Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47 results about "Benzyl peroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of phosphorus-containing flame-retardant polymethyl methacrylate resin

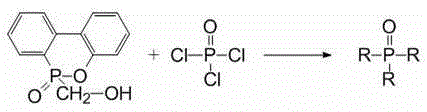

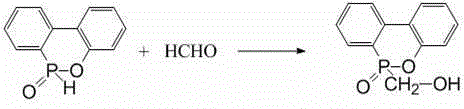

The invention relates to a preparation method of phosphorus-containing flame-retardant polymethyl methacrylate resin. A formula for preparing the phosphorus-containing flame-retardant polymethyl methacrylate resin comprises the following components by weight percent: 17.92 to 22.65 percent of tri((6-oxo-6H-dibenz [c,e][1,2] oxaphosphorin-6-yl)methyl) phosphate, 78.16 to 82.39 percent of methyl methacrylate and 0.16 to 0.76 percent of benzoperoxide. The preparation method comprises the following steps: adding a formula amount of methyl methacrylate, tri((6-oxo-6H-dibenz [c,e][1,2] oxaphosphorin-6-yl)methyl) phosphate and initiator benzoperoxide into a reaction container, stirring about 52 min at 85.2 DEG C, allowing the system to be viscous, then pouring a prepolymer into a mold, cooling to about 40 DEG C, performing the heat insulation for 6h, then heating to 80 DEG C, and performing the heat insulation for 12h to obtain the flame-retardant polymethyl methacrylate resin.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

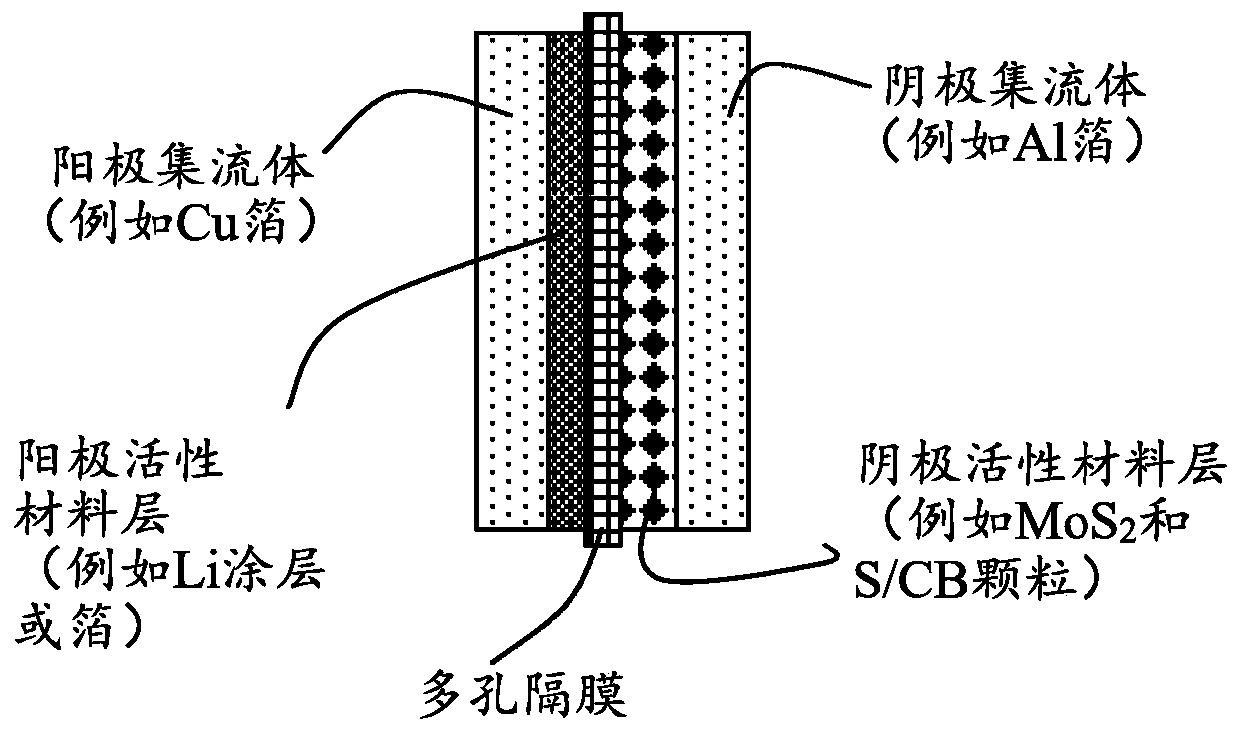

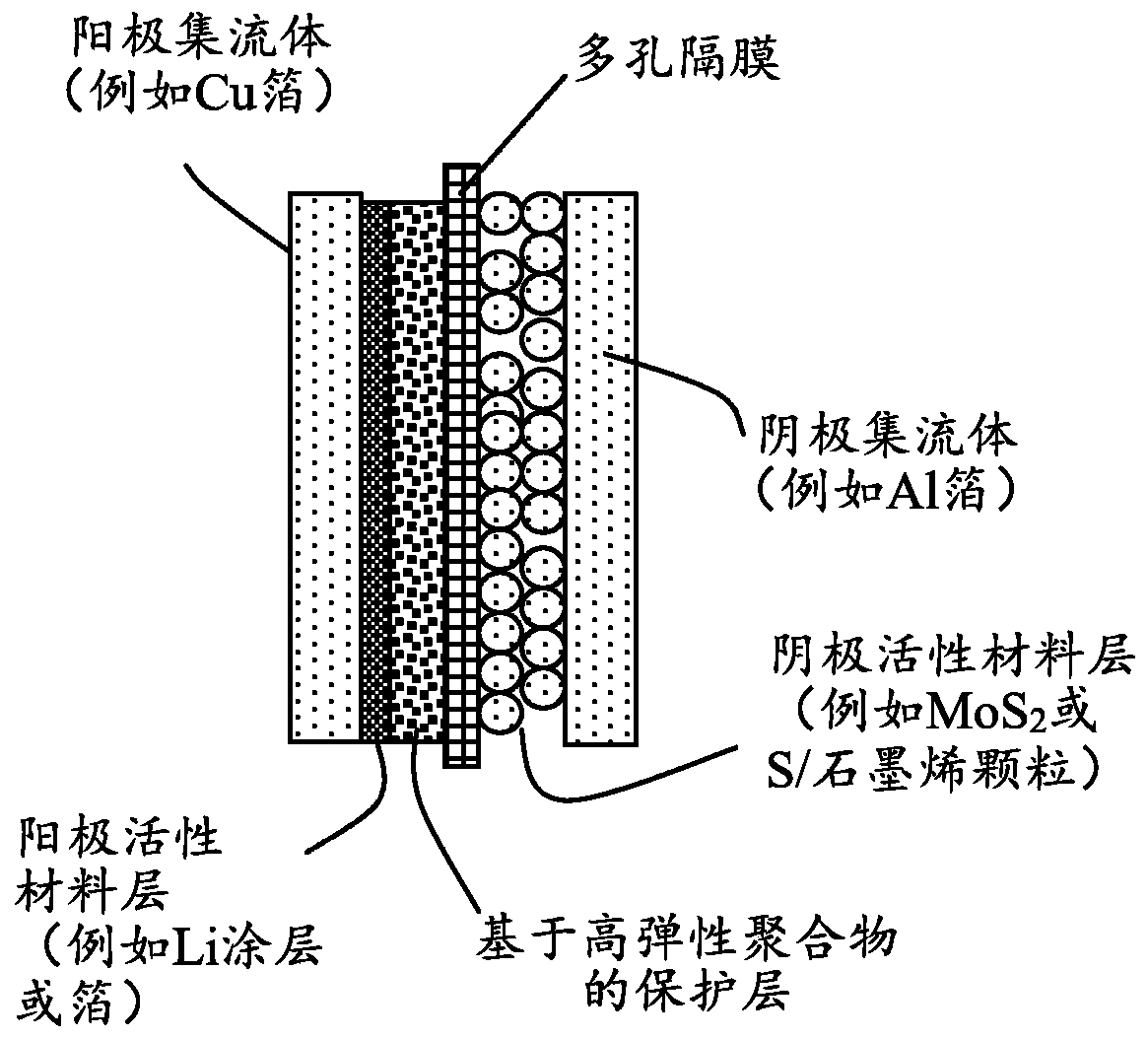

Lithium anode-protecting polymer layer for a lithium metal secondary battery and manufacturing method

Provided is lithium secondary battery comprising a cathode, an anode, and an electrolyte or separator-electrolyte assembly disposed between the cathode and the anode, wherein the anode comprises: (a)a foil or coating of lithium or lithium alloy; and (b) a thin layer of a high-elasticity polymer disposed between the foil / coating and the electrolyte (or separator-electrolyte assembly), having a recoverable tensile strain no less than 2%, a lithium ion conductivity no less than 10-6 S / cm at room temperature, and a thickness from 1 nm to 10 [mu]m, wherein the high-elasticity polymer contains a cross-linked network of polymer chains having an ether linkage, nitrile-derived linkage, benzo peroxide-derived linkage, ethylene oxide linkage, propylene oxide linkage, vinyl alcohol linkage, cyano-resin linkage, triacrylate monomer-derived linkage, tetraacrylate monomer-derived linkage, or a combination thereof in the cross-linked network of polymer chains.

