Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

225results about How to "Meet industry requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

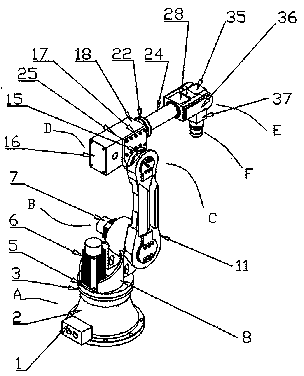

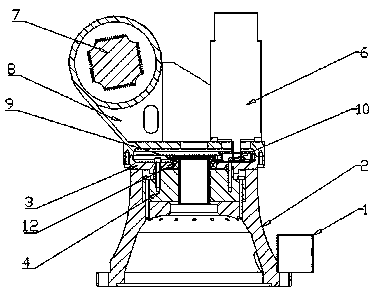

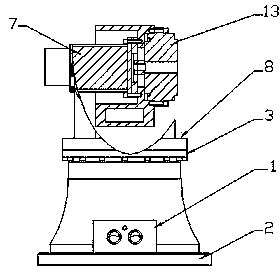

Six-axis degree-of-freedom manipulator

InactiveCN103568002AAvoid jitterCompact structureProgramme-controlled manipulatorControl systemDegrees of freedom

The invention discloses a six-axis degree-of-freedom manipulator. The six-axis degree-of-freedom manipulator comprises a base, wherein the base is in transmission connection with a first transmission mechanism, a second transmission mechanism, a third transmission mechanism, a fourth transmission mechanism, a fifth transmission mechanism and a sixth transmission mechanism in sequence, wherein the six transmission mechanism is in transmission connection with a mechanical palm part. A series of functions such as welding, spraying and handling are combined, the newest servo control system is adopted, and a series of new functions which can meet the industrial production of users are developed on the platform. The conventional complex transmission process is greatly simplified in the aspect of mechanical transmission, and the characteristic that bevel gear mesh type transmission is generally adopted by the conventional six axes is cancelled, so that the manipulator has a compacter structure and higher transmission efficiency, is more accurate in control and can effectively prevent the situation of jitter due to joint movement.

Owner:RIZHAO POLYTECHNIC

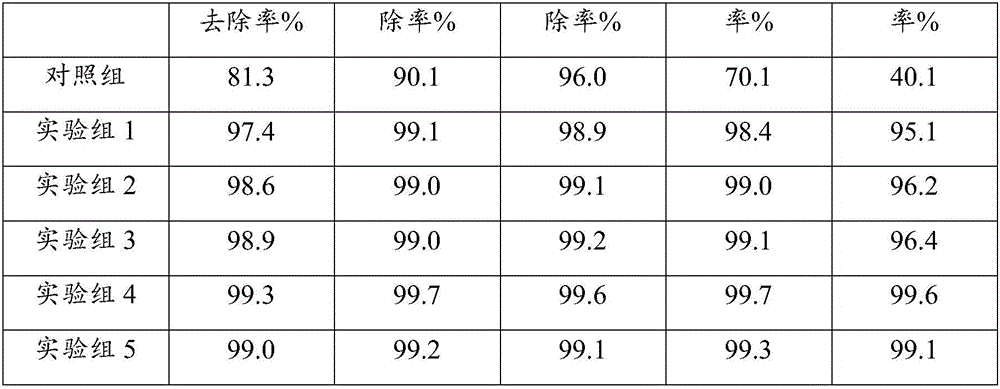

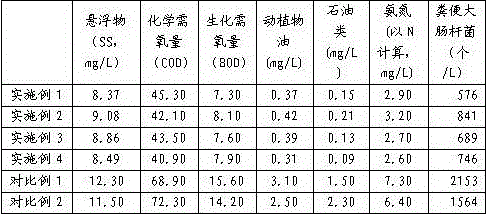

Compound bactericide for treating sewage and sewage treatment method thereof

ActiveCN106701633AGood removal effectFunction increaseFungiBacteriaOperabilityBULK ACTIVE INGREDIENT

The invention discloses compound bactericide for treating sewage and a sewage treatment method thereof, and belongs to the technical field of sewage treatment. The compound bactericide comprises the following active ingredients from following strains: rhodopseudomonas, anaerobic ammonium oxidation bacteria, candida utilis, thiobacillus denitrificans, white-rot fungi, lactobacillus plantarum, bifidobacterium, lactobacillus acidophilus, green nonsulfur bacteria, phosphorus-accumulating bacteria, aspergillus oryzae, nitrosomas, streptomyces, bacillus subtilis and propionibacterium acidipropionici. The invention also provides the method using the compound bactericide to treat the sewage. The compound bactericide and the sewage treatment method have the advantages that the effect of treating sewage is better, the technology is simple, the implementing is easy, the operability is strong, the pollution to environment is avoided, the industrial requirements are met, and the application prospect is better.

Owner:哈尔滨明慧生物技术开发有限公司

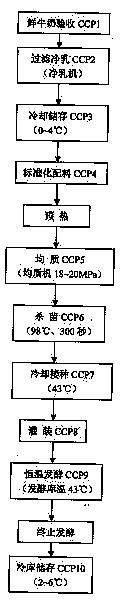

Fresh flower yoghourt and production method

InactiveCN103783158AReasonable process structureConsistent appearance and colorMilk preparationSugarFermentation

The invention relates to fresh flower yoghourt and a production method. The fresh flower yoghourt mainly comprises an isotrope acidification fermented product of edible fresh flower sugaring flower mud and fresh milk and has the unadulterated special flower nourishing smell, and the fresh flower is one or more of rose, arabian jasmine flowers, osmanthus fragrans, lily and lotus. The production method comprises the following steps of cleaning fresh petals, carrying out pickling on the fresh petals by using granulated sugar, carrying out low-temperature fermentation on the fresh petals, pulping, grinding the fresh pedals into mud, carrying out high-temperature sterilization on the fresh petals for later use, filtering and cleaning fresh milk passing acceptance inspection, and storing the fresh milk for later use at 0-4 DEG C; and mixing the flower mud and the fresh milk according to a proportion, simultaneously adding an emulsifying agent to carry out homogenization treatment, introducing fermentation bacteria after sterilization, and carrying out constant-temperature fermentation on the fermentation bacteria to obtain a finished fresh flower yoghourt. The fresh flower yoghourt has the characteristics that the texture is delicate and uniform, uniform fluid is formed after stirring, and can be pulled to be filiform, an appearance does not have fine particles, the luster is bright, the surface is flat, smooth and bright, the fresh flower yoghourt has mellow smell with the combination of fragrance and fermented milk, and the fresh flower yoghourt is tender, sour and sweet.

