A kind of method that benzyl peroxide is prepared by toluene liquid-phase air oxidation method

A technology of benzyl peroxide and air oxidation, applied in the field of preparation of organic compounds and preparation of benzyl peroxide, which can solve the problems of chlorine in products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

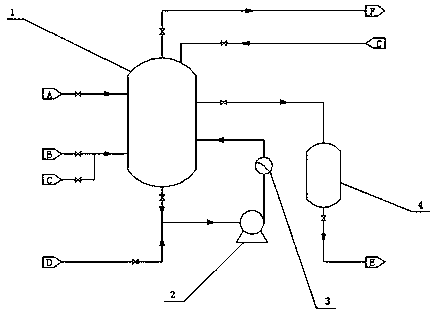

Image

Examples

Embodiment 1

[0028] Embodiment 1 A method for preparing benzyl peroxide by liquid-phase air oxidation of toluene comprises the following steps:

[0029] (1) Catalyst preparation

[0030] The catalyst cobalt naphthenate, the initiator benzyl peroxide and the auxiliary agent bisphosphonate are dissolved and homogenized in toluene, and then heated to 60°C to obtain a catalyst preparation solution;

[0031] The chemical name of the auxiliary agent bisphosphonate is: 1-hydroxyethylidene-1,1-diphosphonic acid (two) octyl ester;

[0032] (2) Pretreatment of raw materials

[0033] After the air is filtered, it is compressed to a pressure of 1.3MPa (G) and then preheated to a temperature of 160°C to obtain high-temperature compressed air;

[0034] Compress the circulating tail gas to a pressure of 1.3MPa (G) and preheat it to a temperature of 160°C to obtain a high-temperature compressed tail gas;

[0035] Heat and pressurize toluene to 160°C, high-temperature and high-pressure toluene with a pr...

Embodiment 2

[0043] Embodiment 2 A method for preparing benzyl peroxide by liquid-phase air oxidation of toluene comprises the following steps:

[0044] (1) Catalyst preparation

[0045] The catalyst cobalt acetate, the initiator cumene hydroperoxide and the auxiliary agent bisphosphonate are dissolved and homogenized in toluene, and then heated to 70°C to obtain a catalyst preparation solution;

[0046] The chemical name of the auxiliary agent bisphosphonate is: 1-hydroxyethylidene-1,1-diphosphonic acid (two) octyl ester;

[0047] (2) Pretreatment of raw materials

[0048] Compress the air after filtering to a pressure of 1.4MPa(G) and preheat it to a temperature of 170°C to obtain high-temperature compressed air;

[0049] Compress nitrogen to a pressure of 1.4MPa(G) and then preheat to a temperature of 170°C to obtain high-temperature and high-pressure nitrogen;

[0050] Heat and pressurize toluene to 170°C and high temperature and high pressure toluene with a pressure of 1.4MPa(G); ...

Embodiment 3

[0058] Embodiment 3 A method for preparing benzyl peroxide by liquid-phase air oxidation of toluene comprises the following steps:

[0059] (1) Catalyst preparation

[0060] The catalyst cobalt benzoate, the initiator hydrogen peroxide and the auxiliary agent bisphosphonate are dissolved and homogenized in toluene, and then heated to 80° C. to obtain a catalyst preparation solution;

[0061] The chemical name of the auxiliary agent bisphosphonate is: 1-hydroxyethylidene-1,1-diphosphonic acid (two) octyl ester;

[0062] (2) Pretreatment of raw materials

[0063] Compress the air after filtering to a pressure of 1.5MPa(G) and preheat it to a temperature of 180°C to obtain high-temperature compressed air;

[0064] Compress the circulating tail gas to a pressure of 1.5MPa(G) and preheat it to a temperature of 180°C to obtain a high-temperature compressed tail gas;

[0065] Heat and pressurize toluene to 180°C, high-temperature and high-pressure toluene with a pressure of 1.5MPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com