Owner:NANOTEK INSTR

Thermoplastic-elastomer-modified polymethyl methacrylate color antiskid paint

The invention provides a thermoplastic-elastomer-modified polymethyl methacrylate color antiskid paint. The paint is of a three-component reaction type and comprises a component A, a component B and a component C, wherein the ratio of the component A to the component B to the component C is 100 to (50-200) to (5-30); and the paint is formed by mixing the three components. The component A is MMA resin liquid modified by thermoplastic elastomer and tackifying resin, the component B is graded waste tire rubber particles, and the component C is formed by mixing and dissolving 2 to 3 parts of benz peroxide and 10 to 30 parts of dibutyl phthalate. The thermoplastic-elastomer-modified polymethyl methacrylate color antiskid paint has beneficial effects that an energy-saving, high-efficient and durable color antiskid paint for roads and bridges is provided, the cost can be reduced, the energy consumption can be reduced, the economic benefit and social benefit can be improved, and various technical indexes of the paint can reach or exceed that of the color antiskid paint sold in the market.

Owner:广东立得新材料科技有限公司

Polyphenyl thioether composite material for 3D printing and preparation method thereof

The invention provides a polyphenyl thioether composite material for 3D printing and a preparation method thereof. The preparation method comprises the following steps: dissolving N-vinyl-2-pyrrolidone in ethanol, adding benzoperoxide, standing at room temperature, sequentially adding terephthalic acid and ethyl alpha-cyanoacrylate, stirring at room temperature, adding polyphenyl thioether particles, heating while stirring, and cooling to room temperature, thereby obtaining the polyphenyl thioether composite material for 3D printing. The polyphenyl thioether composite material can be used for 3D printing within the temperature range of 40-70 DEG C, can not block the 3D printer injector, and overcomes the defect that the polyphenyl thioether consumable 3D printing needs to melt the high-molecular polymers under high-temperature conditions; and the preparation method has the advantages of simple technique and low production cost, is convenient for popularization and application, and enriches the varieties of the 3D printing consumables.

Owner:TAICANG BIQI NEW MATERIAL RES & DEV

Steel wire mesh skeleton composite tube

The invention discloses steel wire mesh skeleton composite tube. The tube is prepared from the following raw materials in parts by mass: 15-55 parts of HDPE, 3-18 parts of LDPE, 6-24 parts of LLDPE, 2-20 parts of EVA, 4-18 parts of drawing-grade polypropylene, 5-10 parts of montmorillonite, 10 parts of white carbon black, 1-10 parts of barium sulfate, 10-20 parts of graphite, 5-15 parts of carbon nanotube, 8-20 parts of polyimide fibers, 0.5-4 parts of a silane coupling agent KH151, 1-2 parts of diphenyl ketone, 1-10 parts of a composite lubricant, 0.01-0.2 part of nano-silver, 0.5-5 parts of flavonol, 0.5-5 parts of zinc stearate, 1-5 parts of polyacrylamide, 5-10 parts of methyl methacrylate, 1-5 parts of 2,4-dichlorobenzoyl peroxide and 10-20 parts of 6-ethoxy-2,2,4-trimethyl-1,2-dihydro-quinoline. The mechanical properties, impact property, deformation degree, aging resistance and stain resistance of the tube prepared from the raw materials are significantly and greatly increased.

