Kitchen waste oil-water-solid separation device of kitchen waste

A technology for kitchen waste and separation device, which is applied in the directions of liquid separation, separation method, grease/oily substance/float removal device, etc. Continuous processing operations, insufficient separation effect, etc., to achieve the effects of good environmental adaptability, significant economic benefits, and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

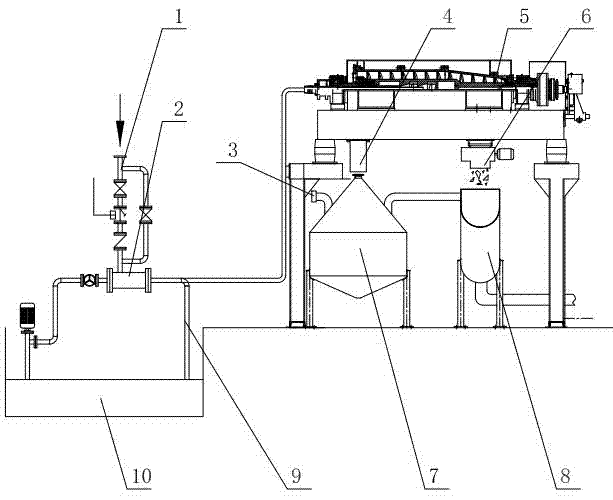

[0016] Such as figure 1 As shown, the oil-water-solid separation device for kitchen waste according to the present invention consists of three sections: a steam mixing section, a solid-liquid separation section and an oil-water separation section. After the kitchen waste is pulverized by a pulverizer, solid slag particles with a particle size of about 10×10 mm are mixed with the liquid in the slag-liquid mixing tank 10 to form a mixture with a moisture content of about 80% to 90%, which is sucked by the sludge pump Afterwards, it is sent to the steam mixing section. The steam mixing section is equipped with a steam-water mixer 2. The steam inlet of the steam-water mixer 2 is input into the high-temperature steam through the steam adding pipeline 1 composed of a manual valve and a solenoid valve arranged in parallel, and the suction port o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com