High-flash-point safe alkyd anticorrosive coating and preparation process thereof

A technology of anti-corrosion coating and preparation process, applied in anti-corrosion coatings, polyester coatings, coatings and other directions, can solve the problems of poor salt spray resistance, harmful to human health, low safety, etc. Chemical resistance, effect of increasing crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

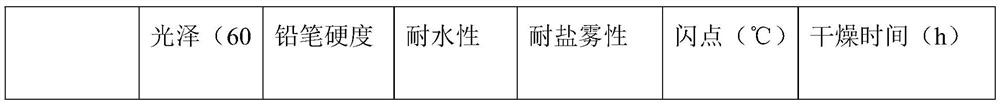

Examples

Embodiment 1

[0042] Mix high iodine value oleic acid alkyd resin, titanium dioxide, nano-barium sulfate and ultrasonically disperse, grind, add high flash point solvent under stirring condition, then add emulsified water at 60°C, emulsify for 40min, then add high-efficiency drying agent agent to obtain a high flash point safe alkyd anti-corrosion coating;

[0043] The high flash point solvent is dipropylene glycol methyl ether;

[0044] In parts by weight, the emulsified water consists of: 10 parts of water-based epoxy emulsifier, 60 parts of deionized water; the preparation method of the water-based epoxy emulsifier is as follows: epoxy resin, polyetheramine, Water ethanol was stirred at 60°C for 5 hours under the protection of argon; after vacuum distillation at 60°C, acetic acid was added, ultrasonically dispersed, and reacted at 55°C for 1 hour to obtain a water-based epoxy emulsifier;

[0045] In terms of parts by weight, the content of each component in the anti-corrosion coating is...

Embodiment 2

[0055] Mix high iodine value oleic acid alkyd resin, titanium dioxide, nano-barium sulfate and ultrasonically disperse, grind, add high flash point solvent under stirring condition, then add emulsified water at 70°C, emulsify for 30 minutes, then add high-efficiency drying agent agent to obtain a high flash point safe alkyd anti-corrosion coating;

[0056] The high flash point solvent is diethylene glycol ether;

[0057] In parts by weight, the composition of the emulsified water is: 15 parts of water-based epoxy emulsifier, 65 parts of deionized water; the preparation method of the water-based epoxy emulsifier is as follows: epoxy resin, polyether amine, Water ethanol was stirred at 70°C for 4 hours under the protection of argon; after vacuum distillation at 80°C, acetic acid was added, ultrasonically dispersed, and reacted at 75°C for 0.8h to obtain a water-based epoxy emulsifier;

[0058] In terms of parts by weight, the content of each component in the anti-corrosion coat...

Embodiment 3

[0068] Mix high iodine value oleic acid alkyd resin, titanium dioxide, nano-barium sulfate and ultrasonically disperse, grind, add high flash point solvent under stirring condition, then add emulsified water at 80°C, emulsify for 20min, then add high-efficiency drying agent agent to obtain a high flash point safe alkyd anti-corrosion coating;

[0069] The high flash point solvent is ethylene glycol diacetate;

[0070] In parts by weight, the emulsified water consists of: 20 parts of water-based epoxy emulsifier, 70 parts of deionized water; the preparation method of the water-based epoxy emulsifier is as follows: epoxy resin, polyether amine, Water ethanol was stirred at 80°C for 3 hours under the protection of argon; after vacuum distillation at 90°C, acetic acid was added, ultrasonically dispersed, and reacted at 80°C for 0.5h to obtain a water-based epoxy emulsifier;

[0071] In terms of parts by weight, the content of each component in the anti-corrosion coating is: 40 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com