Owner:深圳市心立方节能新技术有限公司

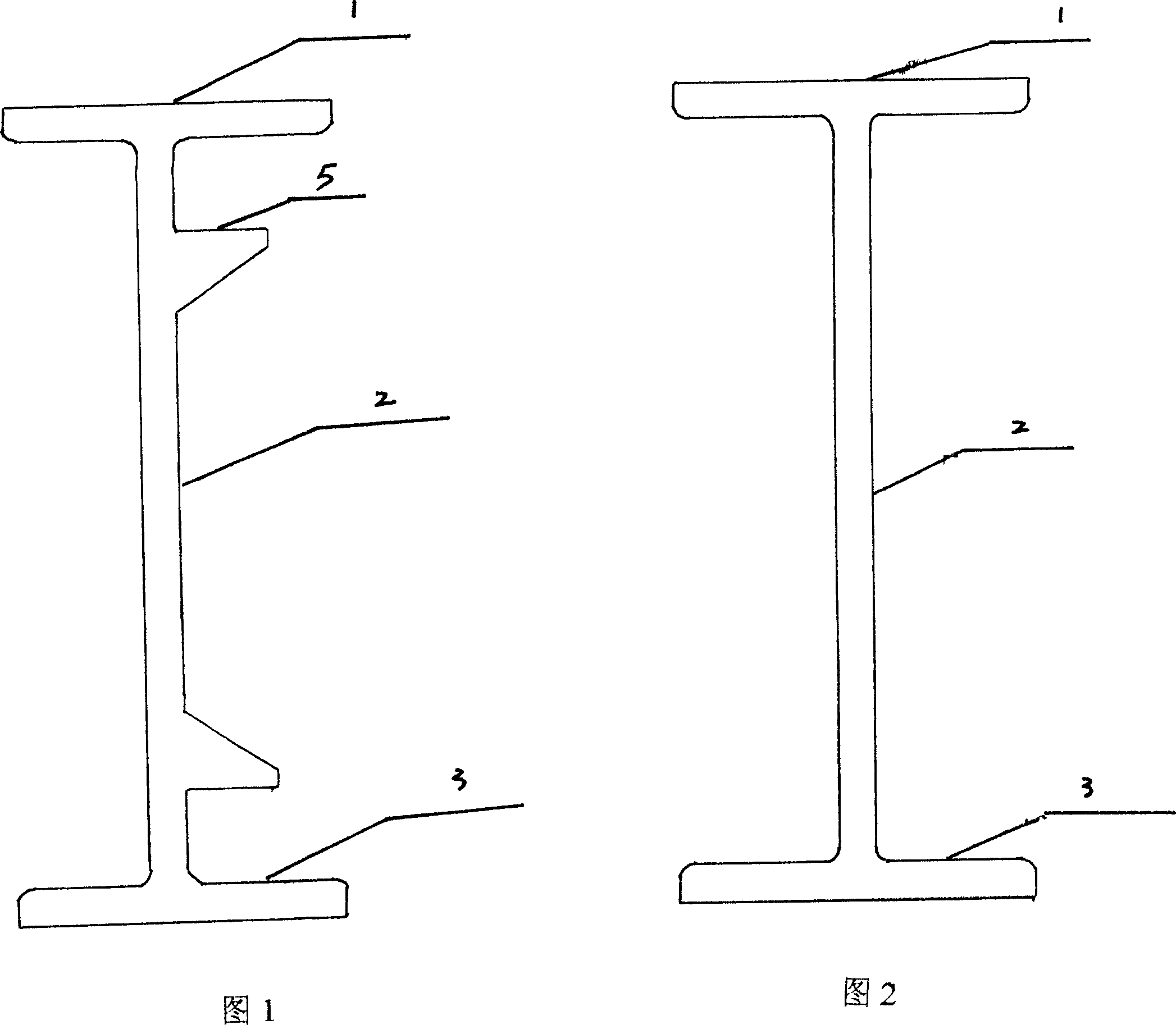

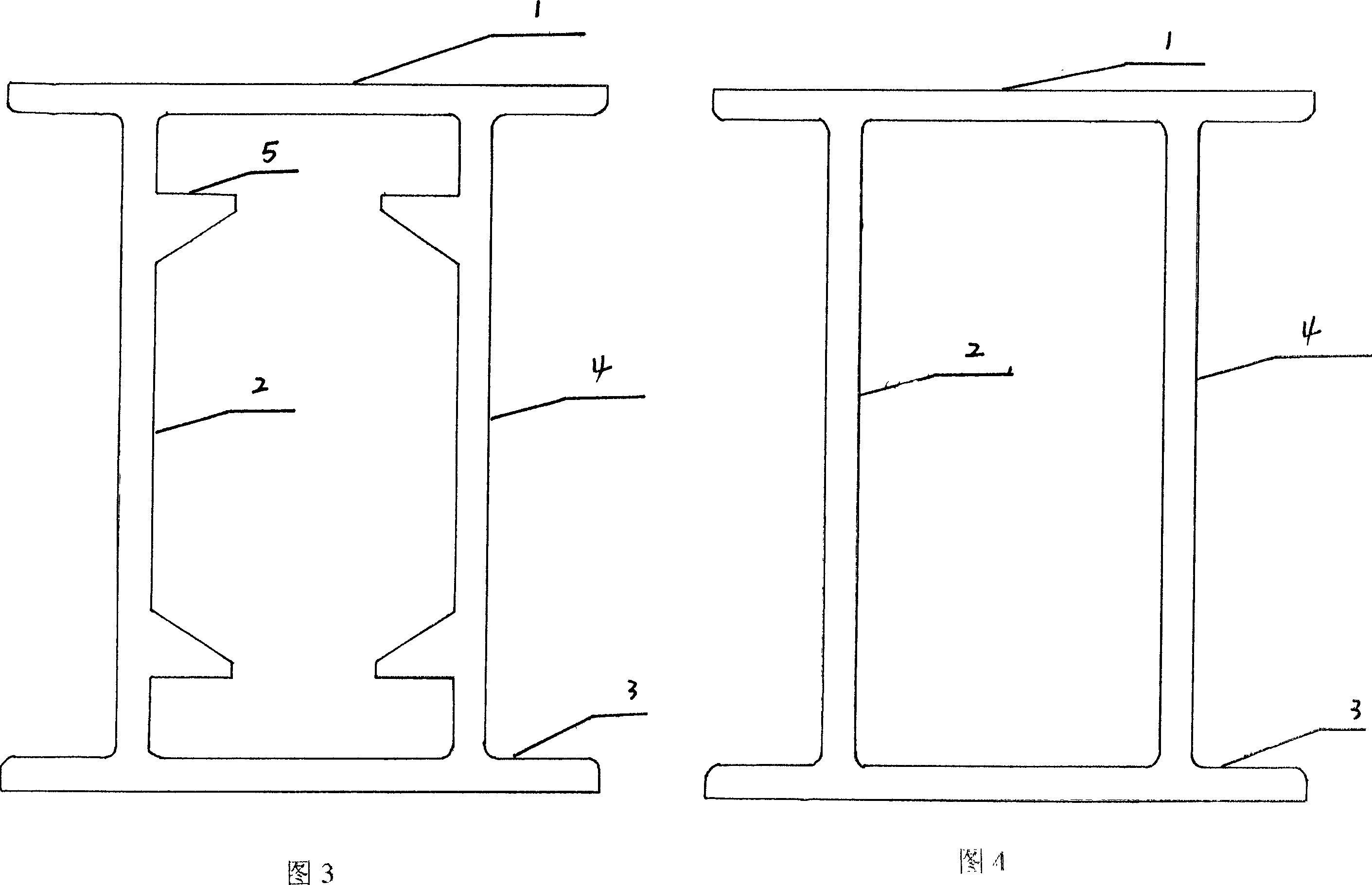

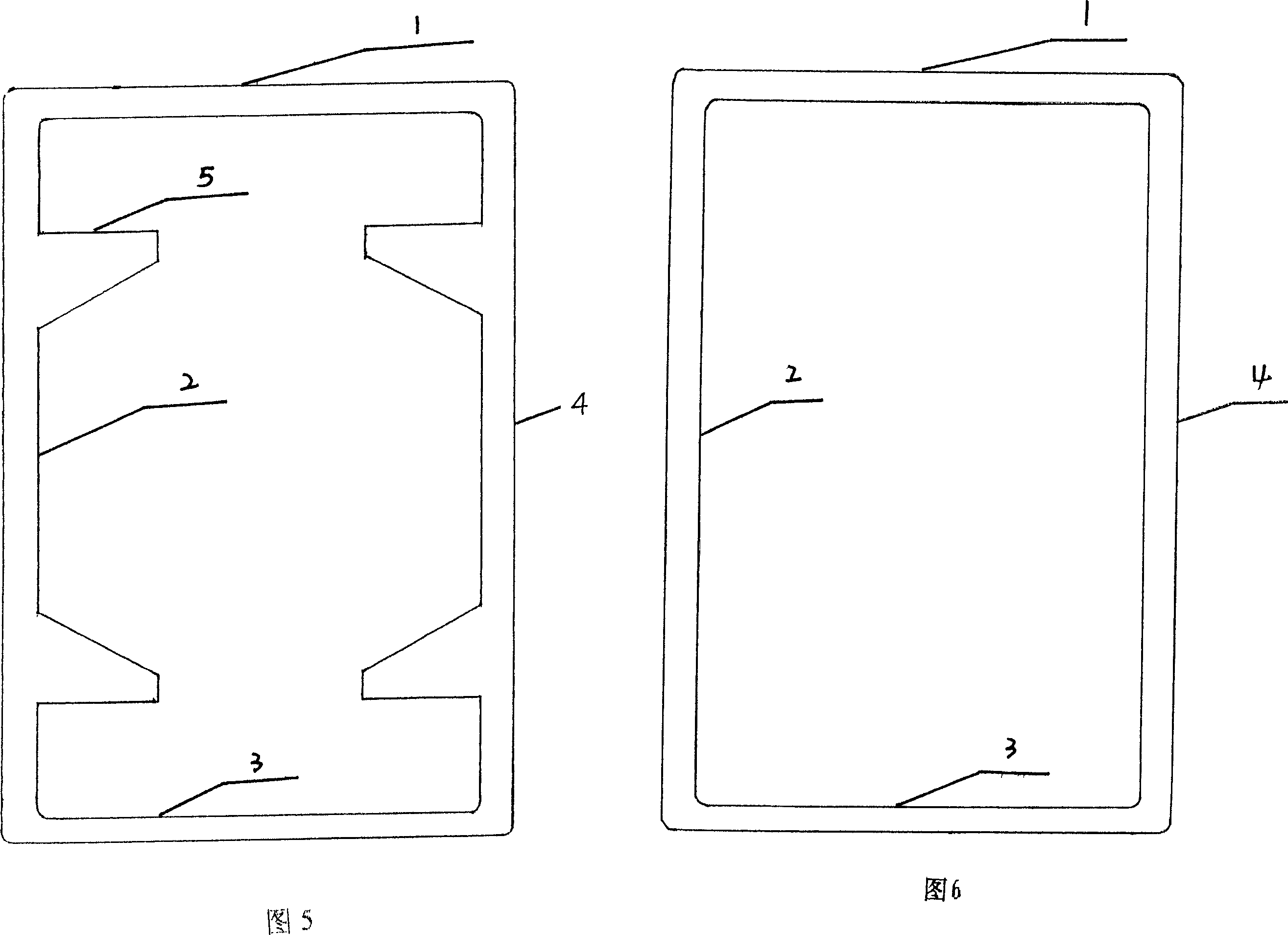

Dedicated frame for resin-based composite material sulfuration machine, repairing machine and its production method

The invention discloses a vulcanizer of resin-based composite material, specific rack of repairing machine and manufacturing method, which comprises the following parts: 36-58% resin, 35-58% fiber, 1-2% hardener dibenzoyl peroxide, 1-2% accelerant, 0.5-2.5% aging retarder, 1-3% color paste and 0.5-4% fire retardant.