Owner:HONGHE YUNNIU DAIRY IND

Abrasive silicon dioxide for low-abrasion high-cleaning-power toothpaste and preparation method thereof

The invention belongs to the technical field of silicon dioxide for toothpaste and relates to abrasive silicon dioxide for low-abrasion high-cleaning-power toothpaste and a preparation method thereof. The preparation method comprises: S1, liquefying solid sodium silicate; S2, mixing dilute sulfuric acid and silicon dioxide powder, adding sodium silicate solution under stirring until pH is 2-3, and stirring to obtain acidic silicon sol; S3, injecting the sodium silicate solution and sodium chloride solution, stirring, heating, adding sulfuric acid until pH is 10-11, and adding the acidic silicon sol; S4, adding both the sodium silicate solution and sulfuric acid, keeping pH to be 9.0-9.5, after the sodium silicate solution is completely added, continuing to add sulfuric acid until pH is 2-3, ageing, press-filtering, washing, and drying and crushing to obtain the abrasive silicon dioxide for low-abrasion high-cleaning-power toothpaste; RDA value of the abrasive silicon dioxide is 120-140, PCR value is 120-140, PCR / RDA is 0.86-1, and the abrasive silicon dioxide has low abrasion and high cleaning powder.

Owner:GUANGZHOU FEIXUE MATERIAL TECH

Coating for centrifugal casting and preparation method

ActiveCN104588572ASimple paint formulationSimple preparation processFoundry mouldsFoundry coresAmmonium dodecyl sulfateQuartz

A coating for centrifugal casting is prepared by the following raw materials in parts by weight: 1-5 parts of rectorite, 0.1-0.7 part of sodium carboxymethylcellulose, 50-60 parts of quartz powder, 0.01-0.5 part of dodecyl ammonium sulfate and 40-45 parts of water. The coating disclosed by the invention is simple in formula, low in cost and simple in manufacturing process; and a cast-in type cylinder sleeve meeting industry requirements can be prepared together with the centrifugal casting process.

Owner:ZYNP GRP

Low-temperature automobile expansion adhesive and preparation method thereof

ActiveCN110684486AHigh foaming ratioNot prone to collapse and shrinkage problemsNon-macromolecular adhesive additivesMacromolecular adhesive additivesVulcanizationFoaming agent

The invention discloses a low-temperature automobile expansion adhesive. The low-temperature automobile expansion adhesive is made of the following raw materials in parts by weight: 100 parts of a polymer, 3-5 parts of a peroxide vulcanization agent, 0.5-3 parts of a vulcanization auxiliary agent, 5-15 parts of a foaming agent, 0.5-8 parts of a foaming activator, 1-10 parts of a filler, 2-15 partsof a tackifier, 0.5-3 parts of a lubricant, 0-2 parts of an antioxidant, and 0-10 parts of a flame retardant. According to the low-temperature automobile expansion adhesive, the raw material composition is carefully chosen, the content of each raw material is optimized, and the prepared low-temperature automobile expansion adhesive has high foaming ratio and small product density, and can fill large cavities. The expansion adhesive has high bonding strength with an ABS framework member. The expansion adhesive has good high-temperature baking stability. The expansion adhesive after foaming isnot easy to collapse and shrink. The low-temperature foaming performance and high-temperature foaming ratio are well balanced. The storage stability is good, the product quality is stable, and a storage period is relatively long.

Owner:浙江杰上杰新材料股份有限公司

Heat insulation energy-saving material and preparation method thereof

InactiveCN107324776AExtended service lifeLow thermal conductivityCeramic materials productionClaywaresSodium silicateSodium carboxymethylcellulose

The invention discloses a heat insulation energy-saving material. The heat insulation energy-saving material comprises the following components in parts by weight: 60-80 parts of cement, 30-40 parts of mineral cotton, 20-30 parts of sodium silicate, 10-30 parts of natural zeolite powder, 10-20 parts of coal ash, 5-15 parts of mullite fibers, 3-8 parts of floating beads, 5-10 parts of polyvinyl alcohol, 2-8 parts of carboxymethyl cellulose, 5-10 parts of a nano inorganic oxide, 8-15 parts of glass beads, 3-8 parts of glass fibers and 4-10 parts of an additive. The heat insulation energy-saving material is prepared by such processes as grinding dispersion, high-temperature mixing, standing cooling, sieving separation, pressing molding and high-temperature sintering. The heat insulation energy-saving material has the advantages of fire resistance, long service life, small heat conduction coefficient, environmental friendliness and the like, and meanwhile, has good acid and alkali corrosion resistance and ultrahigh weatherability.

