic assistance of microwave-ultrasonic waves, so that the essential oil extraction efficiency is increased, and the extraction time is shortened; citrus pectin and citrus cellulose nanocrystals are extracted from citrus peel residues, and the citrus cellulose nanocrystals are modified, so that the volatility of the essential oil is slowed down, and the effectiveness of the essential oil is prolonged; or the citrus pectin is emulsified to improve the stability and oxidation resistance of the soothing essential oil; and the citrus pectin, chitosan powder and glycerin are used as a carrying system, an essential oil mixed solution is added. A concentration of the citrus pectin in a chitosan solution is limited to be 6.5-8 mg / mL, crosslinking of chitosan and the citrus pectin is completed, the antibacterial property of the essential oil is improved, and meanwhile, the stability of the soothing essential oil is greatly improved, the irritation is reduced, and the bioavailability is improved.

Owner:上海月月舒妇女用品有限公司

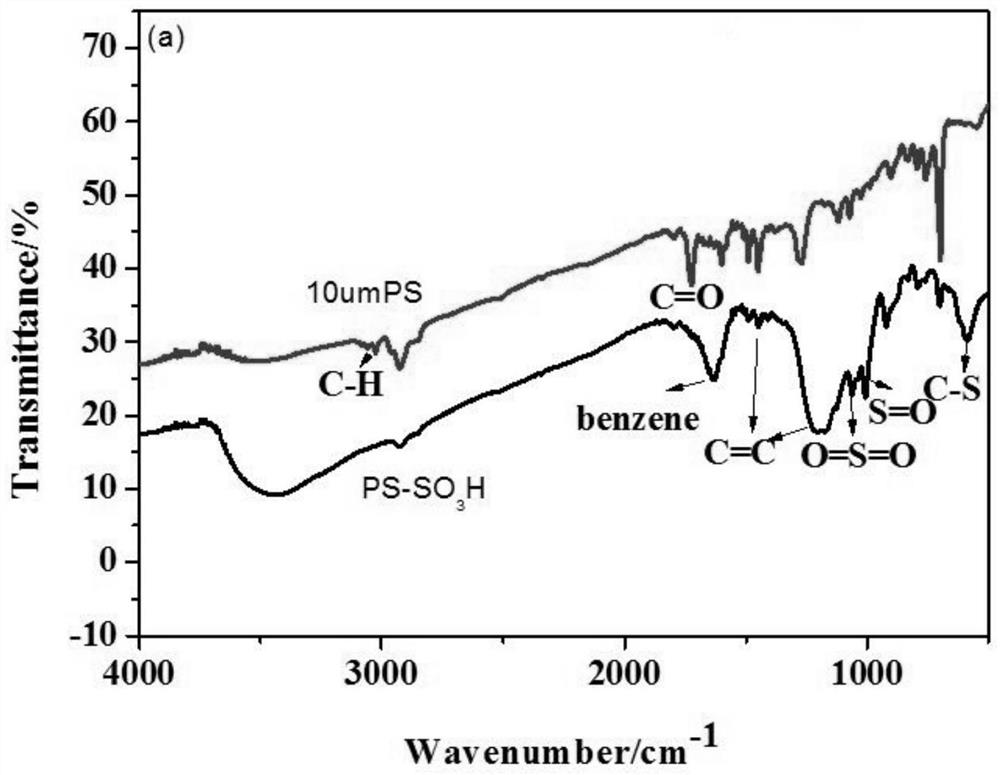

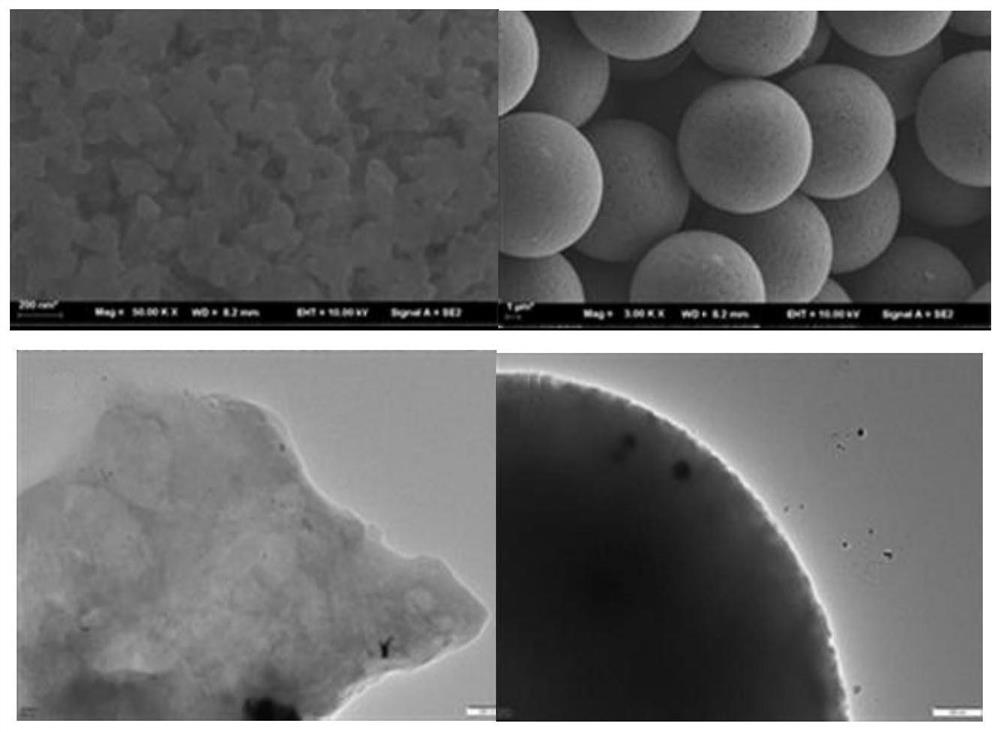

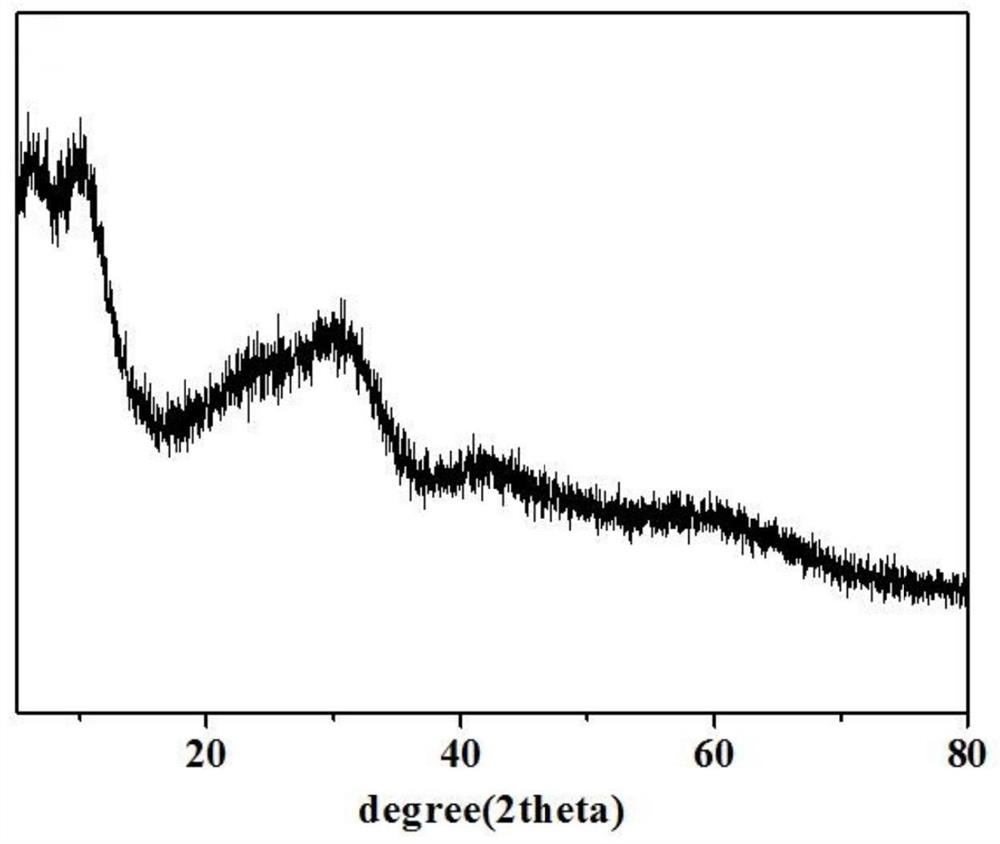

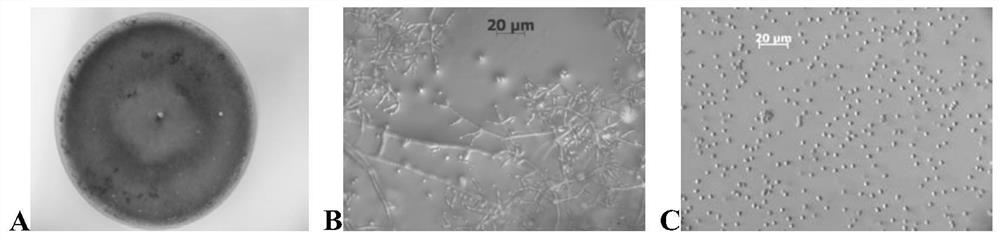

Preparation of sulfonic acid modified polystyrene microspheres and method for catalyzing conversion of furfuryl alcohol into ethyl levulinate by using sulfonic acid modified polystyrene microspheres