Owner:丁宇

Preparation method of high-strength anti-dazzling coating layer

The invention provides a preparation method of a high-strength anti-dazzling coating layer. A formula comprises a shells, methyl methacrylate, gamma-methacyloxypropyltrimethoxylsilane, an ethanol solvent, benzyl peroxide and nano titanium oxide; the preparation method of the coating layer comprises the steps that the shells are placed into a ball milling machine to be milled; the methyl methacrylate, the gamma-methacyloxypropyltrimethoxylsilane, the ethanol solvent, the benzyl peroxide and a tetraethoxysilane solution are added to a reactor to perform reaction; shell powder and a mixed solution are mixed, aerated and stirred; other components are added to an icy water bath; spraying and roasting are conducted to obtain the high-strength anti-dazzling coating layer. The high-strength anti-dazzling coating layer has the advantages of better hardness and substrate adhesion force, the service life of the coating layer is prolonged which the protecting effect on a substrate can be enhancedby the powerful wear resistance and anti-impacting performance of the coating layer, the anti-dazzling effect is strong, the permeable rate of a visible light is high, and the quality of a product isimproved.

Owner:TIANJIN ZHONGYA HUITONG SCI & TECH CO LTD

Manufacturing method of resin for high-frequency copper clad plates

The invention discloses a manufacturing method of a resin for high-frequency copper clad plates, which comprises the following steps: adding toluene and benzoperoxide into a reaction kettle, and dissolving by stirring; adding polyphenylether and allyl bisphenol A, heating the reaction kettle to 90 DEG C, and reacting for 60 minutes; adding dicumyl peroxide and triallyl cyanate, and continuing reaction for 90 minutes while keeping the temperature at 90 DEG C; and after the reaction time finishes, immediately starting a cooler to cool to 50 DEG C below. The prepared resin effectively lowers the dielectric constant and dielectric loss of the copper clad plate, wherein the dielectric constant is lowered from 4.8 to 3.4, and the dielectric loss is lowered from 0.02 to 0.01 below. The resin is suitable for requirements of high-frequency electronic materials. The manufacturing technique is suitable for the existing copper clad plate production technique, and reduces the equipment investment. The copper clad plate has better processibility than other high-frequency plates.

Owner:铜陵浩荣华科复合基板有限公司

Preparation method of ethylenediamine modified maleic anhydride polylactide-glycolide polymer

ActiveCN104177553AImprove hydrophilicityAlleviate acid build-upEthylenediamineBiocompatibility Testing

The invention provides a preparation method of an ethylenediamine modified maleic anhydride polylactide-glycolide polymer disclosed as Formula (I), which comprises the following steps: by using D,L-lactide, glycolide and maleic anhydride as raw materials, stannous octanoate as a catalyst and benzoperoxide as an initiator, carrying out polymerization in an ampoule bottle under high-vacuum conditions to prepare maleic anhydride polylactide-glycolide (MPLGA), adding a trichloromethane solution of ethylenediamine into a trichloromethane solution of the MPLGA while stirring, keeping the temperature at lower than 10 DEG C for 5-10 minutes, reacting at room temperature for 30-60 minutes, dropwisely adding the product into excessive solvent, precipitating, washing with deionized water to a neutral state, and carrying out vacuum drying to constant weight, thereby obtaining the ethylenediamine modified maleic anhydride polylactide-glycolide polymer solid. The product has higher hydrophilicity and biocompatibility.