Owner:HEFEI WANZHIJING DOORS & WINDOWS CO LTD

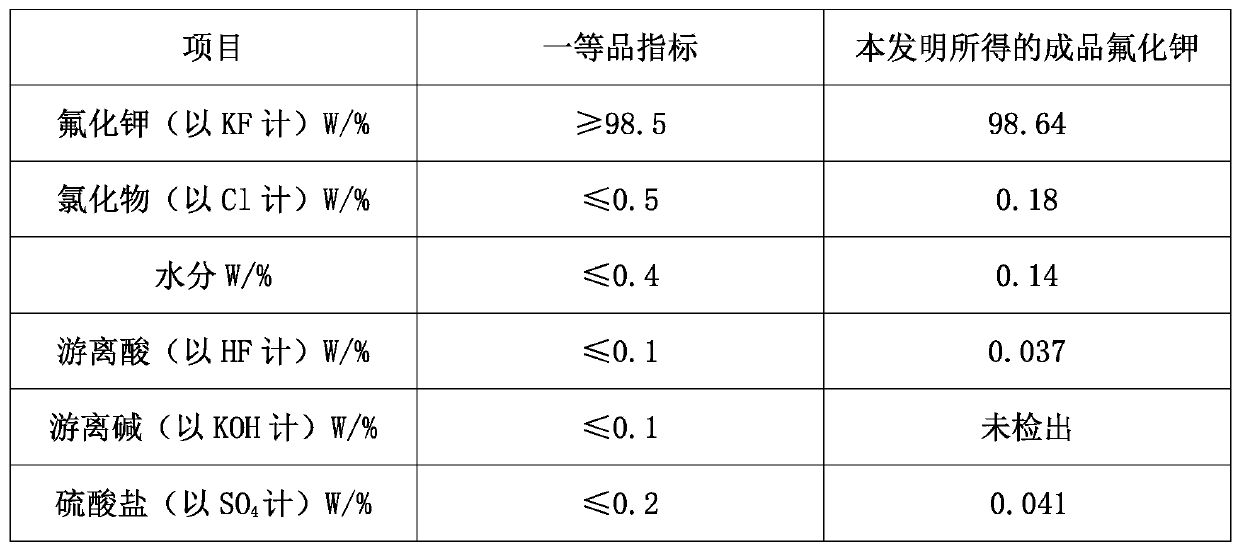

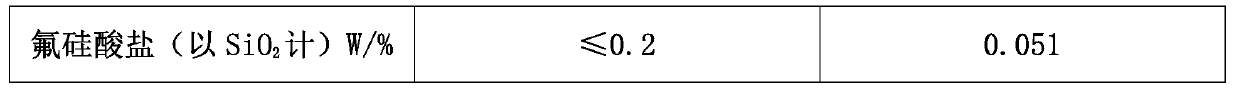

Method for preparing potassium fluoride with white carbon black as co-product by using fluorosilicic acid as raw material

InactiveCN110510640AReduce procurement costsModerate dosageSilicaAlkali metal fluoridesPotassium fluoridePotassium

The invention relates to a method for preparing potassium fluoride with white carbon black as co-product by using fluorosilicic acid as a raw material. The method comprises the following steps: S1 dissolving potassium chloride and filtering to obtain potassium chloride solution; S2, injecting the potassium chloride solution obtained by S1 into the fluorosilicic acid solution for reaction, and after the reaction is completed, stirring, filtering and washing to obtain the potassium fluorosilicate filter cake; S3, adding water in proportion to the potassium fluosilicate filter cake obtained in the step S2 and stirring into a paste to obtain potassium fluosilicate slurry, and then injecting potassium hydroxide solution into the slurry to carry out reaction; S4, after the reaction is completed,filtering the mixed slurry obtained in the step S3 to obtain a silica filter cake and a filtrate containing potassium fluoride. The invention uses fluorosilicic acid as a raw material to prepare potassium fluoride with white carbon black as co-product, and the by-product potassium chloride and by-product silicofluoric acid from hydrofluoric acid industry are used as main raw materials to preparehigh purity potassium fluoride with high added value white carbon black as co-product. Compared with the raw materials in the neutralization method in which potassium hydroxide and hydrofluoric acid are reacted are used for the longest time at present, the production cost of the method is low.

Owner:内蒙古星汉新材料有限公司

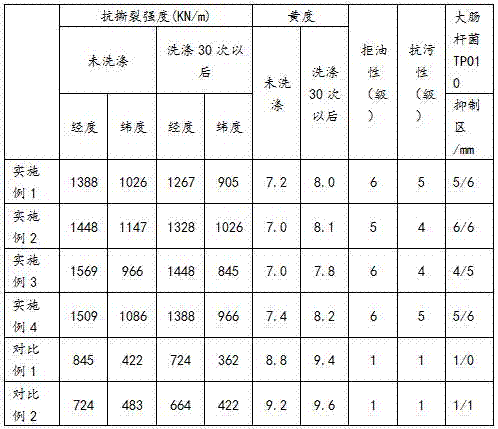

Dirt-proof and antibacterial textile fabric and preparation method thereof

InactiveCN107177902AHas oil-resistant propertiesHigh strengthConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsYarnPolyester

The invention discloses dirt-proof and antibacterial textile fabric and a preparation method thereof. The textile fabric is prepared from raw materials in parts by weight as follows: 5-10 parts of polyester yarn and 10-20 parts of folium artemisiae argyi fiber, 10-18 parts of soybean fiber, 5-15 parts of polylactic acid fiber, 15-20 parts of water-absorptive fiber, 8-15 parts of polyacrylonitrile fiber, 10-15 parts of polyethylene terephthalate, 1-4 parts of hexamethyl cyclotrisiloxane, 2-5 parts of polyvinylpyrrolidone, 1-2 parts of alkaline pectinase, 2-5 parts of tung oil anhydride, 1-3 parts of tea saponin, 2-3 parts of benzoyl peroxide butyl acetate, 1-2 parts of acetyl tri-n-hexyl citrate, 3-6 parts of potassium chloride, 1-4 parts of a coupling agent, 2-5 parts of a dispersant and 2-3 parts of a heat stabilizer. The prepared dirt-proof and antibacterial spinning fabric has an oil rub resistance characteristic and is high in strength, durable and broad in application range; besides, the invention further discloses a corresponding preparation method.

