High-performance control cable

A control cable, high-performance technology, applied in the direction of insulated cables, communication cables, cables, etc., can solve the problems of difficult to guarantee work safety and reliability, insulation layer burning, affecting the normal operation of control cables, etc., to achieve thermal conductivity and flame retardant. Good performance, enhanced flame retardant performance, excellent thermal conductivity and flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

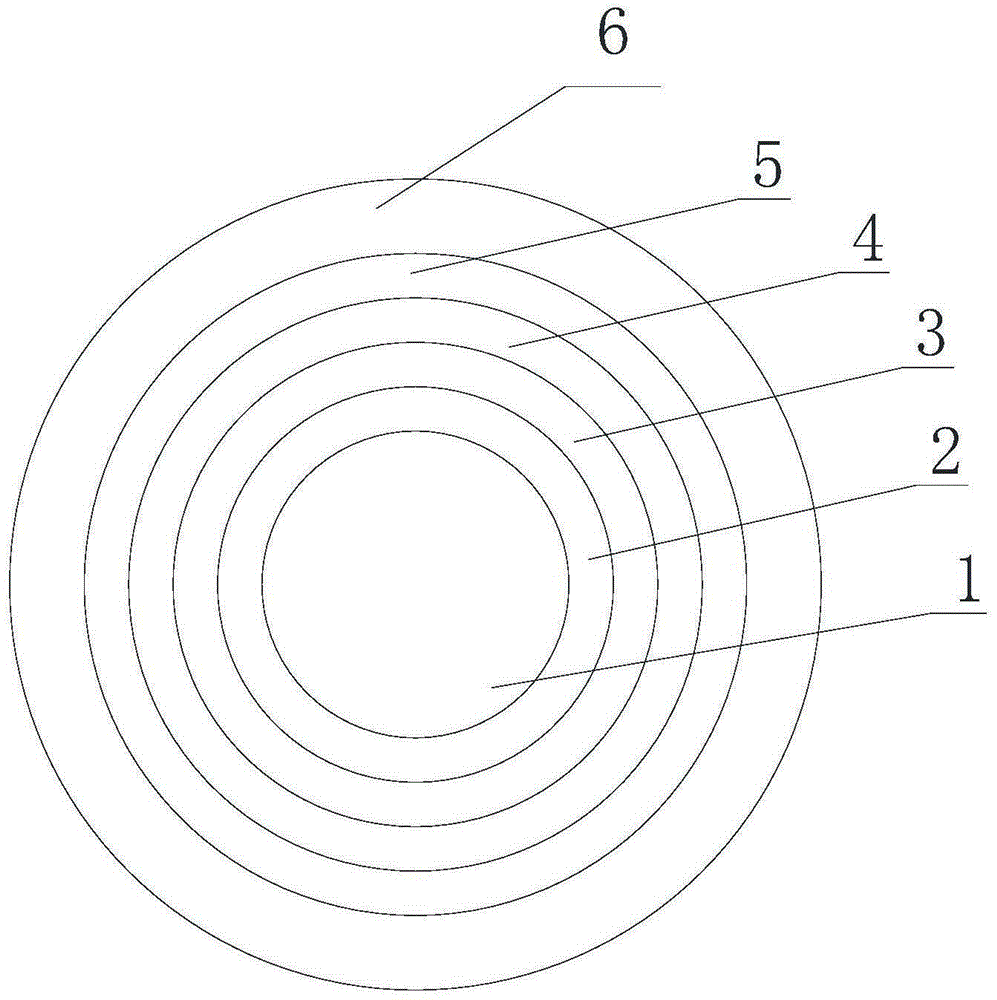

[0017] refer to figure 1 , a high-performance control cable, including a cable core 1, an insulating layer 2, a cooling inner lining layer 3, a refractory layer 4, a metal armor layer 5 and a sheath layer 6 are sequentially arranged outside the cable core 1; wherein the insulating layer 2 adopts Made of low-smoke halogen-free polyolefin material.

[0018] The raw materials of low-smoke halogen-free polyolefin materials include by weight: 35 parts of polyvinyl chloride, 20 parts of propylene-ethylene copolymer, 30 parts of methyl vinyl silicone rubber, 1.5 parts of tetrapropylbenzenesulfonyl, isopropyl tri (Dioctyl pyrophosphate) titanate 2 parts, caprolactam 2 parts, magnesium oxide 3 parts, 2,4-dichlorobenzoyl peroxide 1.5 parts, alkylated diphenylamine 3 parts, 2-mercaptobenzimidazole 1 part of zinc salt, 2.5 parts of magnesium stearate, 30 parts of diatomaceous earth, 20 parts of cerium dioxide, 20 parts of polyvinyl chloride nitrile fiber, 2.5 parts of anti-aging agent, a...

Embodiment 2

[0020] refer to figure 1 , a high-performance control cable, including a cable core 1, an insulating layer 2, a cooling inner lining layer 3, a refractory layer 4, a metal armor layer 5 and a sheath layer 6 are sequentially arranged outside the cable core 1; wherein the insulating layer 2 adopts Made of low-smoke halogen-free polyolefin material.

[0021] The raw materials of low-smoke halogen-free polyolefin materials include by weight: 20 parts of polyvinyl chloride, 40 parts of propylene-ethylene copolymer, 15 parts of methyl vinyl silicone rubber, 2.5 parts of tetrapropyl benzene sulfonyl, isopropyl three (Dioctyl pyrophosphate) titanate 1.2 parts, caprolactam 6 parts, magnesium oxide 1 part, 2,4-dichlorobenzoyl peroxide 3.5 parts, alkylated diphenylamine 1 part, 2-mercaptobenzimidazole 2 parts of zinc salt, 0.5 part of magnesium stearate, 50 parts of diatomaceous earth, 10 parts of cerium dioxide, 50 parts of polyvinyl chloride nitrile fiber, 0.5 part of anti-aging agent...

Embodiment 3

[0023] refer to figure 1 , a high-performance control cable, including a cable core 1, an insulating layer 2, a cooling inner lining layer 3, a refractory layer 4, a metal armor layer 5 and a sheath layer 6 are sequentially arranged outside the cable core 1; wherein the insulating layer 2 adopts Made of low-smoke halogen-free polyolefin material.

[0024] The raw materials of low-smoke halogen-free polyolefin materials include by weight: 34 parts of polyvinyl chloride, 32 parts of propylene-ethylene copolymer, 25 parts of methyl vinyl silicone rubber, 1.8 parts of tetrapropylbenzenesulfonyl, isopropyl tri (Dioctyl pyrophosphate) titanate 1.8 parts, caprolactam 3 parts, magnesium oxide 2.5 parts, 2,4-dichlorobenzoyl peroxide 2 parts, alkylated diphenylamine 2.4 parts, 2-mercaptobenzimidazole 1.6 parts of zinc salt, 2.3 parts of magnesium stearate, 35 parts of diatomaceous earth, 17 parts of cerium dioxide, 40 parts of polyvinyl chloride nitrile fiber, 1.6 parts of anti-aging a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com