Preparation of sulfonic acid modified polystyrene microspheres and method for catalyzing conversion of furfuryl alcohol into ethyl levulinate by using sulfonic acid modified polystyrene microspheres

A technology of polystyrene microspheres and polystyrene, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, and can solve the problems of large mass transfer resistance, poor catalyst stability, and poor thermal stability. Achieve the effect of easy recycling, stable structure and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

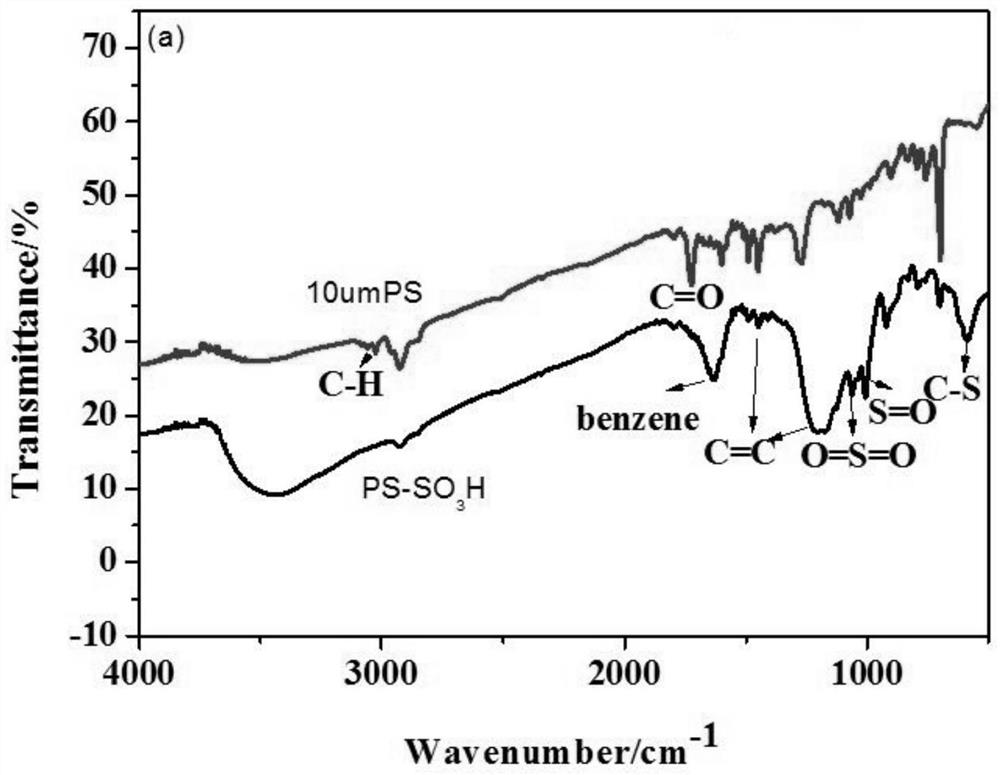

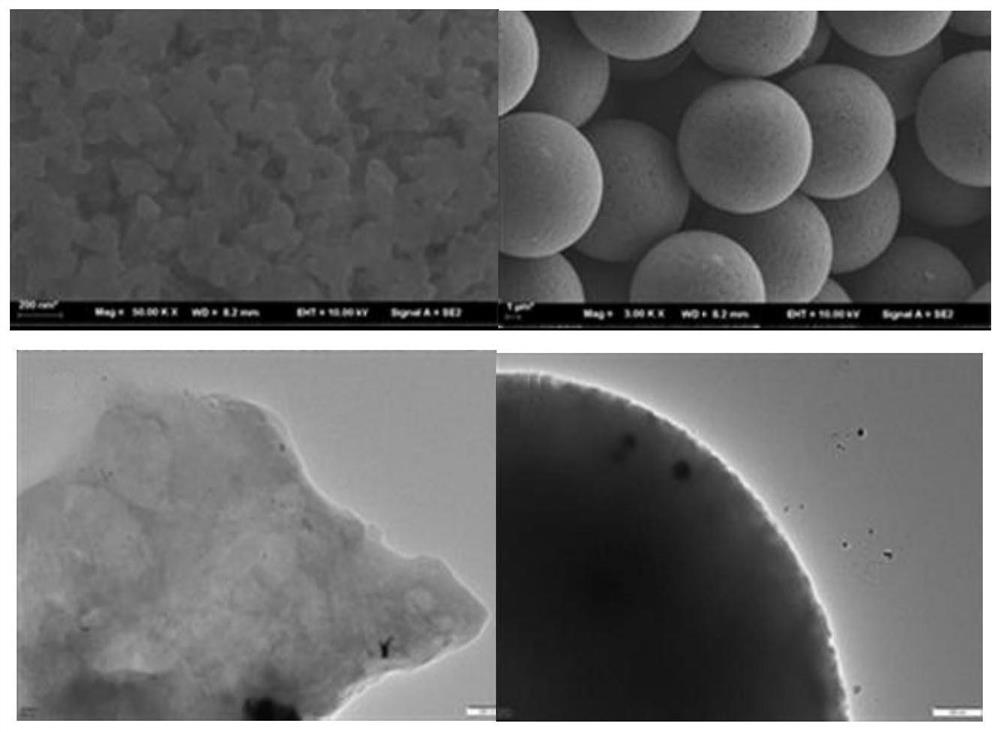

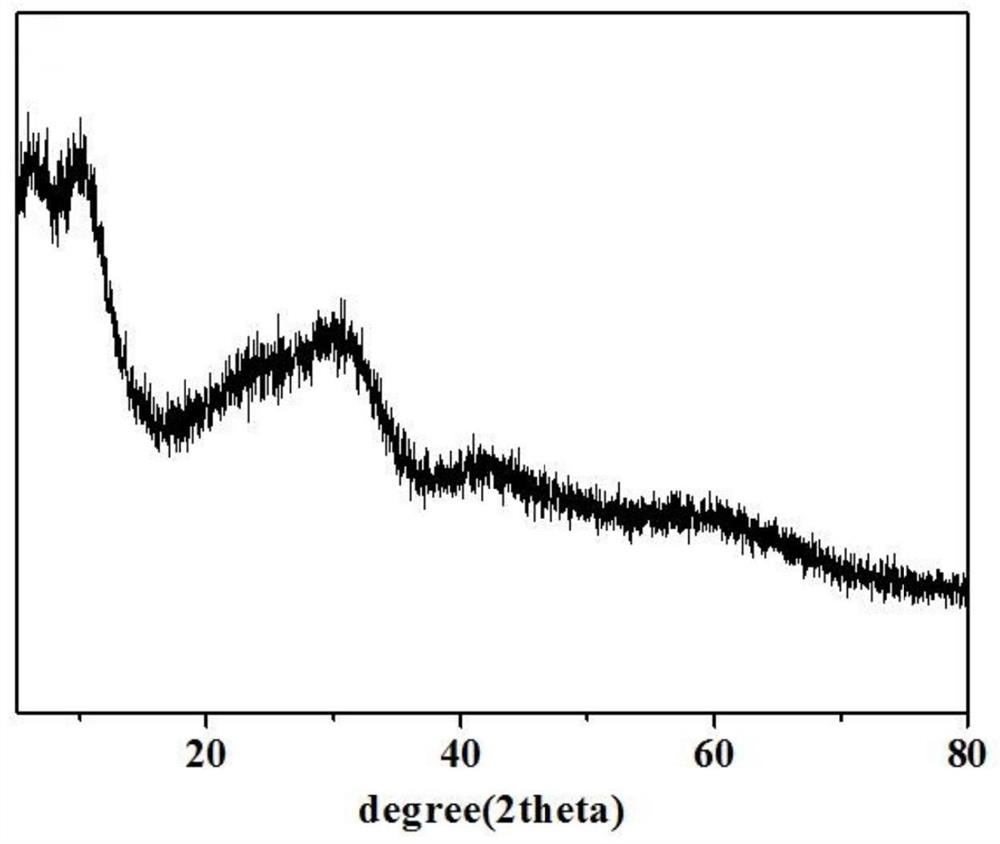

[0068] Embodiment 1 prepares sulfonic acid group polystyrene microsphere catalyst

[0069] (1) After weighing 0.6g of benzoyl peroxide and dissolving it in 15g of styrene, mix it with 35mL of ethanol, 50mL of ethylene glycol methyl ether and 1.8g of PVP (130W) solution, and react at 80°C for 24h after passing through nitrogen to obtain 3um polystyrene seed microspheres (3-PS);

[0070] (2) Dissolve 0.25g of sodium dodecylbenzenesulfonate (SDS) in 80mL of water, then add 1.05g of butyl phthalate (DBP), and mix uniformly through ultrasonic to form emulsion A; 0.5g (1 ) prepared seed microspheres were dispersed in 7.5mL water to form a dispersion; and the dispersion was added to the emulsion, and stirred at room temperature (200rpm) for 20h to obtain a mixed solution A;

[0071] Add 3g of styrene (St), 5g of divinylbenzene (DVB), 8g of toluene and 0.1g of benzoyl peroxide (BPO) into 80mL of aqueous solution, and ultrasonically mix to form emulsion B; add emulsion B to the mixing...

