Dedicated frame for resin-based composite material sulfuration machine, repairing machine and its production method

A technology of composite materials and production methods, applied in the field of special racks, can solve the problems of mechanical handling equipment that cannot be used, labor intensity of operators, and insufficient bending strength, etc., and achieve the effect of light weight, low cost, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

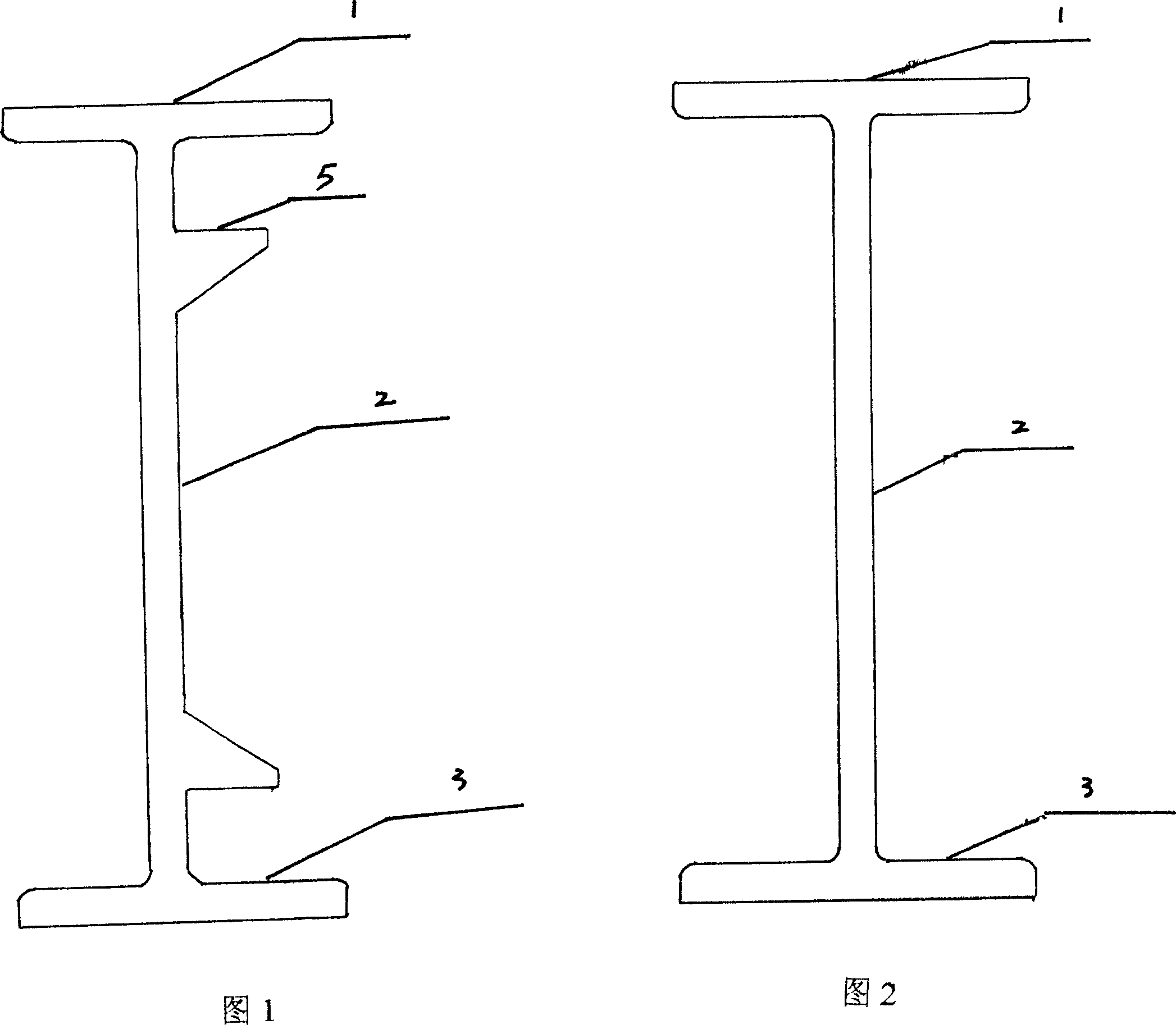

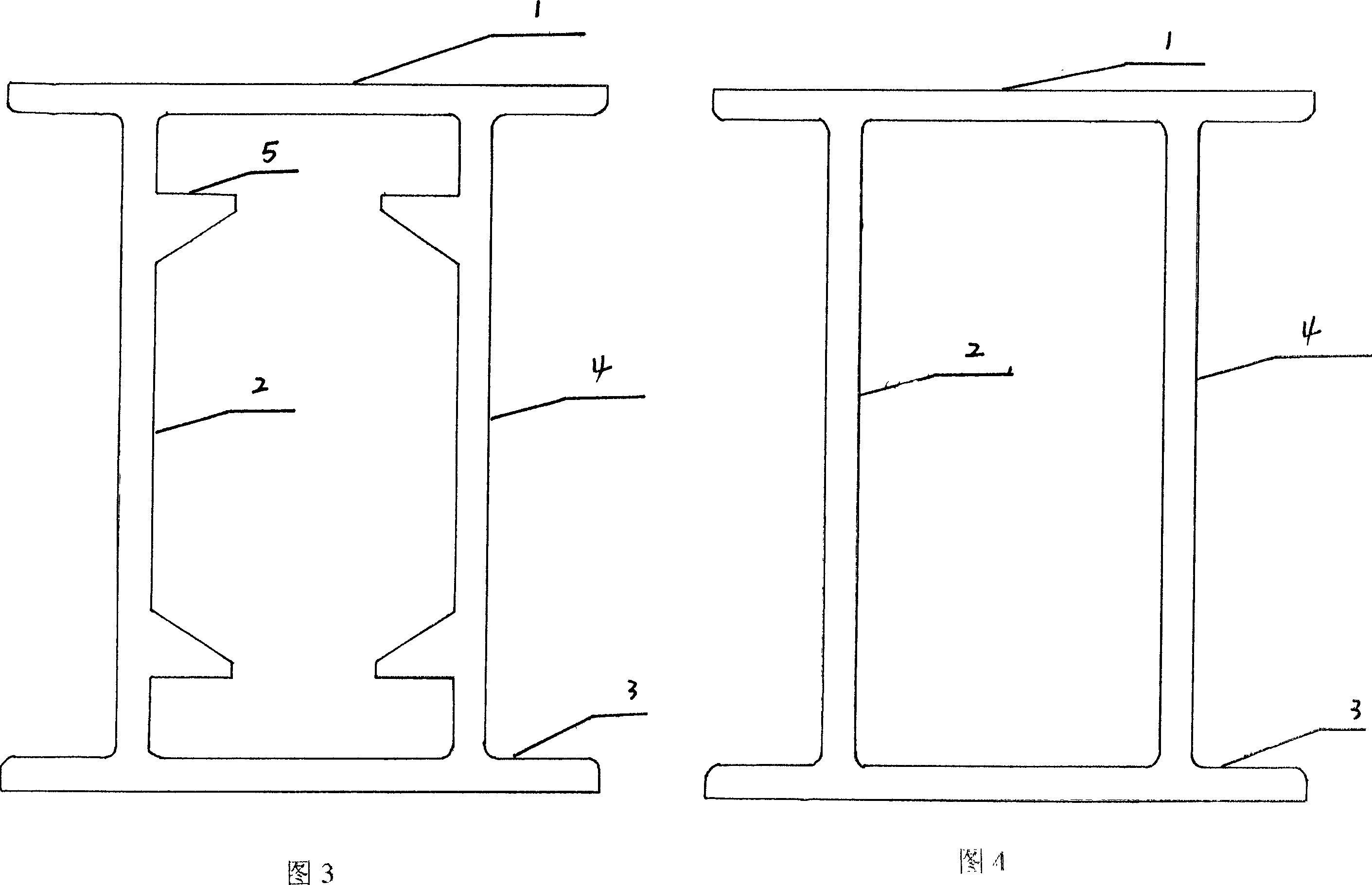

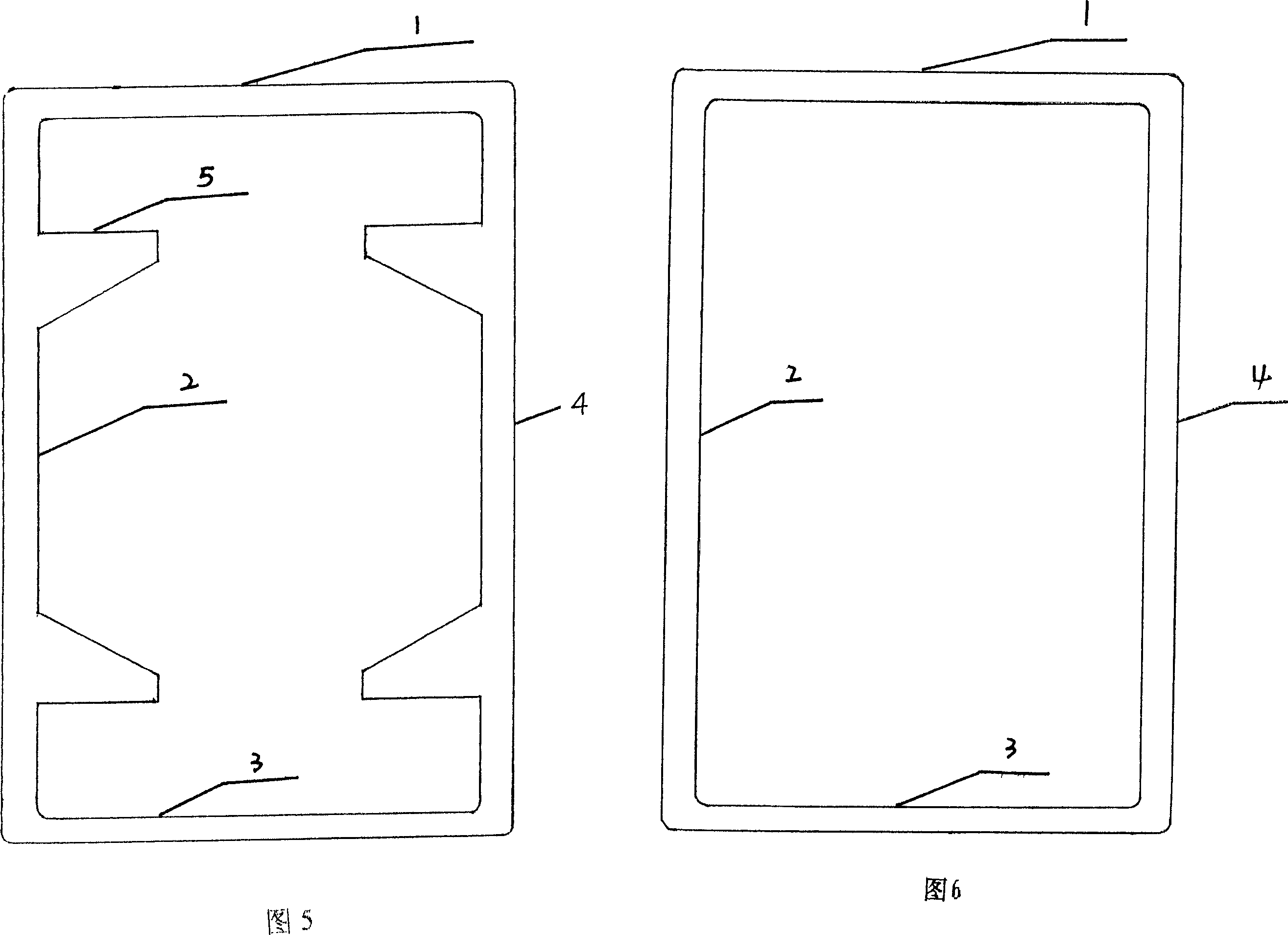

[0021] As shown in Figure 1-7, the composite materials used in resin-based composite vulcanizers and repair machine special frames are composed of unsaturated polyester resin, glass fiber bundle yarn, composite unidirectional fiber mat, and benzoyl peroxide. Percent by weight: 36 parts of unsaturated polyester resin, 25 parts of glass fiber bundle yarn, 26 parts of composite unidirectional fiber mat, 2 parts of benzoyl peroxide curing agent, 2 parts of accelerator, 4 parts of flame retardant, color paste 3 parts, anti-aging agent 2 parts.

