Outdoor work garment fabric and preparation method thereof

A technology for work clothes and fabrics, applied in textiles, fabrics, textiles and papermaking, etc., can solve the problems of difficulty in cleaning clothes and difficult to remove bacteria, and achieve the effect of good moisture absorption and ventilation performance, sufficient raw materials, and light texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

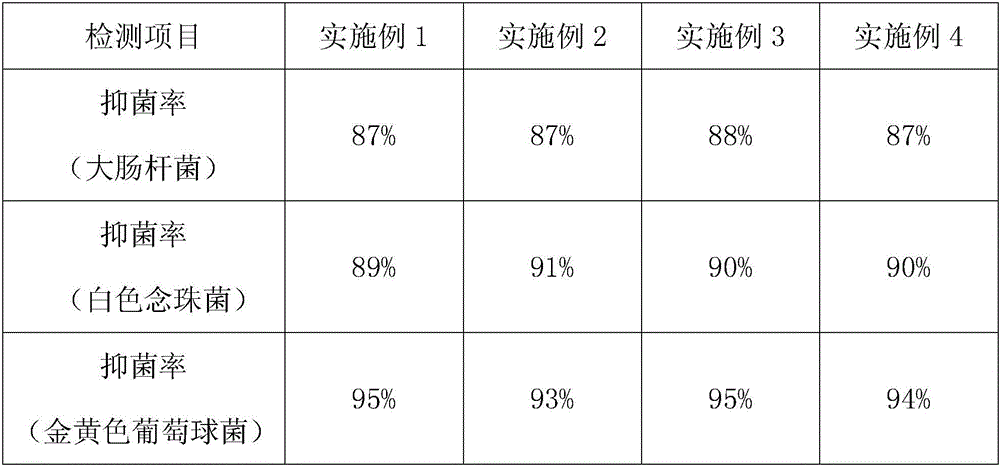

Examples

Embodiment 1

[0027] An outdoor workwear fabric is woven from ramie fibers pretreated with a modified coating treatment agent.

[0028] The main components of the modified coating treatment agent are shape memory polyurethane coating agent, expanded vermiculite superfine powder and titanium dioxide.

[0029] The expanded vermiculite superfine powder is mechanically ground the expanded vermiculite into a superfine powder state, passed through a 600-mesh sieve, and the under-sieve is taken.

[0030] A fabric for outdoor work clothes and a preparation method thereof, comprising the following steps:

[0031] A. Pretreatment: first add shape memory polyurethane coating agent and appropriate amount of water into the mixer, after stirring for 12 minutes, add expanded vermiculite superfine powder, continue stirring for 25 minutes, then add nano titanium dioxide, after stirring evenly, add ramie fiber, And stand still for 10 hours, carry out pretreatment;

[0032] B. Opening and cleaning: send the...

Embodiment 2

[0041] An outdoor workwear fabric is woven from ramie fibers pretreated with a modified coating treatment agent.

[0042] The main components of the modified coating treatment agent are shape memory polyurethane coating agent and expanded vermiculite superfine powder.

[0043] The expanded vermiculite superfine powder is mechanically ground the expanded vermiculite into a superfine powder state, passed through a 600-mesh sieve, and the under-sieve is taken.

[0044] A fabric for outdoor work clothes and a preparation method thereof, comprising the following steps:

[0045] A. Pretreatment: first add shape memory polyurethane coating agent and appropriate amount of water into the mixer, after stirring for 15 minutes, add expanded vermiculite superfine powder, after stirring evenly, add ramie fiber, and let it stand for 8 hours for pretreatment ;

[0046] B. Opening and cleaning: send the ramie fiber into the cotton opener for opening and cleaning;

[0047] C. Carding: Cardin...

Embodiment 3

[0055] An outdoor workwear fabric is woven from ramie fibers pretreated with a modified coating treatment agent.

[0056] The main components of the modified coating treatment agent are polyurethane coating agent, expanded vermiculite superfine powder and titanium dioxide.

[0057] The expanded vermiculite superfine powder is mechanically ground the expanded vermiculite into a superfine powder state, passed through a 600-mesh sieve, and the under-sieve is taken.

[0058] A fabric for outdoor work clothes and a preparation method thereof, comprising the following steps:

[0059] A. Pretreatment: first add polyurethane coating agent and appropriate amount of water into the mixer, after stirring for 12 minutes, add expanded vermiculite superfine powder, continue stirring for 20 minutes, then add nano-titanium dioxide, after stirring evenly, add ramie fiber, and let it stand Put 9 hours, carry out pretreatment;

[0060] B. Opening and cleaning: send the ramie fiber into the cotton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com