Embodiment 2

[0079] Embodiment 2 catalytically prepares ethyl levulinate

[0080] (1) Weigh 1mmol furfuryl alcohol, 0.075g PS-SO 3 H catalyst and 4mL ethanol are added in the 25mL reactor with magneton;

[0081] (2) The above reactor was placed in an oil bath at 120° C. and stirred for 2 hours, and cooled to room temperature after the reaction was completed.

[0082] Take 1 mL of the reacted solution and use gas phase (GC) to measure the conversion rate of furfuryl alcohol and the yield of ethyl levulinate. The conversion rate of furfuryl alcohol was 99.7%, and the yield of ethyl levulinate was 94.1%.

Embodiment 3

[0083] Embodiment 3 catalytically prepares ethyl levulinate

[0084] (1) Weigh 1mmol furfuryl alcohol, 0.075g PS-SO 3 H and 4mL of ethanol were added to a 25mL reactor with magnets;

[0085] (2) Place the above reactor in an oil bath at 120° C. and stir for 1.5 h. After the reaction is completed, cool to room temperature. Take 1 mL of the reacted solution and use GC to measure the conversion rate of furfuryl alcohol and the yield of ethyl levulinate.

[0086] The amount of microspheres in step (1) was changed from 0.075 g to 0.025, 0.05 and 0.10 respectively, and other conditions were unchanged; 1 mL of the reaction solution was taken to measure the conversion rate of furfuryl alcohol and the yield of ethyl levulinate by GC. The result is as Figure 7 Shown, PS-SO 3 When the amount of catalyst H was 0.025, 0.05, 0.075 and 0.10 g, the yields of ethyl levulinate obtained were 87.32%, 92.55%, 94.7% and 86%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com