Owner:SUZHOU DANFANG TEXTILE R & D

Fast treating method for copper mine waste water

InactiveCN106430754AReduce copper contentReduce organic contentWaste water treatment from quariesWater/sewage treatment with mechanical oscillationsActivated sludgeAluminium chloride

The invention discloses a fast treating method for copper mine waste water. A mixture composed of poly aluminium chloride, potassium ferrate, dimethyl diallyl ammonium chloride, potassium feldspar, bissuccinimide, quartz sand, polyacrylamide, diethylenetriaminepenta acid, urea, citric acid and activated sludge is adopted as a cleaning agent, matched with a flocculating agent with polyferric sulfate, bentonite, zeolite powder, ethoxylated lauryl alcohol sulfate and alum as constituents, and assisted with technologies of deep oxidation, flocculation, ultrasound, resin adsorption, filtration, sterilization, membrane separation and the like, therefore, the copper content and the COD value in the copper mine waste water are effectively reduced, industrial requirements can be met, and the method has a good application prospect.

Owner:吴小慧

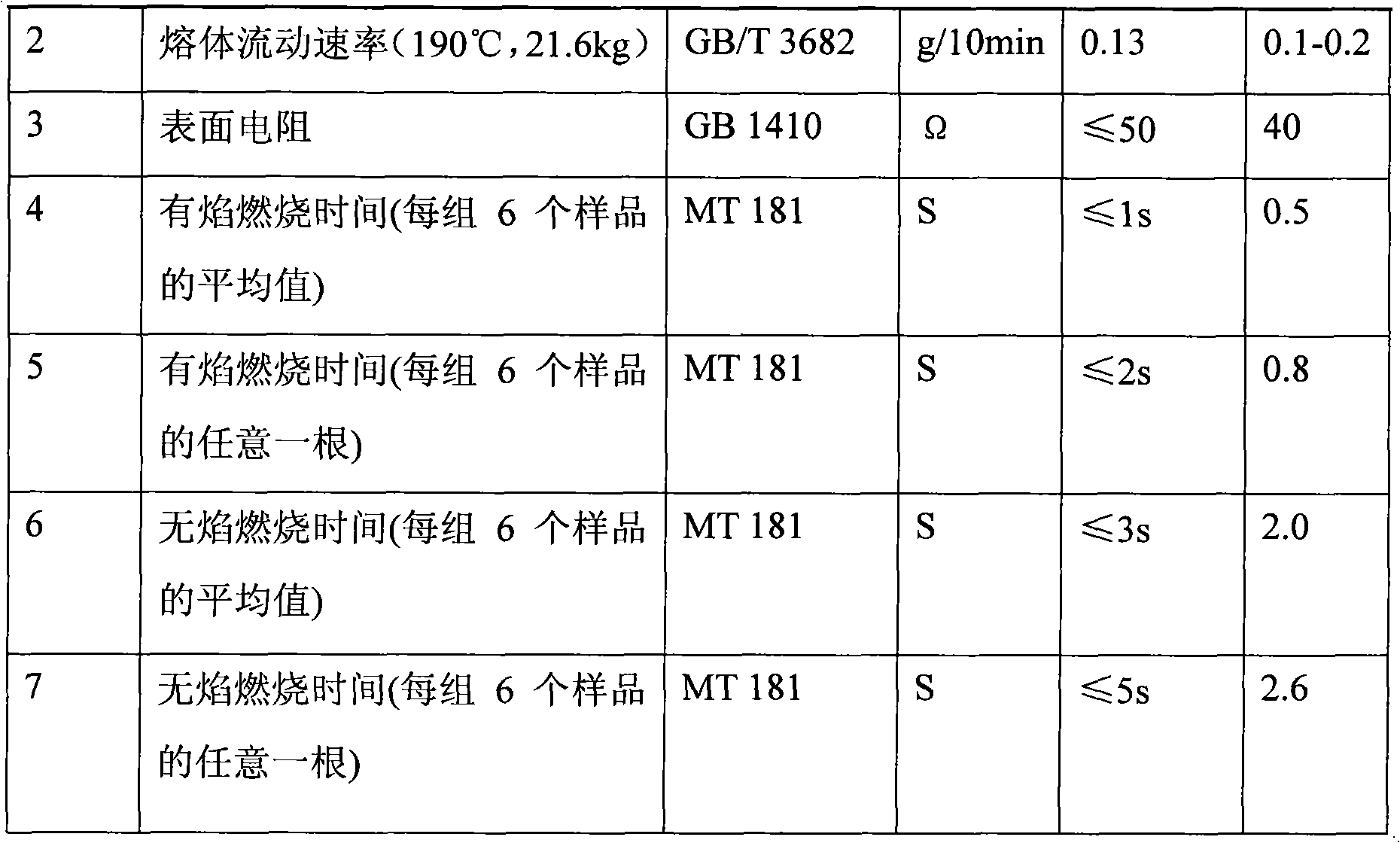

Flame retardant and antistatic polyethylene for mine gas drainage pipeline and preparation method thereof

The invention belongs to the technical field of flame retardant and antistatic polyethylene materials and particularly relates to flame retardant and antistatic polyethylene for a mine gas drainage pipeline and a preparation method thereof. The polyethylene comprises the following components in parts by weight: 90-100 parts of polyethylene, 5-25 parts of metal powder, 10-30 parts of flame retardant, 2-10 parts of stabilizer 5-25 parts of carbon black. The preparation method comprises the following steps: mixing the materials at a high speed, extruding by virtue of a double screw extruder, cutting and granulating; and drying. Metal powder is added in the polyethylene; the carbon black can be used for effectively reducing the electric resistance of the polyethylene; and the surface resistance of the modified polyethylene is 1*10<4>-1*10<6>, thus the polyethylene provided by the invention is the best antistatic material. The added flame retardant is a superfine inorganic flame retardant and the flame retardant effect can reach the V0 level; and good processability and mechanical properties are maintained.