InactiveCN113578383AThe synthesis steps are simpleRaw materials are cheap and easy to getOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsFunctionalized polystyrenePolymer science

The invention discloses preparation of sulfonic acid modified polystyrene microspheres and a method for catalyzing conversion of furfuryl alcohol into ethyl levulinate by using the sulfonic acid modified polystyrene microspheres, and belongs to the technical field of heterogeneous catalysis. The sulfonic acid functionalized polystyrene microsphere catalyst is prepared in a specific emulsion polymerization swelling mode, synthesis steps are simple, raw materials are cheap and easy to obtain, the specific surface area is large, and the raw materials are easy to recover; meanwhile, the catalyst can also be used for catalytic reaction, furfuryl alcohol is reduced into ethyl levulinate in a high-selectivity mode, the catalytic performance cannot be reduced after repeated use, and the requirement for green and sustainable development is met.

Owner:JIANGNAN UNIV

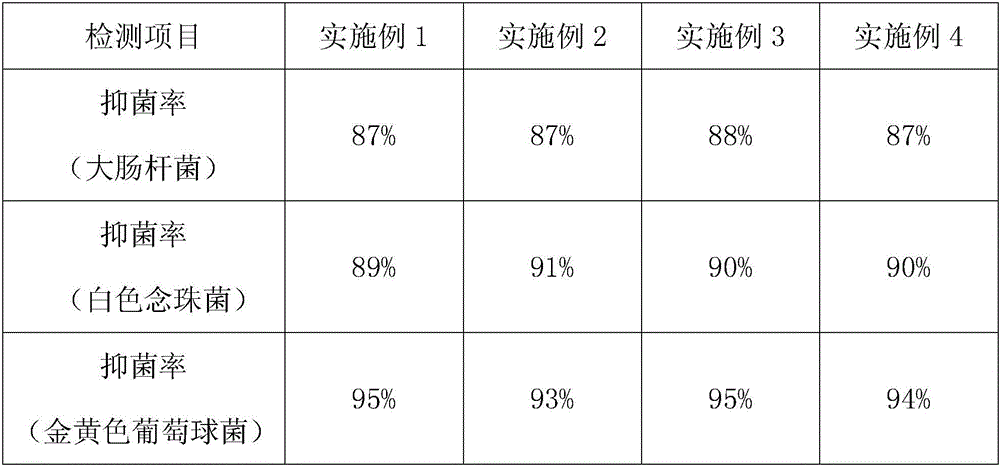

A high-strength polylactic acid functional composite material with antibacterial and electromagnetic shielding properties and its preparation method

ActiveCN112876827BImprove mechanical propertiesImprove antibacterial propertiesMagnetic/electric field screeningAnti bacteriaAntibacterial property

The invention discloses a high-strength polylactic acid functional composite material with antibacterial and electromagnetic shielding properties and a preparation method thereof. The composite material comprises the following components in parts by weight: 100 parts of polylactic acid, 2 to 6 parts of nano lignin, zinc oxide 5-15 parts per silver compound. The present invention is to carry out a controllable nanometerization of the original lignin, and prepare a zinc oxide / silver composite, and use the nano-lignin to disperse the zinc oxide / silver composite in situ and cast it with a polylactic acid solvent to prepare a composite with high mechanical properties. , excellent antibacterial performance and high-efficiency electromagnetic shielding function integrated polylactic acid composite material. The invention greatly broadens the scope of application of lignin, realizes the waste utilization of lignin resources, enables lignin to play the dual roles of enhancer and dispersant, and prepares a bio-based polylactic acid functional material with multiple functions based on integration, which can It meets the requirements of the harsh use environment in the market, and also conforms to the concept of green and sustainable development.