Owner:HUNAN UNIV OF SCI & TECH

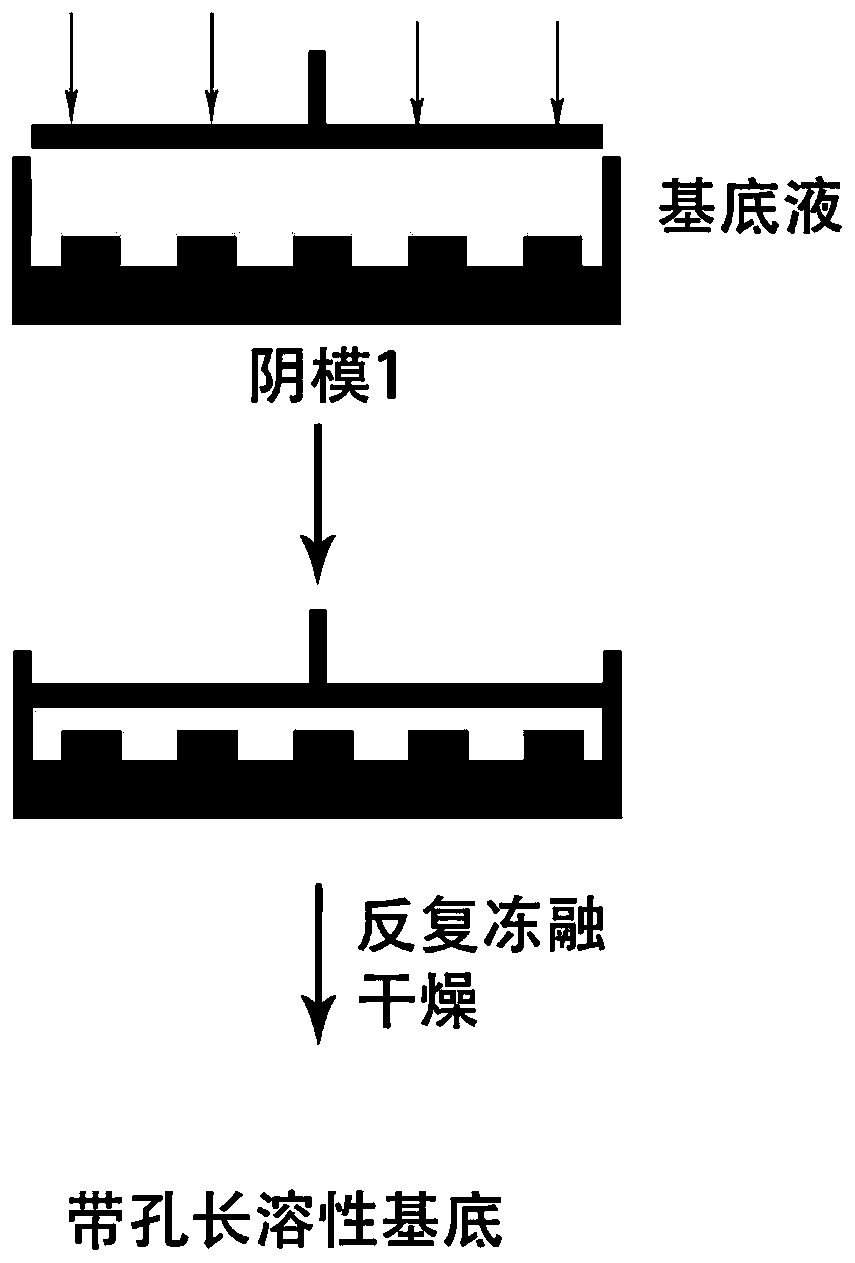

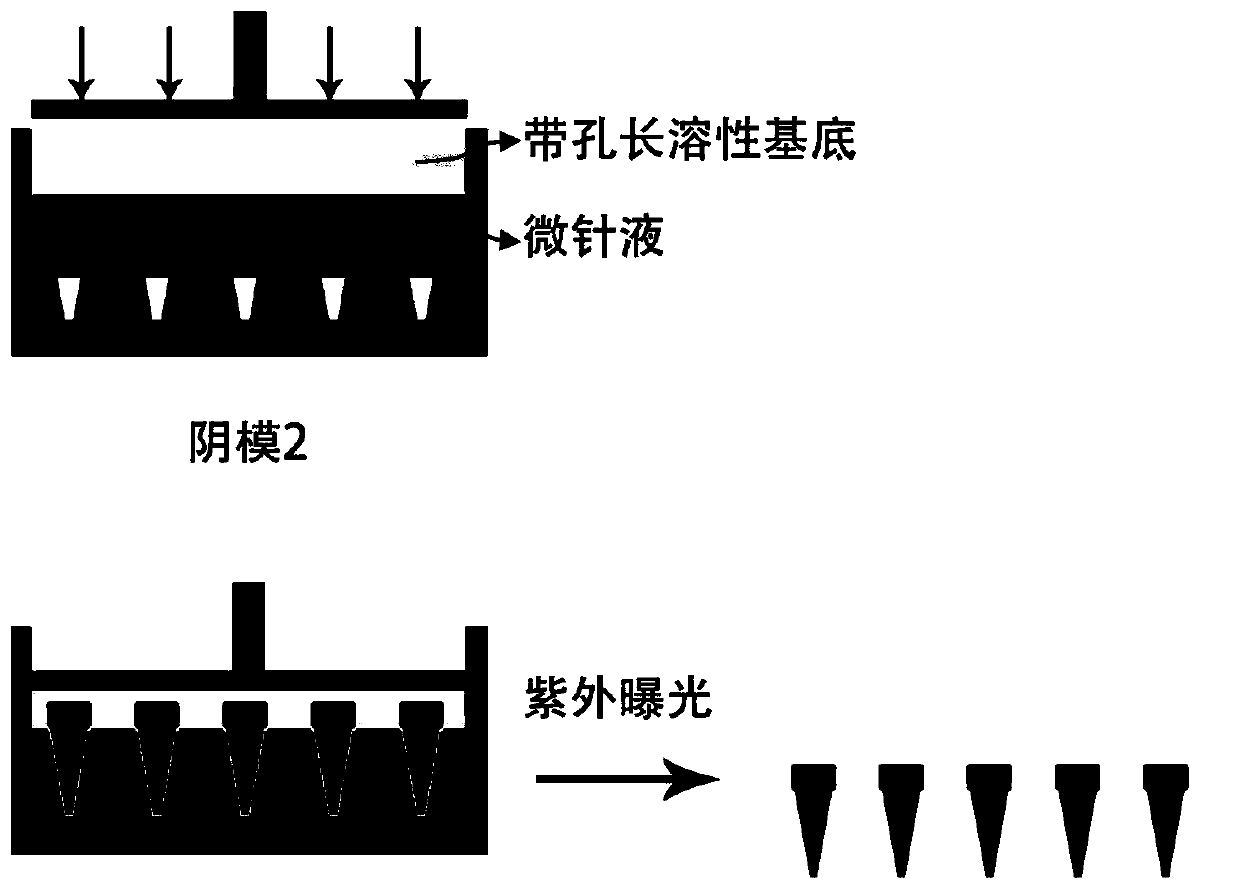

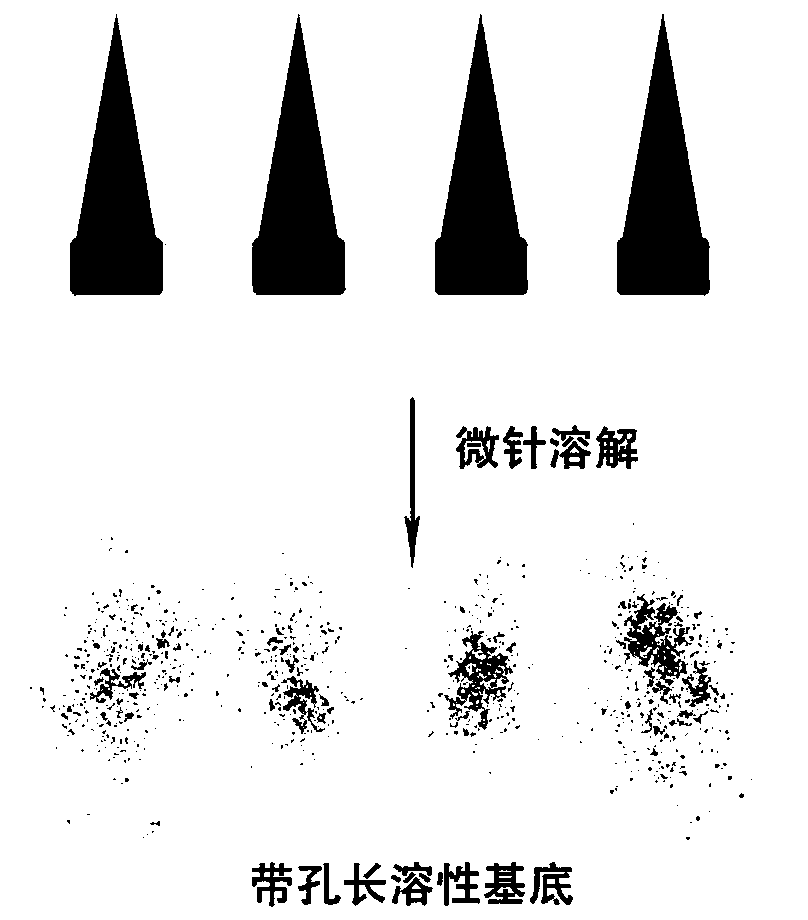

Microneedle patch for relieving skin acnes and preparation method thereof

ActiveCN110755529AStable structurePromote rewetSalicyclic acid active ingredientsHydroxy compound active ingredientsPolyvinyl alcoholOtic Agents

The invention relates to a microneedle patch for relieving skin acnes and a preparation method thereof. The microneedle patch comprises needle points and a base with holes, wherein raw materials of the needle points comprise soluble materials and medicine for relieving the skin acnes; raw materials of the base with holes comprise an excipient, a penetrating agent and medicine for relieving the skin acnes; the medicine for relieving the skin acnes is in the needle points and the base with the holes and is respectively and independently selected from at least one of vitamin A type medicine, radix salviae miltiorrhizae extracts, chrysanthemum flower extracts, benzoperoxide, eugenol, aloe extracts, azelaic acid and salicylic acid; the soluble material comprises at least one of hyaluronic acidand hyaluronate; and the excipient comprises polyvinyl alcohol and lactic acid / hydroxyacetic acid copolymers. The microneedle patch can fast achieve good anti-acne effects, and can also effectively prevent the pore blockage and secondary infection.

Owner:广州新济薇娜生物科技有限公司

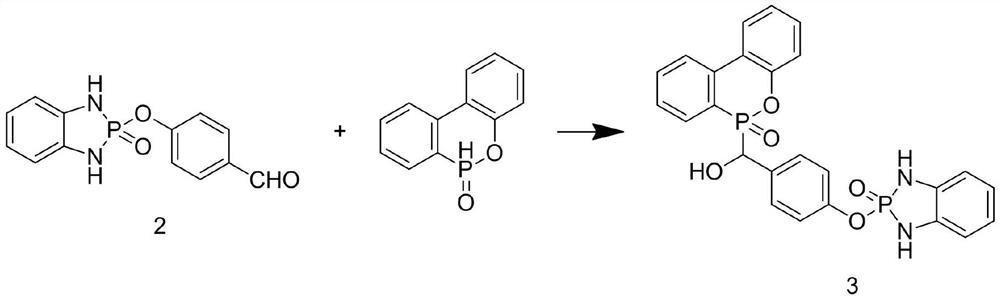

Immunosorbent for removing inflammatory factors in blood and preparation method thereof

ActiveCN108855003BGood blood compatibilityGood biocompatibilityOther blood circulation devicesOther chemical processesAlkaneInflammatory factors

Owner:NANKAI UNIV

Compositions and methods used to treat acne and candida

Disclosed herein is a water-soluble chelated complex of a co-polymer of N-acetylglucosamine-glucosamine pyrithione sale (AGP). This composition is characterized by a highly viscose texture with excellent surface properties and extremely long acting antimicrobial activity. AGP's antimicrobial activity against acne bacteria has been found superior to the benzyl peroxide the leading acne medication. In addition, AGP has been proven to be effective against many pathogenic yeast. AGP has the potential to be useful as a long acting broad-spectrum antimicrobial composition in a variety of dermatological medicaments and cosmetics.

Owner:PRO PHARMA

Strengthening agent prepared from fly ash

The invention discloses a reinforcing agent prepared from fly ash, which includes component A and component B. The component A is composed of the following raw materials in parts by mass: 100 parts of unsaturated polyester resin; crosslinking agent: 0.5 ~2 parts; white carbon black: 0.5~2.5 parts; dimethylaniline: 0.5~1.5 parts; fly ash: 300~450 parts; the B component includes the following raw materials in parts by mass: 50% benzyl peroxide Acyl paste: 50 parts; one or a mixture of heavy calcium, talc, kaolin: 50 parts. Prepare component A and component B separately. After the preparation is completed, sample and mix component A and component B at a mass ratio of 100:2-10 to obtain the final product. The reinforcing agent prepared from fly ash has the advantages of simple preparation process, low cost, economic benefits, environmental protection and the ability to turn waste into wealth.