[0022] As shown in Figure 8-9, the production method of the resin-based composite vulcanizer and the special frame of the repair machine is as follows: 1. 36 parts of unsaturated polyester resins are mixed with 2 parts of benzoyl peroxide for curing Agent, 2 parts of accelerator, 4 parts of flame retardant, 3 parts of color paste, 2 parts of anti-aging agent, mix well, and place in the dipping tank of the pultrusion machine. 2. The pultrus...

Embodiment 2

[0024] As shown in Figure 1-7, the special frame (profile) for resin-based composite vulcanizing machine and repair machine includes: frame (profile) material, structural shape (Figure 1-7), and the composite material is composed of unsaturated Composed of polyester resin, glass fiber bundle yarn, composite unidirectional fiber mat, and benzoyl peroxide, its percentage by weight is: 58 parts of unsaturated polyester resin, 13 parts of glass fiber bundle yarn, 25 parts of composite unidirectional fiber mat, 1 part of benzoyl peroxide curing agent, 1 part of accelerator, 0.5 part of flame retardant, 1 part of color paste, 0.5 part of anti-aging agent.

[0025] As shown in Figure 8-9, the production method of resin-based composite vulcanizer and repair machine special frame (profile), its process steps are: 1.58 parts of unsaturated polyester resin, and equipped with 1 part of benzyl peroxide Acyl curing agent, 1 part of accelerator, 0.5 part of flame retardant, 1 part of color p...

Embodiment 3

[0027] As shown in Figure 1-7, the special frame (profile) for resin-based composite vulcanizing machine and repair machine includes: frame (profile) material, structural shape (Figure 1-7), and the composite material is composed of unsaturated Composed of polyester resin, glass fiber bundle yarn, composite unidirectional fiber mat, and benzoyl peroxide, the percentages by weight are: 53.5 parts of unsaturated polyester resin, 16.5 parts of glass fiber bundle yarn, 18.5 parts of composite unidirectional fiber mat, 1.5 parts of benzoyl peroxide curing agent, 2 parts of accelerator, 4 parts of flame retardant, 2.5 parts of color paste, 1.5 parts of anti-aging agent.

[0028]As shown in Figure 8-9, the production method of resin-based composite vulcanizer and repair machine special frame (profile), its process steps are: 1.53.5 parts of unsaturated polyester resin, and equipped with 1.5 parts of benzyl peroxide Acyl curing agent, 2 parts of accelerator, 4 parts of flame retardant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com