Colored hand cart tire rubber material filled with semi-wet modified attapulgite and preparation method of colored hand cart tire rubber material

A technology for modifying attapulgite and attapulgite, applied in special tires, vehicle parts, tire parts and other directions, can solve the problems of easy aggregation, large specific surface area and high surface activity, and achieve high mechanical strength and high vulcanization efficiency. , The effect of good processing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

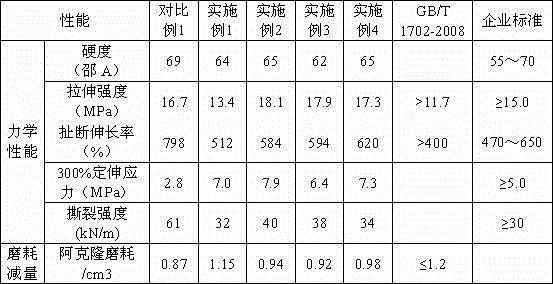

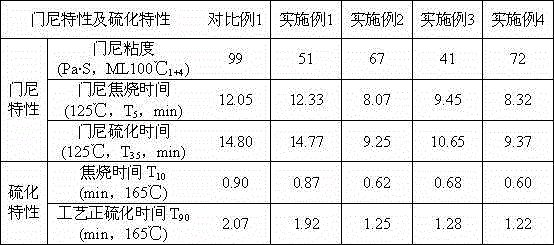

Embodiment 1

[0032] First adjust the roller distance of the double-roller mill to 0.1mm, add 70g of natural rubber thin pass plasticizing 8 times; adjust the roller distance to 0.5mm, add 30g of styrene-butadiene rubber thin pass until the mixing is uniform; adjust the roller distance to 2.0mm, When the rubber material is covered with rolls and there is a small amount of accumulated glue, add 6.0g plasticizer solid coumarone, 0.4g phthalocyanine green, 2.0g antioxidant SP-C, 1.5g antioxidant MB, 8.0g zinc oxide, 4.0g Stearic acid until mixed evenly; then add 60g of semi-wet modified attapulgite, 1.2g of accelerator NOBS, and 0.5g of accelerator DM in sequence; when the material is completely eaten, adjust the roller distance to 0.5mm, and pack it 4 times; Then adjust the roller distance to 2.5mm, add 0.2g accelerator TMTD and 1.4g insoluble sulfur in turn, adjust the roller distance to 0.2mm when the material is completely eaten, and pack it 6 times; control the mixing temperature at about ...

Embodiment 2

[0034] First adjust the roller distance of the double-roller mill to 0.1mm, add 70g of natural rubber thin pass plasticizing 9 times; adjust the roller distance to 0.5mm, add 30g of styrene-butadiene rubber thin pass until the mixing is uniform; adjust the roller distance to 2.0mm, When the rubber material is covered with rolls and there is a small amount of accumulated glue, add 5.0g plasticizer solid coumarone, 0.4g benzidine yellow, 2.0g antioxidant SP-C, 1.5g antioxidant MB, 7.0g zinc oxide, 3.5 Add 20g of precipitated white carbon black, 0.6g of solid polyethylene glycol, 40g of semi-wet modified attapulgite, 1.2g of accelerator NOBS, and 0.5g of accelerator DM in turn; When the material is complete, adjust the roller distance to 0.5mm, and pack the thin pass three times; then adjust the roller distance to 2.5mm, add 0.2g accelerator TMTD, 1.4g insoluble sulfur in turn, and adjust the roller distance to 0.2mm when the material is complete, thin Pack the mixture 7 times; c...

Embodiment 3

[0036] First adjust the roller distance of the double-roller mill to 0.1mm, add 70g of natural rubber thin pass plasticizing 10 times; adjust the roller distance to 0.5mm, add 30g of styrene-butadiene rubber thin pass until the mixing is uniform; adjust the roller distance to 2.0mm, When the rubber material is covered with rolls and there is a small amount of accumulated glue, add 4.0g plasticizer solid coumarone, 0.5g phthalocyanine blue, 2.0g antioxidant SP-C, 1.5g antioxidant MB, 5.0g zinc oxide, 2.0 G stearic acid until mixed evenly; then add 20g precipitated white carbon black, 0.6g solid polyethylene glycol, 20g semi-wet modified attapulgite, 1.2g accelerator NOBS; adjust the roller distance when the material is completely eaten to 0.5mm, pack 2 times with Botong; then adjust the roller distance to 2.2mm, add 0.2g accelerator TMTD and 1.4g insoluble sulfur in turn, adjust the roller distance to 0.2mm when the material is completely eaten, and pack 8 times with Botong; Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com