Owner:SHANGHAI BANZAN MACROMOLECULE MATERIAL

Martensitic stainless steel and manufacturing method thereof

Owner:BAOSTEEL DESHENG STAINLESS STEEL

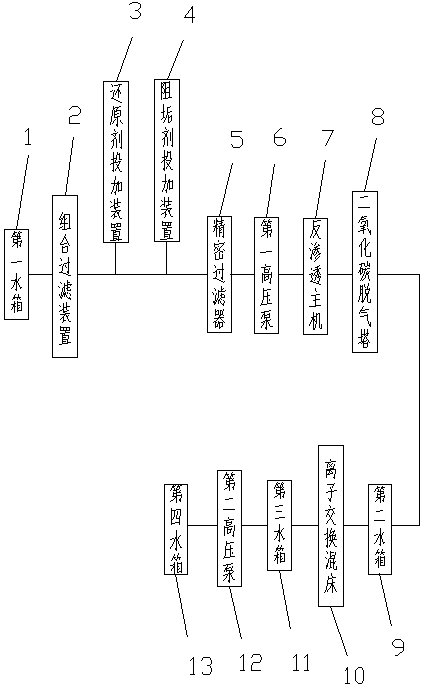

High-pressure boiler feedwater treatment system

InactiveCN103253793ALow costMeet industry requirementsGeneral water supply conservationWater/sewage treatment by ion-exchangeReverse osmosisIon exchange

The invention discloses a high-pressure boiler feedwater treatment system which comprises a first water tank, a combined filtering device, a reducing agent adding device, a scale inhibitor adding device, a precision filter, a first high-pressure pump, a reverse osmosis host, a carbon dioxide degassing tower, a second water tank, an ion exchange mixed bed, a third water tank, a second high-pressure pump and a fourth water tank, wherein the first water tank, the combined filtering device, the reducing agent adding device, the scale inhibitor adding device, the precision filter, the high-pressure pump, the reverse osmosis host, the carbon dioxide degassing tower, the second water tank, the ion exchange mixed bed, the third water tank, the second high-pressure pump and the fourth water tank are connected sequentially through a water pipeline. Through the way, the system disclosed by the invention has low cost, and the produced desalted water can sufficiently meet the requirements of the industry.

Owner:徐臻毅

High-strength high-flame-resistance cable material and preparation method thereof

The invention discloses a high-strength high-flame-resistance cable material. The high-strength high-flame-resistance cable material comprises, by weight, 40 to 60 parts of high-density polyethylene, 30 to 40 parts of phenolic resin, 20 to 30 parts of epoxy resin, 10 to 30 parts of triphenyl phosphate (TPP), 15 to 30 parts of decabromodiphenylethane, 10 to 20 parts of carbon fibers, 5 to 15 parts of calcium stearate, 15 to 25 parts of nanometer aluminum hydroxide, 5 to 10 parts of nanometer calcium carbonate, 2 to 8 parts of nanometer titanium dioxide, 5 to 15 parts of nanometer organosilicon, 3 to 8 parts of antimony oxide, 5 to 15 parts of zinc borate, 4 to 10 parts of calcite powder, 3 to 10 parts of talcum powder, 1 to 5 parts of diatomite, 3 to 8 parts of a fire retardant, 2 to 6 parts of an anti-oxidant, 1 to 5 parts of a plasticizer and 10 to 20 parts of a modified filling material. The cable material prepared in the invention has high strength, good stretching resistance and excellent flame resistance and can meet requirements of the related industry.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

Method for preparing novel energy-saving heat-insulating material

The invention provides a method for preparing a novel energy-saving heat-insulating material. The method comprises the following preparation steps: a. mixing bentonite, slag, fly ash, quartz sand anda common-salt aqueous solution, and carrying out uniform stirring, so as to obtain slurry I; b. mixing fibers, polystyrene foamed particles, water glass, redispersible latex powder, a foamer, a foam stabilizer and water, and carrying out a foaming reaction, so as to obtain slurry II; c. slowly stirring the slurry II, carrying out defoaming, then, carrying out filtering, and removing solid particles, so as to obtain slurry III; and d. mixing the slurry I and the slurry III, adding calcium carbide, a water reducing agent, titanium dioxide, chitosan and hollow glass beads, carrying out high-temperature pressurizing, carrying out high-speed stirring, then, injecting the mixture into a twin-screw extruder, carrying out melting and extruding, then, introducing the extruded substance into a mold,carrying out limited pressurizing, and carrying out curing, thereby obtaining the novel energy-saving heat-insulating material. The material prepared by the method is wide in source and low in cost,and the preparation method is easy in operation and is applicable to industrial large-scale production manufacturing.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

Preparation method of ultralow-temperature TA7ELI titanium alloy plate

ActiveCN109013738AImprove ultra-low temperature deformation performancePromote homogenizationMetal rolling arrangementsAcid washingRoom temperature

The invention discloses a preparation method of an ultralow-temperature TA7ELI titanium alloy plate. The method comprises the following steps: (1) a TA7ELI titanium alloy plate blank is heated for thefirst time; (2) the TA7ELI titanium alloy plate blank is rolled as a first semi-finished plate blank after primary heating; (3) the first semi-finished plate blank is formed to a second semi-finishedplate blank through polishing, acid washing and cutting in sequence; (4) the second semi-finished plate blank is heated for the second time; (5) the second semi-finished plate blank is rolled as a second semi-finished plate blank after secondary heating; and (6) the second semi-finished plate blank is straightened after insulation, and is cooled in air to reach the room temperature to obtain theTA7ELI titanium alloy plate. The high-temperature heating treatment and the reversing rolling method are adopted to provide larger deformation space for twin deformation, in the leading deformation role, of the plate under ultralow temperature; and the plate blank structure uniformity is promoted to obtain the ultralow-temperature TA7ELI titanium alloy plate.

