A kind of ultra-high strength and high bonding performance fiber reinforced concrete and its preparation method

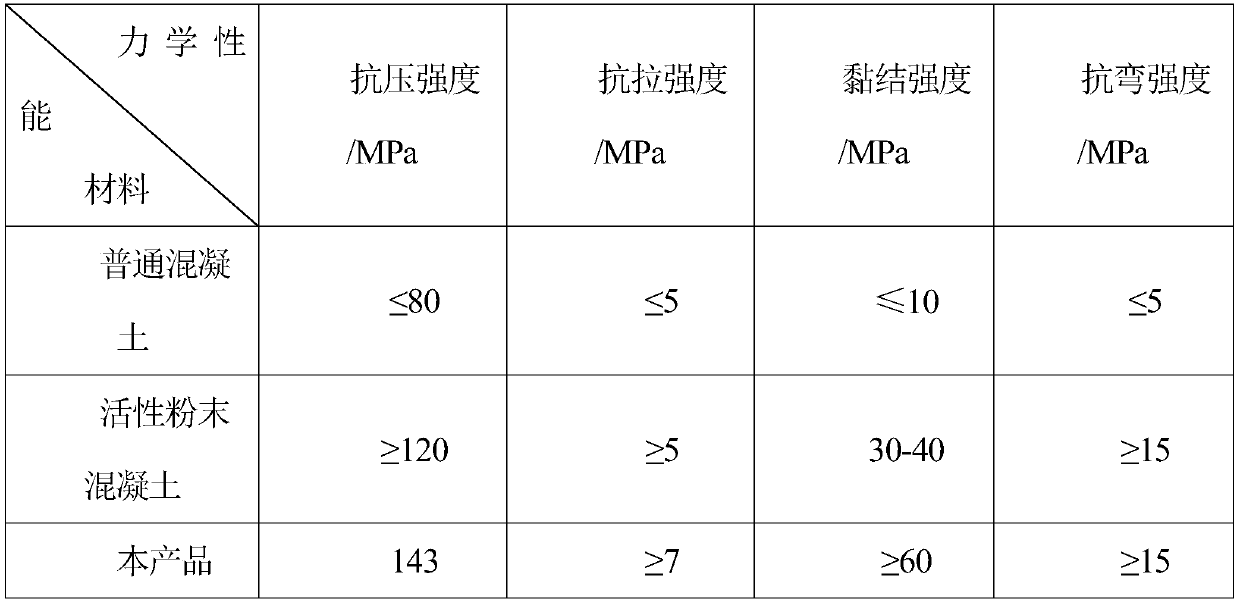

An ultra-high-strength, fiber-reinforced technology, applied in the field of building materials, can solve harsh environments such as exposure to seashores, freeze-thaw areas, and aggressive atmospheres, restricting the development and application of high-performance fiber-reinforced concrete, and the preparation technology is difficult to large-scale Promotion and other issues, to achieve high volume stability and economy, easy to promote, and improve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Raw materials

[0039] 1. Cement

[0040] Select P·O 42.5 cement with stable quality and good performance, and conduct an adaptability test with polycarboxylate concrete superplasticizer before use. The test method adopts the current building materials industry standard "Cement and Water Reducer Capacitance test method "JC / T 1083-2008 method, good compatibility with polycarboxylate concrete superplasticizer. The performance indicators of the selected cement meet the requirements of the relevant current national standards, and its alkali content is low, its heat of hydration is low, and its water demand is also low.

[0041] 2. Fine aggregate

[0042] Quartz powder and quartz sand 1: Quartz sand 2: Quartz sand 3: Quartz sand 4 Choose by mass ratio, SiO 2 The content is 99.72%, TFe 2 o 3 The content is 0.024%. The raw material quartz ore used in the production of quartz sand is a pure natural silicate mineral with hard texture, wear resistance and stable chemical...

Embodiment 2

[0066] Example 2: The mix ratio of the ultra-high strength and high bonding performance fiber reinforced concrete of this example is shown in the following table, and its raw material selection and preparation method are the same as in Example 1

[0067] Material cement water Silica fume Quartz powder Quartz sand 1 Quartz sand 2 Quartz sand 3 Quartz sand 4 Superplasticizer steel fiber Mass / kg 850 180 190 200 127 190 222 317 30 150

Embodiment 3

[0068] Example 3: The ratio of the ultra-high strength and high bonding performance fiber-reinforced concrete in this example is shown in the following table, and its raw material selection and preparation method are the same as in Example 1

[0069] Material cement water Silica fume Quartz powder Quartz sand 1 Quartz sand 2 Quartz sand 3 Quartz sand 4 Superplasticizer steel fiber Mass / kg 850 200 180 200 127 190 222 317 20 250

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com