Owner:NANJING FORESTRY UNIV

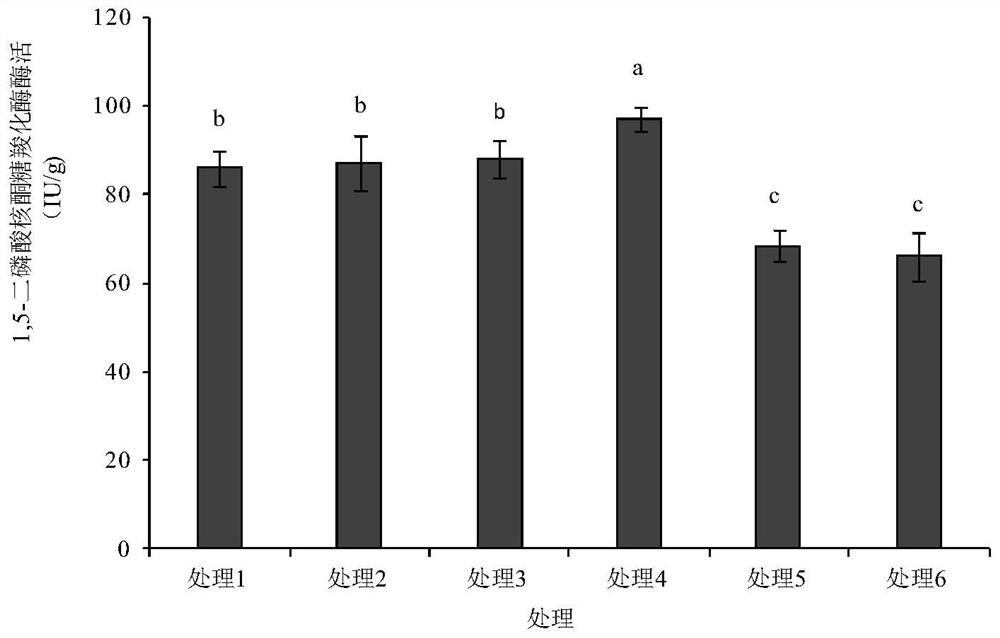

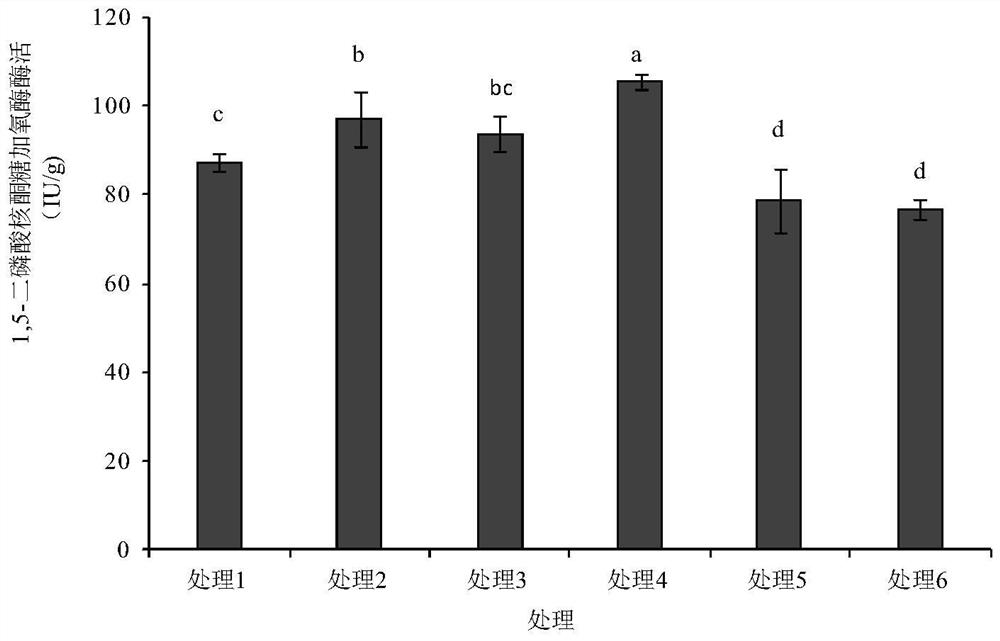

Trichoderma harzianum and application thereof as well as anthracnose-resistant microbial agent for promoting growth and development of strawberries

The invention discloses trichoderma harzianum, application thereof and a microbial agent capable of resisting anthracnose and promoting growth and development of strawberries. The invention discloses trichoderma harzianum CM-26, which is classified and named as trichoderma harzianum, and the preservation number of the trichoderma harzianum CM-26 is CGMCC (China General Microbiological Culture Collection Center) NO.40010. The microbial agent comprises a fermentation broth of the trichoderma harzianum, and can further comprise potassium alginate or / and a raspberry leaf extract. The microbial agent prepared from the trichoderma harzianum has remarkable effects in the aspects of promoting strawberry growth, promoting photosynthesis and preventing and controlling strawberry anthracnose.