Owner:WESTERN TITANIUM TECH

Medical composite resin infusion bag material and preparation method thereof

The invention discloses a medical composite resin infusion bag material and a preparation method thereof. PVC (polyvinyl chloride) resin and polypropylene resin serve as main components, polyethylene glycol, octenyl succinic acid modified starch, polyethylene glycol terephthalate, cellulose acetate fibers, calcium lignosulphonate, 4, 5-epoxy tetrahydrophthalate, 1-(3-dimethyl aminopropyl)-3-ethyl carbimide, coconut oil fatty acid monoethanolamine, sea-foam stone powder, gas phase while lamp black, linolenic acid, dispersing agents and stabilizing agents are added and subjected to processes such as mixing, stirring, high-temperature sintering, crushing, high-pressure calcining, acid dipping, ultrasonic dispersion, screw extrusion and injection molding to prepare the medical composite resin infusion bag material. The medical composite resin infusion bag material has excellent high temperature resistance, stretching resistance and abrasion resistance, can meet industrial requirements and has a good application prospect.

Owner:金福兴

Titanium dioxide added modified composite ceramic material and preparation method thereof

The invention discloses a titanium dioxide added modified composite ceramic material and a preparation method thereof. The titanium dioxide added modified composite ceramic material is prepared from the following raw materials in parts by weight: 3 to 8 parts of titanium dioxide, 30 to 45 parts of alumina ceramic powder, 5 to 10 parts of clay, 4 to 7 parts of niobium nitride, 5 to 8 parts of carbon black, 2 to 6 parts of polyethylene wax, 3 to 8 parts of vinyltriethoxysilane, 3 to 6 parts of polyaluminosiloxane, 1 to 4 parts of dicumyl peroxide, 4 to 8 parts of vinyl carboxylate, 2 to 4 parts of tetramethylammonium hydroxide, 1 to 5 parts of polyethylene glycol, 1 to 2 parts of aluminum nitride, 1 to 4 parts of magnesium oxide, 2 to 5 parts of barium sulfate, 3 to 6 parts of sodium boride, 1 to 2 parts of molybdenum disilicide, 1 to 4 parts of antioxidant, 2 to 5 parts of stabilizing agent and 1 to 2 parts of coupling agent. The prepared titanium dioxide added modified composite ceramic material is stable in performance, resistant to corrosion, resistant to wear and high in strength. Meanwhile, the invention also discloses the corresponding preparation method.

Owner:SUZHOU LUOTELAN NEW MATERIAL TECH

Harmless processing method of food pickling wastewater

InactiveCN106186536AImprove processing efficiencyNo pollution in the processFatty/oily/floating substances removal devicesWater contaminantsEmission standardOperability

The invention discloses a harmless processing method of food pickling wastewater. Mainly, a flocculant of a special formula and the wastewater are stirred for reaction, and processed water meeting the emission standard is obtained through the processing of a multi-medium filter, the metabolic processing of an aeration tank compound microorganism bacterium agent, the electric coagulation processing of high-voltage pulses, the eluting and filtering of ion exchange resin, the stirring, standing and filtering of a special compound wastewater processing agent and the reverse osmosis processing of a high-pressure pump. According to the processed water obtained through the wastewater processing method of the optimization process, wastewater processing efficiency is high, and the emitted processed water can reach the national standard; meanwhile, the method is simple in process, strong in operability, free of environment pollution and capable of meeting the industry requirements and has good application prospects.

Owner:吴小慧

Method for treating city sewage

InactiveCN106007119AImprove processing efficiencyNo pollution in the processWater/sewage treatment by irradiationSpecific water treatment objectivesBenzoyl peroxideIon exchange

The invention discloses a method for treating urban sewage, which comprises corn starch-acrylamide graft copolymer, carboxymethyl chitosan, soybean protein extract, ferric chloride, ethoxyquinoline, and benzyl peroxide Acyl, sodium cyclamate, polylactic acid, butyl p-hydroxybenzoate, hydroxyethylidene diphosphonic acid, licorice extract, allantoin as the compound sewage treatment agent and sewage stirring reaction, after ultrasonic treatment, The ion exchange column is eluted through the column, the flocculant is stirred and flocculated and precipitated, the flocculation supernatant is passed through the column adsorption resin, membrane filter is filtered, sterilized, and the treated water of the discharge standard is obtained. The method has high sewage treatment efficiency, and the discharged treated water can reach the national standard. At the same time, the process is simple and easy, the operability is strong, and it has no pollution to the environment, which can meet the requirements of the industry and has a good application prospect.

Owner:陈昌

Breathable anti-abrasion anti-electrostatic and waterproof fabric and preparing method thereof

InactiveCN107740197AStable and guaranteed waterproof levelBreathable and wear-resistantConjugated cellulose/protein artificial filamentsArtificial filament heat treatmentPolyesterEthanolamine synthesis

The invention relates to the field of fabric production, in particular to a breathable anti-abrasion anti-electrostatic and waterproof fabric and a preparing method thereof. The fabric is formed by blending cotton and linen fiber, viscosity fiber and anti-electrostatic polyester fiber; the fabric is prepared from, by weight, 30-40 parts of cotton and linen fiber, 35-40 parts of viscosity fiber, 30-40 parts of anti-electrostatic polyester fiber, 33-46 parts of polylactic acid, 25-38 parts of metasilicic acid trimethyl ester, 22-28 parts of dilauryl thiodipropionate, 21-25 parts of sodium dodecyl benzene sulfonate, 13-17 parts of phosphatidyl ethanolamine, 9-14 parts of potassium metabisulfite, 8-9 parts of cetyl trimethyl ammonium bromide, 8-9 parts of hydroxypropyl starches, 5-7 parts of nano silicon dioxide, 5-7 parts of sodium cetyl sulfate, 4-6 parts of linoleic acid, 3-4 parts of silane coupling agent, 3-4 parts of binding agent and 180 parts of deionized water.