Owner:ORDOS CITY YISHAN COAL APPLIED CHEM RES INST

Antistatic power protection tube and preparation method thereof

The invention discloses an antistatic electric power protection tube and a preparation method thereof, and belongs to the technical field of electric power tubing. The preparation method of the electric power protection tube comprises the following steps: 1, weighing raw materials; 2, adding polyethylene resin, ethylene propylene diene monomer, morpholine tetrasulfide, magnesium oxide, p-tert-butylphenol formaldehyde resin, 2, 4-dichlorobenzoyl peroxide and sodium carbonate into a mixing machine, performing mixing, and obtaining a premix; 3, adding modified graphene, di-n-octyltin dilaurate and dilauryl thiodipropionate into the premix, and obtaining a mixture; 4, carrying out extrusion granulation on the mixture, and carrying out extrusion molding, cooling and cutting to obtain the antistatic electric power protection tube, wherein the modified graphene has good antistatic capability and meets the requirements; in addition, the modifier is a flame-retardant component, so that a better flame-retardant effect can be achieved without adding a flame retardant, and the mechanical properties and processability of the power protection tube are maintained.

Owner:ANHUI RUIFENG PIPE IND CO LTD

Formula and use method of lens anti-fog wet tissue

InactiveCN112457922AImprove clarityAvoid affecting the line of sightInorganic/elemental detergent compounding agentsLens cleaning compositionsMethacrylate methylDioxyethylene Ether

The invention discloses a formula and a use method of a lens anti-fog wet tissue. According to the formula and the use method of the lens anti-fog wet tissue, the lens anti-fog wet tissue is preparedfrom the following raw materials: 1-3 parts of acrylic acid, 8-10 parts of methyl methacrylate, 2-5 parts of ethyl methacrylate, 8-10 parts of butyl methacrylate, 60-80 parts of butanone, 2-5 parts ofbenzoyl peroxide, 10-20 parts of a silver ion antibacterial agent, 30-50 parts of ethanol and 1-3 parts of fatty alcohol-polyoxyethylene ether sodium sulfate. Ethyl methacrylate mixed with fatty alcohol-polyoxyethylene ether sodium sulfate can be effectively attached to the surfaces of the lenses to prevent the lenses from fogging to influence the sight of people, so that the personal safety of people wearing the lenses is improved; silver ion disinfection powder is added into the anti-fog wet tissue, so that the surface of the lens is sterilized and disinfected while the lens is placed in the anti-fog agent and fogged, the face of a human body is prevented from being in contact with infectious microbes, the personal safety of people during use is guaranteed, and the product characteristics of the anti-fog wet tissue are improved.

Owner:南昌迈进科技有限公司

Method for preparing 2-bromo-fluorobenzyl bromide

InactiveCN102070397AReduce manufacturing costImprove securityHalogenated hydrocarbon preparationOrganic synthesisSulfite salt

The invention relates to the field of organic synthesis, in particular to a method for preparing 2-bromo-fluorobenzyl bromide, which comprises the following steps: (1) in the presence of an organic or inorganic solvent, adding a 2-bromo-6-fluorotoluene compound and 40-mass-percent hydrobromic acid and dripping 30-mass-percent hydrogen peroxide under a lighting condition, and reacting for 6 to 24 hours, wherein the molar ratio of 2-bromo-6-fluorotoluene to HBr is 1:(1-3.5) and the molar ratio of the 2-bromo-6-fluorotoluene to H2O2 is 1:(1-3.5); and (2) washing the reaction solution with saturated sodium sulfite solution and water, drying the reaction solution with anhydrous sodium sulfate, evaporating solvent under a reduced pressure, and obtaining the 2-bromo-6-fluorotoluene compound by silica gel column chromatography. In the method, the hydrobromic acid and hydrogen peroxide are used in place of the traditional N-bromosuccinimide brominating agent, so the production cost is reduced; and lighting is used in place of a benzoyl peroxide initiator, so method has the advantages of mild reaction conditions, high product purity, high yield and the like.

Owner:CHANGZHOU UNIV

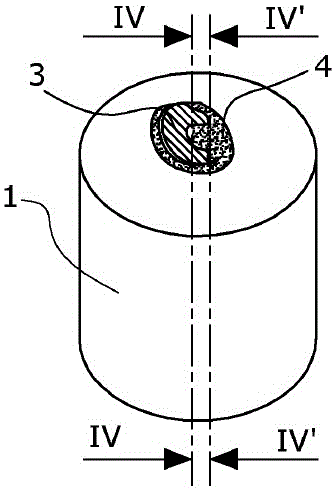

Water-tree-retardant crosslinked polyethylene cable material and cable prepared from same

InactiveCN104910503AEffective protectionNot easily oxidizedInsulated cablesInsulated conductorsLinear low-density polyethyleneLow-density polyethylene

The invention belongs to the technical field of materials and wire cables, and relates to a water-tree-retardant crosslinked polyethylene cable material. The invention is characterized in that the cable material is prepared from linear low-density polyethylene, styrene, polyurethane thermoplastic elastomer, polyethyleneglycol, ethylene-ethyl acetate copolymer, polyethylene wax or paraffin, commercially available nucleator 4030 for wire cable plastics, di-tert-butyl peroxide, benzoperoxide, commercially available antioxidant 300 for plastics or commercially available antioxidant 1010 for plastics or commercially available antioxidant 168 for plastics, and carbon black, wherein the weight ratio of the linear low-density polyethylene to the styrene is 8-10. The invention also relates to a preparation method of the cable material and a water-tree-retardant cable using the cable material. The cable has the advantages of favorable waterproofing effect, simple structure, more stable electric / mechanical / environmental properties, higher reliability and the like, is easy to produce and does not generate water trees.

Owner:JIANGSU ZHONGLI GRP CO LTD

Benzoxazine resin/ethylene-propylene-diene rubber composite heat insulating layer and preparation method thereof

The invention relates to a benzoxazine resin / ethylene-propylene-diene rubber composite heat insulating layer and a preparation method thereof and belongs to the technical field of heat insulation of solid rocket engines. Raw materials of the composite heat insulating layer comprise the following components in parts by mass: 100 parts of ethylene-propylene-diene rubber, 30-100 parts of benzoxazineresin, 10-15 parts of ablation-resistant fibers, 3-30 parts of solid packing, 6 -12 parts of flame-retardant system, 2-5 parts of process additives and 4.5-9 parts of vulcanization system, wherein thevulcanization system comprises a vulcanizing agent, a co-vulcanizing catalyst and an accelerant, the vulcanizing agent is at least one of sulfur, dicumyl peroxide and benzoyl peroxide, and the co-vulcanizing catalyst is 2-methylimidazole or 4-methylimidazole. The heat insulating layer not only has the favorable heat, mechanical and process properties of an ethylene-propylene-diene rubber heat insulating layer and good compatibility with various propellants and shell materials, but also has high char yield and ablation resistance (the linear ablation rate is 0.02-0.06 mm / s).

Owner:SHANGHAI AEROSPACE CHEM ENG INST

Air-brake hose material

The invention discloses an air-brake hose material which comprises the following raw materials in parts by weight: 93-100 parts of ethylene-propylene-diene monomer rubber 4770R, 7-10 parts of polydicyclopentadiene, 4-5 parts of polyvinylidene fluoride, 2-3 parts of polyvinyl alcohol, 1-2 parts of fenbendazole, 4-6 parts of poly(butyl acrylate), 2-3 parts of monopotassium phosphate, 0.2-0.4 part of trimethylhexamethylenediamine, 2-4 parts of calcium aluminate, 4-7 parts of carbon fiber, 20-24 parts of carbon black, 1-1.6 parts of 2,4-dichlorobenzoyl peroxide, 0.8-1 part of an accelerating agent CSB, 0.4-1 part of an accelerating agent CPB and 16-27 parts of a composite filler. An air-brake hose provided by the invention is good in positioning performance, high in overall strength and good in aging resistance and corrosion resistance.

