Highly-oil-resistant rubber-hose inner-layer rubber material filled with low-molecular-weight PPC premix and preparation method thereof

A low-molecular-weight, premixed technology, applied in the field of rubber products, can solve the problems of high temperature resistance and oil resistance, which cannot meet the high performance requirements of rubber parts, inconvenient weighing and use, and expensive special rubber. Refining energy consumption, vulcanization efficiency is equivalent, and the effect of improving mechanics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

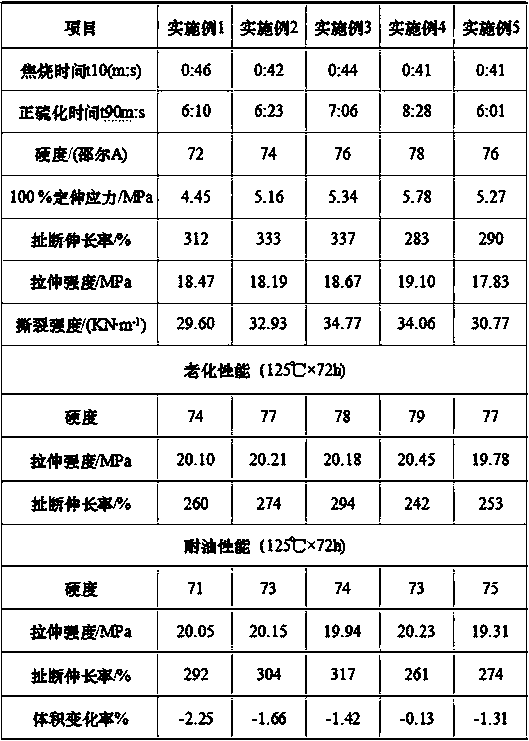

Embodiment 1—5

[0024] The premix of the low molecular weight PPC that embodiment 1-5 uses is all prepared by this method, and the preparation step of the premix of low molecular weight PPC is as follows:

[0025] The low molecular weight PPC for premixing in the present invention is provided by Jiangsu Zhongke Jinlong Chemical Co., Ltd. Specifically, it is the product of the reaction between carbon dioxide and propylene oxide produced in the company's cassava fermentation process to produce alcohol. It is a low-molecular-weight PPC with a number-average molecular weight between 2000 and 4500, and its appearance is a white transparent viscous liquid.

[0026] Preparation of low-molecular-weight PPC premix: Step 1) Heat low-molecular-weight PPC to 65±1°C, then add maleic anhydride (MA) and mix and stir for 1 hour to make maleic anhydride (MA) in PPC Completely dissolved in the medium, the mass ratio is PPC:maleic anhydride=10:2, to prepare modified PPC;

[0027] Step 2) Add the modified PPC p...

Embodiment 1

[0029] First adjust the roller distance of the double-roller mill to 0.1mm, add 80g of nitrile rubber Botong for 4 times, add 20g of hydrogenated nitrile rubber for plasticizing 3 times; adjust the roller distance to 0.5mm, add nitrile rubber and hydrogenated butadiene rubber Thin the nitrile rubber until the mixing is uniform; adjust the roller distance to 2.3mm, when the rubber material is wrapped around the roller and there is a small amount of accumulated rubber, add 4.5g zinc oxide, 1.7g stearic acid, 1.1g anti-aging agent BLE, 1.3g anti-aging 4010NA, until mixed evenly; then add 63g of carbon black N550, 8g of plasticizer DOS; 4.4g of low molecular weight PPC premix; Roll distance to 2.5mm, add 3g dicumyl peroxide (curing agent DCP) and 1.8g vulcanization aid TAIC in sequence, adjust the roller distance to 0.3mm when the material is completely eaten, and pack it 5 times; mixing temperature control At about 50°C, adjust the roller distance to 3.5 mm to thicken the lower s...

Embodiment 2

[0031] First adjust the roller distance of the double-roller mill to 0.1mm, add 80g of nitrile rubber Botong for 4 times, add 20g of hydrogenated nitrile rubber for plasticizing 4 times; adjust the roller distance to 0.5mm, add nitrile rubber and hydrogenated butadiene rubber Thin the nitrile rubber until the mixing is uniform; adjust the roller distance to 2.2mm, when the rubber material wraps the roller and has a small amount of accumulated rubber, add 4.5g zinc oxide, 1.4g stearic acid, 1.5g anti-aging agent BLE, 1.2g anti-aging Add agent 4010NA until it is evenly mixed; then add 60g of carbon black N550, 5g of plasticizer DOS; 11g of low molecular weight PPC premix; Gap to 2.5mm, add 2.5g dicumyl peroxide (curing agent DCP) and 2.2g vulcanization aid TAIC in turn, adjust the roller distance to 0.3mm when the material is completely eaten, and pack it 5 times; mixing temperature control At about 50°C, adjust the roller distance to 3.5 mm and thicken the lower sheet to prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com