Owner:JIANGSU AOYANG SHIJIA CLOTHING CO LTD

Soil improvement fertilizer for improving sandy soil and preparation method thereof

InactiveCN106348872AImprove fertilityReduce the degree of desertificationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPeatMonopotassium phosphate

The invention discloses a soil improvement fertilizer for improving sandy soil and a preparing method thereof. The soil improvement fertilizer is prepared from coal gangue powder, polyisocyanate, potash feldspar, montmorillonite, carbamide, straw powder, peat humic acid, biochemical fulvic acid, protonated chitosan, konjaku flour, animal manure, seignette salt, sulfonates, monopotassium phosphate, nano titania, dispersant and a water retention agent. The soil improvement fertilizer for improving sandy soil is prepared by incinerating, grinding, filtering, ultrasonic high-speed dispersion, microwave treatment, prilling and stoving. The soil improvement fertilizer for improving sandy soil has the advantages of improving soil fertility effectively, reducing desertification degree and low production cost. The soil improvement fertilizer for improving sandy soil can meet the requirements of the industry. Moreover, the soil improvement fertilizer for improving sandy soil has a good application prospect.

Owner:何晓东

Environment-friendly anti-bacteria mold-proof composite fiber board and preparation method thereof

ActiveCN106272869AStable in natureNo pollution in the processWood treatment detailsReed/straw treatmentFiberMelamine phosphate

The invention discloses an environment-friendly anti-bacteria mold-proof composite fiber board and a preparation method thereof. The environment-friendly anti-bacteria mold-proof composite fiber board is prepared from, by weight, 5-8 parts of poplar leaves, 5-10 parts of wood flour, 5-9 parts of crop stalk, 3-6 parts of kieselguhr, 7-15 parts of polyurethane, 5-10 parts of polyether, 5-8 parts of acetate fiber, 2-4 parts of DL-benzylsuccinic acid, 3-5 parts of ethylene glycol monostearate, 1-3 parts of melamine phosphate, 2-6 parts of styrene-acrylic emulsion, 1-4 parts of a silane coupling agent, 2-3 parts of an antioxidant and 2-5 parts of an adhesive. The prepared environment-friendly anti-bacteria mold-proof composite fiber board is stable in character, resistant to mold and environmentally friendly, and causes no pollution to environment.

Owner:NANJING SHI DAN LI DEORATION MATERIAL CO LTD

Conveyer belt reproduction polymer compounded rubber material

InactiveCN106243414AImprove performanceTake full advantage of abrasion resistanceFiberRubber material

The invention relates to the technique of preparation of a conveyer belt rubber material, particularly to a conveyer belt reproduction polymer compounded rubber material. The conveyer belt reproduction polymer compounded rubber material comprises the following components in parts by weight: 1-10 parts of methyl vinyl silicone rubber, 1-8 parts of natural rubber, 1-6 parts of butadiene rubber, 1-3 parts of butadiene styrene rubber, 1-3 parts of carbon fiber reinforced plastic, 1-2 parts of zinc oxide, 0.1-1 part of stearic acid, 1-5 parts of carbon black, 0.1-1 part of coumarone, 1-2 parts of an accelerant, 1-3 parts of an antiager and 0.1-1 part of sulphur. The conveyer belt reproduction polymer compounded rubber material is used for reproducing a conveyer belt, is synthesized from the methyl vinyl silicone rubber and part of polymer rubbers, has the excellent performance of high abrasion resistance, high strength and shock resistance, and accords with the industry requirement.

Owner:山西佰得拓普工贸有限公司

Efficient heavy metal wastewater flocculating agent based on plant extracts and preparation method thereof

InactiveCN106854009AImprove flocculation abilityTo achieve the treatment effectWater contaminantsWater/sewage treatment by flocculation/precipitationFiberPhosphate

The invention discloses an efficient heavy metal wastewater flocculating agent based on plant extracts and a preparation method thereof. The efficient heavy metal wastewater flocculating agent is prepared from the following raw materials in parts by weight: 2 to 5 parts of purslane extract, 1 to 4 parts of dandelion extract, 2 to 8 parts of dry lotus leaves, 5 to 10 parts of wheat straw, 10 to 15 parts of Selaginella tamariscina leaves, 1 to 4 parts of reed straw, 3 to 9 parts of hydroxyapatite, 2 to 6 parts of phosphate ore, 5 to 8 parts of oyster shell powder, 2 to 9 parts of trass volcanic ash, 7 to 10 parts of polylactic acid fiber, 5 to 12 parts of hydroxy acrylic resin, 5 to 9 parts of fatty alcohol-polyoxyethylene ether, 6 to 9 parts of Arabic gum, 3 to 9 parts of nano calcium sulfate, 5 to 10 parts of sodium diethylhexyl sulfosuccinate, 1 to 2 parts of sulfur, 1 to 4 parts of acraldehyde, 2 to 7 parts of magnesium silicate, 3 to 6 parts of gallotannic acid, 4 to 8 parts of a heat stabilizer, 2 to 5 parts of a coupling agent and 1 to 3 parts of a coagulant aid. The prepared wastewater flocculating agent is safe, stable and high in flocculation ability, metal ions can be effectively chelated, and the effect of wastewater treatment is reached. Simultaneously, the invention also discloses a corresponding preparation method.