Owner:WUHU JIACHENG ELECTRONICS TECH

Two-component adhesive for bonding artificial teeth to a denture base

ActiveCN105008448AWon't failWill not cause failureEster polymer adhesivesOrganic non-macromolecular adhesiveGlycidyl methacrylateMeth-

A mixture containing at least one first component A and at least one second component B, characterized in that said at least one first component A comprises a methyl methacrylate, a copolymer of methyl methacrylate dissolved in excess methyl methacrylate, optionally comprising, additionally dissolved therein, atleast one polyfunctional (meth)acrylate, especially ethylene glycol dimethacrylate, butanediol dimethacrylate, hexanediol dimethacrylate, triethylene glycol dimethacrylate (TEGDMA), tetraethylene glycol dimethacrylate, diurethane dimeth- acrylate, bis(hydroxymethacryloyloxypropoxy)phenylpropane (bis-GMA), polyethylene glycol dimethacrylate, trimethylolpropane trimethacrylate, ditrimethylol- propane tetraacrylate;and a peroxide-based free-radical initiator, wherein said copolymer of methyl methacrylate is present in an amount of 30-50 parts by weight dissolved in a solution of 65-85 parts by weight of monomeric methyl methacrylate and 3-15 parts by weight of the polyfunctional (meth)acrylate, especially the triethylene glycol dimethacrylate (TEGDMA), mixed with a solution of 0.5 to 3 parts by weight of said peroxide-based free-radical initiator, especially dibenzoyl peroxide, in 70-90 parts by weight of monomeric methyl methacrylate, and said at least one second component B comprises methyl methacrylate and a tertiary amine.

Owner:VITA ZAHNFABRIK H RAUTER GMBH & CO KG

Acrylate modified rubber pressure-sensitive adhesive, and acrylate modified rubber pressure-sensitive adhesive tape and preparation method thereof

InactiveCN112194989AImprove adhesionImprove aging resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceGlycerol

The invention relates to the technical field of pressure-sensitive adhesives, in particular to an acrylate modified rubber pressure-sensitive adhesive, and an acrylate modified rubber pressure-sensitive adhesive tape and a preparation method thereof. The acrylate modified rubber pressure-sensitive adhesive is composed of a component A and a component B. The component A comprises the following rawmaterials by weight: 40-50 parts of cis-1,4-polyisoprene, 2-4 parts of acrylic acid, 30-35 parts of methylbenzene, 0.2-0.4 part of benzoperoxide and 2-4 parts of hydroxypropyl methacrylate. The component B comprises the following raw materials by weight: 6-8 parts of terpene resin, 6-8 parts of coumarone resin, 1-2 parts of glycerol, 0.5-1.5 parts of an anti-aging agent and 0.6-0.8 part of a cross-linking agent. Compared with existing special pressure-sensitive adhesives for PET pressure-sensitive adhesive tapes, the acrylate modified rubber pressure-sensitive adhesive tape of the invention has the characteristics of better aging resistance, better adhesion to a PET base material, higher peel strength and excellent high viscosity.

Owner:广东安利华新材料科技有限公司

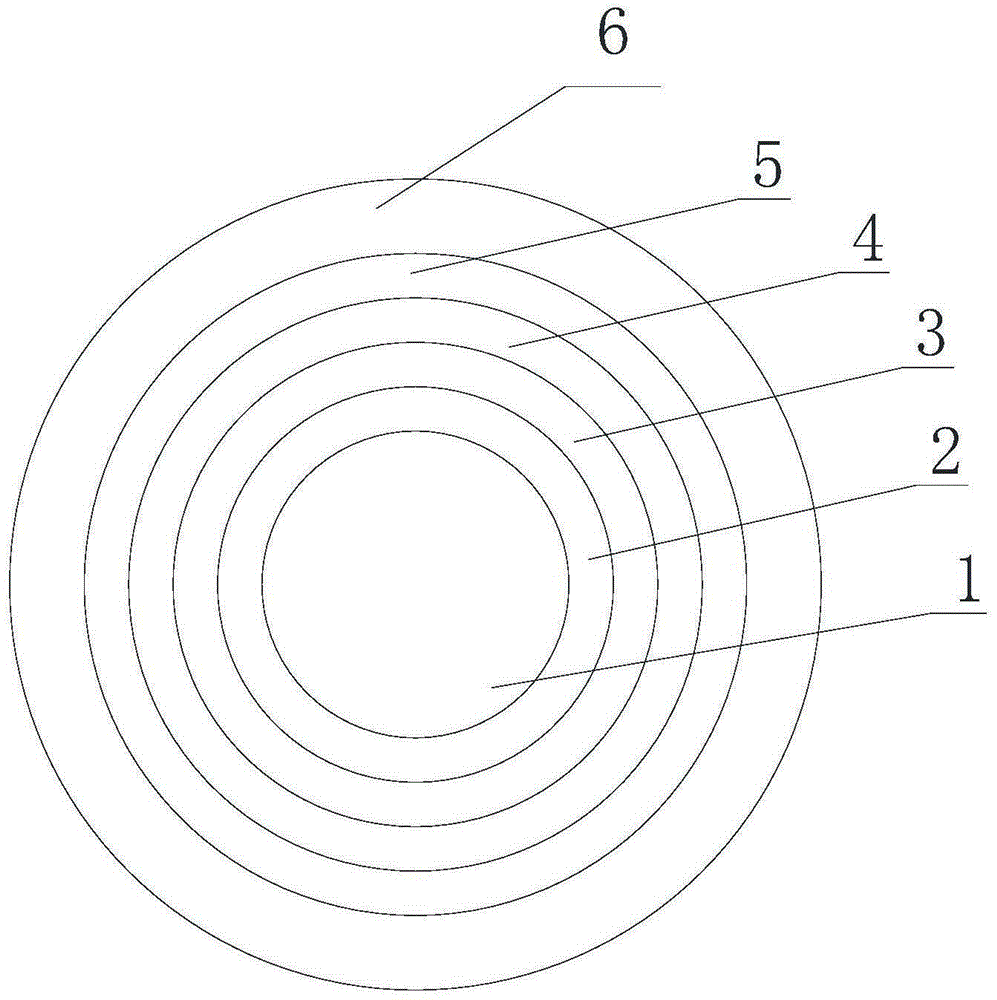

High-performance control cable

ActiveCN105206323AImprove thermal conductivityImprove flame retardant performanceInsulated cablesCommunication cablesFiberPolyolefin

The invention discloses a high-performance control cable which comprises a cable core. An insulating layer, a temperature decreasing lining layer, a flame retardant layer, a metal armoring layer and a sheath layer are sequentially arranged outside the cable core. The insulating layer is made of a low-smoke zero-halogen polyolefin material which is prepared from, by weight, polyvinyl chloride, a propylene-vinyl copolymer, methyl vinyl silicone rubber, tetra propyl phenylsulfonyl, isopropyl tri(pyrophosphoric acid) titanate, caprolactam, magnesium oxide, 2,4-dichlorobenzoyl peroxide, alkylated diphenylamine, 2-mercaptobenzimidazol zincate, magnesium stearate, kieselguhr, ceric oxide, polyvinyl chloride nitrile fibers, anti-aging agents and antioxidants. The cable is good in thermal conductivity and excellent in flame retardant performance.

Owner:蓝德能源科技股份有限公司

CPE (Chlorinated polyethylene) coated quartz sand modified low-density polyethylene foam material and preparation method thereof

ActiveCN103102565AImprove interfacial bond strengthHigh tensile strengthLow-density polyethylenePolymer science

The invention discloses a CPE (chlorinated polyethylene) coated quartz sand modified low-density polyethylene foam material. The low-density polyethylene foam material is prepared from the following raw materials in parts by weight: 60-100 parts of LDPE (low-density polyethylene), 0-40 parts of LLDPE (linear low-density polyethylene), 30-40 parts of CPE, 10-20 parts of quartz sand, 2-3 parts of vinyl tris(beta-methoxyethoxy) silane, 5-10 parts of triphenyl phosphate, 4-6 parts of 4,4'-oxydibenzenesulfonyl hydrazide, 2-3 parts of ammonium bicarbonate, 5-8 parts of n-butyl methacrylate, 1-1.5 parts of 2,4-dichlorobenzoyl peroxide, 2-3 parts of zinc stearate, 1-2 parts of calcium stearate, 1-2 parts of lead sulfate tribasic, 2-3 parts of polyethylene wax, 3-5 parts of modified tree ash, 1-2 parts of ultraviolet light absorber THUV-328 and 2-3 parts of antioxidant 264. The CPE-coated quartz sand modified low-density polyethylene foam material disclosed by the invention is light in weight, soft, high in strength and good in rebound resilience, the foaming effect is ideal, and bubble holes are uniform, small and dense, so that the CPE-coated quartz sand modified low-density polyethylene foam material is good in fire resistance, resistant to chemical corrosion and ageing and is durable in use.

