Two-component adhesive for bonding artificial teeth to a denture base

A technology for denture bases and artificial teeth, applied in the direction of non-polymer organic compound adhesives, adhesive types, ester copolymer adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030]50 g of a copolymer of methyl methacrylate (Degacryl® MW 332 from Evonik, Germany) was dissolved in 100 g of methacrylic acid supplied by Lehmann & Voss & Co. A mixture of methyl ester and 10 g of triethylene glycol dimethacrylate (TEGDMA) (Luvomaxx® TEDMA). Then, 2 g of benzoyl peroxide was dissolved in 80 g of methyl methacrylate, and 120 g of the first solution was added to the solution to obtain component A.

[0031] Component B was prepared as follows: 3 grams of N,N-dimethyl-p-toluidine were dissolved in 75 grams of methyl methacrylate.

example 2

[0033] Component A as prepared in Example 1 was mixed with the mentioned B component in a ratio of 2:1 at room temperature. For example, an applicator brush is used to apply the mixture to areas of the denture base in contact with the base surface of the tooth, and / or the base surface of the artificial tooth. The denture thus prepared is placed in the corresponding alveolus of the base. The prostheses thus prepared were stored overnight in an annealing oven at 37 °C for adhesive curing.

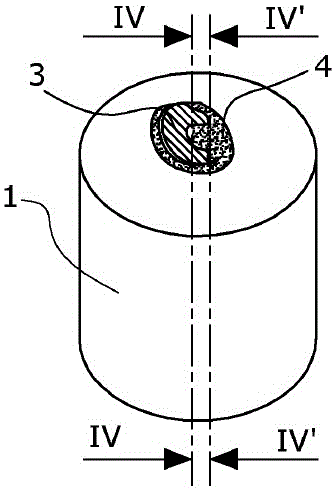

[0034] Using test samples prepared in the same way ( figure 1 and figure 2 ), fracture test according to standard DIN 13998. The prosthesis only shows areas of cohesive fracture in the tooth and / or base ( image 3 and Figure 4 ).

[0035] List of reference signs:

[0036] 1. Test specimens for fracture tests according to DIN 13998

[0037] 2. Denture bonded to test specimen

[0038] 3. Denture residue after adhesive failure

[0039] 4. Adhesive residue

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com