Owner:SUZHOU DINGYU ENERGY EFFICIENT EQUIP

Chitosan added textile dye and preparation method thereof

InactiveCN107177993AImprove printing and dyeing effectNo damageDyeing processSOAPPolyvinylpyrrolidone

The invention discloses chitosan added textile dye and a preparation method thereof. The textile dye is prepared from the following raw materials in parts by weight: 30-50 parts of a natural dye raw material, 1-3 parts of an organic dying raw material, 10-15 parts of chitosan, 1-5 parts of ethylcellulose, 2-4 parts of sodium dodecyl sulfate, 4-8 parts of diethanolamine, 1-4 parts of malic acid, 4-7 parts of aluminum potassium sulfate dodecahydrate, 1-3 parts of polyvinylpyrrolidone, 4-8 parts of polyoxyethylene octylphenol ether, 1-2 parts of amylopectin, 1-3 parts of dibutyltin dilaurate, 3-6 parts of iron oxide red, 1-3 parts of sulfonated oil, 1-4 parts of soap powder, 2-5 parts of oxalic acid, 2-5 parts of a coupling agent and 1-4 parts of an aid. The prepared chitosan added textile dye is good in printing and dyeing effect and is friendly and damage-free to fabric. The invention further discloses the preparation method of the chitosan added textile dye.

Owner:WUJIANG YISHENG TEXTILE

Organic polymer-based composite graphene electrode material and preparation method therefor

ActiveCN106328240AImprove conductivityHigh dielectric constantCarbon-silicon compound conductorsCable/conductor manufactureCyclohexanoneCharge discharge

The invention discloses an organic polymer-based composite graphene electrode material. The organic polymer-based composite graphene electrode material is prepared by the steps of taking graphene, rare earth, polyacrylamide, polypyrrole, polystyrene, a polylactic acid-hydroxyacetic acid copolymer, polytetramethylene glycol succinate, manganese trifluoride, dimethylacetamide, and magnesium hydrate as main components, adding N-methylbutyl piperdine bis(trifluoromethyl sulfonyl)imide), pentaethylene glycol, dimethyl carbonate, N, N-dimethyl formamide, silicon dioxide, cyclohexanone, starch aluminium octenylsuccinate, a dispersing agent, a silane coupling agent and an adhesive, and performing processes of ultrasonic dispersion, stirring and banburying, mixing in an inert gas environment, spraying and drying, electrode coating with a material, and the like in auxiliary manner. The prepared organic polymer-based composite graphene electrode material is excellent in electrical conductivity, high in dielectric constant, good in charge-discharge performance, capable of satisfying industrial requirements, and relatively high in application prospect.

Owner:广州顺倬能源科技有限公司

High-affinity medical antibacterial glycolide material and preparation method thereof

The invention discloses a high-affinity medical antibacterial glycolide material. The material is prepared from, by weight, 45-55 parts of polyglycollide, 40-50 parts of N,N'-ethylene hisstearamide, 40-50 parts of collagen, 35-45 parts of 1,6-ethylene glycol dimethacrylate, 25-35 parts of N,N'-ethylene hisstearamide, 20-26 parts of bi-maleamidic acid, 18-22 parts of polyvinyl alcohol condensed glyoxal, 10-12 parts of glass fiber, 10-12 parts of fimbrin, 5-8 parts of wollastonite powder, 4-6 parts of nano titanium dioxide, 4-6 parts of aluminum silicate ceramic fiber, 3-5 parts of acetyl triethyl citrate, 2-4 parts of stabilizer and 2-4 parts of coupling agent. The prepared high-affinity medical antibacterial glycolide material is good in biocompatibility and antibacterial performance, has certain flexibility and mechanical strength and can meet industrial requirements. Meanwhile, the invention further discloses a corresponding preparation method.

Owner:何仁英

High-strength carbon fiber based composite ceramic material and preparation method thereof

The invention discloses a high-strength carbon fiber based composite ceramic material and a preparation method thereof. The high-strength carbon fiber based composite ceramic material is prepared from the following raw materials in parts by weight: 30-40 parts of ceramic powder, 5-8 parts of hydroxyapatite, 5-8 parts of celsian, 5-6 parts of lepidolite, 12-15 parts of cellulose acetate fiber, 2-5 parts of polyurethane, 2-3 parts of tert-butyl hydroperoxide, 3-6 parts of trimethoxy silane, 1-4 parts of methylsilanetriyl triacetate, 4-7 parts of sodium lignin sulfonate, 2-5 parts of hydroxy propyl acrylate, 1-4 parts of polyethylene glycol, 4-8 parts of sodium laurylsulfonate, 1-2 parts of aluminum nitride, 1-4 parts of ammonium chloride, 2-5 parts of ferric oxide, 2-6 parts of cuprous oxide, 2-5 parts of sodium silicate, 1-2 parts of sodium tripolyphosphate, 1-4 parts of an antioxidant, 2-5 parts of a stabilizer and 1-2 parts of a coupling agent. The prepared high-strength carbon fiber based composite ceramic material is stable in property, high in strength, not liable to deform, good in high temperature resistance and good in heat conduction property. Meanwhile the invention further discloses a corresponding preparation method.

Owner:SUZHOU LUOTELAN NEW MATERIAL TECH

Anti-bacterial and acid-alkali-resistant medical material and preparation method thereof

InactiveCN106479097AImprove antibacterial propertiesGood acid and alkali resistancePolyethylene glycolSulfanilamide

The invention discloses an anti-bacterial and acid-alkali-resistant medical material and a preparation method thereof. The medical material is prepared from main ingredients including pharmaceutical grade polyvinyl alcohol, polypropylene resin, poly-3-hydroxybutyrate and polyethylene glycol fatty acid ester mixed with pentaerythritol oleate, octenyl succinic acid modified starch, citrate, N-butylcyanoacrylate, sulfanilamide, sodium citrate, polyactic acid fibers, aluminium silicate ceramic fibers, magnesium carbonate, gaseous-phase white carbon black, malic acid, a dispersing agent and a stabilizer by mixing, stirring, high-temperature sintering, grinding, high-pressure calcination, acid leaching, ultrasonic dispersion, screw extrusion, injection molding treatment and the like. The anti-bacterial and acid-alkali-resistant medical material has an excellent anti-bacterial property and acid and alkali resistance, can meet requirements of the industry and has better application prospect.

Owner:金福兴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com