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS

Low-carbon ferrochromium powder

InactiveCN104815980AThe ratio of ingredients is reliable and reasonableIncrease profitIron powderSulfur

The invention provides a low-carbon ferrochromium powder, which comprises the following components in percentage by weight: 60-80% of chromium powder, 0.03-0.045% of carbon powder, 0.85-1.28% of silicon powder, 0.015-0.032% of phosphorus powder, 0.015-0.028% of sulfur powder and the balance of iron powder. The low-carbon ferrochromium powder has the benefits as follows: the low-carbon ferrochromium powder is reliable and reasonable in component proportion and high in utilization ratio in the smelting process, generates few pollutants and impurities, has a better economic value and a better use value, and meets the requirements of sustainable development of environmental protection.

Owner:南通市金易焊接材料有限公司

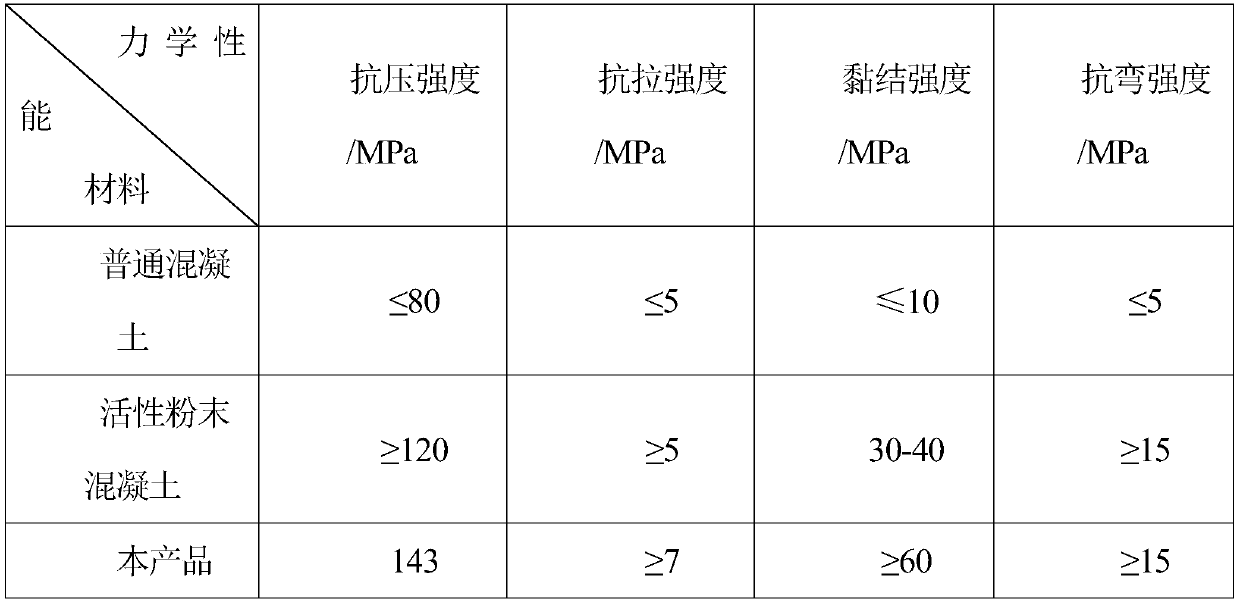

A kind of ultra-high strength and high bonding performance fiber reinforced concrete and its preparation method

A fiber-reinforced concrete with ultra-high strength and high bonding performance and a preparation method thereof. The fiber-reinforced concrete is prepared according to the following weight ratio: cement: water: silica fume: quartz powder: quartz sand 1: quartz sand 2: quartz sand 3: quartz Sand 4: Water reducer: steel fiber = 850: 180-200:180-210:200:127:190:222:317:20-30:150-250. The preparation method is as follows: first pour all the quartz sand, cement and silica fume into the mixer in sequence, and stir; add water and water reducing agent, stir; add steel fiber, stir, and discharge. Under the condition of outdoor curing for 28 days, the compressive strength of the concrete is ≥140MPa, and the bonding strength with the deformed steel bar is ≥60MPa, which greatly improves the compressive strength of the concrete, and the bonding strength between the steel bar and the concrete can greatly improve the reinforced concrete components. Reinforcement ratio, reducing the thickness of the protective layer, improving the bearing capacity and durability of structural components, has good economic benefits.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Transmission shaft detection device of auxiliary power device of vehicle