Owner:重庆锋胜包装材料有限公司

High-strength composite fiber

InactiveCN104480570AHigh strengthImprove performanceConjugated synthetic polymer artificial filamentsLanolinStearic acid

The invention relates to a high-strength composite fiber which is prepared from the following raw materials in parts by weight: 1-3 parts of silver nitrate, 6-10 parts of benzoperoxide, 5-9 parts of dolomite, 4-8 parts of limestone, 7-11 parts of brucite fiber, 3-8 parts of aluminum oxide, 6-11 parts of calcium oxide, 4-8 parts of stearic acid, 5-10 parts of boron fiber, 2-6 parts of polytetrafluoroethylene, 5-11 parts of lanolin wax polyoxypropylene ether and 8-13 parts of trimethylolpropane glycidol ether. The high-strength composite fiber has the advantages of high strength, uniform fiber distribution, favorable elasticity and favorable comprehensive properties.

Owner:QINGDAO LAOXIANG TEA PROD

Modified resin-type waterproof paint

A disclosed modified resin-type waterproof paint is prepared from the following raw materials in parts by weight: 1.5-2.8 parts of chlorinated paraffin, 2.3-3.5 parts of cobalt trifluoroacetylacetonate, 3.8-6.5 parts of phenolic resin, 1.2-2.1 parts of fatty alcohol polyoxyethylene ether, 5-10 parts of ethanol, 2.5-3.6 parts of thulium trifluoroacetylacetonate, 1.3-3.6 parts of methyl methacrylate-butadiene-styrene terpolymer and 2.5-3.5 parts of tert-butyl peroxybenzoate. Compared with conventional waterproof paints, the modified resin-type waterproof paint is used for water prevention of buildings such as basements, toilets, kitchens, pools and the like, does not need heating when used, helps to reduce environmental pollution, is low in manufacturing cost, simple to construct and operate, good in waterproof performance when constructed on the base of multiple wet or dried materials, free of toxicity and harm and long in service life, and is a relatively ideal waterproof material.

Owner:QINGDAO HAIBAN PLASTIC IND & TRADE

A steel mesh skeleton composite pipe

The invention discloses a steel mesh skeleton composite pipe, which comprises the following raw material components in parts by mass: 15-55 parts of HDPE, 3-18 parts of LDPE, 6-24 parts of LLDPE, 2-20 parts of EVA, drawing grade 4-18 parts of polypropylene, 5-10 parts of montmorillonite, 1-10 parts of white carbon black, 1-10 parts of barium sulfate, 10-20 parts of graphite, 5-15 parts of carbon nanometer, 8- 20 parts, 0.5-4 parts of silane coupling agent KH 151, 1-2 parts of benzophenone, 1-10 parts of composite lubricant, 0.01-0.2 parts of nano silver, 0.5-5 parts of flavonol, 0.5 parts of zinc stearate -5 parts, 1-5 parts of polyacrylamide, 5-10 parts of methyl methacrylate, 1-5 parts of 2,4-dichlorobenzoyl peroxide, 6-ethoxy-2,2,4- 10-20 parts of trimethyl-1,2-dihydroquinoline. The mechanical properties, impact resistance, deformability, anti-aging performance and anti-fouling performance of the pipe made of the raw material of the invention are significantly and greatly improved.

Owner:深圳市心立方节能新技术有限公司

Skin-care facial cleanser

InactiveCN103655236AReduce manufacturing costGood skin care and cleansing effectCosmetic preparationsToilet preparationsCleansers skinMedicine

The invention discloses a skin-care facial cleanser, comprising the following components by weight percent: 20-30 parts of salicylic acid, 5-10 parts of benzyl peroxide, 15-25 parts of glycollic acid, 5-10 parts of medicated scrubs, 5-10 parts of bamboo charcoal powder, 5-9 parts of beewax and 2000-3000 parts of deionized water. The skin-care facial cleanser disclosed by the invention is low in preparation cost, good in skin-care and face-cleaning effects, free of irritation, low in susceptibility and suitable for various skins, and face skins are not allergic after the skin-care facial cleanser is used for a long period of time.

Owner:QINGDAO ANXIN MEDICAL DEVICES

Water-glass-containing compression-resistant impervious wear-resistant reinforced concrete drainage pipe and preparation method thereof

InactiveCN106810186ALarge specific surface areaSmall particle sizeShaping reinforcementsMeth-Resin matrix

The invention discloses a water-glass-containing compression-resistant impervious wear-resistant reinforced concrete drainage pipe and a preparation method thereof. The invention is characterized in that the drainage pipe is prepared from fly ash, mineral slag powder, metakaolin, gypsum, sodium sulfate, a naphthalene high efficiency water reducing agent, sand, gravel, a bisphenol A epoxy resin E-44, benzoperoxide, acrylic acid, N,N-dimethylethanolamine, organic montmorillonite, cement, steel fibers, calcined diatomite, steel bars, urea, sodium methylsiliconate, potassium dichromate, water glass and the like. The water-based epoxy resin is prepared by graft copolymerization, thereby obtaining the polymer-cement base material interpenetrating-network structure. The organic montmorillonite used as the filler is added into the water-based epoxy resin matrix by high-polymer solution intercalation to prepare the water-based epoxy resin / montmorillonite nano composite material. The uniform intense magnetic field is applied to the steel fiber reinforced concrete mixture to prepare the one-way-distributed steel fiber reinforced concrete, so the fibers have high utilization ratio and favorable reinforcement effect.

Owner:阜阳市华顺水泥制品有限公司

Preparation method of oil-resistant cable sheath material

ActiveCN104974391AHigh volume resistivityIncreased vertical burn ratingRubber insulatorsInsulated cablesThioureaDecabromodiphenyl ether

The invention discloses a preparation method of an oil-resistant cable sheath material, which comprises the following steps: compounding 45-67 parts by weight of chloroprene rubber and 8-23 parts by weight of polyvinyl chloride in a Banbury mixer, keeping the temperature, and cooling to room temperature; adding 12-20 parts of decabromodiphenyl oxide, 1-9 parts of ethylene thiourea, 5-15 parts of benzoperoxide, 8-21 parts of aluminum hydroxide, 1-13 parts of dioctyl epoxytetrahydrophthalate and 4-17 parts of polyvinyl butyral, compounding for 3-5 minutes adding 3-14 parts of lubricant and 3-16 parts of antioxidant 1010, and compounding for 2-4 minutes; and carrying out thin passing in an open mill, and extruding through a double screw extruder. The cable sheath material has the advantages of higher volume resistivity, higher vertical burning grade and higher oil resistance. The method has the advantages of simple preparation technique and reasonable time and temperature control settings, and can be widely used in industrial production.

Owner:武汉市钢电电线制造有限公司

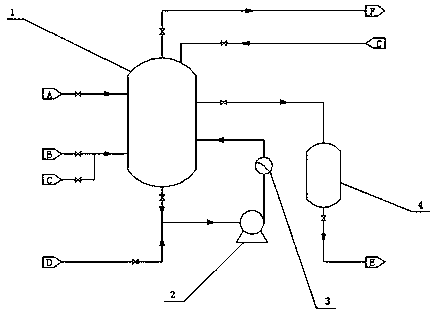

A kind of method that benzyl peroxide is prepared by toluene liquid-phase air oxidation method

ActiveCN106831521BGuaranteed oxygen contentAchieve the purpose of obtainingOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsToluene oxidationReaction temperature

The invention discloses a method for preparing benzyl peroxide by adopting a toluene liquid-phase air oxidation method. Under the synergistic effect of a catalyst, an initiator and an assistant, toluene and oxygen in the air perform oxidizing reaction to generate the benzyl peroxide, the balance of reaction temperature is ensured by adopting an external circulated cooling mode, pressure balance in a toluene oxidation reactor is controlled according to the discharge amount of high-temperature compressed tail gas or nitrogen or reaction tail gas led from the upper portion of the reactor, the reaction process is full-automatically controlled, and safe, stable and continuous reaction is ensured. The oxygen content in the reaction tail gas is ensured by controlling the high-temperature compressed tail gas or nitrogen led from the lower portion of the reactor and reaction conditions, and higher toluene conversion rate is ensured. The product benzyl peroxide can serve as a raw production material of benzene-alcohol, aromatic aldehyde, aromatic acid and benzyl ester, and the method is a green and environment-friendly no-chloride involved process.

Owner:湖北科林博伦新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com