InactiveCN108152523AReasonable and perfect designEasy to knowLinear/angular speed measurementDrive shaftSolar power

The invention discloses a transmission shaft detection device of an auxiliary power device of a vehicle. The device comprises a vehicle body. A solar panel is arranged on the upper end of the vehiclebody. An electric control box is fixed inside the vehicle body. A charging conversion module electrically connected with the solar panel is arranged in the electric control box. The other side of thecharging conversion module is connected in series with a battery arranged inside the electric control box. The other side of the battery is provided with a single-chip microcomputer arranged inside the electric control box. An alarm fixed on the inner wall of the vehicle body is arranged above the electric control box. According to the invention, the solar panel, the charging conversion module, the battery, the single-chip microcomputer, the electric control box, the alarm, an angle displacement sensor, a drive shaft body, a fixation sleeve, an indicator lamp, an input interface and an outputinterface are arranged; the problem that detection and alarm devices of equipment are not completely set is solved; and the problem that solar power generation is unavailable is solved.

Owner:斯凯伦动力设备科技(兴化)有限公司

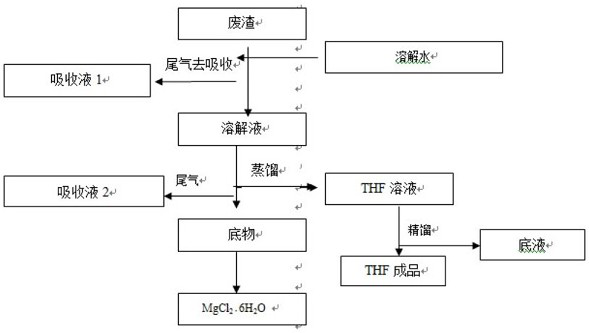

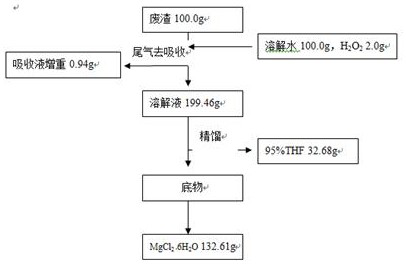

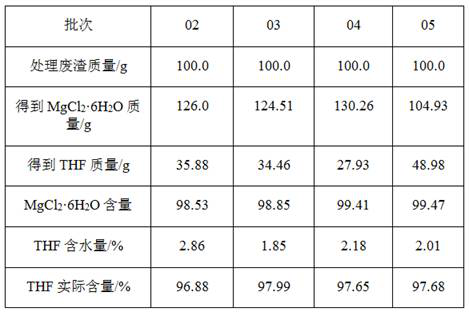

A method for recovering magnesium chloride and co-producing tetrahydrofuran from Grignard reaction waste residue

ActiveCN110002481BAvoid reactionControl the throw rateOrganic chemistryMagnesium chloridesHydration reactionEnvironmental engineering

The invention relates to a method for recovering magnesium chloride and co-producing tetrahydrofuran from Grignard reaction waste residue. The method comprises the following specific steps: step 1, dissolving: passing through N 2 Under the condition of protection, the waste residue of the complex is gradually added to the dissolved water, and a small amount of hydrogen peroxide is added to the dissolved water to oxidize trimethylphosphorus into stable trimethylphosphine, and a small amount of unreacted trimethylphosphorus can be Nitrogen enters the tail gas spray absorption device to be oxidized and absorbed; step 2, rectification and recovery of tetrahydrofuran: the dissolved material is rectified to recover tetrahydrofuran, and then a small amount of water is distilled to achieve the crystallization state of the substrate; step 3, magnesium chloride hexahydrate slices: bottom After the temperature of the product rises to a certain temperature, the solidification crystallization condition of magnesium chloride hexahydrate is reached, and it can be directly cooled and sliced to obtain magnesium chloride hexahydrate. By adopting the technical scheme of the invention, while recovering the magnesium chloride in the Grignard reaction waste residue, tetrahydrofuran can be co-produced to increase the recovery benefit.

Owner:SHANDONG WEIFANG RAINBOW CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com